❖❖ Scootacar Somethinga littledifferent fromHunslet GardenRail Gettinggoing withthegarden gauges LNER B1 Platforms fora Platformsfora 5inchgauge model Clock Case Making acase for aregulator timepiece AdamHeslop’s winding engine TH EATM OS PH ER IC EN GI NE TH EO RI GI NA LM AGAZ IN EF OR MO DE LE NG IN EE RS Vol. 232 No.4742 3– 16 May2024 Join ouronlinecommunity www.model-engineer.co.uk

Park Commercialdirector: NigelHole Publishing director: DanSavage SUBSCRIPTION Full subscription rates(butsee page 606for offer): (12months, 26 issues,inc post andpacking)–UK £128.70. Export ratesare also available, UK subscriptionsare zero-rated forthe purposes of ValueAddedTax Enquiries: subscriptions@mortons.co.uk

PRINTAND DISTRIBUTIONS

Printedby: WilliamGibbons &Son,26Planetary Road,Willenhall, West Midlands,WV133XB Distribution by: SeymourDistributionLimited, 2EastPoultry Avenue,LondonEC1A9PT

EDITORIALCONTRIBUTION

Accepted photographsand articles will be paid for upon publication. Itemswecannotuse will be returned if accompaniedbya stampedaddressed envelope andrecordeddeliverymustclearly statesoand enclosesufficient postage. In commonwithpractice on otherperiodicals,all material is sent or returned at thecontributor’s ownriskand neitherModel Engineer, theeditor, thestaff norMortons MediaLtd canbe held responsiblefor loss or damage,howsoever caused.The opinions expressedinModel Engineer arenot necessarily thoseofthe editor or staff. This periodical must not, withoutthe writtenconsent of the publishers first beinggiven,belent, sold,hired outor otherwisedisposedofina mutilatedcondition or in otherunauthorisedcover by wayoftrade or annexed to or as part of anypublicationoradvertising,literary or pictorialmannerwhatsoever.

http://www.facebook.com/modelengineersworkshop

http://twitter.com/ modelengineers

608 SMOKERINGS

News,views andcomment on theworld of modelengineering

609 AN ADMIRALTYCASEFOR A REGULATOR

Adrian Garner showsthatmakinganelegant case fora regulatortimepiece does notrequire sophisticatedwoodworkingskills

612 SMEE NEWS

Martin Kyte reportsfromthe Societyof Modeland Experimental Engineers.

614 THEMIDLANDSGARDENRAIL SHOW

John Arrowsmith visits Warwickshire to see what’sgoing on in thesmallergauges.

619 BUILDING 3020 CORNWALL IN 5INCHGAUGE

JimClarkbuildsa modelofFrancis Trevithick’s LNWR 2-2-2locomotive.

625 HUNSLET’SSCOOTACAR

RogerBackhouse looksatone of afamous locomotive manufacturer’s lesserknown products

629 ATMOSPHERICENGINES OF THEEIGHTEENTH CENTURY

DavidHulse presents aseriesofmodels illustrating thedevelopment of theforerunner to thehigh-pressure steamengine.

633 ALOOKATLOCOMOTIVE 030 T8157

Rhys Owen takesa look at alocomotive made by theSACMinFrancetoa German design

637 ATWINTANDEM COMPOUND STEAMENGINE

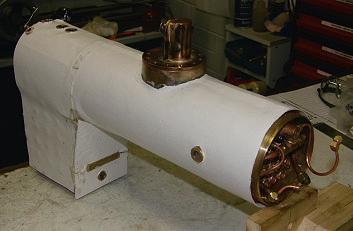

Graeme Quayle presents an interesting design fora compound windingengine.

641 REDESIGNING AGAS BURNER

Graham AstburymodifiesT.E.Haynes’s original burner design fora hotair engine to runonpropane rather than town gas.

643 BUTTERSIDE DOWN

SteveGoodbody returnswithfurther tales of thetrials andtribulations of amodel engineer’s life

647 LNER B1 LOCOMOTIVE

Doug Hewson presents atruetoscale fiveinch gaugemodel of Thompson’s B1

652 CLUB NEWS

GeoffTheasby compilesthe latestfrommodel engineeringclubs around theworld

655 CLUB DIARY Future Events.

www.model-engineer.co.uk 603

Vol. 232 No.4742 3– 16 May 2024

MediaGroup Ltd, MediaCentre, Morton Way, Horncastle,Lincs LN96JR Tel: 01507 529589 Fax: 01507 371066 ©2023 MortonsMedia ISSN 0026-7325

Evans

Deputy editor: DianeCarney Designer: DruckMedia Pvt. Ltd. Club News: GeoffTheasby Illustrator:

Publisher: SteveO’Hara

SERVICES

Answerphone24hr help@classicmagazines.co.uk www.classicmagazines.co.uk ADVERTISING GROUPHEADOFINVESTMENT– Lifestyle& TractorPublications |www.talk-media.uk MasonPonti mason@talk-media.co.uk A: Talk Media, TheGranary,Downs Court, YaldingHill, Yalding, Kent ME18 6AL Investment Manager: KarenDavies karen@talk-media.uk PUBLISHING Salesand distribution manager:

Marketingmanager:

PublishedbyMortons

www.model-engineer.co.uk EDITORIAL Editor: Martin R.

MEeditor@mortons.co.uk

GrahameChambers

CUSTOMER

GeneralQueries andBackIssues 01507 529529 Monday-Friday: 8.30am-5pm

Carl Smith

Charlotte

ON TH E CO VER ... Adam Heslop’s windingengineof1806 built by DavidHulse to onesixteenth scale (photo by DavidHulse). This issuewas publishedonMay 3, 2024. Thenextwill be on sale on May17, 2024. Scootacar Something a little different diff from Hunslet Garden Rail Getting going with the garden gauges LNER B1 Platf fo 5inch gauge nch model Clock Case Making fo egulator ulator timepiece timepie Adam Heslop’s winding engine THEATMOSPHERIC ENGINE TMOS ERIC GI THEORIGINALMAGAZINEFOR MODELENGINEERS SUBSCRIBE&SAVEUP TO49%Seepage606for details www.model-engineer.co.uk 619 641

SUBSCRIBE ANDSAVE

Enjoy12monthsfor just £68

PRINT ONLY

Quar terly direc tdebit for £19

1year direc tdebit for £68

1year credit/debit card for £74

PR INT +D IGITAL DIGITAL ONLY

Quar terly direc tdebit for £22*

1year direct debit for £85*

1year credit/debit card for £88*

1year direc tdebit for £50*

1year credit/debit card for £54*

*Any digital subscription package includes access to theonlinearchive.

Greatreasons to subscribe

>> Free UK deliver ytoyourdoor or instantdownload to your digital device

>> Save moneyonshop prices

>> Nevermiss an issue

>> Receiveyourissue before it goesonsale in the shop

classicmagazines.co.uk/ MEDPS 01507 529529 and quote MEDPS Lines areopen from 8.30am-5pm weekdays GMT Ofer ends De ce mb er 31,2024. Subscriptionswills tart with thenex tavailab le issue. Dire ct De bitp ay me nt sw illcontinueonthe agre ed plan unless youtellusother wise Tov iewthe privac yp olic yfor MMGLtd (pub lisher of Mo de lEnginee r),p leasev isit ww w. mortons.co.uk/privac y Pl ease vi si tw ww.c lass ic maga zi ne s.co.u k/ te rm sfor fu ll te rm s&con di tions . ( 8

AtmosphericEngines

DIANE CARNEY Assistant Editor MARTIN EVANS Editor

DIANE CARNEY Assistant Editor MARTIN EVANS Editor

Iknowmanyreaders have been followingwithinterest RonFitzgerald’sexcellent series on thedevelopment of thesteam engine.Up to now, of course,the storyhas really been that of the atmospheric engine,ratherthanthe steamengine, as in the former case thepower is derivedfromthe pressure of theatmosphereacting on acylinderevacuated by condensing steam. Thestory is nowmovingintothe realm of the real steamengine, wherethe powercomes from thepressure of highpressure steamand Ron’s series will soon move onto the storyofRichard Trevithick’s development(andpatenting) of thehighpressure steam engine.Itwas this development that made thesteam locomotive aviableproposition as ahigh-pressure steam engine requires much smaller cylinders than an atmospheric engine

Thestory of theatmospheric engine spansmoreorless thewhole of theeighteenth century, from 1712,when it wasinventedbyThomas Newcomen.Itwas later improved by JamesWattwith theaddition of theseparate condenser. Allthiswillbe familiartoreaders of Ron’s series!

DartmouthMuseum. If that is toofar to go thereare lots of good photographsonDavid’s website. More details are availableinDavid’s article.

Thermodynamics andMore

Many yearsago Ihad the good fortunetostudy foran engineeringdegree. Youcould arguethatwhatyou learnin an engineeringdegreeisnot actual engineeringbut rather thescience behind thepractice of engineering– more slide rule than spanner. Perhaps thecourseshouldmore properly be called‘engineering science’,asindeed it is at Oxford (I wasn’t at Oxford –the otherplace whereI studied calleditsimply‘engineering’, although it hadoriginally been called‘mechanical sciences’).Nevertheless, Ispent many happy hours in thethermodynamicslab runningvarious gasengines, dismantlingdieselengines and throwing coal into afurnace Allinthe interestsofscience of course as were trying to determinethe efficiencyofthe enginesand comparethem to thetheoretical maximum. My university hada very nice collectionofvarious kindsof engines– almost as good as theLondonScience Museum –soitwas afascinating place to be

oldwhenI studieditand –like many areasofengineering science– wasformulated afterthe creation of many of themachinesdepending on it (I believe Ihave‘smoked’this subjectbefore…)

We spentsometime provingthatancient rulesof thumbwereactually correct. Forinstance, themedieval cathedralbuildershad what wascalledthe ‘middlethird’ rule.Theyusedgeometrical methodstoplotthe lines of forcethrough structures to ensure that what they were buildingwould stay up –it wasvital that theselines did notleave theconfines of the stonework. In particular,a column wouldonlybestable if thelines of forcepassed throughthe middlethird of thecross sectionofthe column.Otherwise it wasat risk of buckling. Iremember Mr Frankl taking us through themathematics and– lo andbehold! –the middle thirdruleisexactly correct Ourmechanics lecturer demonstrated mathematically howthe trailerofanarticulated lorry should be loaded to avoidthe hazard of ‘snaking’ wherethe trailerbecomes uncontrollable– well known (I imagine) to anyhaulier butnicetohaveitconfirmed mathematically.

Mar tin Evans can be contacted on the mobile number or email belowand would be delighted to receive your contributions, in the form of items of correspondence, comment or ar ticles.

07710-192953

MEeditor@mortons.co.uk

DavidHulse hasspent much of thelasthalfcentury building onesixteenth scalemodelsof eighteenth centuryengines, covering theentirehistory of atmosphericengines.He presents them in this issue, starting on page 629. These engineswereusedmostly forpumping andwinding in minesand were generally built into theenginehouse.The authenticity of David’smodels extendstothe construction of thebuildings usingindividual bricks –bythe thousands. I sawone of David’smodels at theMidlandsModel EngineeringExhibitiona few yearsago andI canconfirm that they areindeed very impressive pieces of work.You cansee allthe models at the

What Ididn’trealisefully at thetimewas howrecenta lot of thescience underpinning engineeringis. Isuppose we allthought it wasengraved in stone. Electromagnetic induction, forinstance, had only been discovered 140 yearsbefore(1831)byFaraday (and also by Henry, in 1832). Consequently,electriccurrent couldbegenerated rather than derivedfromvoltaic piles(didyou know that the word ‘battery’was coined by Benjamin Franklin?) Current electricity, when I wasa student, hadonlybeen generally availablefor acentury or,for many,far less than that –whenI wasaninfant ourhouse waslit by gas. The scienceofthermodynamics wasonlyabout acentury or so

Practicalengineering does notalwaysprecede the elucidationofthe science though.A nice example is orbitalmechanics.The principles were established by IsaacNewtoninthe seventeenth centuryand elaborated by Halley(of the comet) andGauss, amongst others.Its applicationto engineering, though,had to wait untilthe twentiethcentury when it wasusedtotakemen to the moon andtosling shot thetwo Voyagerprobesout of thesolar system andintodeep space.

So –engineeringand science –chicken andegg –which came first?Hardtoansweras each inspires or begets the other. Perhaps, as in theriddle, thereisnosimpleanswer- it dependsonwhich chicken, or whichegg, you’re referring to

ModelEngineer 3May 2024

608

An Admir al ty Ca se fo ra Re gul ato r raReg ul ator

PA RT 1

Adrian Garner makesa simple butgood-looking case fora regulator timepiece.

The regulatortimepiece is apopular workshop projectbothfor horologistsand model engineers. Thedesignneeds only afew wheelstobecut andhas theadded appeal of precisiontimekeeping. Many descriptions of their construction have been publishedinthe ModelEngineer as well as otherjournals (table1).

Theemphasisofmostof thesearticleshas been on the mechanism. Thecase, usually of classicshape,has nearly always been describedlastand ofteninfar less detail. This is unfortunate. Thecaseneeds to be attractive to displayall theworkput into making the mechanismand,importantly, it needstoberigid andallow access to themechanism for setting up andadjustment. In many of thedesigns published access to themechanism is restricted.Indeed,itisoften

Examples of publishedconstructionseries. Table1

Month-goingRegulator

more restricted than forthe typicallongcaseclock where thecompletehood canbe removedbyslidingitforward

This wasobviously a concernwhenthe makers of theregulator forthe admiralty in Portsmouth setabout their design as describedbyDerek Roberts(ref1). In this design an extended hood consisting of thesides,door andtop can be liftedout of thebaseunit leavingjustthe back andbase securedtothe wall. Normally only thedoor wouldbeopened forwinding butwhenrequired twopeoplecan easily liftoff thehood usingone hand on each handle andone on the toptoensureitisbalanced. This makesaccess to the movement apleasure. Beinga modelengineer rather than woodworker,the design (photo1 and fg 1)does notinvolve dovetail joints or similar. Thereisa surprising amount of metalworkinvolved.

Thebezel of thefaceonmy regulatoris11.125inchesin diameter.The case dimensions will need to be increasedifyour Thecompleted admiraltycase.

609 www.model-engineer.co.uk >>

Claude B. Reeve ModelEngineer 26 May1960 to 21 July 1960

Timepiece Claude B. Reeve ModelEngineer 6May 1966 to 7 October1966

Alan Timmins ModelEngineer March1981

EnglishRegulator,Machinedand Constructed John Wilding ModelEngineer November

Clock PeterHeinmann ModelEngineer 12 February

GravityEscapementClock

AWeightDrivenRegulator

AWatchmaker’sWorkshopRegulator

to March1983 An

1981 to October1982 ARegulator

1999 to 24 September 1999

Clock PeterHeinmann ModelEngineer 28 November

2002 to 11 July 2003

John

ModelEngineer

1

Making aRegulator to aNew Design

Reynolds

January2015 to February 2016

Generalarrangement

bezelislarger. Themaximum swingona Myford latheis 10 inches whichhas often been used as thebezel size in descriptions of regulators This mightlook alittlesmall in this case and, in my view,is alittle‘mean’. Either thecase dimensions couldbeadjusted or onecould breakout anduse themillingmachine to generate alargerfaceand bezel. (A descriptionofhow Idid this for my regulatoriswiththe editor of thesistermagazine, Model EngineersWorkshop.)

Construction

Theback/base sectionofthe case should be made first (photo2).

Thetypical long case is essentially abox structure whichprovidesrigiditytothe back on whichthe mechanism andpendulumare mounted. In this design thebackofthe case is free standing anditis thereforeessentially abeam supported at just oneend (the base). Withoutfurther support it will bend.Suchsupport could be provided by boltingthe back to thewallata number of points.Indeed alllongcases should be securedtoa wall at onepoint,atleast,toavoid them beingtoppled over.It is,however,inconvenientto have to pass multiple bolts throughthe back into awall in adomesticenvironment,

especially as most walls are neither at norvertical

It is unclearfromthe pictures howthe back of theAdmiralty clockwas supported.There are clearlyvisible boltsthrough the back of thecasebut it appears that thebackwas structurally rigidevenwhen notagainst a wall.

To ensure rigidity Itook two actions. First, thebackconsists of twoplywood boards,one 12 x1895x 340mmand one

18 x1895x 321mmsecured together by glue andscrews leavinganequal lip on each side.Boardsthissizeweretoo bigfor me to cutaccurately from sheet material so Ihad them cuttosize. Blockboard wouldbea good alternative andarguablymorerigid and less inclined to warp

Second,I have bolted twoC beamstothe rear of theback (photo3).

Thesebeams aremadefrom 2.5mmthick mild steel and measure20x 40 x2.5mm. They canbeobtainedintwo metrelengths (ref2)and are easily cutwitha hacksaw to theneeded lengths. It is essentialthatthesebeams are

610 ModelEngineer 3May 2024

Oneofthe Cbeamsecuringnutswith6mm thread,turnedbrass washer and acorn nut.

Thebasewiththe hood andregulator movement removed.

22

GeneralArrangement 55 .7 5 15.8125 10.125 Fig 1 2 3 4

TheC beamsmounted on thebackof thecase.

Case

mountedwiththe open section of theC facing thecasebackin ordertooptimiserigidity. The suppliers of thesebeams can providematchingchannelnuts threaded 6mmfor this purpose. IusedLoctite to secure short lengthsof6mm studding into thesenutswhich mate with turned brasswashers and blackenedacorn nuts at the front(photo4).

Icut thebeams aboutfour inches shortatthe bottomto allowthe case to be setbackto thewallwhilstavoidingskirting boards.Inany eventthe iron work cannotbeseen from the side as theC beamsare hidden by twoedgingstrips(see drawing)

It will be foundthatthese C beamsnot only providerigidity butalsowill correct most of anywarpinthe plyboards.

Base

Iused19mm‘planed allround’ Sapele forthe base structure (fg 2). Thefront of thebase is toowidetobemadefrom oneboard andsoI gluedtwo boards together with five o 20 biscuits to providestrength. Before gluing thesetogether, Iroutedthe grooves on the sidesofeachtofitthe tongues routed on each of thesides. This routingcould have been done aftergluingtogetherbut theboardsare easier to handle whilstsmaller.

Therails inside thebase whichsupport thehood were then cut, gluedand screwedto both therearofthe frontofthe base andthe case back.I also addedthe vertical supportsto thebackthatsecurethe side panels of thebase(photo5). It will be notedthatthese extend

over theback. Oneproblem with notbeing able to cut my ownply sections is that thelower sectionofthe back wouldideally be wideratthe base.Thisisnot,however,a bigproblem.After gluing the base together I cut ly filler pieces andglued theseinplace (photo6).

dry runfitting thebaseto thebackestablishedthatall assembledcorrectly (photo7).

1x 0.75 edging strips Fig 2

Four screws (two each side) were addedtoatthisstage to ensure alignmentduringgluing. Afew notesabout gluing the base to theback:

● t leastfive clam s are needed to ensure allistight.

● As forthe drytest, thecase back needed to extend out over thebench to alloweasy access. To avoidthe whole over balancingthe case back wasclamped to thebench

● To ensure allwas square a pieceofwoodwas cutdead s uare to fit thebase It was left slightly shortallowing packingtopushthe base square whilstgluing.

●To be continued

REFERENCE

Ref 1 EnglishPrecision Pendulum Clocks,page 256, by Derek Roberts published by Schiffer Books.

Ref 2 Direct Channel Support Systems, www. directchannel.uk.com

Screw& glue back boards together Gluedfillerpieces 6mm ebony

Base

Glue &screw upperrails

Biscuit& glue frontboardstogether Crosssection

Tongue &groove sidestofront boards

611 CL OCK CA SE www.model-engineer.co.uk

Thebasesides,front andcasebackready forassembly

Thefillerpiece gluedbetween thecase back andbasesides

5 6 2 2 2 22 12.625 14.375 15.875 0.75 8.125 0.75 Base 10.125 2mmebony 16 .8 75 19 12mm/18mmbackboards

Lots of clamps needed to glue up thebase. Note thetemporary rectangleofwood wedgedwithveneer strips to ensure allremains square.

7

SME EN ews SMEE Ne ws Co

nser ving aL ar ge Sing le Cy lin der Mill En g inegi ne

Martin Kyte hasthe latestfrom theSociety of Modeland Experimental Engineers.

One of thebenefits of having alonghistory is that hasa large collectionofartefacts that hysically show theactivities of modelengineersfromthe earlydaysu tomoderntimes However holdingsucha large collection some of which areofhistoricalim ortance to thehobby comes with a res onsibilityto ee eachitem in good condition his really demandsa rolling rogramme of conservation andwe arefortunate to have afew memberswho arewillingand able to carry outthiswor recentitemtobetreated to this rogramme is the mill engine o andthis rocesswas thesub ect of ourmonthly main meeting delivered by llen erman whorecentlycom leted its conservation o isa fairly largee am le of asingle cylindermillenginebuilt by r H oughton anddonated to theSociety in 1984 (photo1 hereare models by Harry oughton in the collectionincluding abeam engine several mill engines in variousconfigurations acou leofbrass cannons anda articularly interesting erryweatherthree cylinder

fire um Inotethe fire um becauseHarry wor ed for erryweatherfrom and robably becauseofthatit is articularly accurate and detailed urcurrent chairman llen erman describedthe model as beinga well made single cylindermill engine of inch bore a ro imately and inch stro e Itisaround inches long andweighsinat a ro imately lb It hasa disc cran driving asi s o e

ywheel inchesdiameter two ballgovernorcontrols ase aratesteam valvedriven by belt andbevel gears ain steaminlet is by awheel valve hereare brassdrain coc son thesideofthe cylinder here is anon reversing eccentric o erated slidevalve and sli ercross head he aint scheme is dar green and bright engine artsona light grey sha ed linth he engine wasinsomething of asorry conditionhavingbeen steamed

612 ModelEngineer 3May 2024

SMEE

1

Asinglecylindermill engine built by Mr H.C. Roughton

at variousshows whereit ac uired aliberal coat of heavy steamoil whichattracteda fair amount of dirt andgrime over theyears from beingdis layed withouta case

ll smodelsare in thecareofour tationary ngine ommitteewho lay down some clearrules as to what canand cannotbedone to theengines sthe basic aimisthe reservation and re air of otentially historical ob ects nothingmustbedone that cannotbeundonesoany attem ttorestore li enew must be resisted ochanges or modifications areallowed

documentationofall stages of the rocess should be e t andeffortsto rotect theitem againstfurther deterioration should be underta en ome initialobservations were made andthe engine waslubricatedand runfor a while on air llennoted that theengineran very smoothly andwas self startingona ressure of to ar he initialassessmentwas that a thorough cleanwas re uired andthe base in articular wouldbenefitfroma re aint nce ermission to re aintthe wooden base of theenginewas given llen wasready to start Having notedthe valvetiming with hotogra hsand te t the engine wasready fora stri down anda thorough clean isassembly wasreasonably straight forwardwith llen ta ing care to ta e co ious hotogra hsof arts and subassemblies heengine em loysnumerousta er ins andgib head eys the latterre uiring aremoval tool loo ingli ea thin wedgewith onestraightand oneconcave edge llen wasfortunate that Harry hadthought to include ta edholes in thecylinder head for ac ing screws as the gas et washolding thehead on e tremelyfirmly photo2

neadventure in a ob li e this is identifyingthe various threadsusedonthe fi ings t onetimeitwas thoughtthat thefittingswere butthey turned outtobe hitworth to a manwiththe e ce tionof However one s ecial wasthe cylinderheadfi ingswhich had hitworthstuds with nuts of he agonstogivethe right scalea earance heengineitselfwas in retty good conditionwithbrightslide bars andwell reservedgreen aintwor heenginehad howeverbeen runmanytimes on steamand asmentioned steamoil haddoneits wor in creating grimeand attracting dust anddirt hewooden base hadbeen articularly affected by this anda lotof llen swor wasinvolvedinbringingthat bac to condition roduct called tri Itsuccessfully removedall of theold aint once thebed studshad been rotectedwithtubing hebase wasgiven alight sandingand an undercoatand finally ato coat in Ivorytocontrastwell with thegreen bed late everal months were allowedfor the ainttofully dry hecylinderbore rovedto be in very good conditionand removalofthe iston revealed an interestingfeature in that

thesteel iston s orteda single brass istonringwhich was uite wide anddiagonally s lit ll of the aintwor wascleaned usingcommon detergents and lentyofelbow grease he e osedmetal artswerebrought bac to conditionwitha mi ofwire wool buffwheels wetand dry a erand brassbrushes he governor in photo3 showsboth thee cellent wor manshi of themodel andthe glow rather than shine of the metalwor In fact hoto is a rime illustration of good conservancywiththe tiny im erfectionsand atina of time remainingona nice clean mechanism

ne ngine ommittee ermittedmodification is seen in photo4 whichisthe removal of the lain co ertubetothe main steamglobe valvewhich is re laced with anew ange to ta e a mm ush fitting for nylonair tubing Itisintended that theenginewill only be run on airinthe future andthis allows sim le connectionto thecom ressor urtherwor will involvethe construction of adis lay case andthe engine cangobac ondis lay at arshall House ftere lainingtousthe techni ues he used in bringing this lovely modelbac to ro er conditionweweretreated to ademonstration of theengine running nelovelyfeature whichwas uic lycommented on was theslowrunning of theengine robably hel ed somewhat by thecom aratively largesi eofthe model It s very nice to seeanengineli ethis runningatsomething li ethe s eed it wouldhaveo erated at in full si e

llenhas done afew of these conservationsnow andwe as asociety are very grateful to himfor hiseffortsin reserving ourheritagebothfor andthe en oymentofmanyat future showswhenthe engine gets an outing ormoreinformation about andreasons for oining us leasevisit ourwebsite at www sm ee co u

613 SMEE www.model-engineer.co.uk

ME

2

Cylinderheadshowing thelocations of thejacking screws. The angedc nnecti n r c pressed air

3 4

Thegovernor.

The Mi dl an ds Gard en Ra il Sho w

John Arrowsmith catchesup with what is goingonin thesmallergauges.

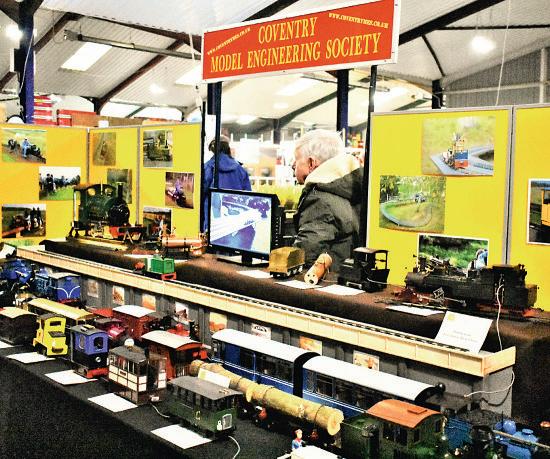

The 2024 Midlands Garden Rail show opened to visitors on Saturday 2nd andSunday3rd Marchatthe Warwickshire Events Centre with good attendancesonboth days.The prevailingweather provided some soggy parking conditions butasusual this didnot detervisitors. There were 12 operatinglayouts covering everygauge currently in this area of miniature railway modelling. In addition, fivestaticdis laysbymodel engineeringclubs addedtothe attractions.

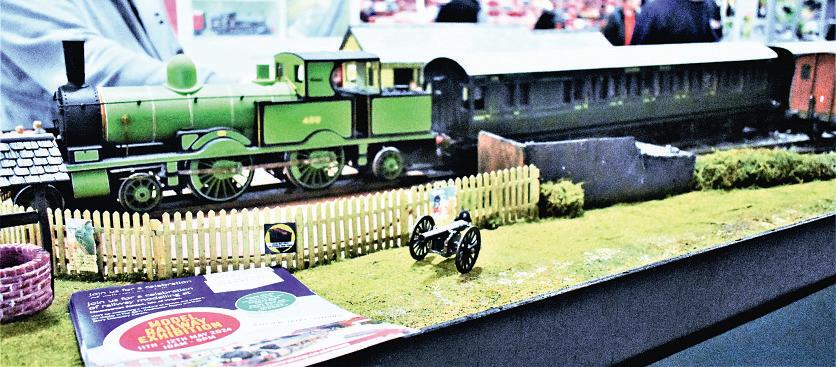

Twolarge workinglayouts caught theeye on entering themainhall. The Midsomer Norton layout in Gauge1 standard scaleisa layout basedonthe Somerset & Dorset JointRailway stationat Midsomer Norton just south of Bath (photos 1 and 2). This largelayoutwas always busy with allthe bigfourcompanies representedtogetherwiththe BR standardsand anumber of pre-grouping locomotives.

Thescenicworkaroundthe stationareashows offwhat atypical stationofthatera should have with buildings andstation furnitureofthe period.The locomotive pool hada varietyoflarge powerful enginesinsteam andtaking typicalrollingstock around thetrack system.These enginescover awiderange of fuel ty esfromcoalfired

to radiocontrolledbatteries

It alladdstothe atmosphere with that familiarhot oiland steamaroma mixing with the methylated spirit emissions from othermodels. Therewas always lots of operations and plenty of spectators watching andtalking to theoperators.

Theother largelayoutto greet visitors wasthe Hampton EndBranch linelink, serving thevillage of HamptonEnd

This colourfullayoutagain has plenty of stockmovementto watch(photos 3 and 4)and has awidevariety of motive power to providethe serviceswith both Britishand Continental prototypes in action.The scenic effectsare very good with some innovative displays as part of this.For example, therockclimbers scalinga tracksidecliffwall- they could have been railway engineers judgingbythe orange overalls andhardhats(photo5).

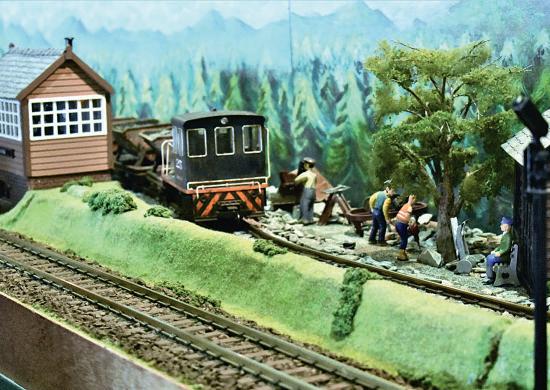

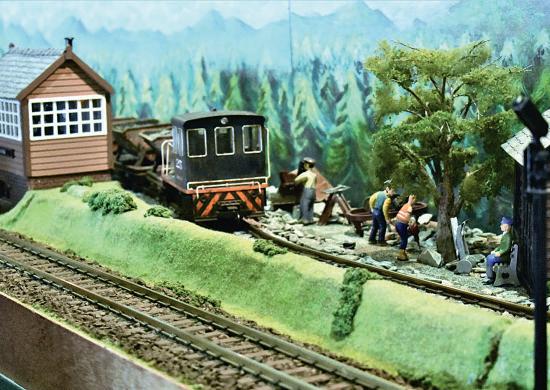

Afurther largelayoutwas that displayedbythe 16 mm AssociationModular Layout whichwas another well detailedpresentationwith plenty of trackactiontowatch andenjoy (photo6). There wasa good varietyofscenery

614 ModelEngineer 3May 2024

Theextensive Midsomer Norton layout in themainstation area

AGWR King waitsbythe signal boxfor itsnexttrain

1 2

on this modelwithsome excellent detail. Thebrewery on onesidehad averyunusual meansofmovingwagons whichlooked likea regular earthmover convertedtowork on therailway.A delightful smallerlayoutwas the32mm gaugelivesteam presentation named Pen-Y-Bont. Depicting asmall Welshslate railway, thefascinating detail of this railway wasthatall thefoliage andtrees areall real andliving plants.The plants have been chosen fortheir littleleaves

and owers his givesthe railway auniqueappearance sincethe colourschangewith thetimeofyearand monthit is seen.The selectionofplants is excellentand does make foranimpressive littlerailway (photo7).

The Loft City CentralRailway is alarge layout approximately 7000ftinG scaleshowing offa lifetimecollectionofthe vintage‘Playmobile’models. It is full of very colourfuldetail andisverywellpresented With such awidevariety

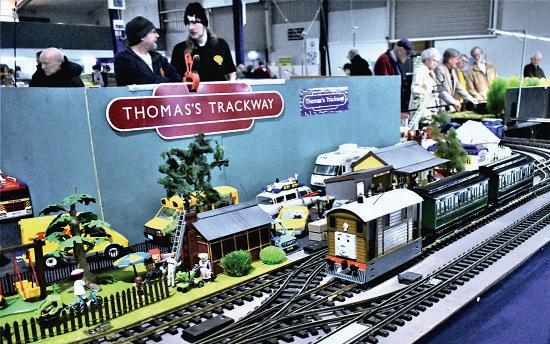

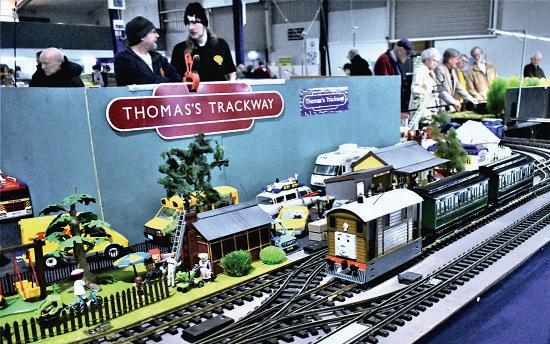

of detail it is impossibleto describe everything.Itwas arealcrowd pleaserwithso much activity.Ina similarguise was Thomas’s Trackway, a 45mmgauge LGBtrack built layout representing therailway basedonthe popularReverend WilbertAwdry’s Thomas the Tank Engine stories. Built to entertainchildren, it showed many of Thomas’s friendsand rollingstock in averycolourful

andpleasingsetting (photo8). Aregular layout that always attendsthisshowisthe fine scale LoughMotivePower Depot whichislooselybased on thetrack plan of Slough MPDasshown in E. Lyon’s book of GreatWestern Engine Sheds of 1949.Thiswas inside theWindsor Curve andfor the layout hasbeenstraightened outtofitthe baseboards hence the‘looselybased’description

615 GARDE NR AI L www.model-engineer.co.uk >>

Threetypes of motive poweronthe HamptonEnd layout

Asplendidshedand motive poweronthe 16mmAssociation modularlayout.

5 6

Arethese rail engineersorjustclimbers at HamptonEnd?

7 3

Motive powertospare as thesetwo littlesaddletanks driftround thePen-Y-Bont railway

4

Thetrack gang workinghardatHampton End

8

Onefor theenthusiasts wasthe colourfulThomasTrackwaylayout.

It hassomefine detail andvery realisticfittingsand showsthe depotatthe endofsteam with a wide varietyofmotivepower on shed andatone endthe diesel andrefillingde ot photo9). Modelengineeringclubs do featureinthisshowaswell andboththe Bromsgrove

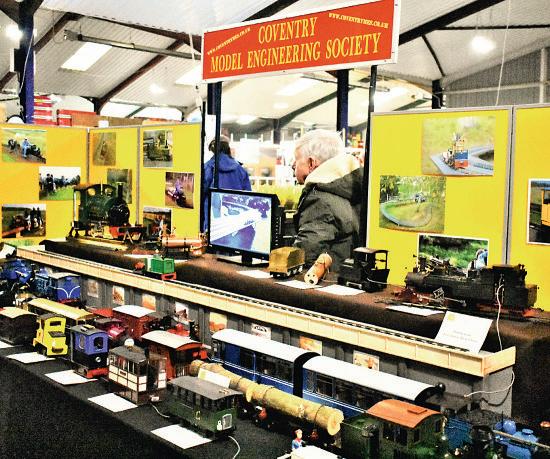

SME andthe Coventry MES hadsomeinteresting and informativedisplaystoenjoy, showingthe interest thereisin thesmaller scales formodel engineers. Concentrating on thegardengauges, the Bromsgrove standhad awide rangeofmodelsonshow,

some scratchbuilt andsome kitbuilt together with some proprietarymodels(photo10). Thereisanother interesting littlestory here as well. Oneof theiryoungestmembers Harry, whois9,islearningtodrive both hisfather’ssteam loco andthe club’s electric locos. In addition,hehas an interest in thesmallerscalesand was disa ointedtofind that his collectionofLEGOengines were notgaugedtosuitgarden railway tracks,sohehas starteda processofre-gauging them to suit theclub’stracks. Hopefully thephotograph showsthe progress made so far(photo11). TheBromsgrove club aretobecongratulated in encouragingthisyoung man to getinvolvedwiththissort of projectand theinformation

andskills he is learning at the moment will translateintoa youngengineer whowill be really involved in theclubashe gets older- perhapsanother lessontobelearned there!

On the Coventry Society display(photo12)was another finewide rangingselection of models built andconstructed by members. Thelittle3½ inch gauge‘Tich’ built by Terry Timms wasanexcellent exampleofwhatcan by produced from thebasic LBSC design andthe scrapbox.The cylinders were made from hexagonbar andthe engine is fittedwith alschaert svalve gear (photos 13 and 14). It is beautifully finishedand erry told me it goes as well as it looks. Thesamebuilder had some interestinglittlemoulds

616 ModelEngineer 3May 2024

Mighty steampower on shed on theLough MPDlayout.

Oneoftwo well made ‘LION’ models on theBromsgrovedisplay

ALEGOmodel re-gaugedtorun on 45mm trackby9-yearold Harry from Bromsgrove.

11

12 9

TheCoventryMES provided awiderange of well-built models on theirdisplay

13 10

This excellent exampleofa 3½ inch gauge‘Tich’was built by Terry Timms.

he hadmadetoprovide super details to hisother garden railway models.The axlebox s ringswerefine whitemetal castings foruse on hisClass 8shunter.Terry told me he hasbuilt 19 locomotivesin totalsofar andusesall the modern techniques to create allhis models andequipment He hashis own3Dprinting machinewhich helpswiththe detail. It wasa very interesting conversation with afine model engineer (photo15).

The National 2½ Inch Gauge Association hadtheir usual comprehensivedisplay of models andfittingsonshowto demonstratewhatthisgauge hastoofferfor thoseinterested in theslightly larger gaugeof models TheGauge 3Society is thescenicsideofthe 2½ inch gaugerailway enthusiasts andtheyprovideda selection of models androllingstock anda scalemodel of aCornish Engine as thetypeofbuilding

that canbeusedinthe layouts (photos 16 and 17). Another club whichisprogressing well with theirnew outdoor railway is the Leamington andWarwick ModelRailway Society who, during 2023,havebuilt a newlayoutnot farfromthe exhibition venue. It comprises about90metresoftrack

suitable foroperating Gauge 1and Gscale locomotives both steamand electric in a landscaped setting with good access andparking.Itwill be interestingtosee howthey progress in thenext12months. The Gauge1 ModelRailway Association didnot have a s ecificlayoutthisyearbut provided alarge displayboard with details of everything they represent.

Back to theoperating layoutsnow andthe popular GScale publicitylayout

provided agrand show of the waythisgauge canoperate anddemonstrate therange of models andequipment currently availablefor devotees (photo1 ). In complete contrast to theselarge very active layouts, thelittle7mm scale presentation ‘CommonRoad’ is asmall Ogauge layout based on aformerwagon workswith thesamenameinStafford.It waspresented as an Inglenook shunting puzzlecontaining some excellentbuildings and trackworkwithgoodrolling

617 GARDE NR AI L www.model-engineer.co.uk >>

Thewelldetailedcab on theTich.

15 14

Terry Timms also built this well detailedClass 8shunter

16

ACornish engine modelonthe Gauge3 Society display.

17

Thedisplay of locomotivesand stockfromthe Gauge3 Society.

18

Thecolourful GScale publicitylayout.

stockand locomotivesina very compactspace (photo19).

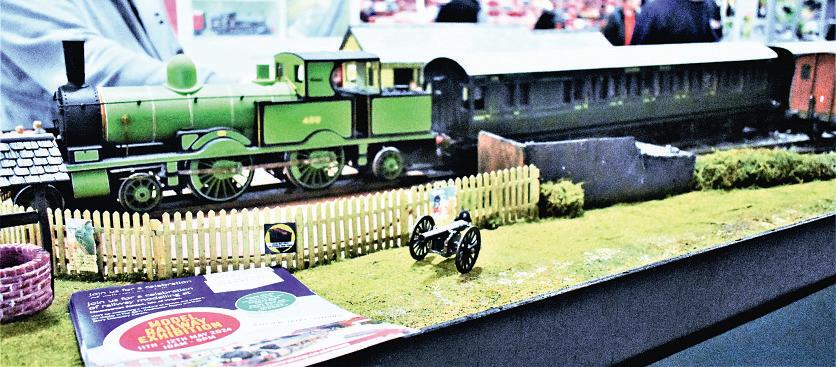

new finescale layout was ‘Blackgang’, afictionalstation on theIsleofWhite andbased on thetrack plan forBembridge. Well made andpresented,all thelocomotives andstock are either scratchbuilt or kits and it made forsomeexcellent prototypes operatingintypical IoWscenery (photos 20 and 21).

TheGauge 1Vintage Trains Group hadtheir usual resentation of thesefine models of yesteryear together with acircuit of Gauge2 railway whichmadefor an interestinglayout. It was difficult to seethe difference between thetwo gauges when they were closetogetherbut it made foraninteresting presentation (photo22). The last layout at theshowwas that by theBerry Hill VisitorCentre at CatherinedeBarnes. Known locally as ‘CatneyBarnes’,this well presentedlittlelayout wasa representation of the Berry Hill Estate Railway which wasbased on SirPercival Hayward’s15inchgauge railway

That just aboutsumsup this year’s Midlands Garden Rail Show whichwas well supported particularly on Saturday andI hope this excellent smallershowwill be repeated againnextyearasit is well wortha visitifyou are thinking of downsizing from thelargermodel engineering models.Mythanksasusual to everyone whoprovided informationand details

618 ModelEngineer 3May 2024

CommonRoad, a7 mm scalegoodsyard.

Blackgang,anAdams Tank 4-4-2, pulls into thestation

Interestingdetailonthe Blackgangdisplay

19 21

AGauge 2LNWR4-6-2 locomotive andtrain

20 22

ME

BUILDING 3020 BUI LDING CORNWALL WALL in 5Inch Gauge aug

PA RT 5

JimClark buildsthe

famous LNWR 2-2-2– thefrst locomotive earmarked forpreservation.

Making theboiler

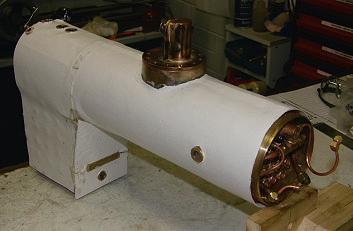

Continuedfromp.558

M.E.4741 April19

Rightfromthe startofthis project, theboilerloomed as significant challengeand has been alimitingfactorinmany otherparts of thedesign(fg 15, 16 and 17). No doubtI wasnow asking myself similar questionstothose that the designersofthe original Cornwall,Francis Trevithick and John Ramsbottom, wouldhave been asking allthose years

ago: howtoget thebiggest possibleboilerinbetween thosehugedriving wheels? Andhow to getitslung as low as possible, to keep thecentre of gravitylow?

In my case,there wasan additional question:How to make it look as much like thepreserved Cornwall as possible?

Fortunately, thebasic boiler design wasnot difficult a

standard straight barrelcopper boiler(photo 5 and 6) with afirebo dro ingdown between theinner frames, designed to theAustralian MiniatureBoilerSafety Committee(AMBSC) code ote to otherbuilder If youare intendingtobuild this model, please ensure that you checkwithyourlocal boiler inspectorbeforecommencing buildingthe boilerfromthese

619 www.model-engineer.co.uk >>

Side elevationand partialcross-sectionofthe boilerfor Cornwall

Frame Outlineofinnerframe Frame Fr am e Trailingaxle 5/16 x32 Bl ow do wn Fusibleplug Door hinge Front mount 3/ 8x 32 3/8x 32 Manifold (injector whistle& blower) Axle pump clack(RHSonly) Safety valves 2off Ø3/16bore 5/16 x32 Smokebox 3/ 8x 32 Dome 3/8x 32 3/8x 32 Ca bf ro nt 3/8x 32 Allstays 1/4" copper rivets or plainØ6.35mm rod Maxstaypitch 27.5 Bronze brazethroatplate joint then silver solder external strap 3/8x 32 12 xM5cap screws on 62 PCD Centre stay extendsinto fireboxfor arch support Stainlesssteel arch 3/ 8x 32 Side ElevationAnd SectionAnd SectionOfCopperBoiler View From Below Drivingaxle Frame Fixing ring forsmokebox (securewithstainless screws) Frontflexiblesupport Fabricatefrom0.8mm stainlesssteel,fix to drivingaxleframe stretcher 6.35 71 51 11 0 74 56 50 297 152 65 45 26 26 26 25 25 25 27 27 60 90 50 46 418 96 96 6. 35 39

Fig 15

Ø12.71.6wall

Boilertobeconstructed in accordance with AustralianMiniature BoilerSafetyCommittee(AMBSC) Code part 1, issue8,2012.

Workingpressure -700kPa (100 PSI)

Allboilerplates- 3mmcoppersheet

Stays- Ø6.35solid copperbar

Blower stay -Ø6.35 x1.63WTcopperpipe

Firetubes- Ø12.7x 16 WT copperpipe

Notes:

Allbushesphosphorbronze

Boilerworking pressure -700kPa

Boilerflooded watervolume- 3litres

PV value- 0.7MPa x3L= 2.1MPa/L

Approx.heating surfacearea(flues) -2010 cm ²

Approx.heating surfacearea(firebox) -720 cm²

Approx.heating surfacearea(total) -2730cm²

Safety valveorifice diameter -2 xØ4.76 (2 xØ3/16)

620 ModelEngineer 3May 2024 Endelevationsofthe boilerfor Cornwall Rolledbarrel(O.D. 110mm) 18 offØ1/2" tubes Fr am e Fr am e Fr am e Fr am e 3/ 8x 32 3/ 8x 32 Injector clack 3/8x 32 Tender clack 3/8x 32 Filler/airlineclack 5/16 x32 Watergauge 5/16 x32 Pressure gauge 1/4x 40 Hollow blower stay Solid stay Backhead Detail 5/16 x32 3/8x 32 Backhead Development Boilernumber Cu tt in go ut lin e Bronze brazebarreljoint then silver solder internal butt strap Arch support stays

30° FrontTubePlate Detail Ø110 Ø104 96 6.35 71.3 96 6.4 80 65.3 Ø44 42 26 27 27 52. 1 20 27 20 20 25 45 30 37 .5 24 .5 27 25 122 84 32.5 13 10 35 35 22 5 26 r13 12 50 27 27 27 18 18 Ø1Ø110 04 Ø98 13 16 Ø110 Ø104 Ø11 Ø6.4 Ø3 Ø50 Ø1.6 Ø11 Ø12.7 Ø12.7 Ø12.7 Be nd in go ut lin e Ø12.3 Ø12.3

16

Fig

DIANE CARNEY Assistant Editor MARTIN EVANS Editor

DIANE CARNEY Assistant Editor MARTIN EVANS Editor