ACompactDividingHead

SMALL RADIUSES

No.332

TURNINGSMALLRADIUSES Makethisrobustandaccuratedividingheadfor yourmillingmachine GetmoreoutofyourworkshopwithMEW Jointheconversationat: www.model-engineer.co.uk AHOSTOFIDEAS-BRIANWOODSHARESHISWORKSHOPWISDOM. THEBEGINNINGSOF MODELENGINEERING. TIPSFORFITTINGSCREWSINDIFFICULTPLACES. WORKSHOPTALES –JAMESC.CREBBIN,PIONEERMODELENGINEER. JACQUESMAUREL’SPARADOXICALGEAR DEMONSTRATOR. GETREADYFORTHEBIGSHOW–SNEAKPREVIEWOFMMEX2023. HESIERANDMONOSOUPAPE–MODELENGINEERINGINNEWZEALAND. NEWSFROMWARCO. PLUSALLYOURREGULARFAVOURITES! CARRIAGEDIAL FORANEMCO MAXIMAT GrahamMeek achievesaccuracy usingshifted gearprofiles Masteranessentialworkshoptechnique withtheArtfulDodger THEMAGAZINEFORHOBBYENGINEERS,MAKERSANDMODELLERSOCTOBER2023ISSUE332WWW.MODEL-ENGINEER.CO.UK ATILTINGTABLE AnotherpracticalworkshopaccessoryfromMikeCox Oct 23 TURNING

INSIDETHISPACKEDISSUE:

EDITORIAL

Editor: NeilWyatt

Designer: DruckMediaPvt.Ltd.

Publisher: SteveO’Hara

Bypost: ModelEngineers’Workshop, MortonsMediaGroup,MediaCentre, MortonWay,Horncastle,LincsLN96JR Tel: 01507529589 Fax: 01507371006

Email: meweditor@mortons.co.uk

©2022MortonsMediaISSN0033-8923

CUSTOMERSERVICES

GeneralQueries&BackIssues

01507529529

Monday-Friday:8.30-5pm

Answerphone24hr

ADVERTISING

Groupadvertisingmanager: SueKeily

Advertising: AngelaPrice aprice@mortons.co.ukTel:01507529411

ByPost: ModelEngineers’Workshopadvertising, MortonsMediaGroup,MediaCentre, MortonWay,Horncastle,LincsLN96JR

PUBLISHING

SalesandDistributionManager: CarlSmith

MarketingManager: CharlottePark

CommercialDirector: NigelHole

PublishingDirector: DanSavage

Publishedby: MortonsMediaGroup, MediaCentre,MortonWay,Horncastle, LincsLN96JR

SUBSCRIPTION

Fullsubscriptionrates(butseepage54foroffer): (12months12issues,incpostandpacking)–UK £56.40.Exportratesarealsoavailable–seepage 46formoredetails.UKsubscriptionsarezeroratedforthepurposeofValueAddedTax. Enquiries:subscriptions@mortons.co.uk

PRINTANDDISTRIBUTIONS

Printedby:WilliamGibbons&SonWolverhampton

Distributionby:SeymourDistributionLimited, 2EastPoultryAvenue,London,EC1A9PT TelNo:02074294000

EDITORIALCONTRIBUTIONS

Acceptedphotographsandarticleswillbepaidforuponpublication.Itemswecannot usewillbereturnedifaccompaniedbyastampedaddressedenvelope,andrecorded deliverymustclearlystatesoandenclosesuf cientpostage.Incommonwithpractice onotherperiodicals,allmaterialissentorreturnedat thecontributorsownriskandneither ModelEngineers’WorkshopMagazine theeditor,thestaffnorMortonsMediaLtdcanbeheldresponsibleforloss ordamage,howsoevercaused.TheopinionsexpressedinMEWarenot necessarilythoseoftheeditororstaff.Thisperiodicalmustnot,withoutthewritten consentofthepublishers rstbeinggiven,belent,sold,hiredoutorotherwise disposedofinamutilatedconditionor,inanyunauthorisedcoverbywayoftradeor annexedtooraspartofanypublicationoradvertising, literaryorpictorialmatterwhatsoever.

Thisissuewaspublishedon8September2023. Thenextissuewillbeonsale13October2023.

Onthe Editor'sBench

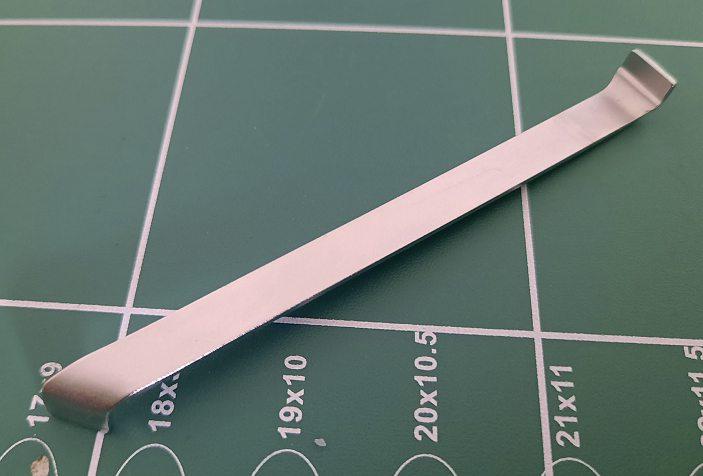

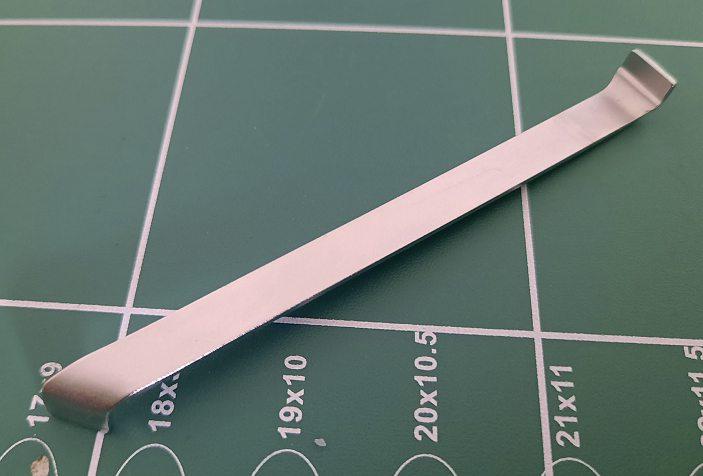

AMysteryTool

Iknowwhatthis‘mystery’toolis,asI boughtit.Infact,Ihadtoorderitfrom theUnitedStates!Icouldhavemade one,butdespiteitssimplicity,itwould haveneededtobebentupfromalarger pieceofstainlesssteel,amaterialthatis arightpaintoworkneatlyandagood smooth nishisessential.Now,I’msure manyreaderswillbeabletoguessit’s basicfunction(no,itisn’tatirelever!) buthowmanyofyoucansayexactly whatthepurposeofthislittleobjectis?

ASteadyHand

Iwasgivenanicemicrophone,butthe capsuleinithadanintermittentfault. Eventuallygaveupontrackingitdown andorderedacoupleofmid-range capsulesthathadasimilarfrequency responseandotherproperties.The rstwas neandreplacedtheoriginal withonlyminormodi cationstothe xingarrangements.Ididn’thavean immediateuseforthesparecapsulebut noticedthatthesmallsecondarycoil hadbothitsconnectionsbroken.Not essentialforthemicrophonetowork, thiscoilactsasa‘humbucker’reducing thepickupofextraneouselectrical

noise.Itwasmorethanalittlestrainon myeyesightandthesteadinessofmy hands,butIwaspleasedtobeabletoreconnectthecoilsuccessfullywithsome newireandasmallsolderingirontip.

BriquetteCutter

MyapologiestoNickWebbfor accidentallycreditinghis‘briquettecutter’ tiptosomebodyelseinthelastissue.

NeilWyatt

3 October2023

4 October 2023

5 October2023

9 ACompactDividingHead. Webeginashortserieswithdetailed plansandinstructionsforbuildingthis excellentcompactdividingheadfrom ChrisHallaway.

16 TipsandHints,someold, somenew,someborrowed. BrainWoodsharesavaluable compendiumofworkshopwisdom.

26 Companyprofile–Warco. Behindthescenestomeettwoofthe employeesatWarco,oneofthewellestablishedsupplierstothehobby.

28 ImprovingaTangential Flycutter. AnupdatefromHowardLewiswith furtherimprovementstohistool describedinissue316.

31 IntroducingMulti-Tools StubMandrelgivesbeginnersabrief introductiontothesehandydevices.

34 Squaringthecircle.

GrahamMeekhastackledthe conundrumofmakingusefuldials forcarriagehandlesforavarietyof machines.TheEmcoMaximatproved particularlychallenging.

42 WorkshopTales.

WerecallJamesCrebbin,oneofthe originalfoundersoftheSMEEandhis workshop.

43 ATiltingMillingTable. ThishandyworktablebyMikeCoxis heldinatiltingvicetoallowthemilling ofanglessurfaces.

47 FromtheArchives. Celebrating125yearsofModelEngineer withpagesfromtheveryfirstissue.

50 TheMidlandsModel EngineeringExhibition. Thelatestnewsaguidetothetrade standsatMMEXinOctober2023.

54 Beginner’sWorkshop. ThismonthGeometerexplainssome waystoassemblescrewsintoawkward locations.

55 ArtfulDodges. Inthismonth’sdodge,JohnSmith looksatwaystomakesmallconvex andconcaveradiuses.

59 “Filengrène”–So ware forGearDesign.

JacquesMaurelcompletesthemaking ofademonstrationofFerguson’s GearParadox.

Contents ModelEngineers’Workshop www.model-engineer.co.uk 6 19 £5.75 Oct 23 No.332 INSIDETHISPACKEDISSUE: TURNINGSMALLRADIUSES Makethisrobustandaccuratediv yourmillingmachine GetmoreoutofyourworkshopwithMEW Jointheconversationat: www.model-engineer.co.uk AHOSTOFIDEAS-BRIANWOODSHARES HISWORKSHOP WISDOM. THEBEGINNINGSOF MODELENGINEERING TIPSFOR FITTINGSCREWS INDIFFICULTPLACES. WORKSHOPTALES –JAMESC.CREBBIN,PIONEERMODELENGINEER. JACQUES MAUREL’SPARADOXICALGEAR DEMONSTRATOR. GET READYFORTHE BIGSHOW –SNEAKPREVIEW OFMMEX2023 HESIERANDMONOSOUPAPE –MODELENGINEERINGIN NEW ZEALAND. NEWSFROMWARCO. PLUSALLYOURREGULARFAVOURITES! CARRIAGE DIAL FOR AN EMCO MAXIMAT Graham Meek achievesaccuracy usingshifted gearprofiles Masteranessentialworkshoptechnique withtheArtfulDodger GAZINEFORHOBBYENGINEERS,MAKERSANDMODELLERSOCTOBER2023ISSUE332 WWW.MODEL-ENGINEER.CO.UK ATILTINGTABLE Anotherpractical workshopaccessoryfromMike Cox TURNING SMALL RADIUSES ACompactDividingHead SUBSCRIBETODAY! GETYOURFAVOURITE MAGAZINEFORLESS DELIVEREDTOYOURDOOR! Seepage54-55fordetails.

31

Comingup… inournextissue

www.model-engineer.co.uk

3 OntheEditor’sBench. Theeditorrescuesamicrophoneinsertandchallengesreaders toidentifyandobscurespecialisttool.

22 ScribeALine.

Anotherfineselectionoffeedbackandcommentfromreaders. Wearealwayskeentohearfromyou–justsendanemailto meweditor@mortons.co.uk.

40 OntheWire. Ourmonthlyroundupofnewsfromtheworldofengineering.

58 Readers’Tips

Ourwinnerthismonthhasatipforlathespeedreadouts.Send yourtipstomeweditor@mortons.co.uk,youcouldwinaprize.

66 Readers’Classifieds

Anothergreatselectionofreaders’saleandwantedads.

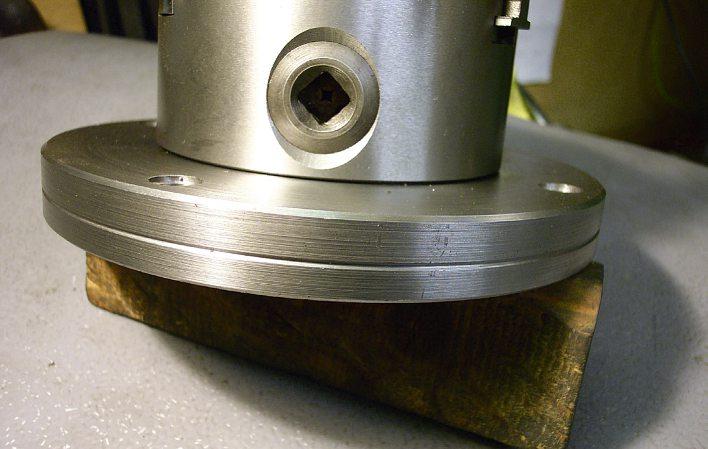

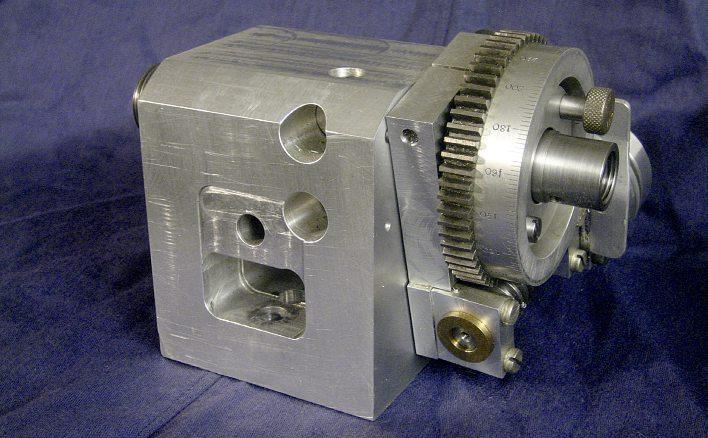

ONTHECOVER

OurcovershowsChrisHallaway’s CompactDividingHead, seepages9-15.

THISMONTH’SBONUSCONTENT

LogOntoTheWebsiteforExtraContent:

AllthelinksinJacquesMaurel’sarticleongeardesignaretobefoundat: www.model-engineer.co.uk/filengrene

Otherhottopicsontheforuminclude: Machinery’sHandbook Isitworthgettingacopy?ByDalboy. AllthingsBeaverMill Anopenthreadforanyoneowningor workingon.aBeaverMillbyRobertJames3.

Help!Excessivemachinemarks! WhereamIgoingwrong?By MargaretTrelawny

Steamrocketmotorcycleupdate. Steamrocketmotorcyclecourse recordattemptbyWindy

ComeandhaveaChat!

Aswellasplentyofengineeringandhobbyrelateddiscussion,we arehappyforforummemberstouseittoshareadviceandsupport. Comeandjoinus–it’sfreetoallreaders!

October2023 7 BernardTowersshareshis designforanER15indexer. Regulars No.332 INSIDETHISPACKEDISSUE: TURNINGSMALLRADIUSES Makethisrobustandaccuratedividingheadfor yourmillingmachine GetmoreoutofyourworkshopwithMEW Jointheconversationat: www.model-engineer.co.uk AHOSTOFIDEAS-BRIANWOODSHARESHISWORKSHOPWISDOM. THEBEGINNINGSOF –JAMESC.CREBBIN,PIONEERMODELENGINEER. JACQUESMAUREL’SPARADOXICALGEAR DEMONSTRATOR. GETREADYFORTHEBIGSHOW–SNEAKPREVIEWOFMMEX2023. HESIERANDMONOSOUPAPE–MODELENGINEERINGINNEWZEALAND. NEWSFROMWARCO. PLUSALLYOURREGULARFAVOURITES! CARRIAGEDIAL FORANEMCO MAXIMAT GrahamMeek achievesaccuracy usingshifted gearprofiles Masteranessentialworkshoptechnique withtheArtfulDodger THEMAGAZINEFORHOBBYENGINEERS,MAKERSANDMODELLERSOCTOBER2023ISSUE332WWW.MODEL-ENGINEER.CO.UK ATILTINGTABLE AnotherpracticalworkshopaccessoryfromMikeCox TURNING SMALL RADIUSES ACompactDividingHead

Visitour Website

ModelEngineershashtag#MEW

WhynotfollowusonTwitter?twitter.com/

HOMEFEATURESWORKSHOPEVENTSFORUMSALBUMS

CLASSIFIEDSEXTRASUBSCRIBEARCHIVESUPPLIERS

CompactDividing HeadPart1

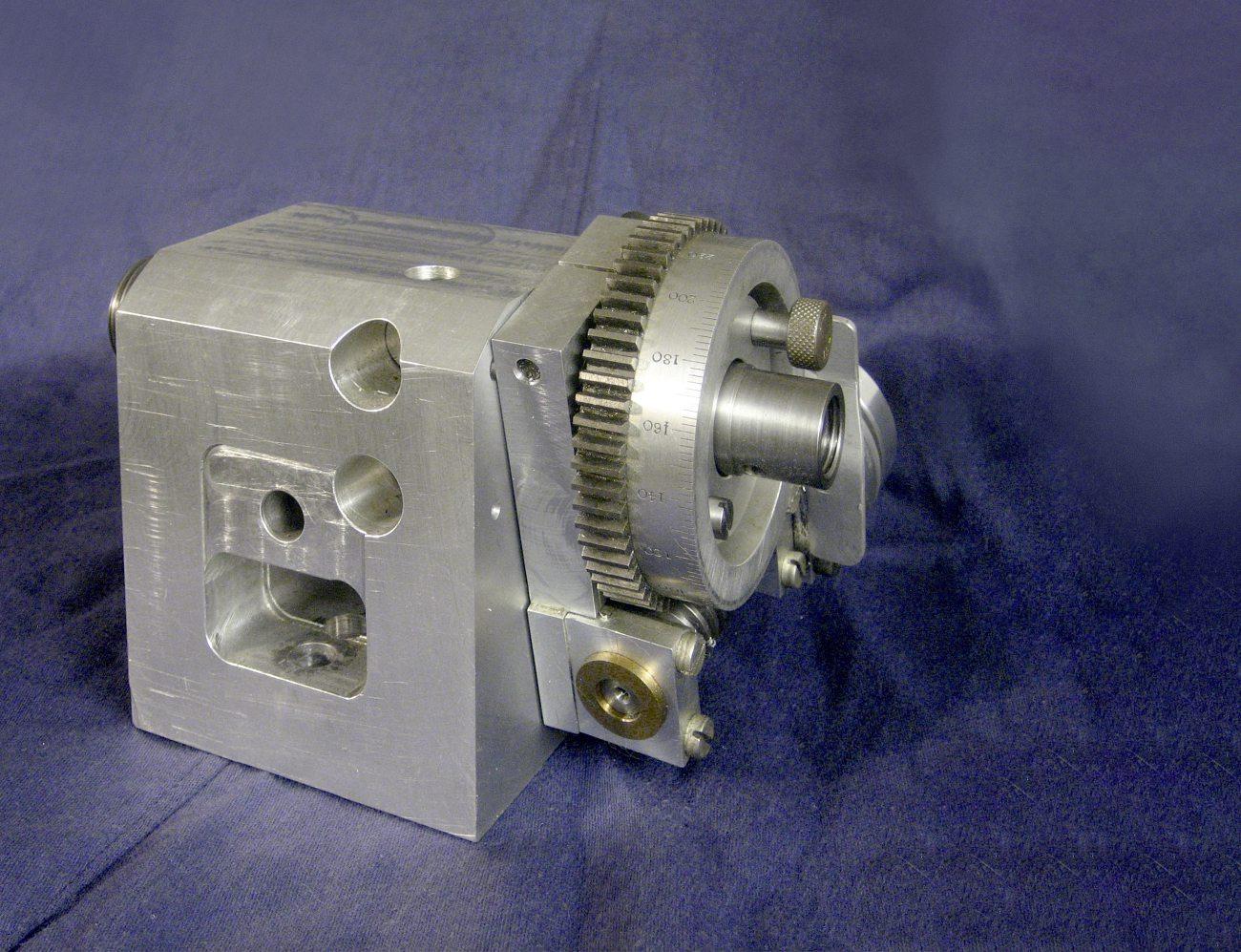

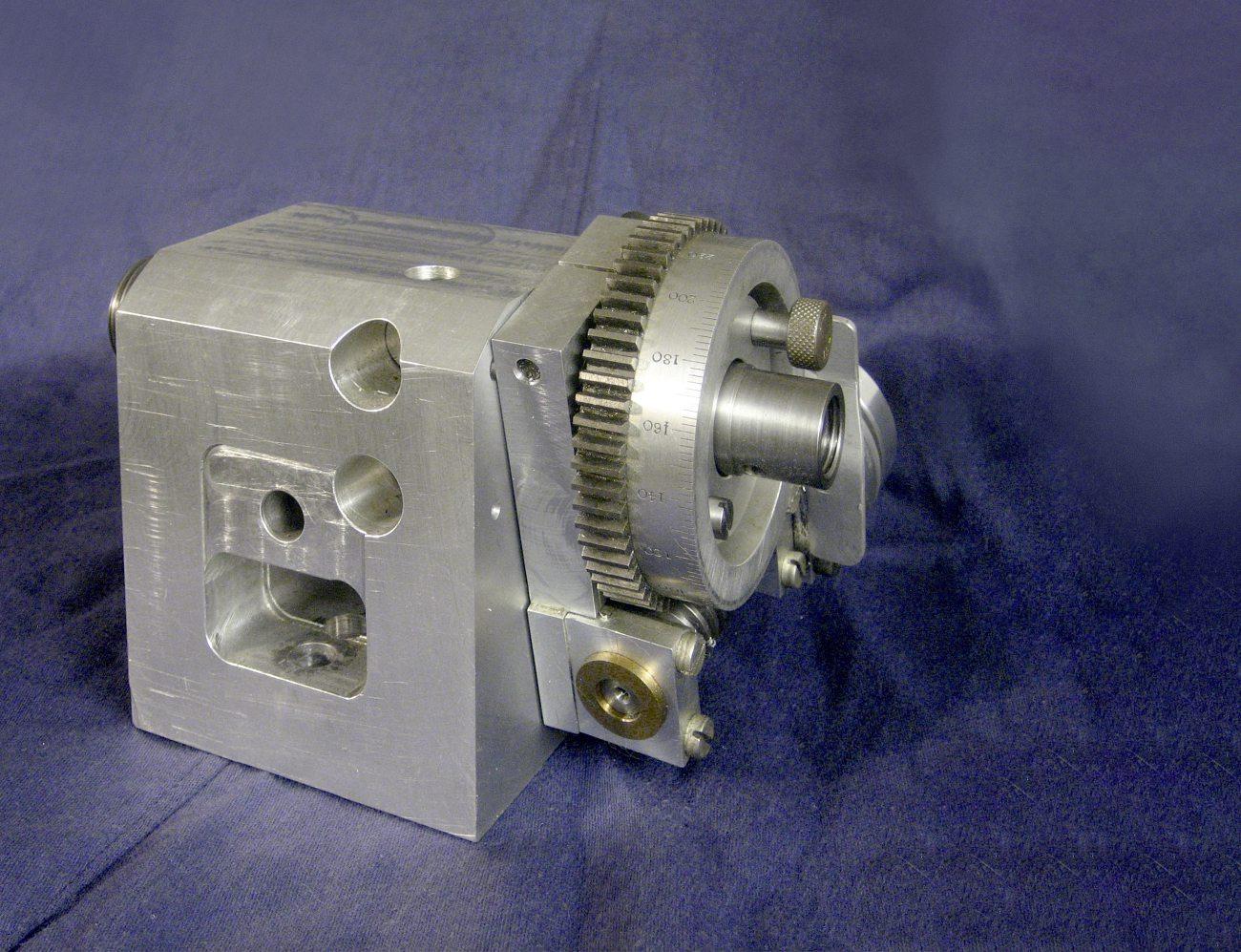

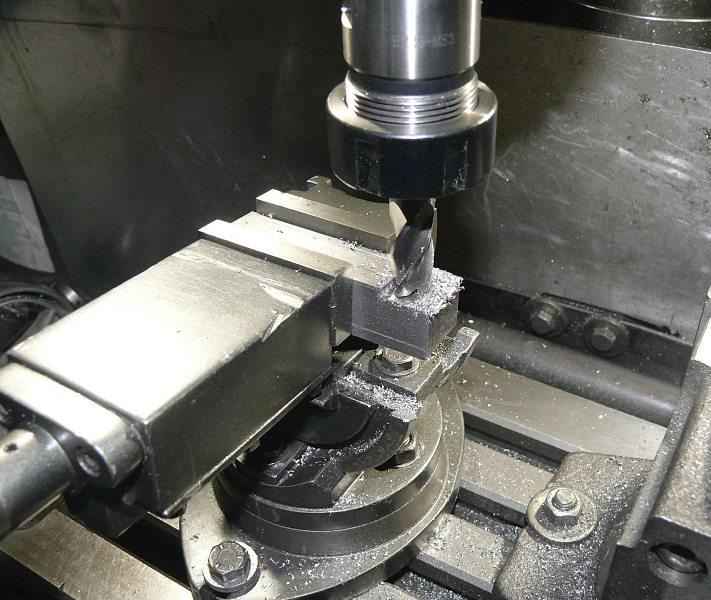

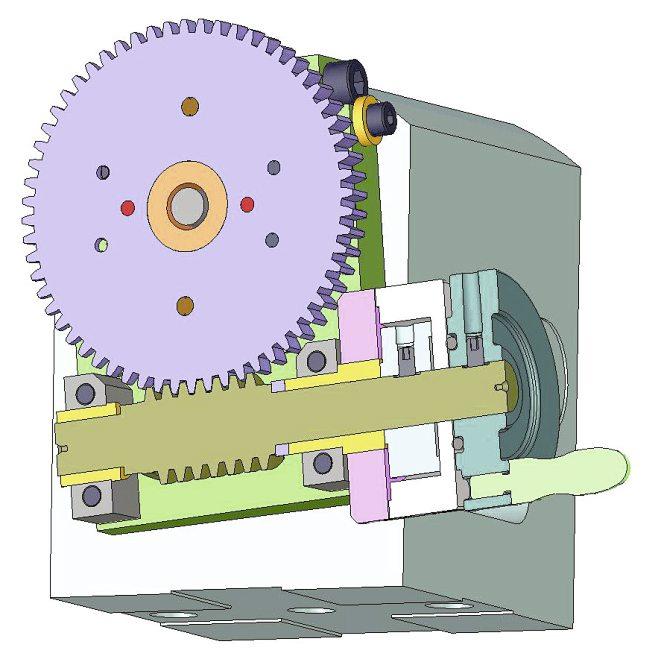

ChrisHallawaydesignedandmadethisCompactDividingHead(CDH)about thirtyyearsagoforusewithhobbysizemillingmachines.

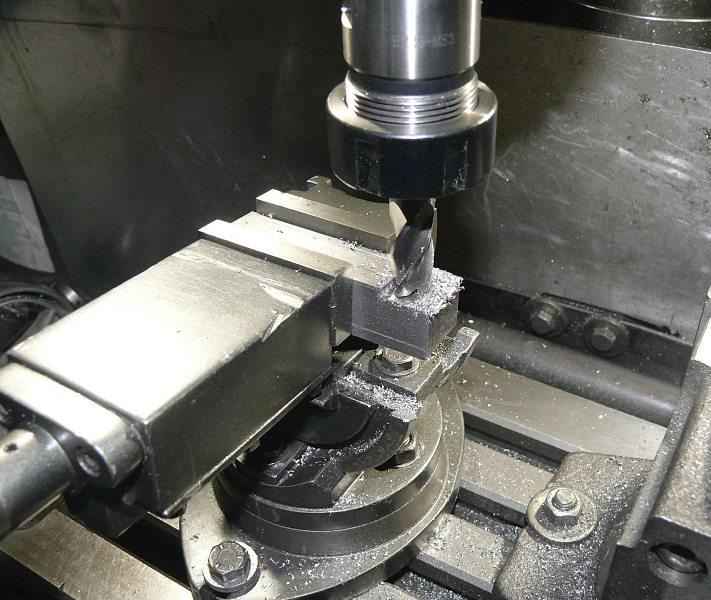

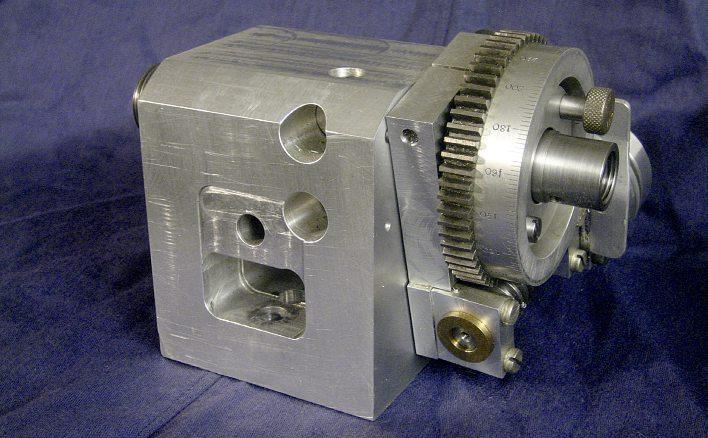

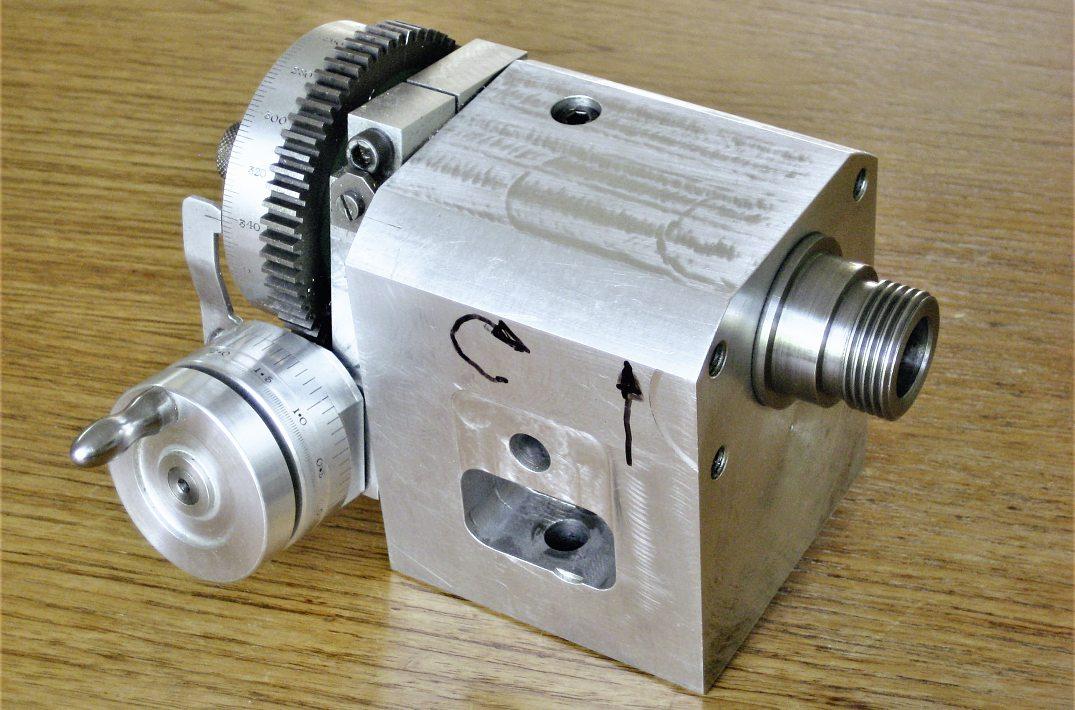

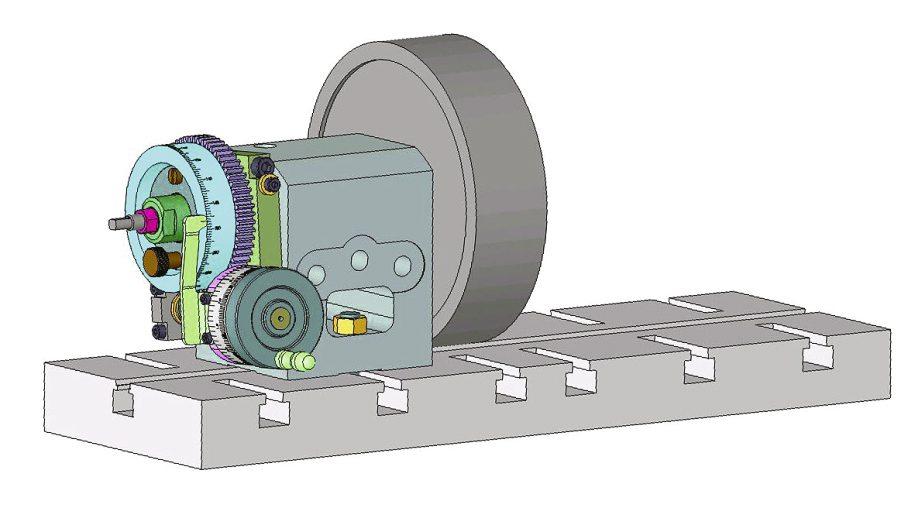

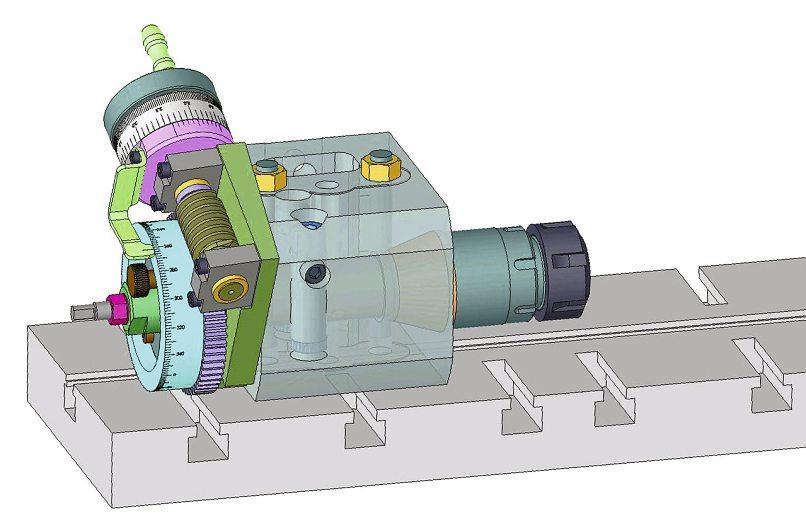

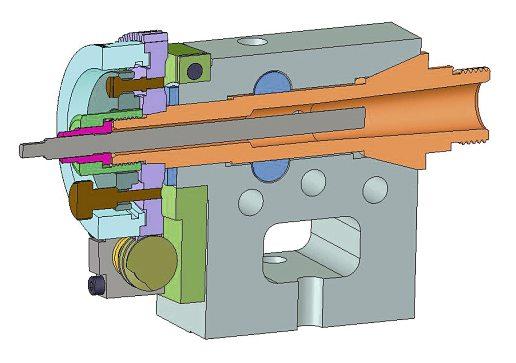

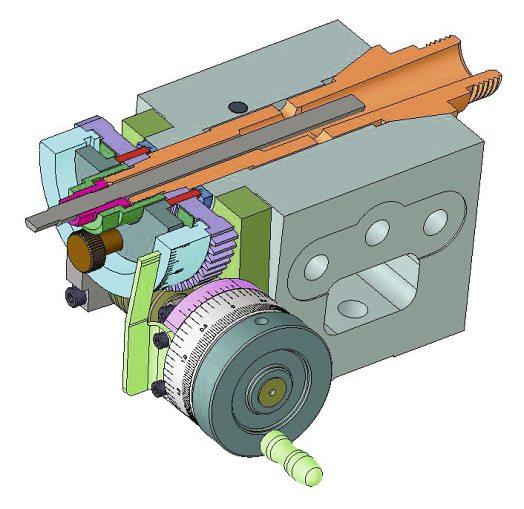

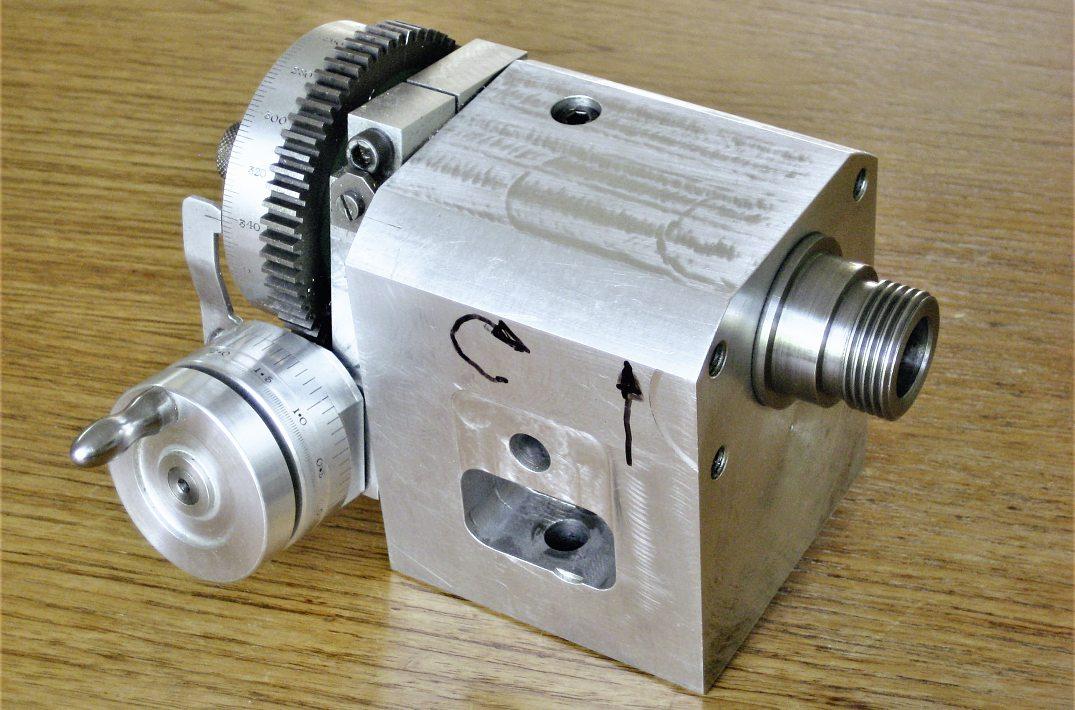

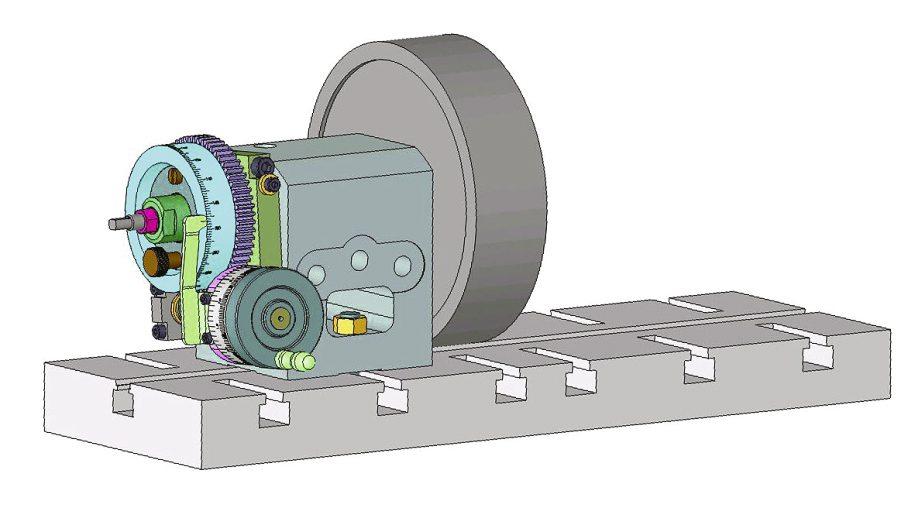

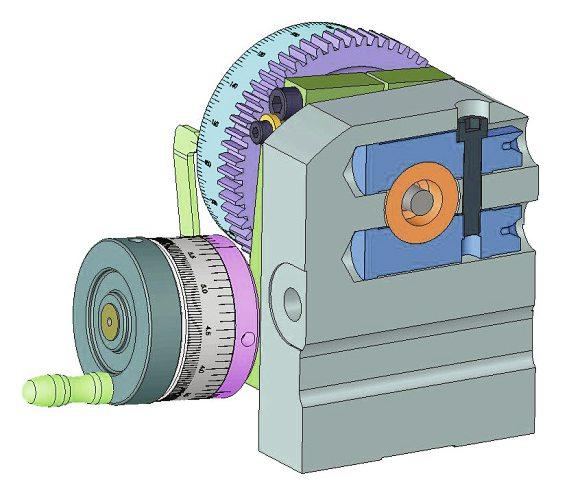

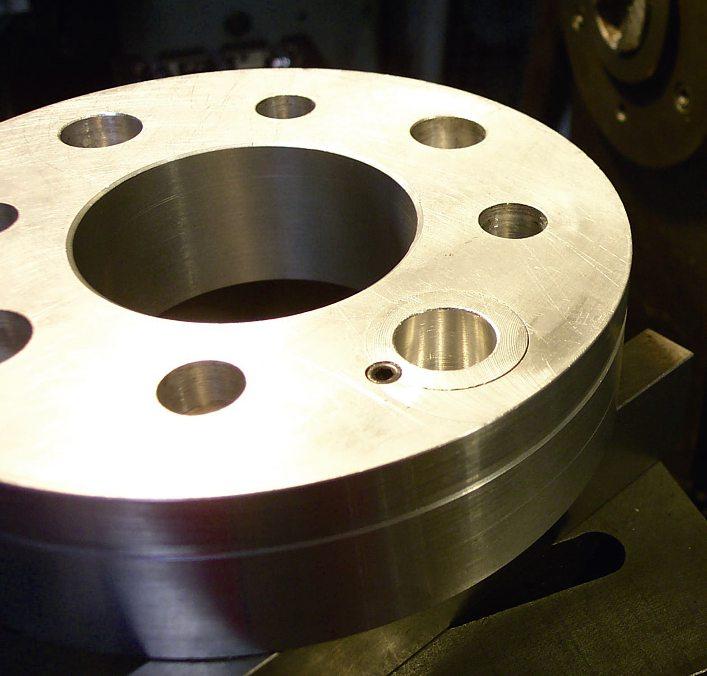

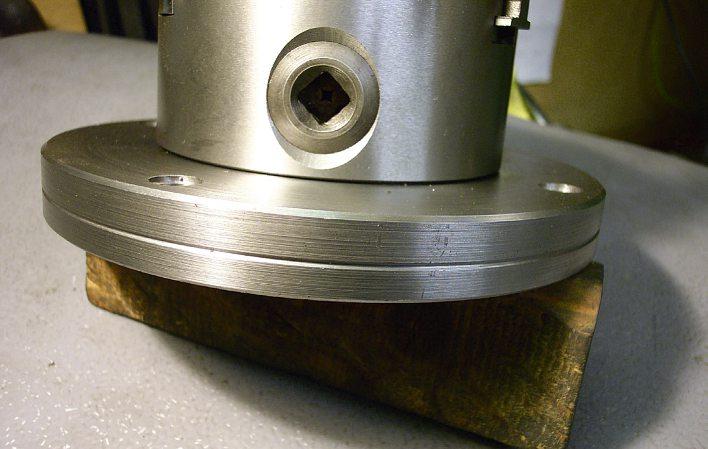

Smallermillingmachineshave limitedheadroomabovethe table,soIdesignedandbuiltthe compactdividingheadin photos1 and 2.Inordertomakemaximumuseof existinglatheaccessories(3and4-jaw chucks,colletholder,centre,catchplate, faceplate,etc.)thespindlenoseandbore mustreplicatethoseoftheuser’slathe, aMyfordSuper7inmycase.Detailsfor Myford7serieslathesareshown.The mainsha centrelineis3.1inchesabove themainmountingfaceandsoisableto accommodatea6-inchdiameter,4-jaw chuck.

ThisCDHisarrangedformounting atthele -handendofthemilling

2

› October2023 9

Head

CompactDividing

GeneralView(front)

1

GeneralView(back)

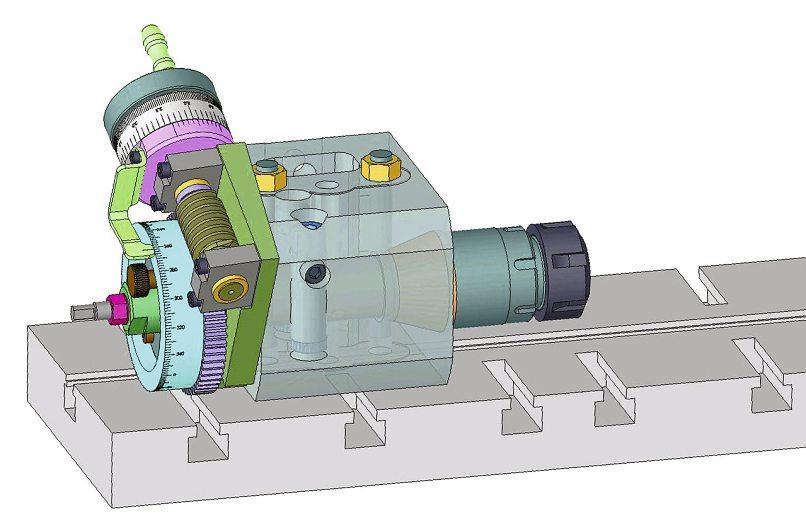

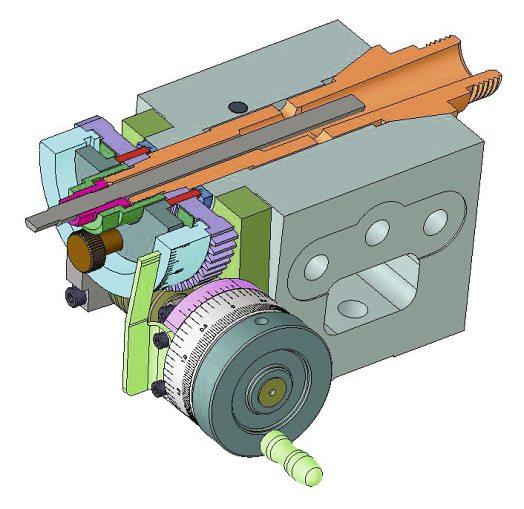

machinetable g.1, asisusual.If verticalspaceistighttheCDHcanbe mountedonitsside, g.2,whichsaves 1.5inchesinspindleheightbutwhich alsolimitsthesizeoftheworkpieceand itsmounting.Inthisposition,inorder tobeabletoreadthedegreescales, thewormsha anditsbracketmustbe repositionedthroughabout45degrees andadi erentdesignofzerobracket tted.Unfortunately,inthismode,the handwheeldialanditsverniermustbe readupsidedown.

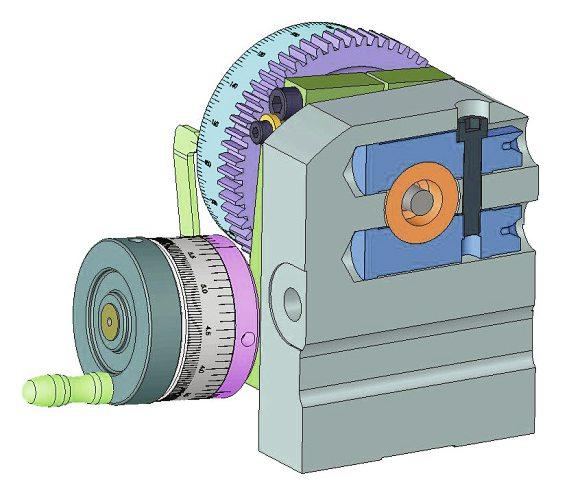

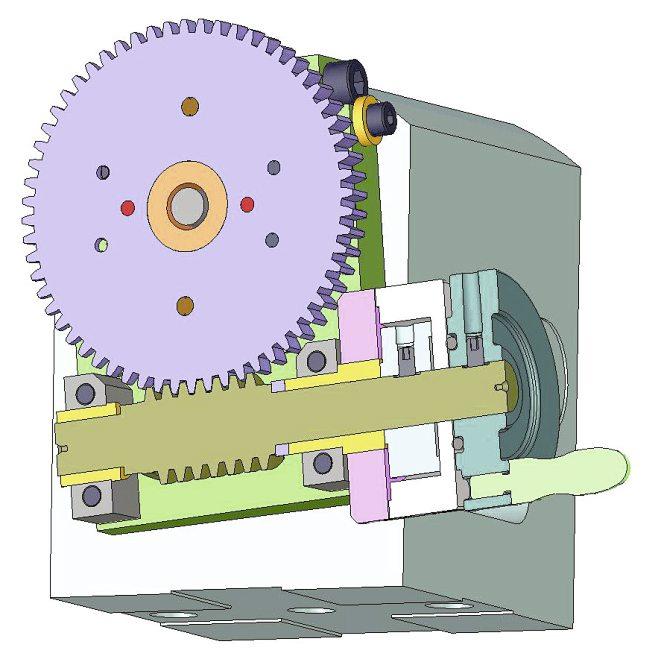

Asisusual,themainsha isdriven byawormandwormwheel.The wormwheel,whichistheonlymajor boughtoutitem,isamodi edMyford 60toothchangewheel.Aspecialtool needstobegroundtoscrewcutthe wormpro lewhichmateswiththe 20diametralpitch(DP),14.5degree pressureangle(PA)wormwheel.

Becausethewormwheelisactuallya spurgear,thematingwormhastobe setatitsownhelixangletotheplane ofthegeartoobtainpropermeshing.

Ifaccuracyisimportantforyour intendeduse,thewormwheelshould behobbedlikethegenuineMyford item.Wheelsindexedandcutwith Brown&Sharpecutterswhichproduce onlyapproximateinvoluteformswill certainlyintroduceerrorsoftoothform andspacingandwillcompromisethe nalresults.

ModelEngineers’Workshop www.model-engineer.co.uk 10 23 26 22 32 24 40 31 33 25 1 8 7 15 16 17 30 18

Figure1.MountedonBase

Figure2.MountedonSide

Notasgoodasapukkaenveloping Wormwheelbutithassurvivedmany yearsofamateurusewithoutnoticeable wear.

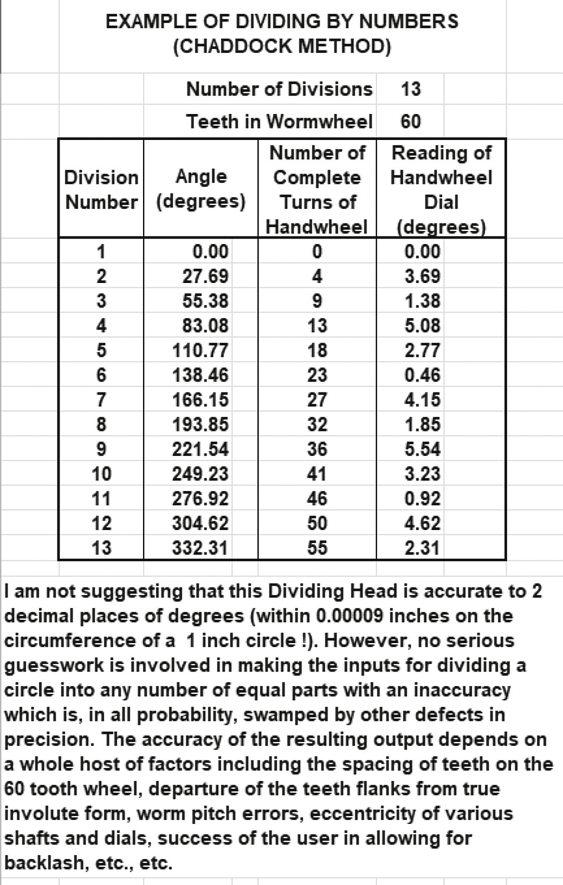

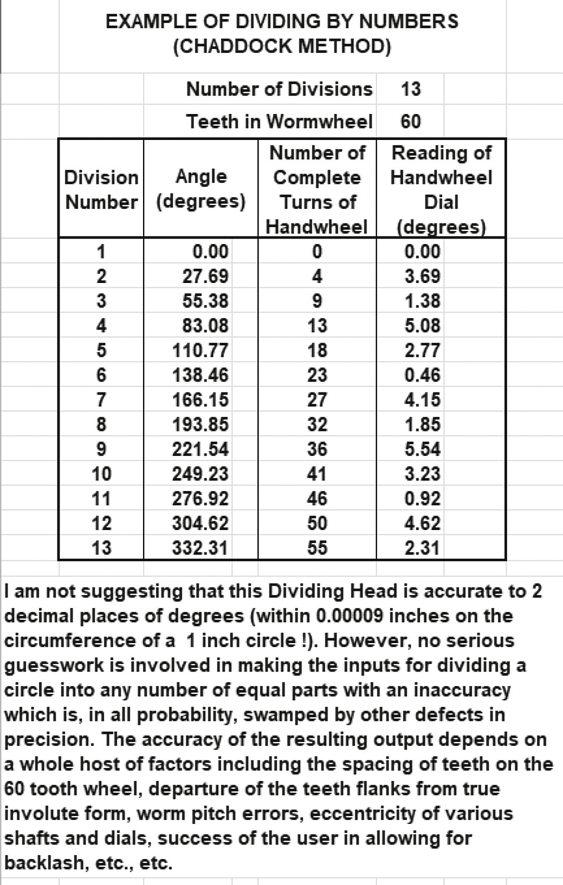

Boththemainsha andtheworm sha are ttedwithfrictionsettingdials, thelattercarryingavernierallowing anglestotwoplacesofdecimaldegrees tobeeasilydialledin.Divisionplates arenotincludedinthedesignas,for modelengineeringwhererepetition workisinfrequent,youmayaswell drillholes,etc.intothejobitselfrather thanintoadivisionplateandtheninto thejob.Anynumberofequallyspaced holes,faces,etc.maybesetupfroma tableofanglescalculatedusingahand calculator,Microso Excelspreadsheet, etc.assuggestedbyProfessorD.H. Chaddock.The Table1 showsan exampleforThirteenequallyspaced features.Becausethereisadegree dialonthemainsha ,thereisnoneed tocounthandwheelturnsnotingthat losingtrackofturnsisafrequentsource ofdi cultyinoperationsofthissort. AdownloadableExcelspreadsheet whichcancalculateanynumberof equallyspaceddivisionsupto400is referencedattheendofthearticle(and willbedownloadablefromwww.modelengineer.co.uk).

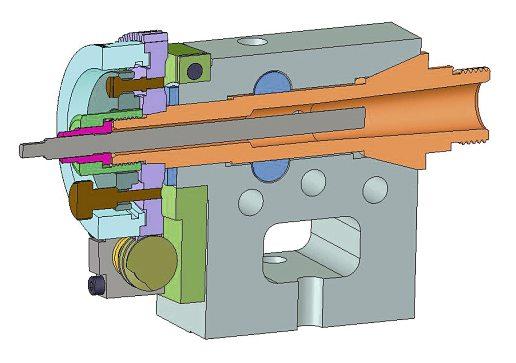

Theoriginalintentionwasthat themainshaftwouldbelockedin positionbypullingitaxiallyintothe taperednosebearing.Thisprovedto beineffectiveinpreventingrotation soapairofclampingbarswasadded togripthecentresectionofthe shaft fig.3. Theoriginallocking

› October2023 11

Head

CompactDividing

4 19 21 20 27 28 29 2 3

Figure3.CrossSectionthroughClampingBars

11 9 6 10

MountedinclinedonanAnglePlate 14 13 12 5

Figure4.CrossSection,verticalthroughMainshaftFigure5.CrossSection,horizontalthroughMainshaft

brakingwhen,forexample,hobbing gears.Asneitherofthetwolocking mechanismsimposessideloadson themainshafttheyareunlikelyto

Thebodywasmachinedfrom5-inch diameterforgedaluminiumbarand contributestotheratherlow,easily

ModelEngineers’Workshop www.model-engineer.co.uk 12

mechanism,visibleincrosssections, figs4 and 5 ,hasbeenretained asausefulmeansofadjusting bearingclearanceandproviding 3

affectpositioningaccuracy.

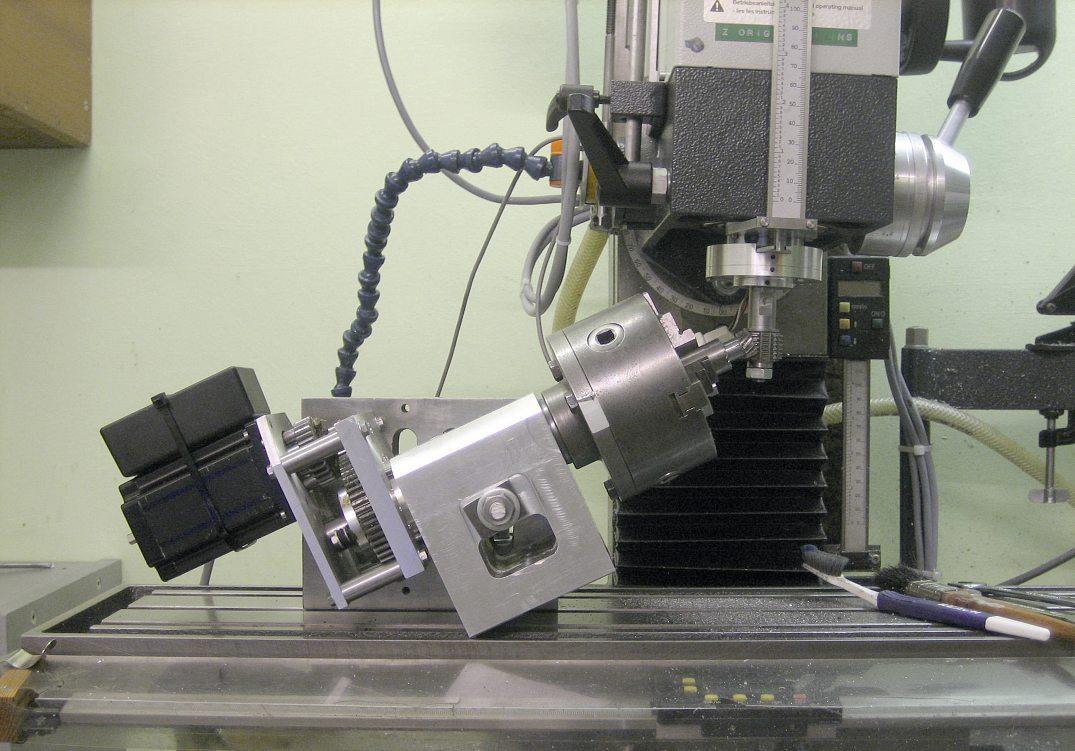

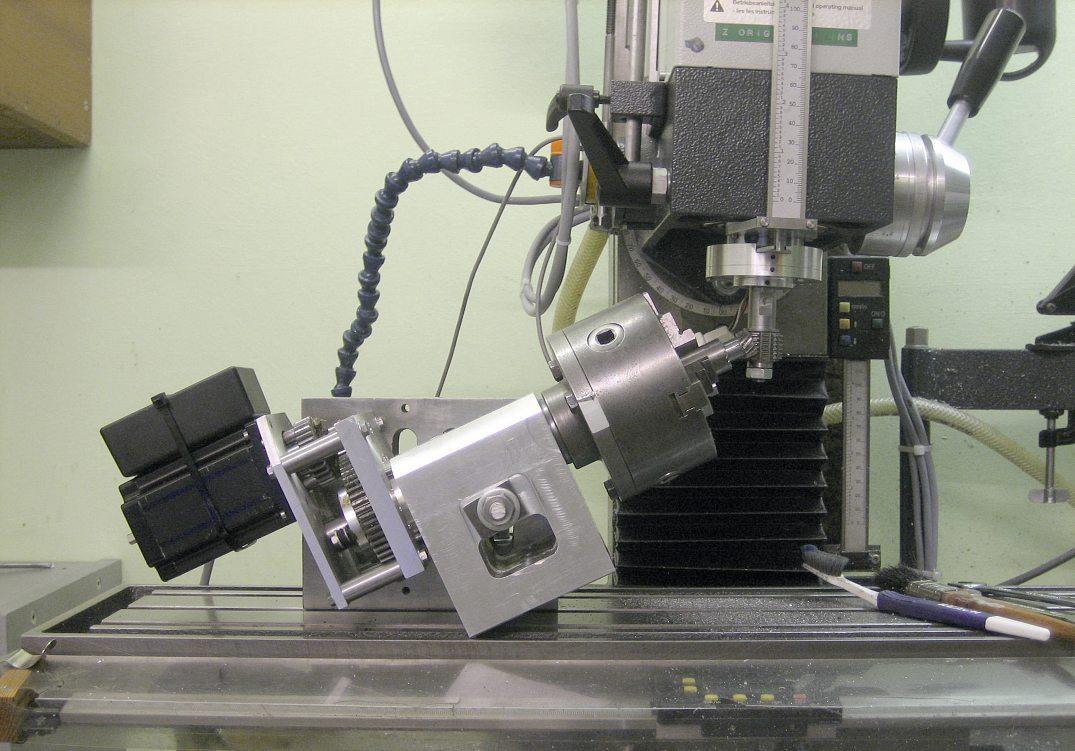

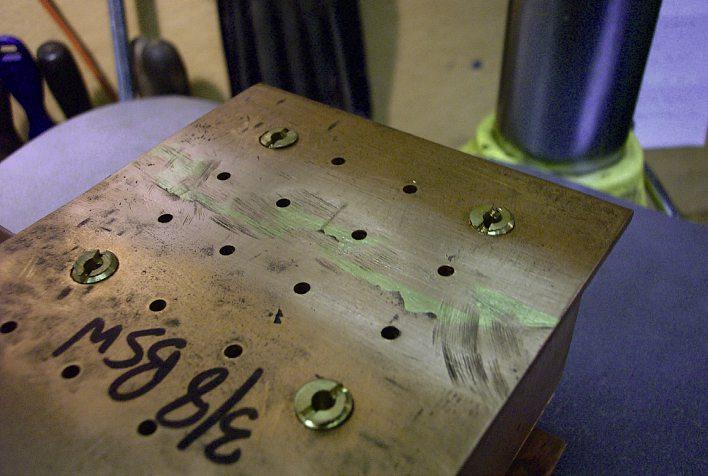

handledoverallweightof8lbs.Itcan beclampedtoamillingmachinetable bystuds,teenuts,nuts,etc.through suitablyspacedverticalholesinthe lowersectionor,ifangledmountingis required,toanangleplateviahorizontal holesandbolts, photo3

Alldetailedpartsandmodi cationsto the60-toothgearweremachinedusing myMyfordSuper7latheandDoreWestburymillingmachine.

Thedrawbar,essentialforretaining Morsetaper2(MT2)mounteditems againstsideandvibratoryloads,is arrangedforselfejectionsoimpact releaseisunnecessary.MyDore Westburymillcanonlyaccommodatea 5/16BSFdrawbarsoallmyMT2items carrya0.500inchdiameter,male/ femaleadaptertogetfromwhatever threadtheycamewithto5/16BSF female.Ifyourpreferreddrawbar isotherthanthis,theMainsha andDrawbarSleevewillneedtobe modi edtosuit.

Itwasfoundlaterthat,withthe additionofasteppermotoranddrive, thedividingheadcouldserveas theworkholdingpartofaspurand helicalgearhobbingset-upinspired byanarticleinMEW193byJohnPace (photo3)

MakingtheCompact DividingHead

Atthetimethisdividingheadwasmade, BAandWhitworthformfastenerswere readilyavailable.Asthisismuchlessthe casenow,metricfastenershavebeen substitutedinthedrawings.Howeveras mymachinesandmeasuringequipment areinchbased,drawingdimensions andturnedthreadsconformtothisold system.AndIdocheatbyusingafull 1-10by0.1mmsetofmetricdrillswhere 1/64inchstepsinImperialdrillsetsare toocoarse.Mostdimensionsaregivenin inchesto3decimalplaces.Noparticular accuracyistherebyimplied.

Inthelightofexperienceandof furtherthought,otherminorchanges havebeenmadesothedrawingsare showingsmalldi erencesfromthe photographsoftheoriginal.

Severalcross-sectionsarepresented forinformation.Thishopefully helpsinsortingoutwhatmatters andwhatdoesn’t,seealso g.6, enablingbuilderstoalterpartstosuit

October2023 13 CompactDividing Head 36 37 38 39 38 35 34

Table2PartsList SubAssy Balloon Number PartName No O Notes BodyAssy 1 Body 13stages 2 ClampBarUpper 12stages 3 ClampBarLower12stages 4 Capscrew 1M6x30 Mainsha Assy 5 Mainsha 16 CircularLever17 WormwheelDial18 Wormwheel1 Mod.Myford60t. ch’gear 9 PivotScrew110 Thumbscrew111 ThrustWasher112 Capscrew 4M3x6 13 GearDialRetaining Plate 214 ThrustPin 215 TubeNut 116 DrawbarSleeve1-

Figure6.CrossSectionthroughWormshaft

theiravailablematerial,toolingand preferences.Colouringofpartsinthe various guresisforidenti cationonly, thereisnomaterialcodeorartistic impressionintended.

Withtheexceptionofthespindlenose andtheworm,sizesarenotcriticalbut ofcoursewhereparts ttogethercare needstobetakentoachieveappropriate clearances.Thisisnothingnewandisthe usualprocedureinmodelengineering. Inafewplaces,describedinthetext, machiningsequencesneedtobe observedtoachievethedesiredresults. Itissuggestedthatmajorpartsbemade intheordergivenbelow.

Wherecalculations,explanations andderivationswhichdonotdirectly affectdimensionswouldinterrupt thenarrative,theyhavebeen

appendedasfiguresseparatedfrom themaintext.

Balloonnumbersfrom Table2,the listofparts andreferencedinthe gures preceedpartnamesinwhatfollows.

1Body

Myexperienceofaluminiumcastings producedformodelengineering hasbeenpoorso,ifanalternativeto forgedaluminiumalloyasnotedon thedrawing, g.7,isneeded,Iwould suggestcastiron.

Stage1.Startbycreatingall6 mutuallyperpendicular atfaces leavingenoughonthelengthtoclean upbothendsinthelathe(thespigot onthebackendismachineddown later).Iusedanangleplateandclamps todothisbecauseIfoundthatmy

viceandnotveryrigidmillingmachine consistentlyproducedrightangles thatweren’t.Thecoupleproduced bytighteningthevicewasbending (happilynotpermanently!)theviceand machinetable.

Drilland,whereindicated,tapallthe holesfollowedbyendmilling(probably frombothsides)therectangular throughholewhichprovidesaccess for ttingnutstothesecuringstuds. Nospacingorsizeareshownforthe holeswhichtakethestudsclamping theCDHtothemillingmachinetable, angleplate,etc.asthisdependsonthe machineinquestionandtheselected studsize.Holeswillusuallybesetto suittee-slotspacingtogetherwitha centrallyplacedholeshouldangled mountingbeenvisaged.Inthelatter case,additionalsecuritywouldnormally beprovidedbystops.

Theeighttappedmountingholes inthefrontandrearfacesarespaced tosuittheMyford11inchfaceplate. Ifyouneedtochangetheirpositions tosuityourequipmentcheckthat youarenotdiggingintosomething important.Careshouldalsobetaken tokeepthesha boreasnearas possibleparalleltothebottomand sidemountingfaces.

Stage2.Boltthebackfacetothe faceplateandadjustsothatthebore positionrunstrue.Faceandthenbore fromthefronttodrawingdimensions usingtheMainsha asagauge.Aimto havethespigotfaceontheMainsha proudofthefrontfaceoftheBodyby 0.125inches.

FitthepartiallymachinedClamp Barsandtighteninpositionwiththe6 mmcapscrewbeforeboringthemto asliding tonthe1.000inchdiameter sectionoftheMainsha .Removethe ClampBars.

Stage3.Nowboltthefrontfaceto thefaceplateandadjustsothatthe 0.930inchesbearingborerunstrue. Facebacktodrawingdimensions.This willremovemostofthe4tappedholes which,togetherwithsimilaritemsatthe front,areredundantoncemachiningis complete.

FinallyenlargetheholefortheClamp Barcapscrewtodrawingdimension whichwillallowtheClampBarstoselfalignontheMainsha

l Tobecontinued

ModelEngineers’Workshop www.model-engineer.co.uk 14 17 Drawbar 1Wormsha BracketAssy 18 WormBracket119 Capscrew 1M6x40 20 Capscrew 1M4x10 21 Retainer 122 WormBearing BlockRH 123 WormBearing BlockLH 124 Capscrew 4M4x30 25 WormBearingRH126 WormBearingLH127 ZeroBracket Clamp 128 Grubscrew 1M4x6 29 PlainNylonPlug M4 130 ZeroBracket131 ZeroBracketSide132 Capscrew 2M3x10 Wormsha Assy 33 Wormsha 134 Handle 135 Handwheel136 HandwheelDial137 HandwheelDial Collar 138 Grubscrew 2M4x6 39 ORing 1BS1806-116 40 Wormsha Thrust Collar 1-

October2023 15 CompactDividing Head 18° Ø2.000 Ø1.560 Ø0.930 3thruholes Øtosuitstuds pos’ntosuitT-slots 3thruholes Øtosuit studs Ø0.433 Ø0.236 Ø0.625 x2 0.025 1.310 1.310 0.690 r2.500 0.695 0.780 0.780 Ø1.200 Ø1.725 Ø1.050 Ø0.252 1.680 1.050 3.100 1.000 M8x0.780 fullthread 8places 4.000 3.200 2.520 1.600 r0.250 4places r0.500 3places 1.0001.000 1.710 0.500 1.000 0.500 3.100 4.200 0.550 1.900 0.025 0.525 0.525 0.900 1.100 0.750 0.900 0.550 3.885 3.385 3.360 Part1.BodyStage1 Mat’l:6082T6orsimilarforgedaluminiumalloy

Part1.BodyStage2 Part1.BodyStage3

Figure7.Threestagesofmachiningthebody

Tipsandhints,some old,somenew,some borrowed

…someengineers’blue?BrianWoodsharessomeusefulideasfortheworkshop.

IapproachedtheEditorrecentlywitha coupleoftipsforpublicationinMEW, completelyunawareofbeingthe winnerinapreviouso eringthatwas abouttobeissued.Iwasaskednicelyto acceptadi erentmethodforthesetobe publishedinScribeaLinetoavoidbeing labelledas‘hoggingtheslot’towhichof courseIagreed.

Itsetmethinkingthoughasthereare severalmoreoftheseconsideredworthy ofpassingonandthisistheresult;a mixedbagofdodgesandtheliketobe goingonwith.

Trickswithwoodscrews

Toshi tightwoodscrewsthathave rustedintothewoodworkoverthe years,myfatherusedtobelttheendof thescrewdriverhardtoshockthegrip andthen tighten thescrewslightly beforeundoingitinthenormalway. Themethodhelpedreducethefrequent

riskof‘cam-out’withslotheaded screwswhichchewsuptheslot,a curseoftheheaddesignandespecially dis guringonbrassscrewssoo en usedinfurniture.

Itworksequallywellonmoderncross headscrewsandafurtherre nementI havefoundhelpfulistogreasescrews usedinoutdoorprojects,especially incaseswherewallplugsareused. Greasingalsohelpswhendrivingthem homeintopredrilledholesinhardwood.

Distancecollarforcon dence inrepetitivebatchwork.

PartofwhatIdoiscommissionwork forlocalbusinesses.Arecentfurniture andglassprojectrequiredasetofeight matchinglengthsupportlegstobe suppliedin30mmdiameterstainless steelbar.

Therewasotherworkformetodoin thisproject,butthelengthrequiredof

theselegsexceededwhatmylathecould accommodate.Agoodfriendo ered metheuseofhisbigWillsonlathewith itslargeborespindlesothatIcould comfortablydrillandthreadM10holes forlevellingfeaturesintotheends.The barsweresawnalittleoverlongfrom lengthsofmaterialfrommysupplier.

Withoutameasurementofthespindle borebeforehandtomakealengthstop, andtobecertaintheyallmatchedfor lengthwithin1mm,Iturnedupaclosettingcollarwithasidegripscrewto functionasatoolingreferencestop.

Havingfacedoneendofabar,the collarwasslidonandsecuredforlength attheotherendbyrulermeasurement withboththerulerandbarbuttedup againstasolidsurface.Then,withthe lengthofthebaroutofsightdownthe lathespindle,Ifacedtheendgrippedin thechucktojustkisstheouterfaceof thecollar,knowingthatthebarlength wouldbecorrect.Toprotectthecollar frominadvertentmachiningandthus anythinning,Ihadpreviouslycoatedthe ‘stop’facewithablackmarkerpenasan indicatorofimpendingcontact.

Theremainingsevenbarswere allmachinedasabatchbythesame methodto“identicallengths”asrequired inthebriefIacceptedontakingthejob, usingthe rstoneforreferenceineach case;a erwhichIdrilledandtappedall eightwiththeworkgrippedclosetothe chuckinthenormalway.

Usingananglegrinderon brazedcopperandbrassjoints

Thisdiscoverycameaboutbypure chance.Ihadextendedboth rebox sidesonacopperboilerforatraction enginebymakingcastellatedjointsand completedthejointsbybronzebrazing,

ModelEngineers’Workshop www.model-engineer.co.uk 16

1

Anglegrinderresultsoncopper

leavingexcessbrazematerialtoremove a erwards.“Trytheanglegrinder”I thought.Thecopper/brazematerial promptlycloggedthemetalcuttingdisc whichthenstartedtotearupthesurface Iwastryingtosmoothout.

Thiswasofcourseataweekendwith suppliersclosedandallIhadle inthe boxwasapartiallyuseddiscformasonry work.Itwasaclassiccaseofchoosing eithermuckornettles,soI ttedthis discindesperation.Tomysurpriseit proceededtodoamagni centjobif gentlestrokeswereused,withnothing tooaggressive.Therewasnoclogging atall.

Photograph1 showstheresultI wasabletoachieve.Itisnotperfect byanymeans,someoftheprevious discdamageisevidentbutitworked alotfasterthanothermorearduous manualmethods.

Variousaspectsofworkshop design

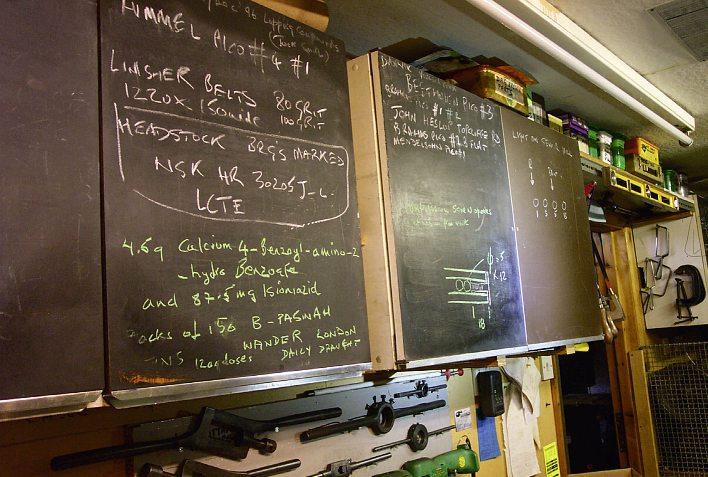

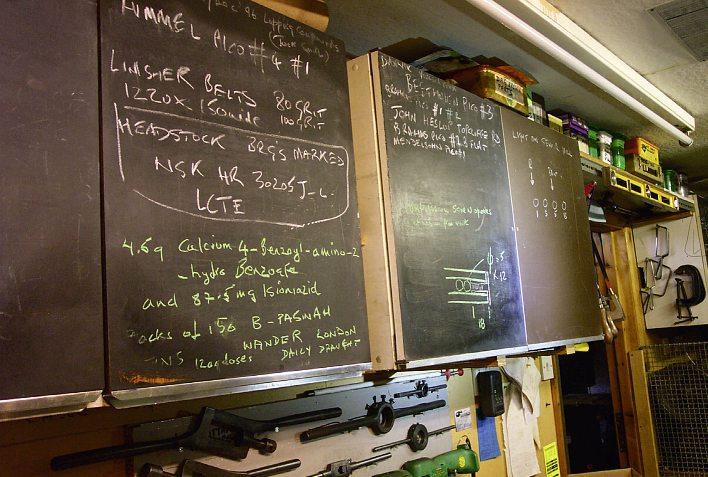

Smallblackboardsontheworkshopwall. Thesearejustredundantwallcupboards fromanoldWimpeykitchen,withthe doorspaintedinblackboardpaint.They makegreatplanningfeaturesthatcanbe usedrepeatedlyfornotesonmachining sequences,buyinglists,remindersand soon.

Thecupboardsthemselvescontain massesofstu ,collectivelyquite heavyandkeepitallcleanandout oftheway.Theywerenotmadeto supportthepotentialweightIwould belikelytostoreinthem,sowere

strengthenedbystrongbackscut fromshutteringplyandscrewedtothe framesofeach.Thebottomedgewas ‘footed’intoalengthofDexionslotted anglesecuredtothewallwiththe mountingleg ttedupright.

Eachcupboardwasscrewedback throughtheDexiontothewallbehind. Topreventtoppling,thetopswerealso screwedbacktotheblockwallbehind theinsulationboardsusingtheexisting steelcornerreinforcingplatesthathad beenbuiltintothem.

Photograph2 isaviewoftherun offittedunits.Aftersuchattentionto detailinfittingthem,anddespitethe considerableweightnowcontained withinthem,theyhaveneededno attentionatallafternearly30years inposition.

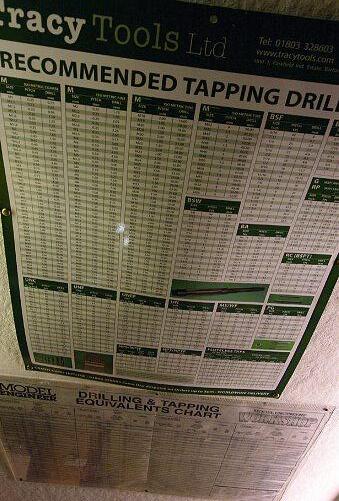

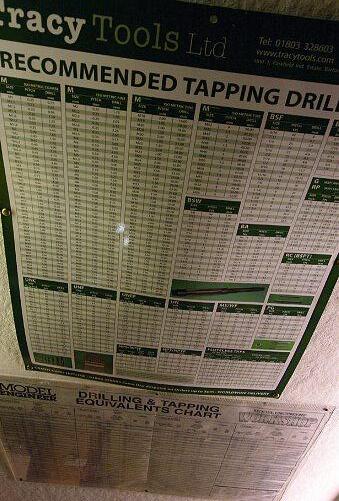

Spaceisatapremiuminmyworkshop (what’snew?Ihearyousay),something probablytrueofmostowner’s workshopsandcertainlysointhiscase. Withnospacele onthewalls,itwasall usedupalongtimeago,somereference chartsaremountedbehindPerspex sheetsupontheceiling.Atleasttheyare welllitupthere!

Photograph3 isaviewofthem, betweentheoverheadstriplights.It doesmeancraningyournecktoread them,somethingIcanstilldowithout fallingover!

Sitingthebenchvice.UnusuallyI chosetomountmyviceatanangleon theendofthelongandverycluttered bench.Havinganykindof atsurfacein myworkshopisfatalandtendstoattract

whatmywifecallsjunkbutisinfacta valuableresourcetobeminedforthings.

Photograph4 showsonereasonwhyI choseto tthevicethiswaysothatlong workcanpokeoutofthedoorrather thanrunalongthewholefrontofthe bench.Italsoallowsalittlemorespace behindtheviceforahacksaworlong le tooperateinto

Thesequicktipsmightbenew tosomereaders.

• Whydosomemachineviceshave aVeenotchgrounduprightinthe xedjaw?Togriproundobjectsor

› 17 HintsAnd Tips October2023

2 Ceilingmountedreferencecharts 3 Benchviceangulation 4

Smallblackboards

shortsectionsofbarfordrillingand millwork.

• Apieceofcottonragoveranoilnipple makessuretheoilgoesintothe nippleratherthansquirtingdownthe outside.Ridiculousasitsounds,this dodgeworksremarkablywell.

• Sharpenaroundcentrepunchwithit heldinapowerdrillandrotatedagainst thesideofthegrindingwheel.Best resultscomewiththepunchrotating againstthedirectionofwheelrotation. Pointanglescanbeeasilyseenas grindingproceedsandcanbeadjusted asnecessaryduringtheprocesswhich takesjustmomentstodo.Automatic centrepunches,strippeddowntowork onthehardenedpin,respondwellto thismethod.

• Tosawshapesfromaluminiumorbrass sheet,oneitherametalorwoodcutting machine(withasuitableblade)puta sheetofthree-plypackagingcardboard beneaththesheet.Itstopsalotofthe ear-splittingnoisemadeifjustsawnon thetableandtendstoleaveacleaner cutwithoutitrattlingabout.

• Finetoothslittingsawsworkbest atnomorethan40-50rpmwhile feedingthemsteadilyintothejob. Runthemfasterandtheyveryquickly

blunt,gethotanddistortandworse still,mayrupture.

• Aperfectlyacceptablecentrepunch canbemadefromano cutofrebar. Beingofmediumhardnessitwillneed sharpeningmorefrequentlyoritcan bemadeintoahardertoolbyheating toredheat,quenchinginwater,and temperingtoalightstrawcolour.

Recoveringfrommistakes

Foranovermachinedroundobject intendedto tintoaholefor,say,a brazedjoint,tryraisingthesurfaceby knurlingbeforeassemblingthejoint.If youdonothaveameansofknurling, goaroundtheoutsidediameter(O/D) withacentrepunchtoraiseupaseries ofswellingsaroundeachpunching.It won’tcentraliseaswellasknurlingbut maywellbegoodenoughtorecoverthe situationandholdthejointtogetherfor brazingorwelding.

Inthealternativecasewherethe borehasbeenmadetoolarge,“adding on”methodsarenotavailable,and adi erentapproachisneeded.

Makeasleevebutbeboldand t athick-walledversionthatcanbe anchoredonthejointlinebyalocking screwtopreventlatermovement.

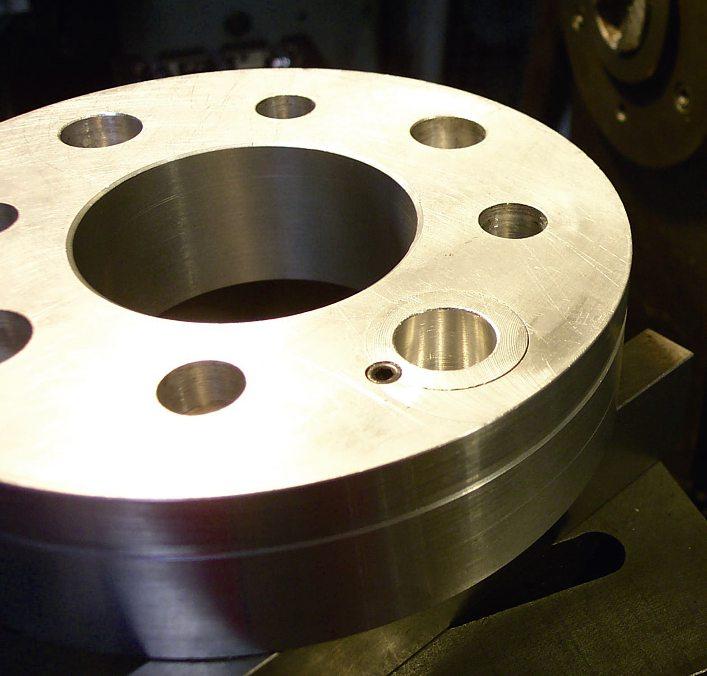

Photograph5 showsaninternally steppedsleeve,withlockingfeature, ttedtocorrectadrillingmistake(not mine)inawheelspacerto tahub withdi erentboltingPCDs.

Onasimilartheme,tosecureaparallel lockingpinacrossajointthatisjusta littletooeasya ttogrip rmlyinthe hole,chopanotchacrossitatabout45 degreeswithasharpcoldchiselandthen tapithome.

Anoldandcheapdodgetoremove stubbornstuds(agoodexample mightbetoremovethoseholding exhaustmanifolds)anda ersoaking withpenetratingoil,istoruntwonuts downontheaccessiblethread,witha washerbetweenthemifspaceallows. Tightenonehardupagainsttheother andunscrewthestudusingthelower nut.Themethodtakesupnospaceand avoidsthecostofastudextractortool.

Useanoldturner’stricktocompletely removetheslightmismatchinsurface heighta erturningthejobaroundina 3-jawlathechuckto nishtheworkfrom theotherdirection.Attheveryleastit spoilsthejobcosmeticallyandtohide thefeature,useaveepointedtoolto machineashallowgrooveatthepointof mismatchtodisguiseit.Ifthejoballows it,turnotherselsewhereonthepiece toreinforcethe“decorative”aspectof thedisguise. Photograph6 showsan exampleinthe angethathasbeen treatedthisway.

Ifastenhousingsorsuchthings thatneedbolting,startingwithone hole,tapped,andboltedtosecureit beforemarkingouttheremainderby usingatransferpunch.Itensuresthe jobhasn’tmovedinthemarkingout process.Thesearesuchusefultoolsin theworkshop,andtheycanbebought insetsofmetricorimperialsizes.Being longandofprecisediameters,theywill reachdownaccuratelyindrilledholes.

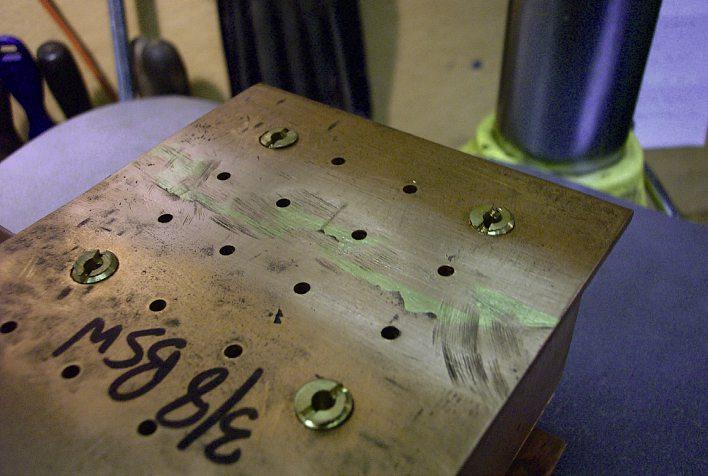

Photograph7 showsanotheruse forthemasprecisionsupportsforlow pro leitemsthatneedmillingwork doingandaretooshorttogetthe workingsurfaceabovethevicejaws whensupporteddirectlyfromthe oor ofthevice.

Someideaslearntfrom YouTubeprofessionals

Astheseweredemonstratedpubliclyon open-sourcematerial,theywereclearly

ModelEngineers’Workshop www.model-engineer.co.uk 18

5

Sleevedrepairofmistakeinholelocation

intendedtobeusedbyothers.But,even so,itiscourteoustoacknowledgethe workofothersandthe rstofthese isfromKeithFennerofTurnwright MachineShopinCapeCodUSA

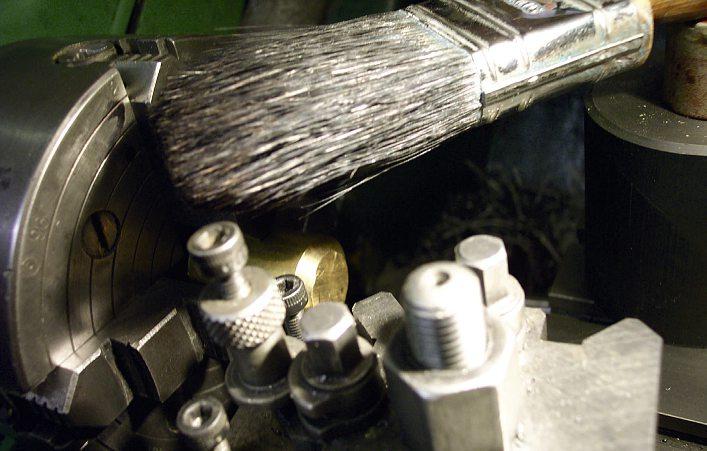

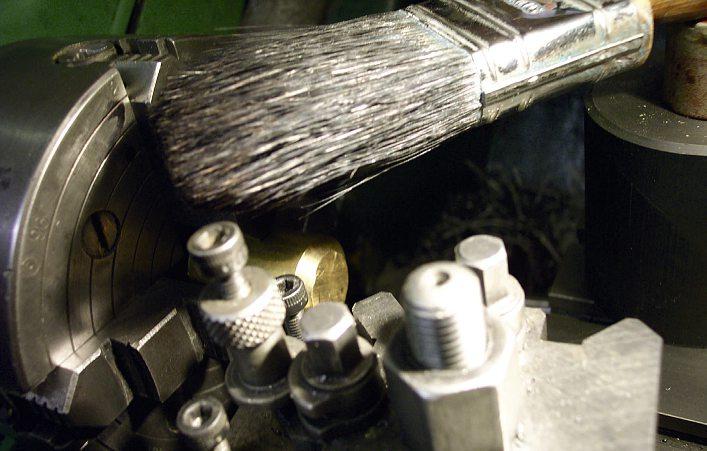

Totametheupwardsprayof unpleasantlysharpbrassorbronze chipsonalathe,heparksawidepaint brushonamagneticholdertorestover thelathetooltiptointerruptthechip path.Ihavereproducedhismethodin photo8. Itstruckmeasbeingespecially imaginative,delightfullysimple,andof negligiblecost.

Ihaveveryrecentlyseenthesame ideainusebyAdamBooth(Aborn79) onbronzebushing.Iimagineitwould workwelloncastironcomponentstoo tolimitthespreadofthedustgenerated inturningthestu .Itisunlikelytobe usefulonsteelcomponents,ifthechips don’tmeltthebrushbristles,curlyswarf willprobablystrangleitanddragitonto thejob.

FromKeithRuckerofVintage Machinery.orgIwouldliketoshare twoofhisideas.Hewastaughtthe rstoneasatraineemillerinthe late1980sbyanoldhandasaquick, elegantlysimple,andreliablemethod ofcentringacutteroverabarorsha tomilloutakeyway,without having totakeanymeasurements.

Hedemonstratedthemethodonhis KearneyandTreckerModelHhorizontal mill,anewtoyrecentlyacquired,buthe rstspentsometimeenthusiastically describingthecontrolfeaturesofit! AdetailIlikedatthetimewasthe deploymentofeitheroneorboth overarmbarsupportssimultaneously usingasmalldiameterfour-lobe capstanonthesideofthemill,engaging themselectivelywitharackcutonthe undersideofeachbar.

Onlaterre ection,Iquestionthevalue indeployingoneoverarmbar.TheUK equivalentwouldbetouseonesideof adovetailoverarm.Ihaveseenanother exampleofthismodelwithoutthe featureandwonderifthatdesignhas beenphasedout.

Despitethatandwithoutanypictures asthiswasaYouTubevideo,whatfollows givesafairdescriptionofthemethod hedemonstrated.Thecomponentwas clampeddownalongoneoftheteeslots inthetableandthusparallelwiththe tablemotion.

› 19 HintsAnd Tips October2023

Transferpunchesinuseasprecisionspacers

Brushde ectingchipsprayfrombrass/bronzeturningwork

6 7 8

Anexampleoftheveeshapeddisguise

Positiontherotarycutterabovethe endwherethekeywayistobecut,run themachineandraisethetablewith thekneecontroltojusttouchthejob withthecutter.Traversethejobacross thecutter.

Thenewlycutsurfacewillofcourse bemuchnarrowerthanthatofthe cutter.Raisethekneealittle,takea furthercutandsweepthejobacrossthe cutteragain.Keepdoingthisinsmall incrementsofkneeelevationuntilthe freshlycutsurfacecanbeseentobe thesamewidthasthecutter.Carefully traversethejobbackandforthso thatthetwosidesareasequalabout thecutterwidthasyoucanjudge.

Thehumaneyeisremarkablygoodat makingsuchcomparisonsandwhen youarehappywiththeresult,lockthe traversemotion.

Windthejobawayandraisethe tablebyhalfthekeywaydepth.The correctdepthforasquareformkeyway ismeasuredfromtheedgeofthecut surface,notthe rsttoucho .Nowlock thekneemotion,engagetablefeed,and cutthekeywayinonepass.Inabusy machineshopwheretimeismoney, thisisasu cientlyaccuratemethod forallbutthemostdemandingwork,

adaptabletoanysha diameterand/or cutterwidth.

InanotherYouTubevideoKeith examinedtheperennialsubjectof trammingtheheadonaverticalmill.He demonstratedonaBridgeport,buthis methodcouldapplyequallywelltoother machines.Hehadasettinggaugewhich featuredathickbasewithastoutcentral barofaboutteninchesorsoinheight ttedintoit.

Ithadbeenmadewithsomecareand precisionandheproduceditfromafelt linedbox,asbe tsagaugerequiring carefulstorage.

Inusethebasesits atontheclean tablesurface,thekneeisraisedtobring thegaugeupclosetotheheadandthe verticalquillofthemachineisextended downbysomesixtoeightinches.

O erthecentralstalkofthegaugeup totouchthequilloveritslengthfrom rstonesideandthenthefront.Any discrepancyintramalignmentinthetwo directionsisrevealedwithagoodlight shiningthroughfromtherearandcan becorrectedaccordingly.Itwasquick, simple,andmadeaveryconvincing demonstration.

Irealisenow,withouthavingseen thismethodbefore,itisthereciprocal

oftheapproachIfavourwithalathe faceorcatchplatemountedonmill spindle ttinghardware,piecesofkit mostworkshopswillalreadypossess. Inthisvariation,theplateiswound downintohardcontactwiththeclean tablesurface.Theheadcanbeadjusted quicklyforalignmentinbothdirections atthesametime,whilstmaintaining thecontactpressureoftheplateonthe tablesurface.

Photograph9 showsitinuse.Here again,agoodlightfromtherearis helpfulforcheckingthetableandplate contacttospotanygapinthejoint betweenthem.Withthismethodyou canavoidusinganypropsatallonamill havingalargediameterquillandbutt thebroadendfaceofthespindledirectly ontothetableinstead.

Ihaveseenvideosmadebyone

She eldprofessional,DavidWilks, ofTooltek,whomadehisliving manufacturinglongandlargediameter trepanningtoolsthatinvolvedtiltingthe millingheadaspartoftheprocess;he madeafeatureofdoingjustthatwitha Bridgeportmill.Inthisvideohereturned adeliberatelymis-alignedtrambackto theengraveddatummarksforverticalin bothdirectionswithinminutes.

ModelEngineers’Workshop www.model-engineer.co.uk 20

9

Tramalignmentaid