RHA backs upgrade funding scheme, but claims new sites are vital

By Tim Wallace

By Tim Wallace

The government has defended claims that a new £100m pledge to improve roadside facilities for HGV drivers doesn’t go far enough.

RHA MD Richard Smith urged ministers to also cut planning red tape to help developers build much-needed new truckstops and reduce distances between facilities.

“We’re pleased to see that service station operators can apply for grants to improve facilities, but thousands of truckers every night are still left without safe and secure places to park,” he said.

“Simplifying planning bureaucracy would help firms develop new sites quicker, which would boost local economies and offer truckers the facilities they deserve.”

However, transport minister Richard Holden told MT: “The bigger issue is capacity rather than necessarily more truckstops and more frequent ones.

“It’s something we see across the country, particularly in the east of England where the use of these places is at around 94%.

“I’m hoping that the facilities are seen rather more in terms of prestige – something that people would like to have, providing good local employment rather than something that is seen as a bit down at heel and not wanted in the local area.

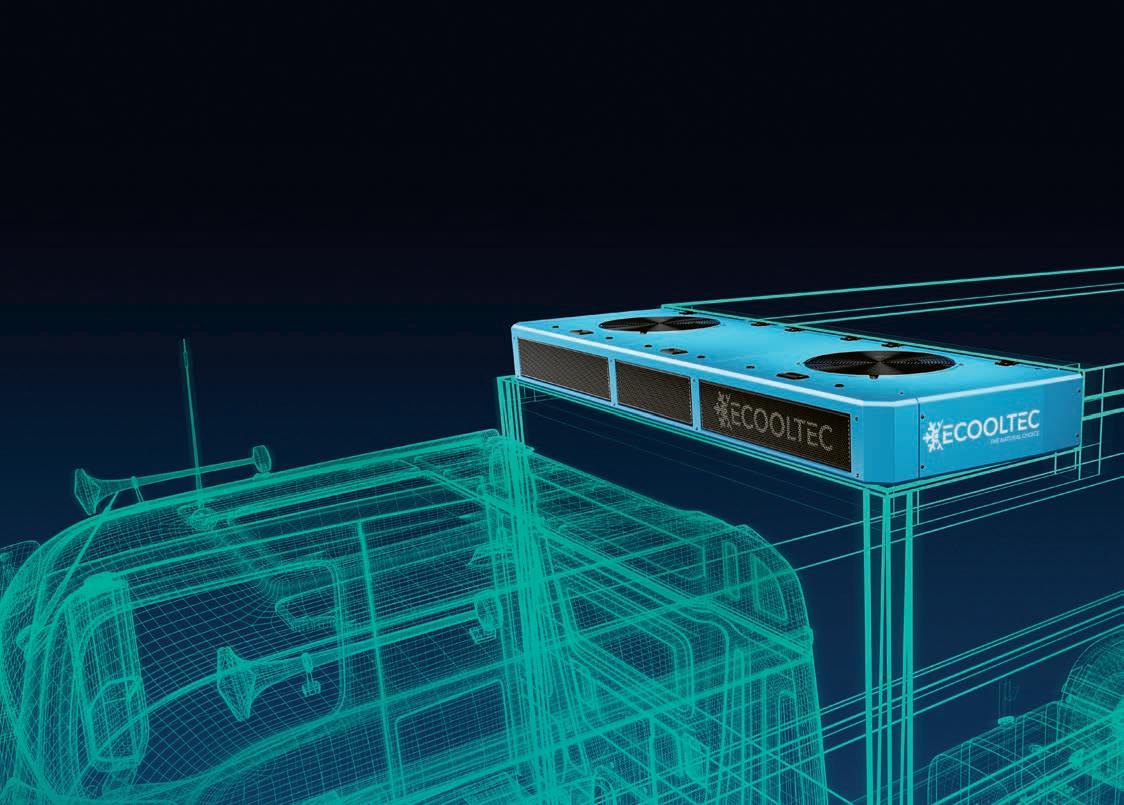

TUNING UP: Renault Trucks’ heavy duty, all-electric range has been unveiled ahead of production at its factory in Bourg-en-Bresse at the end of next year. The E-Tech T and C are for regional distribution and construction and have a design that is specific to their electric motorisation. They come with the trademark graphic signature of the brand’s electric trucks: blue hubcaps, a vertical side stripe and the Renault Trucks E-Tech badge. The front of the vehicles have been brought forward by 115mm and radars have been placed on the sides to increase safety. The chassis is also equipped with a retractable step, maximising the battery space. For all the latest news and information dedicated to the decarbonisation of the commercial vehicle and road freight sector, check out our sister website FreightCarbonZero.com

“Facilities should have good security and facilities and I’m hoping local councils will see them as a positive thing and look favourably on future developments. Obviously individual planning matters are up to individual councils. But if we can show them the government is behind them, it will be a positive step.”

The new scheme will see the DfT match fund up to 50% of the capital cost of an upgrade project for small operators and up to 25% for larger operators. Applications will close on 24 February 2023.

Holden said the funding was intended to be ‘horses for courses’.

“We’re not saying it’s all going to be the big boys,” he said. “We’re trying to ensure smaller stops can be refreshed and maintained and provide the facilities truckers need.”

The scale of the challenge faced by Saints Transport in continuing to trade in the run-up to its administration has been laid bare in a report to creditors.

The air freight haulier succumbed to insolvency in August after more than 50 years of trading, but administrators at KRE Corporate Recovery said problems started back in 2016 when its Colnbrook premises were sold by the landlord.

The head office then had to be moved “at great expense” and this was followed by substantially higher trailer park lease costs due to the proposed third runway

at Heathrow. The report said: “In 2019, DHL exercised the three-year break clause in its five-year contract to take the work in-house; this had a huge effect on turnover of £500,000 to £600,000 per month.”

The same year, a large claim

was made against the company, which led to around £150,000 in solicitor costs and £80,000 in barrister costs.

By the end of 2019, the company had reduced its debts, but Brexit caused a large drop in volumes, followed by the “absolutely catastrophic” effect of Covid.

As well as agreeing a repayment plan with HMRC, director Piers Carroll – who contracted a severe strain of the disease and ended up in intensive care – injected hundreds of thousands of pounds of funds into the business and elected not to take a wage for two months to help with cash flow, but costs continued to mount.

Wilko has sold its distribution centre in Worksop, Nottinghamshire, to logistics giant DHL for £48m to help refinance the business, leasing the site back under a 15-year partnership agreement.

The move comes as Wilko battles to cut costs across the business. In September, the company, which has 402 stores and an online service, brought in manage ment consultant Teneo to help it find savings. The company said the deal is the first in “a series of posi tive partnership benefits”.

Eclipse Distribution has entered administration, just a year after its founder sold the business to a pri vate equity firm.

Business advisory firm Armstrong Watson confirmed it had been appointed as administra tor to the haulage and logistics company on 14 November and staff had lost their jobs.

Wilko said it will continue to invest in its omni channel offer and improve customer experiences.

Working in partnership with DHL means both Wilko and DHL will benefit from scale in property and warehousing.

Wilko chief executive Jerome Saint-Marc said: “This property deal is the right response to the current market conditions and our priorities. We’re making smart choices to allow us to continue to invest in our long-term transformational strategy.”

The company had traded from its base in Loughborough for over 30 years. In a statement, the administrators said: “The company ceased trading shortly before entering administration with the loss of 37 jobs. The administrators have received a number of enquiries regarding the company’s brand and assets.”

Eclipse Distribution operated 39 HGVs out of centres in Loughborough and Nottingham.

In November 2021, private equity firm Winch & Co said it had purchased the business from former owner David Ash as part of a “mandate to find logistics and distribution businesses by which it will grow its group”.

At the time, Winch & Co oper ations director Shaun Swinburn said: “The business is very clean and has proven to be the perfect platform for what we plan to build.”

Menzies Distribution has put in its largest-ever order of vehicles, with more than 600 MAN tractors, curtainsiders, VW Crafters and box trailers due to be delivered by February.

It said the assets will accommodate substantial existing and new business from its clients.

The order includes 173 MAN TG3 tractor units, 150 curtainside trailers, 150 VW Crafters and 18 rigids spanning 18 tonnes and 26 tonnes, as well as 10 triaxle box trailers. Menzies said it would also accelerate its electric vehicle strategy with a 12-month trial of a pre-production, all-electric Ford E-Transit van, suitable for its newstrade, express and parcel operations.

Over a quarter of HGVs, LGVs and commercial cars failed vehi cle enforcement checks between April and June this year, exposing commercial drivers and their employers to the risk of criminal charges.

TrackDays.co.uk investigated DVSA enforcement data, which was published in October. It found that 39% of HGVs were hit with immediate prohibitions.

The report notes that the prohibition could include brake, steering or tyre defects required by law to keep vehicles safe. Half of DVSA checks on LGVs discov

ered a mechanical issue.

The condition of tyres was the most common prohibition defect for LGVs (16%).

Neil Greig, director of policy and research at IAM RoadSmart, said: “Inflation and rising costs are hitting everyone. Putting off simple safety inspections to try to avoid costly expenses can be a short-sighted approach.

“One in three deaths on our roads involve someone driving during the course of work, so there are many lives at stake when safety checks are cut – is that a price worth paying?”

A Peterborough haulage company that was refused its application to operate 50 lorries and 50 trailers has won its appeal that the traffic commissioner had acted unfairly.

REL Haulage will now have its licence application heard at a new public inquiry after the upper tribunal said TC Nick Denton had “erred through conducting what amounted to an unfair hearing and an unfair consideration of the application”.

Denton said the company was not of good repute and claimed that the investors and turnaround specialists behind the company, Andy Scott and Adam Lewis, had a history of failed road haulage companies. He also suggested that the company was already operating HGVs.

REL Haulage claimed Denton had failed to set out some of his concerns in paperwork prior to the PI; that he had made incorrect findings of fact in relation to the investors’ previous business activities; and that the TC had erred in law by “piercing the corporate veil” with respect to the haulier.

The tribunal agreed that the call-up letter did not adequately explain that the conduct of Lewis and Scott was an issue that would be explored at the PI.

London’s Ultra Low Emission Zone (ULEZ) will be expanded to cover all the capital’s boroughs up to the existing LEZ boundary from next August.

Setting out his next steps to tackle the threat of air pollution, the climate emergency and congestion, London mayor Sadiq Khan said the ULEZ had already cut roadside pollution by 44% and its expansion would ensure five million more Londoners could breathe cleaner air.

The expansion will be accompanied by a £110m scrappage scheme to support businesses and sole traders.

Khan said: “The ULEZ so far has been transformational, reducing harmful pollution levels by almost a half in central London.

“But there is still far too much toxic air pollution permanently damaging the health of young Londoners and leading to thousands of early deaths every year, with the greatest number of

deaths in the outer London boroughs.”

Logistics UK said the expansion gave operators within the capital the chance to take active steps and replace their vehicles or upgrade, but that flexibility was required from the mayor.

However, Conservatives in the Greater London Assembly (GLA) condemned the mayor’s plan and

said 60% of Londoners opposed the expansion. Nick Rogers, GLA Conservatives’ transport spokesman added: “This increases to 68% when you exclude organised campaigns – 70% of people who live and 80% of people who work in outer London are against.

“The people have spoken. Sadiq Khan must scrap these plans.”

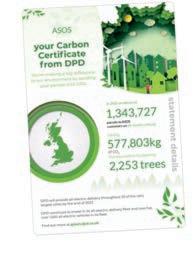

DHL Supply Chain has won a three-year contract with energy supplier SSE and gas distribution com pany SGN to provide logistics support and help deliver essential services.

The new contract will see DHL running operations five days a week for SSE and SGN, as well as providing a 24/7 continuity team for warehouse and transport work. It will work out of two sites, in Thatcham and Glasgow, providing operations support for the delivery

of essential services and sustainable energy solutions.

DHL Supply Chain added that it will also undertake a strategic review of the inbound and outbound supply chains to identify future efficiencies.

It will also provide reverse logistics services, collect ing and transporting used equipment, cables, and materials to be recycled or reused. DHL Supply Chain claims to be collecting 14 tonnes of materials per week this way “with a recycle rate of 98%”.

Unite said it had agreed a “groundbreaking deal” that secured the jobs of tanker drivers employed on Asda and Euro Garages con tracts.

The union said industrial action was on the cards over a perceived threat to the drivers’ jobs, but following a vote among members the employer had come to an agreement.

The drivers on the Asda North and South contracts are employed

on an outsourced basis by Fuel Transport and Logistics (FTL) and those on the Euro Garages contract are employed by Hoyer.

Unite said drivers had become “alarmed” that Asda and Euro Garages’ owners, the Issa brothers, were in the process of rebranding and transforming Euro Garages into Asda on the Move (AOTM) stores and were using low-cost-fuel hauliers. It claimed that this threat ened their members’ jobs.

However, it said talks were scheduled and a deal reached, part of which involved the super market giant changing its contract with FTL so that drivers will continue to deliver fuel until 31 July 2031.

The union added that an agree ment was also reached to transfer the existing AOTM trial site work to FTL, and that if the project is rolled out, then the transport work will be serviced by the company.

Fourth-generation haulier Campeys of Selby has taken delivery of seven new generation DAF XG 450 tractor units, with 12 more scheduled to arrive before Christmas.

Featuring FTG 6x2 mid lift axle configurations, the vehicles are being supplied by Ford & Slater with aftersales support from Pelican DAF in Normanton. Campeys said it was already seeing an average fuel economy return from the 450bhp XGs of over 11mpg and expectations are high that this will improve further.

“We’re really impressed with the DAF XG’s economy,” said transport manager Harry Campey (pictured). “Getting 11mpg straight out of the box is excellent for our operation, and that’s only going to get better once they’re bedded in.”

A Stoke-on-Trent haulage boss and five others have been found guilty of running a large-scale money laundering operation involving up to £150m in cash.

Disqualified director Marcus Hughes was convicted of conspiracy to launder cash at Stoke Crown Court on 18 November, together with transport planners Leon Woolley and Liam Bailey, drivers Nicholas Fern and Damion Morgan and business associate Simon Davies.

Hughes was the effective operator of Genesis 2014 UK, a haulage firm that had its licence revoked in 2021 for the second time in three years.

The regional organised crime unit for the West Midlands became aware of an operation to launder cash through the haulage firm, with Hughes using encrypted phone network Encrochat to communicate with convicted fraudster Craig Johnson in Dubai.

A deal was struck that large sums of cash would be collected at various UK locations with the intention of transporting it to London where it could be transferred onwards and legitimised. The total amount was between £100m and £150m.

The Crown Prosecution Service said French authorities had broken into Encrochat and reported the activity to the British.

On 26 March 2021, two Genesis vehicles were stopped separately and each was found to contain cash totalling around £700,000.

A further £60,000 was recovered from Hughes’ home.

Ice Co Storage & Logistics has acquired East Anglian cold storage and logistics firm Savage Haulage in a multi-million-pound deal.

The purchase sees Ice Co Storage & Logistics expand its geographical footprint in a move that is also aimed at staving off the impact of spiralling inflation and energy costs.

The company, which has sites across Lancashire, Yorkshire and the North East of England, is the distribution arm of Hull-based J Marr Group.

Savage Haulage, run by brothers Martyn and John Savage, has depots in March, Cambridgeshire, and Thetford, Norfolk.

The £5.9m turnover company was established 60 years ago and has O-licences for 33 trucks and 33 trailers.

Ice Co Storage & Logistics operates blast freezing and tempering services, with a 51,000 pallet capacity.

Vehicle financing businesses will need the support of the manufacturers in developing new funding solutions to aid the journey to carbon zero, Close Brothers’ head of national accounts and ESG, Andrew New, told delegates at the recent Logistics UK ‘Delivering decarbonisation’ conference in London.

In a candid presentation, New explained the challenges the finance sector is facing as it seeks to support the logistics industry on its decarbonisation journey.

“Funders are in a similar position to most in the sector,” he said. “Everything we thought we knew [about asset funding vehicles]

is obsolete as we shift to electri fication of trucks. It is essential the finance community steps forward and supports the sector, but the cost and uncertainty is enormous.”

Plotting the future residual values of carbon zero trucks was virtually impossible, he added, saying: “We have no idea what

PepsiCo UK is working with its transport partner Pollock (Scotrans) to replace diesel with hydrotreated vegetable oil (HVO) and power more than one million miles of HGV journeys.

the five-year value of these vehi cles will be.”

Moving forward, New said the finance sector would require early manufacturer support to prime the market, whether that was through buybacks or support for enhanced end of term balloon payments. “No funder will take the sole risk without support,” he said, while also adding the traditional funding approach was changing, with pay per use emerging as a new model. “This will require collaboration between the energy provider, vehicle OEM and the funder,” he concluded.

For an extended review of the presentations and topics covered at the conference see freightcarbonzero.com

Butt.

With an aim to reduce green house gas emissions across its UK supply chain by 1,200 tonnes each year, the food and drinks manu facturer said HVO will be used in lorries travelling between the Quaker Oats mill in Cupar,

Royal Mail is seeking permission from the govern ment to stop Saturday letter deliveries as it tries to reverse its multi-million-pound losses.

Its non-executive chair, Keith Williams, said “urgent reform” was now needed after the business reported a £219m operating loss. He blamed the impact from ongoing industrial action among frontline workers, as well as weak parcel volumes and an inability to deliver productivity improvements.

“Government has now been approached to seek an early move to five-day letter delivery, whilst we

continue to improve parcel services,” he said.

The group’s international parcels subsidiary, GLS, fared better and reported an operating profit of £162m for H1, although this was down 4.1% due to inflation ary pressures. Williams said: “The difference between the performances of our two companies could not be more stark. We have been standing at a crossroads with [union] CWU in the UK for several months.”

The business expects a full-year operating loss of around £350m to £450m, including the impact of 12 days of industrial action.

Scotland and Leicester.

In addition, PepsiCo is introduc ing electric vehicles to move 40,000 pallets of crisps around its distribu tion centre in Leicester.

Since 2017, all of its manufactur ing sites have used 100% renewable electricity, with waste from produc ing Walkers crisps being used to make animal feed and biofuel, as well as fuelling the company’s anaerobic digester. It has a goal of reaching net zero emissions by 2040.

DX Group is investing £3.6m into upgrading its existing depot network.

The move is part of wider growth plans and is expected to be completed by early July 2023.

In the DX Freight division, which specialises in the delivery of irregular dimension and weight items, upgrades are under way or have been completed at depots in Exeter, Middlesbrough,

Northampton, Plymouth, and Thatcham. DX has installed new raised docks, expanded loading areas, and made energy efficiency improvements.

Meanwhile, in the DX Express division, which handles documents and parcels, major upgrades have been made at Gatwick and at the national hub in Nuneaton. These include additional mechanisation as well as environmental initiatives.

DX is in the second year of a

major three-year funding programme, which is anticipated to invest between £20m to £25m across the group. This includes expanding the depot network, vehicles, parcel handling equipment and IT.

The company opened eight new depots over its last financial year, and by the end of its current financial year, in July 2023, expects to have opened a further eight new sites.

A railway bridge in Cambridgeshire has been named as the most bashed in Britain, after drivers struck the structure 33 times in 12 months.

The Stonea Road bridge on the B1098 topped a list released by Network Rail as it

ramps up its ‘Wise Up, Size Up’ campaign to urge drivers and operators to know the heights of their vehicles.

The other big hits in the year to March 2022 were the Lower Downs Road bridge in Wimbledon, South London, which was

hit 18 times and Harlaxton Road bridge in Lincolnshire, which was struck 17 times.

Network Rail said a total of 1,833 bridge strikes were recorded, up from a five-year low of 1,624 in 2020/21.

UK consumer price index (CPI) inflation reached 11.1% in October. Although a 41-year high, this is not exceptional in the current economic climate.

Our chart shows the harmonised index of consumer prices (HICP) inflation rates across Europe. The Eurozone average of 10.6% is the highest since the Euro was established in 1999. Only Switzerland – not in the EU – has a significantly lower inflation at 2.9%. More countries are at the other end of the spectrum.

For example, it was 22% in Hungary and also in the three Baltic states of Estonia, Latvia and Lithuania. Turkey’s rate was an eye-watering 86% in October.

In August the Bank of England forecast UK CPI inflation would be 13% by now. But having raised the bank rate from 2.25% to 3.0% earlier this month, the Bank now believes (Monetary Policy Report, November) CPI inflation will remain close to 11% in December. The Bank anticipates inflation will tumble next year, from 10.1% in Q1 to 5.2% in Q4. Further declines are expected early in 2024, taking CPI down past the 2.0% target level to just 1.1% in Q2.

Most independent forecasters canvassed by the Treasury in November agree broadly with the Bank’s inflation outlook. The average of their forecasts for CPI one year from now is 5.0%.

Gross domestic product (GDP) in Q3 was 0.2% lower than in Q2. This initial estimate (subject to revision next month) is the economy’s first quarterly shrinkage since Q1 2021. It is partly due to the extra bank holiday for the Queen’s funeral, but also reflects efforts to conquer inflation, because raising the bank rate slows the economy.

Manufacturing output was down by 2.3%. So, assuming it must make further bank rate hikes, the Bank of England expects GDP in the current quarter, Q4, to contract by 0.3%.

Two successive quarters of contraction satisfy the definition of a recession, but the Bank is forecasting eight negative quarters. The first, very modest, GDP

growth is not expected until Q3 of 2024. This is a long recession, but unlikely to be deep: the Bank expects the biggest quarterly contraction (in Q2 next year) to be 1.0%, less than half the worst quarterly decline of the 2008/09 recession, which lasted six quarters.

Confidence among UK manu facturers fell to a 29-month low in October. The S&P Global/CIPS UK manufacturing Purchasing Managers’ Index (PMI) dropped from 48.4 in September to 46.2 in October. This widely regarded indexed survey tracks changes of business confidence in around 650 manufacturers, and reflects key aspects like new orders, out put, employment and supplier delivery times.

PMI scores above 50 denote an improvement on the previous month; scores below 50 indicate deterioration.

John Glen, chief economist at the Chartered Institute of Procurement & Supply (CIPS), commented: “The slowdown trend in the manufacturing sector, which has been developing over the last few months, became embedded in October, with new order levels falling at the fastest clip since May 2020, and overall output was down for the fourth consecutive month.”

The pessimism is unsurpris ing because most survey responses came in the chaotic final days of the Truss adminis tration, but the issues run deeper than politics. Despite the pound’s weakness, the PMI survey says exports fell for the ninth succes sive month in October. Companies reported exports were hampered by the weakening global economy, softer Chinese demand, the Ukraine war and ongoing Brexit issues.

After three months of decline, the monthly average price of Brent crude oil rose again, from $89.8/ barrel in September to $93.4 in October. The effect on the diesel price was exacerbated by the pound’s dramatic loss of value against the dollar.

Its October average of just $1.13 was sterling’s lowest monthly

figure since 1985: it was worth 20% more in January. The combined effect was to take October’s typical average bulk diesel price back up to around 150ppl. As this is written in mid-November, this month’s average is shaping up to be much the same again.

Most recent forecasts (November) for Brent’s average

price next year anticipate $90 to $95/barrel. Only a very small minority believe next year’s average will be closer to $80, reckoning that the price will soften as the global economy slows.

For perspective, this year’s average Brent price will be around $102/barrel, barring major price movements in December. n

As 2022 draws to a close I imagine all anyone in the transport and logistics industry can hope is that next year will be a bit more ‘normal’. Brexit, Covid-19 and then Russia’s invasion of Ukraine have made the past six years the most turbulent in a generation and made the credit crunch of 2008 look like a storm in a teacup.

But unless the new PM and his Treasury team can find a magic money tree, it looks like the debt the UK has racked up coping with these upheavals will send us into an inflationary recession – the worst of all economic worlds – in 2023, as operating costs continue to spiral.

Our latest cost tables (p40) show that the outlay on running a 6x2 tractor shot up 20% last year and while rising fuel prices should be passed on to customers in surcharges, the long overdue increases

in driver wages and higher truck prices are harder to recoup.

There is a feeling that first Covid and now the invasion of Ukraine have taken operators’ eyes off the climate change ball, but the government targets to decarbonise the economy loom ever larger on the horizon.

Whether the new wave of commercial vehicles will run on batteries or hydrogen or both is still unclear. Many operators are probably keeping their fingers crossed that the OEMs will pull a rabbit out of the hat in the form of a zero-emission truck that costs and performs the same as diesel. But as any management consultant will tell you ‘hope is not a business strategy’.

From everyone here at MT Towers we wish all our readers a successful and peaceful Christmas and a very happy new year.

As COP27 brought leaders and governments to the table from around the world to discuss the transition towards net zero, this inevitably focused on the need for governments to deliver emission-reducing strategies in the near future.

As low-carbon hydrogen continues to become both economically viable and cost-effective, it is the ideal method for achieving zero emissions for buses, trucks and other commercial fleets.

The newspaper for transport operators

To contact us: Tel: 020 8912 +4 digits

or email: name.surname@roadtransport.com

Editor Steve Hobson 2161

Head of content Tim Wallace 2158

Events and projects editor Hayley Tayler 2165

Group production manager Isabel Burton Senior display sales executive Barnaby Goodman-Smith 2128

Event sales Tim George 0755 7677758

Classified and recruitment advertising

rtmclassified@roadtransport.com

Sales director Emma Rowland 07780 604075

Divisional director Vic Bunby 2121

MT Awards Katy Moyle 2152

Managing director Andy Salter 2171

Editorial office Road Transport

Media, First Floor, Chancery House, St Nicholas Way, Sutton, Surrey SM1 1JB 020 8912 2170

Free copies MT is available free to specified licensed operators under the publisher’s terms of control. For details, email mtsccqueries@roadtransport.com, or call 01772 426705

RoadTransport@abacusemedia.zendesk.com 020 8955 7034

Motor Transport Subscriptions, Abacus, 107-111 Fleet Street, London EC4A 2AB

Rates UK £146/year. Cheques made payable to Motor Transport. Apply online at mtssubs.com

Ben Nyland CEO Loop Energy

A topic of interest to Loop Energy is the UK government’s commitment to accelerating the clean energy transition in the commercial vehicle sector. While the government has already shown a clear willingness to address this, such as its planned investment towards zeroemissions HGVs and its 2021 hydrogen strategy, it will need to support OEMs and fleet operators during the transition to achieve this goal.

Underlining the scale of the challenge is the government’s ‘Transport and environment statistics 2022’ publication, which shows that in 2020 transport was the largest producer of greenhouse gases, responsible for 24% of all emissions, despite Covid-19 restrictions reducing transport across the UK.

These statistics clearly demonstrate the need to decarbonise the HGV sector. As it stands, HGVs are the UK’s second-highest emitting transport mode, accounting for 19% of emissions in 2020. To address this challenge, it will be imperative for the government and the private sector to embrace a range of new energy systems.

We believe that the government can progress its collaboration with the private sector by supporting the OEMs and fleet operators that are already leading the way in developing zero-emissions vehicles.

We are already seeing next-generation hydrogen fuel cells for commercial vehicles deliver fuel-to-wheel efficiency of up to 54%, compared to the typical fuel-to-wheel efficiency of a diesel engine at around 20% to 25%.

To utilise the advancements in hydrogen fuel cell technology, the government must support zero-emissions vehicle pioneers, such as Tevva, to ensure this large portfolio of emissions rapidly decreases. Incentives tailored for both OEMs and fleet operators are critical in progressing hydrogen-electric vehicles from the prototype to fleet deployment phase. Despite hydrogen-electric vehicles providing a low total cost of ownership, high upfront costs pose a barrier to early technology adopters.

Government can also play an important role in boosting local low-carbon hydrogen production and ensuring users have the infrastructure they need to operate efficiently and economically. Regulations around the production of diesel vehicles can also reward ambitious companies who have already made investments to transition away from fossil fuels.

If you would like to contribute to MT’s Viewpoint, email steve.hobson@roadtransport.com

Registered at the Post Office as a newspaper

Published by DVV Media International Ltd © 2022 DVV Media International Ltd

ISSN 0027-206 X

Hauliers offering a traction-only service regu larly take a gamble. Every day they pick up a trailer from a customer without being 100% certain that it is fit to be on the highway.

Responsible drivers will conduct a walkaround check to ensure, for example, that all the mudwings are present and free from major damage and the marker lights are all working. A more searching inspec tion may not be possible or practical especially if it is dark, the rain is hammering down and the customer is adamant that the laden trailer has to leave promptly.

If the driver is subsequently pulled over by the enforce ment authorities and defects are found, however, then the haulier concerned will be held liable; and the driver could be in hot water too.

It is a concern that was highlighted by west of England traffic commissioner Kevin Rooney at the RT Expo show earlier this year. In doing so he referenced one or two of the major home delivery companies who rely heavily on subcontractors to haul large numbers of trailers.

“Some of those unloved trailers may have been picked up and dropped off by half-a-dozen different operators within a very short space of time,” he said. If this happens frequently, and they are not being properly maintained, then this unlikely to bode well for their state of health.

Logistics UK head of engineering policy Phil Lloyd is well aware of the concerns that can arise when a driver is sent to collect a laden third-party trailer.

Drivers can check whether it has a valid MoT certificate by visiting the government’s check-mot.service.gov.uk

Hauliers take on a substantial risk when offering traction-only services. Getting caught with someone else’s poorly maintained trailer could cost you big bucks and hurt your reputation, explains Steve Banner

website and entering the trailer’s identification number, he points out. However there is no standardised means of checking when it last underwent a periodic inspection, he adds.

He believes that every UK trailer should display a bar code which a driver can scan with a smartphone to find out its test status and when it was last inspected. “Remember that the statutory inspection interval of any trailer you collect has to be the same as that of any trail ers you own,” says Lloyd.

WATCH WORDS: Trailers are often picked up by multiple hauliers in a short space of time, meaning maintenence could be lax, TC Kevin Rooney warned

If an MoT is in force, inspection intervals have been adhered to, the driver has satisfied himself or herself on both accounts and has carried out a walk-around check without spotting any defects – and can demon strate that this has been done – then due diligence has been displayed. As a consequence neither the driver nor the tractor unit’s operator should be held respon sible if defects are discovered in a roadside check, Lloyd contends.

“We raised this issue with the DVSA during a recent review of the ‘Guide to maintaining roadworthiness’ and we’re hoping this will bear fruit,” Lloyd says. “A trailer used to display a disc that showed it had been MoT’d, but that requirement has now gone.”

Trailers used on most international journeys now need to be registered with the DVLA, and in response to a Freedom of Information request the agency told MT that as of 11 November, 33,444 trailers had been registered. So would requiring all trailers used domestically to be registered in the same way lead to improved compliance?

“Sounds like a good idea, but it wouldn’t make one jot of difference,” Lloyd replies. “The situation would remain exactly the same.”

The fact that all trucks have to be registered does not of itself mean that they are better looked after.

“Registration might make life simpler when it comes to notifying trailer owners of defects and recalls,” Lloyd continues. “What it could also do though is result in trailers being subjected to a separate taxation regime.”

While bar coding may make life easier for hauliers collecting UK-owned trailers, unfortunately there is no easy means of determining whether a foreign-owned trailer is in test. Furthermore, it will not have undergone a periodic inspection as this is not a requirement in other jurisdictions, Lloyd points out.

So does the standard of maintenance of trailers owned by the e-commerce giants really present a particular hazard to hauliers offering a traction-only service?

With a 350-strong fleet, Slam Transport regularly collects trailers laden with parcels from Amazon and shuttles them between the ecommerce behemoth’s efulfilment centres. Danny Gould, a partner in the Coventry-based haulage company, recalls drivers encoun

NO RISK: Coventry-based Slam Transport says big clients, such as Amazon, minimise risk by investing heavily in trailer maintenence

tering the odd challenge when it first started working for Amazon a few years ago.

“If there was an issue with a trailer when they went to pick it up then they didn’t always know who they should contact to get something done about it,” he says. This was when Amazon was in the early stages of running its own trailers in the UK, he stresses, and things have changed since.

“Nowadays Amazon is completely on the ball,” he observes. “It is clearly very much a safety-conscious company, it’s certainly prepared to make any investments in safety that may be necessary and is very professional.”

Drivers know who they need to speak to if they are faced with a faulty trailer, he says, they get an instant response and will not face pressure to take it out regardless. It will be taken out of service and the load transhipped to another trailer, even though delivery deadlines may be tight.

“If it’s just a bulb out though then our drivers will change it themselves,” he says.

QUICK CHECK: Bar-coding trailers so drivers could check their inspection status would make life easier, says Logistics UK head of engineering policy, Phil Lloyd

Since February 2019 all trailers heading towards most, though not all, European countries from the UK have had to be registered in line with the requirements of the 1968 Vienna Convention on Road Traffic.

The trailer must display its own registration plate, separate from that of the vehicle towing it, and be accompanied by a trailer registration certificate that can be shown to a foreign authority on request.

Trailers that are going to be used in the Republic of Ireland, Spain, Liechtenstein, Cyprus and Malta do not have to be registered. However they must be if they are being hauled through countries where the rules apply (they include France, Germany, Belgium and the Netherlands) to reach these jurisdictions.

A trailer can be registered for £26 at www.gov.uk/register-trailer-to-take-abroad.

The DVLA was unable to say how many trailers had been registered under the scheme and said that the data sought would have to be made the subject of a Freedom of Information request. A request was duly filed but no response had been received at the time of writing.

In any event Amazon trailers do not suffer the sort of wear-and-tear that their counterparts hauling heavy loads such as steel, bricks and blocks, glass and paper do, he points out.

“The loads can be anything from PlayStations to bath sponges, and are usually very light in weight,” he says.

Another haulier who works for Amazon, who asked not to be named, said that the company’s trailers present few problems.

“There have been one or two issues with the doubledecks they operate but everything else seems to be OK,” he observes. “Bear in mind however that the vast major ity of their trailers are probably less than four years old, and it will be interesting to see how they deal with the issues that are bound to arise as they get older.”

“It used to be the case that their yard staff could get a bit awkward if a driver didn’t want to take a trailer because there was a problem with it, but that doesn’t happen now,” he adds. “It’s worth noting that Amazon has a portal that hauliers can access to check the MoT status of any trailer they pick up, and when it was last inspected.”

Says RHA technical director Paul Allera: “I carried out an audit of Amazon’s trailer maintenance arrangements and found nothing wrong with any of the trailers I saw. Not a single thing. Admittedly that was a couple of years or so ago, and the trailers were quite new, but I’ve not been told since by RHA members that they’re experienc ing problems.”

Driver walk-around checks still need to be as thorough as possible however, he stresses, to ensure that anything not spotted by the driver who took charge of the trailer previously is picked up and dealt with. The DVSA road worthiness guide says that a driver’s check should include the trailer’s tyres, wheel fixings, spray suppression and lights.

A senior executive from a leading trailer maintenance specialist can remember when the trailer defect report ing procedures followed by some e-commerce businesses were in some cases wholly inadequate.

“I’m thinking of one company in particular and the days when it first started out, when it had less than a thousand trailers,” he says. “Things have altered massively since though as its fleet has expanded, the guys there are on top of their game, and compliance receives top priority.”

While e-commerce giants such as Amazon can spend cash on ensuring their trailers are rigorously maintained without feeling the pinch, that is not necessarily true of businesses in other sectors of UK industry and com merce. Picking up a trailer from some premises remains a lottery – and one that drivers and hauliers do not always win.

Driver walk-around checks are vital but have their limitations, points out Chris Good. He runs Shrewsburybased Chris Good Haulage and admits to being wary of picking up other people’s trailers.

“You can check the tyres up to a point, but you can’t get to their inner sidewalls,” he says. A hidden inner sidewall may have a suspicious bulge which suggests the tyre has suffered internal damage.

The inspections such trailers have received may not have been nearly as thorough as they ought to be, Good suggests. “I remember seeing one that took the guy no more than four minutes, and the trailer wasn’t put over a pit,” he observes.

A trailer cannot be deemed to have received a full inspection if nobody has examined its underside.

“And how do drivers tell if the brake linings are OK, or if they’re worn right down?” he wonders. That is a point taken up by Mansfield-based Chris Hayes, an owner-driver for some 13 years.

“When I collect trailers and get out onto the highway I regularly find that it’s the brakes on the tractor unit that are doing all the work,” he remarks. “A lot of businesses

and inspection schedule before doing a comprehensive walk-around. But while this may be enough to avoid prosecution, it still might mean unseen dangers lurk inside or underneath

don’t carry out laden brake tests on their trailers until it’s nearly time for their MoT.”

He agrees that walk-around inspections cannot pick up everything.

“An operator I know collected a trailer, his driver was stopped by the DVSA, and they found a crack in one of the airbag pedestals,” he says. “The driver had done a walk-around check but there is no way he could have picked up something like that.

“Fortunately I’ve come across very few major defects myself,” he continues. “Mostly all I’ve seen is the odd missing bulb.

“I nevertheless feel that some leniency should be shown by the authorities towards hauliers – and their drivers – if there is a problem with a trailer they are haul ing that clearly isn’t their own.” n

The DVSA’s ‘Guide to maintaining roadworthiness’ makes it clear that the driver and operator are liable if a trailer collected from a third party has defects.

The guide also states however: “It is best practice for the trailer owner to provide evidence for the operator that first-use checks and safety inspections have been undertaken and demonstrate that there are no outstanding defects reported for the trailer. There must also be a robust system in place to ensure defects identified during the walk-around check, or that develop during use, are recorded and rectified before the tractor/trailer combination is operated in an unroadworthy condition.

“It is strongly recommended that hauliers obtain from the trailer owner or customer the safety inspection interval for the trailer concerned and a copy of the current relevant inspection reports to ensure the trailer has been correctly inspected within the stated frequency.”

The guide points out that the Institute of Road Transport Engineers has produced its own good-practice guide to operating third-party trailers safely and legally.

Innovation is essential to modern logistics. MT canvassed some of the firms offering new approaches to some of the industry’s key problems –injury, recruitment and warehousing space. By Louise Cole

Wincanton’s W2 Labs

Wincanton is the only UK logistics company to run an annual innovation programme with the support of earlystage investor L Marks.

In the most recent round, 26 businesses participated in the 10-week programme, trialling products or solutions across Wincanton’s operations. This allows innovators to test products in a real working environment and measure KPIs, aided by operational and commercial guidance from senior Wincanton management. Wincanton has an Innovation Centre at its Northamptonshire e-fulfilment facility, which is home to the Labs programme.

Wincanton says the Labs programme allows it to assess and adopt new solutions that can become part of its product offering to customers and enhance its operation.

It says the process works best when participants think big, but start small. The Labs process moves quickly, so start-ups that trial a small, more focused element are able to deliver a minimal viable product (MVP). From that, they can learn what needs to be tested and developed in the extended pilot.

The theme for each year’s lab programme is decided by Wincanton’s senior management, with the criteria being that they align with current growth strategy and solve a pain-point for Wincanton or its customers.

Soter Analytics is the brainchild of Matt Hart, CEO and founder, whose original vocation was as a reliability

engineer. “We would analyse breakdown statistics to see which parts suffered the most wear and place sensors on the equipment to manage performance and predict failure before it occurred,” he says. “So I wondered why we don’t capture live data from people before we get injuries.”

Acute injury rarely happens in one traumatic incident, but usually as a result of repeated misuse. The SoterCoach clips onto workers’ clothing (usually the back of the collar) and monitors their movement patterns. Artificial intel ligence measures every movement and classifies the risk to the spine and shoulders. If the person moves in a way likely to cause injury, the monitor will beep and buzz, so helping them to healthy movement patterns.

However, it goes further. All the data points of the job are captured, including the what, where and how of the task itself. The job can then be redesigned to lessen the risk of injury.

“If you have the potential for something to fall off a roof above you, the least efficient safety protocol is to don a helmet,” says Hart. “The most effective is to redesign the task so that nothing unstable is used at height.”

Soter has 80 customers worldwide and monitors about 10,000 workers a day. They typically see between a 40% and 80% reduction in musculo-skeletal injuries. Hart says since W2 labs they have worked with Wincanton, and also leveraged that experience to have meetings with some of the top logistics and courier companies.

“It’s a six-figure investment, but the ROI is £2.50 ➜ 26

to every pound spent,” says Hart. “We are completely changing the way H&S is approached. It’s a comprehen sive solution to one of the world’s oldest problems.”

oneVASTwarehouse was an idea that originated within Wincanton – a virtual brokerage for marginal warehouse space both within the Wincanton network and for thirdparty operators and customers.

oneVASTwarehouse sales director David Haworth says that while we are seeing an increase in availability of warehouse space, there are still several regions with critically short supply. Equally, freight owners can have urgent or seasonal need for a temporary expansion of warehousing space.

Today oneVASTwarehouse has 80 Wincanton-owned or operated sites, and over 700 third-party sites listed. Minimum and maximum quantities are purely based on supply and demand; so far, the minimum has been 200 pallets and the maximum 25,000. Typically, storage is booked for six months, but can be less and sometimes extends to three-year contracts.

Having been conceptualised and trialled through the W2 Labs process, Wincanton created subsidiary oneVASTwarehouse to run its new tech-based offering.

As with all innovation, the product has continued to evolve. Haworth says that an entirely online offering didn’t work so well, as customers and operators both need a solid relationship in order to be confident that storage provided is suited to the freight.

The model has therefore evolved over the past two years to capture the most useful parts of the technology solution, including live mapping of availability, and template capture of the details of warehousing facilities and customer need. This is then followed up by personal support to ensure the confidence of all parties.

It is free for a warehouse to register their space and there is no charge for the connection. The customer pays a service charge on top of the chosen operator’s rate, and oneVASTwarehouse handles all invoicing and payments.

Haworth says the business is successful and the tech nology solution is continuing to be developed. “The industry lacks warehousing capacity in many regions,” he says. “By optimising the sector’s assets, we can improve revenue streams for hauliers, and fulfil a need for freight owners.”

With current pressures on land availability and the need to protect farmland, he says this kind of collaborative approach can limit unnecessary develop ment. Ian Maudsley, head of operations at Preston-based FDC Holdings, says they learned of oneVASTwarehouse through their connection with Wincanton, and have secured a substantial contract through it since signing up.

Every logistics operator knows that hiring is time consum ing and expensive, and a high proportion of new hires can leave within weeks or even days. ThriveMap sought to streamline the process of hiring and make it far more likely that the final match between candidate and job would be a good one.

Research it conducted in 2019 suggested that half of people left jobs prematurely because of a mismatch between their expectations and reality. ThriveMap CEO Chris Platts says the pandemic has exacerbated this trend.

“Churn is expensive and problematic,” he says. “We specialise in creating online assessments that take candi dates through a realistic ‘day in the life’ of the job. This ensures they know exactly what they are applying for.”

This frequently replaces CV screening, which in turn takes out a substantial layer of unconscious bias from the recruitment process. It takes an average of seven minutes for candidates to apply, and 50% of them do so on phones.

The applications include knock-out questions – such as qualification checks.

Interview stage is too late to warn people about the reality of long hours, or a noisy working environment, says Platts. “If they’ve applied and come in to see you, people will agree to anything to get the job even if some will not then want it,” he says. “The earlier you can be candid about the reality of the job the better. Show them the tasks and attributes involved up-front, and 5% to 12% will withdraw straight away. That’s a huge saving in otherwise wasted time and money.”

Following W2, ThriveMap has supported one of Wincanton’s retailer contracts, and is now being rolled out to other divisions. n

A WATCHFUL EYE: The SoterCoach clips onto workers’ clothing (usually the back of the collar, below) and monitors their movement patterns

Rygor Group has undergone a change of ownership following a management buy-out by two of its senior sales staff. The new own ers are John Keogh, formerly the sales director, and Rish Channa, the previous head of truck sales. Keogh has become managing director, while Channa is com mercial director.

The pair have been joined on the board by former finance direc tor Tim Smith in the role of group finance director and Sean Joyce, previously service director, as after sales director.

Rygor Group includes Rygor Commercials, the Mercedes-Benz dealership chain whose nine loca tions extend from Chilcompton and Westbury in the South West, up to Kidderminster and Nuneaton in the Midlands and across to Heathrow. It will shortly be opening a new 44,000 sq ft site at Worton Park in Reading. In addition, the group operates Maxus van and Higer coach fran chises.

Keogh said: “As you can imag

ine, this is an extremely exciting time for us and the future of Rygor Group Ltd. We love the Rygor busi ness and both Rish and I have been working within it for more than a decade. Being able to say that we

are now joint owners of the company is a really special moment for us.

“We have a fantastic team here at Rygor, an award-winning team, and our focus over the past few

years has continued to centre on their progression, well-being and building a positive company culture. We were thrilled to become Great Place to Work certi fied in 2022, as well as standing out for our employee engagement as overall winner at the Institute of Internal Communications Awards.

“This continues to be a key objective for the Rygor business. Over the past year we have imple mented a new appraisal process, an enhanced apprentice programme and a well-being programme. It is our team members who make us strong and successful, and we are greatly looking forward to working with them as Rygor continues to lead the way.

“We will also be focusing on building a more sustainable and greener future for the business and working with brands on elec tric vehicles will be key to this.”

Maritime Transport has placed its first order with Tiger Trailers for 100 curtainsider trailers.

The 13.6m trailers have a clearspan pillarless roof and feature two rear strap pouches, a specific load securing setup, TIR cord, toolbox and SAF drum brake axles. The majority have hardwood floors, but 10 have phenolic non-slip plywood finishes.

Paul Heyhoe, Maritime Transport fleet director, said: “We are pleased to have placed our first order with Tiger Trailers, who met our timescales and specification at a time when production schedules are being delayed across various industries. The new trailers are a welcome addition to our fleet and will bring greater efficiencies and flexibility to our distribution division,

ensuring it is prepared for the substantial growth we have seen in new contracts.”

Maritime’s trailer fleet includes curtainsiders of various apertures, some of which are fitted with tail-lifts to suit their varied duties, along with skeletals of both sliding and fixed types, tippers, gensets and goosenecks. They are pulled by tractor units from Scania, Volvo, and Mercedes-Benz, with more than 1,600 vehicles on the fleet.

Speaking about the order, Stephen Pollock, Tiger Trailers’ business development director, said: “Here at Tiger we are extremely pleased to have welcomed Maritime Transport as a customer, following their decision to place this order for 100 curtainsiders with ourselves. It has been an absolute pleasure to have developed a close working relationship with Paul Heyhoe and his colleagues and we look forward to supporting them.”

Bowker Transport has taken deliv ery of a Volvo FH 460 to mark 50 years of working with Volvo.

The 6x2 tractor unit with I-Save has been given a special livery to commemorate Bowker’s alliance with the manufacturer.

Bill Bowker, director at Bowker Group, said: “This relationship was originally forged 50 years ago, and it is a partnership where customer input plays a vital part in the development of a transport solution. The decision to go with Volvo originally was based upon our opinion that they have the safest and best products, supported by the most effective back-up service in the UK and Europe. As far as we are concerned, we made the right decision, and the relation ship has grown and developed over the years.”

Preston-based Bowker Transport has been in operation for more than a century and is now

one of the UK’s largest familyowned transport operations, with 225 vehicles and 450 trailers. They also have 1.2m sq ft of warehous ing across 10 depots.

Bowker Transport celebrated its centenary in 2019 with a special livery for two Volvo FH tractor units, featuring a blue cab with a wide white band around the middle section and a narrow gold band.

The centenary design has been adapted for the new FH, with the gold colouring wrapped around the top half of the cab and ‘1972 – 2022’ written above the door to mark the 50-year partnership.

Supplied by Thomas Hardie Commercials, the 460hp FH will be used to deliver a variety of goods across the UK and into mainland Europe.

in mind, and feature a microwave, fridge, inverter, DVS kit, strobes and beacons.

“Everything about the vehicles seems to have been designed for absolute peace of mind – from the savings in fuel to the design of the cab,” he said. “The drivers’ wellbeing is clearly considered, and our drivers love them.”

Mercedes-Benz Trucks UK has promoted Stuart Jeggo to sales director, completing the manufacturer’s senior management team line-up.

Jeggo is already wellknown to Mercedes-Benz and FUSO truck customers, having been head of key account management since 2017.

He joined Mercedes-Benz Trucks as a business development manager in 2013, with responsibility for supporting the dealer network in customer service levels, before being promoted to head of strategic accounts and municipal sales in 2016.

He will oversee all vehicle sales to operators in his new position as sales director, from large fleets to owner-drivers, across Mercedes-Benz Trucks and FUSO Canter brands.

Mercedes-Benz Trucks UK MD Heiko Selzam said: “Under Stuart’s leadership the key accounts team successfully changed the shape of our fleet business in the UK, encouraging growth through a clear strategy of building long-term, sustainable partnerships with our customers.”

Jeggo will work alongside customer service and parts director Can Balaban and chief financial officer Rodrigo Landi.

RH Commercial Vehicles (RHCV) has supplied Newhaven-based K&H Bakewell with its first Renault trucks, a pair of T-High 520 6x2 tractor units.

Pete Lowery, director of K&H Bakewell, said he was impressed with the dealer, both in terms of its communications and with the quick delivery of the trucks.

He said: “There is always a demand for new trucks, whether it is to replace old ones or to accom modate rising demand. After speaking with Jim McNeil from RHCV, I was impressed with what he could supply to keep business

booming. I have never had a Renault truck in my fleet, but I was pleasantly surprised at the capabilities of these vehicles and how they can serve the company.”

Lowery has also been impressed with the fuel consumption, and praises the 12.8-litre DTI 13 engine.

“There is a dramatic fuel saving between the Renault trucks and other vehicles in my fleet, meaning they can really benefit operational costs, especially during these times of economic uncertainty,” he told us.

The trucks have been specified with both driver comfort and safety

The trucks were painted by RHCV, but not before the dealer had mocked up a preview image of the livery to allow the haulier to see what it would look like.

Lowery said: “The paintwork on the T-High is brilliant, absolutely top quality. With the added lights, these trucks will really own the road!

“RHCV has been excellent from start to finish. I am very impressed with the great customer service and the superb quality of the vehi cles. This fills me with great confi dence to continue forming a strong relationship between RHCV and K&H Bakewell.”

The haulier, which has been in business for 50 years, runs a 25-strong mixed fleet of trucks.

“I’m really looking forward to deepening my relationships with truck operators, our dealer partners and the wider Mercedes-Benz Trucks team as we continue on the journey towards decarbonisation together. Our industry will transform more in the next five years than it has in the previous 50, and I know we have the right products, the right services and the right team to bring the finest customer experience to everyone,” Jeggo said.

Moving to a new site is an exciting but nervous time for a business, but moving to a new site that has cost £7.5m would quicken the pulse of even the coolest cus tomer. John Biggin, executive chairman of TruckEast, however, seems relaxed at the opening of the Scania dealer’s newest site near Stowmarket.

Located just off junction 47a of the A14, the purposebuilt site on the Lawn Farm Business Park includes office space, a workshop and a body shop, expanding the firm’s offering in the local area. The 3.7-acre site is close to TruckEast’s previous Stowmarket site, but there’s a great deal more space at the new location.

“Where we were in Stowmarket, the company had been there in various guises for over 50 years. You can imagine it’s changed a lot over time and is [now] right in a residential area on a narrow road with a school and old folks home and all sorts around it. It just wasn’t suitable anymore, and was looking very tired. These days, you’ve got to have the right facilities for staff retention and for recruitment. We’ve also got to present the right image. Scania is a premium brand, so we’ve got to portray a premium image – hence the huge investment,” Biggin says.

Sitting alongside the A14, the new site is also a lot more visible and presents its own branding opportunity.

“The frontage alongside the main road is a massive thing,” explains depot manager Matt Castle. “It’s been

TruckEast’s investment in a well-equipped and spacious £7.5m facility near Stowmarket is all about improving staff recruitment and retention and maintaining a premium image

talked about for a very long time and I’m beaming with pride at what we’ve moved into.”

The facility has three drive-through bays with two full-length pits and one half-length pit. There’s a new body shop with a full-size, state-of-the-art spray booth suitable for HGVs and a smaller spray booth for large parts or light commercials. Eight 30m bays are available for servicing, maintenance and repair.

The site also features an ATF lane with its own brake tester, as well as another brake tester for the workshop. “We’ve tried to put the best possible facilities in the work shops to make it as efficient as possible,” explains Biggins.

“We’ve got the nicest office environment for the staff as well. Hopefully, we’ll get a return on all the invest ment at some stage, but this is not about the money, this is a 30-year investment. I’ve been with Scania, the franchise, for 25 years and I have to say, they are very decent, nice people. I’ve really enjoyed my tenure with Scania and I appreciate the standards they set. I was a truck mechanic once and worked on the shop floor.

I’ve seen a fair bit and I’ve personally worked in some not very nice workshops.

“It’s not nice if the floor is covered in oil, the equipment is broken and you haven’t got proper facilities. I wouldn’t want any of my staff to suffer that. Would I want to work here? Yes, I probably would, and that’s got to affect recruitment and retention, which is very important.”

The building has been installed with energy-saving features, including solar panels and LED lighting. There’s also rainwater harvesting and recycling for the automated chassis wash with a dedicated valeting bay, as the new site continues to be used as the PDI centre for the entire TruckEast network.

The site opening was attended by senior Scania staff including executive regional director of Scania Europe

TruckEast’s new site features eight 30m bays, three drive-through bays and a body shop equipped with two spray booths

north region, James Armstrong and MD of Scania Great Britain, Chris Newitt.

“This is the standard [for new sites] but they don’t normally have a spray booth and body shop,” commented Armstrong. “The Scania standards optimise the layout, and it’s much better when you’ve got parts in between two workshops – but it’s not always the case you can get the right size site for such a project. What’s been done [here] is creating a great working environment for the staff,” he added.

At total of 60 staff have moved over to the new location, where more than 100m of racking has been installed for parts stock. There’s also dedicated parking for visitors and trucks and trailers, with a front-of-house reception and driver’s waiting area.

“We are really excited to have opened the doors and welcomed in our customers, as well as our employees. The site offers an extensive range of services and we have a great team in place to support the growing demands of local operators,” depot manager Castle adds. ■

A new facility isn’t the only change at TruckEast, where several significant personnel changes took place over the summer. Harley Coulson became MD and dealer principal, succeeding John Biggin, who took on the role of executive chairman.

Coulson began his career in the Scania UK network as an apprentice at TruckEast, eventually becoming depot manager of the King’s Lynn site. In 2006, Coulson became regional manager and progressed to the role of sales director in 2014.

“After being part of the team at TruckEast for 16 years, it’s an honour to be appointed managing director and dealer principal. Together with my team, I’m focused on further driving the success of the business,” Coulson said.

Carl Johnson has taken on Coulson’s previous role of sales director.

Biggin said: “Harley’s extensive leadership skills and business acumen are two significant assets that will help to continue to drive the business forward. I would like to thank him for his continuous commitment and achievements and wish him the utmost success in his new role as MD of TruckEast.”

He continued: “With a solid Scania background and excellent customer relations, Carl will be a great addition to our company, and we wish him the very best of luck with everything”.

World events and domestic politics have caused last years’ rise in operating costs to continue apace, writes Colin Barnett

The ancient Chinese reputedly had a curse “may you live in interesting times”. Well, times don’t come much more “interesting” than 2022. While the plague that was coronavirus arrived with little warning in 2020, and fortunately seems to be largely under control, no one could have anticipated that post Cold War Europe would see the invasion of Ukraine by its neighbour, Russia.

Putting aside the immense human tragedy of the war, the direct impact of lost components from Ukrainian suppliers on top of the existing semi conductor shortage has exacerbated the poor availability of new vehicles. The situation has also meant that fuel prices are no longer as volatile as in the past two years – now they’re just stuck on high.

Closer to home, we have had unprecedented political turmoil. While many could have predicted the demise of former PM Boris Johnson, who would have expected

ALTERNATIVE FUEL: For comparison, David Batty has put together operating costs for a 6x2 CNG tractor for 44-tonne operation on 6 axles. The price of CNG has been variable in recent months but it now looks more settled. The futures market is forecasting it to cost around £0.95 per kg.

his replacement to come so close to destroying the British economy in a week? Sorting that mess out will take years.

We usually like to brighten up these annual reviews with at least a hint of positivity, but the feedback from our panel of operators has been either bad news or dreadful news. From vehicle acquisition, driver remu neration, tyres, fuel and insurance to borrowing costs and establishment overheads, every element of road transport operating costs has gone up – and often by far more than the double digit inf lation that has come as such a shock to younger generations that they actu ally need the concept to be explained to them. And if you do manage to create a surplus, April’s increase in corporation tax from 19% to 25% for many operators will take another substantial bite.

Unfortunately, the prospects are for things to get much worse before they get better. For example, indications are that some truck prices are set to rise by as much as 25% next year. The grim reality is that the gap between survival and failure is narrowing so rapidly that many operators simply won’t be around to read next year’s MT cost tables. Hopefully we’re wrong, and everyone finds a way through. Here’s to far less interesting times. ■

Per week (£) based on 46 weeks Per day (£) based on a 5-day week Per hour (£) based on an 11-hour day

Fuel Tyres Maintenance & repairs

Subtotal Profit allowance (5%) Total (p/mile)

20,000 miles/year 30,000 miles/year 40,000 miles/year

1,052 210 19.12

16.8 0.76 4.04 21.61 1.1 22.7

265 184 144

1,050 210 19.10

18.1 0.87 4.77 23.71 1.2 24.9

267 186 146

1,095 219 19.91

21.9 1.33 5.25 28.48 1.4 29.9

282 198 156

1,109 222 20.16

25.8 1.76 5.75 33.32 1.7 35.0

290 205 163

Vehicle cost (£)

Fuel cost (p/litre): ex VAT, average monthly MPG

AdBlue cost (p/litre) Depreciation period (years) Residual value (£)

ANNUAL STANDING COSTS (£)

Driver wages and NI

Vehicle insurance

Establishment/overheads

Vehicle tax (VED) based on no RPC but with Levy Depreciation Finance cost

Subtotal Profit allowance (5%)

Total annual standing costs (£)

Per week (£) based on 46 weeks Per day (£) based on a 5-day week Per hour (£) based on an 11-hour day

RUNNING COSTS (P/MILE, 80,000 MILES/YEAR)

Fuel AdBlue (at 6% of fuel consumption) Tyres Maintenance & repairs Subtotal Profit allowance (5%) Total (p/mile)

CHARGE PER MILE (P)

miles/year

ANNUAL STANDING COSTS (£)

wages and NI Vehicle insurance

Vehicle tax (VED) based on E6 & Levy without RPC Depreciation Finance cost Subtotal Profit allowance (5%) Total annual standing costs (£)

STANDING COSTS ALLOCATION

Per week (£) based on 46 weeks Per day (£) based on a 5-day week Per hour (£) based on an 11-hour day

RUNNING COSTS (P/MILE, 60,000 MILES/YEAR)

Fuel AdBlue (at 6% of fuel consumption) Tyres Maintenance & repairs Subtotal Profit allowance (5%) Total (p/mile)

CHARGE PER MILE (P)

40,000 miles/year 60,000 miles/year 80,000 miles/year

32-tonne 4x2 unit, taxed for tandem-axle trailer

84,791 159 10.4 64.0 7 12,372

52,818 3,548 27,083 1,136 10,346 6,130 101,061 5,053 106,114

2,307 461 41.94

70 1.68 2.50 9.44 83.12 4.2 87.28

38-tonne 4x2 unit, taxed for triaxle trailer

84,507 159 9.2 64.0 7 12,775

52,818 4,146 27,452 1,136 10,247 6,328 102,127 5,106 107,234

2,331 466 42.38

79 1.90 2.86 9.55 92.87 4.6 97.52

44-tonne 6x2 unit, taxed for triaxle trailer

87,549 159 8.5 64.0 7 14,712

52,818 4,587 29,872 1,136 10,405 7,289 106,107 5,305 111,413

2,422 484 44.04

85 2.05 3.48 10.03 100.60 5.0 105.63

Tandem-axle trailer (curtainsided) Triaxle trailer (curtainsided)

24,178 12 2,349

25,808 12 2,511

3,684 1,661 5,345 267 5,612

122 24 2.22

3,427 1,829 5,256 263 5,519

120 24 2.18

1.81 3.29 5.10 0.3 5.36

2.80 3.67 6.47 0.3 6.79

42,382 2,098 8,772 165 9,361 2,082 64,860 3,243 68,103

1,480 296 26.92

43 0.74 2.86 8.57 54.69 2.73 57.4

228 171 143

46,225 2,398 12,858 189.5 10,860 2,415 74,945 3,747 78,692

1,711 342 31.10

48 0.84 3.25 9.66 61.93 3.10 65.0

262 196 163

47,877 2,662 17,099 615 14,063 3,112 85,428 4,271 89,699

1,950 390 35.45

56 0.97 3.39 9.19 69.15 3.46 72.6

297 222 185

49,646 3,255 17,960 615 14,975 4,048 90,499 4,525 95,024

2,066 413 37.56

69 1.19 4.52 10.03 84.58 4.23 88.8

326 247 208

49,646 3,255 23,169 1,136 16,286 5,224 98,716 4,936 103,652

2,253 451 40.97

96 1.67 9.90 17.02 124.97 6.25 131.20

390 304 261

Motus Commercials‘ apprenticeship scheme evolves year after year, with a vision to be the best employer in the industry

In the aftermath of Brexit and during the pandemic, money seemed to be the only significant bargain ing chip for many employers in dire need of skilled staff, but salary alone does not buy you loyalty.

Motus Commercials has known this for a long time and the investment and effort it has put into its apprenticeship scheme is now more than reaping the rewards – and not just with its recent MT award win.

The independent commercial vehicle dealer group has had an apprenticeship offering in one form or another for the past 50 years, but it is only relatively recently that it has begun carefully shaping its programme into the highly successful production line of talent that exists today, smoothly filling up the ranks as older technicians start to retire.

People partnership manager Sarah Bardens joined the business in 2018 with a remit to bring together and expand the company’s apprenticeship schemes across the range of technical and non-technical functions that it offers, while at the same time maintaining the quality of these programmes.

“The skills shortage has always been our main driving force, but there’s also an ageing workforce who don’t want to be in a workshop past the age of 65, so you need to bring into the business new, fresh talent,” she says.

“The MD and HR director could see the benefit of that and had been driving it for a few years. I had no automotive experience, but they have and so we blended both together with my apprenticeship knowledge.”

Every year Motus recruits apprentices into each of its workshops – alongside all the departments – and this year showed that it was on the right track, with the high

est volume of apprenticeship vacancies at 70 – a 66% increase in five years.

And despite the challenges facing employers at the moment, staff retention is high; Motus says 96% of apprentices are offered a permanent contract when they complete their programme and 80% of those employed since 2016 are still working for the company.

“It’s evolving,” Bardens says. “Each year we evaluate what we do, what works, what doesn’t work and the return on investment [RoI].”

Unsurprisingly, RoI was singled out by the judges after Motus calculated that for an intake of 50 apprentices a year, its return was potentially in excess of £600,000 over the three-year programme.

But that is not to say the candidates are wrung out like a sponge to eke out every last profitable drop. In fact, Bardens says that in apprentices’ first year, Motus does not expect them to be productive at all and it is only during years two and three that productivity expectations are gradually increased. In this way, stress is not piled onto them and there is plenty of time for learning.

The company sources its apprentices in a variety of ways and does not rely solely on training providers to find them. It has its own recruitment team and gets involved with schools and colleges, as well as spending time engaging with local communities to increase the com pany’s profile:

“We invite lots of young people into our business as work experience placements, which is a useful tool for us to use as well,” Bardens says. “Quite a lot of apprentices have come through from that.”

Its recruitment process is rigorous, with activity days for would-be apprentices, followed by an informal oneon-one manager interview so that Motus can get an idea of a candidate’s skills and personality.

“Then there are work trials,” Bardens adds. “It’s three to five days working with the team so a manager has a chance to assess them and they have a chance to check it out for themselves.

“We do lose some but, on the whole, the recruitment from the work trial is strong.”

Despite this rigour, it can sometimes be tricky for a candidate to gauge whether their career choice is right for them. Bardens says: “There’s a good portion of school leavers who have grown up around and live and breathe engines, but that’s not the same for everyone.

“I often say our industry is a Marmite job. After three months, maybe you’ll get someone who thinks ‘this is not for me’. Workshops can be cold, hot, dirty and noisy, so it’s important to engage with people who really know what they want to do.

“One thing is having the right mentors.”

This is another strong element of Motus’ apprentice ship programme. All of its apprentices are supported by

a dedicated staff member who is there to share their knowledge and expertise, demonstrate best practice and support their mentee.

Motus says this arrangement benefits both parties and provides clear personal development opportunities not always available within a standard team/colleague relationship.

Mentors and apprentices work closely together to prepare for end-point assessments, using guidance and feedback from the training provider and college to inform practice, revision and preparation, with additional support from the people partnership manager who oversees the apprenticeship programme.

Keeping apprentices happy, engaged, learning and pro gressing is often a matter of effective communication and Motus has an impressive range of initiatives with which it is achieving this.

Its apprenticeship handbook outlines key points of their employment; social media and quarterly newsletters keep them up to date with information, business devel opments and to help celebrate achievements; annual surveys, ‘rate my apprenticeship’ feedback and a dedicated apprenticeship suggestions email address helps Motus evolve and develop along the same parallel lines. And last year it launched a weekly podcast for colleagues to communicate their stories that might be relevant to others.

The Motus apprenticeship scheme will never completely replace a standard recruitment programme to attract existing technical brilliance into the company, but as Bardens explains, it is an opportunity to shape fresh minds: “There are no bad habits,” she says.

Our judging panel was impressed with Motus Commercials’ strong awards entry, citing the number of initiatives it has introduced to keep engagement high among its candidates.

Specific reference was made to the apprenticeship handbook, the regular newsletters, monthly and annual awards, as well as its dedicated mentoring support.

“There was an admirable attempt to measure return on investment for apprenticeships,” noted one judge.

“There is a good development system for progression of the trainees in the business and there are well-structured apprenticeship schemes that meet the business’s needs.”