Delivery firm reports on impressive performance across the board

£282.8m, with operating profit rising 22% to £37.8m (2022: £31.1m).

The division’s operating margin leapt to 13.4% (2022: 12.1%), which DX Group said was driven by further improvements in productivity and operational efficiency.

The Hoyer Group has announced its intention to partner with Munich-based private equity firm AUCTUS Capital Partners in a major rebranding and investment plan.

Subject to the approval of competition authorities, Hoyer said the transaction would trigger a strategic growth initiative to strengthen its global performance under the new brand name of Oxalis Logistics.

This would include an investment of more than €100m (£86.7m) into its infrastructure, assets and digitalisation.

The proposal would see a strategic adjustment in the company business models – Global Tank Logistics, Gas and Petroleum Logistics, Supply Chain Sustainability and Intermediate Bulk Containers.

Under the deal, the logistics specialist would hand over its regionally based businesses of petroleum deliveries and bitumen logistics to AUCTUS Capital Partners.

The Hoyer workforce and service delivery to customers would remain unchanged, it added.

DX Group saw pre-tax profit rocket by nearly 50% in the year to 1 July 2023, aided by strong performances from both DX Freight and DX Express and by the acquisition of former Tuffnells depots and customers, following the company’s demise in June this year.

According to DX Group’s final audited results, revenue rose by 10% to £471.2m (2022: £428.2m) while statutory pre-tax profit soared by 46% to £25.4m (2022:

£17.4m). EBITDA also strengthened during the period, up by 20% to £60.2m (2022: £50.3m).

The results revealed an improved group operating margin, which rose to 6.7% (2022: 5.8%). DX confirmed that its target remains between 7.5% and 10.0%.

The group attributed its revenue rise to “strong performances” at both DX Freight and DX Express.

DX Freight delivered a revenue boost of 10% during the period, up from £256.9m in 2022 to

SECURITY FAIL: A Sheffield haulage firm has vowed never to park at Warwick Services again after 13 pallets of high-value sportswear were stolen out of one of its lorries in the middle of the night. Hallam Express said it was “outrageous” that the Welcome Break-operated motorway service area admitted there was no CCTV operating in the parking area when the HGV was targeted. Betsy Simpson, sales and marketing director at the haulier, said she was certain the theft was planned and that someone had been tipped off after only valuable goods were stolen. A Welcome Break spokeswoman said it operated a number of security measures across its sites. “This includes LED lighting so there is improved visibility at night,” she said. “We also have a record of every vehicle coming in and out.”

The group highlighted the division’s “strong” customer retention levels and “significant” new customer wins along with high levels of customer service as key factors in its improved performance.

DX Group said the acquisition of 15 sites from the administrators of Tuffnells Parcels Express, along with the addition of 700 former Tuffnells customers and over 350 former employees, has delivered around £35m of value to the business.

DX Express also delivered improved results, with revenue rising by 10% to £188.4m (2022: £171.3m) and operating profit up 22% to £17.7m (2022: £14.5m).

The division’s operating margin increased to 9.4% (2022: 8.4%), which DX said was driven by “healthy levels of new business” in its parcels department.

A major ransomware attack on KNP Logistics was a key contributor to the group’s demise, administrators have revealed.

According to FRP Advisory, KNP Logistics Group, which includes subsidiaries Knights of Old, Nelson Distribution, Steve Porter Transport and Merlin Supply Chain Solutions, suffered the attack in June this year.

The incident hit key systems, processes and financial information and “adversely impacted” on the group’s financial position and its ability to secure additional investment and funding.

Nelson Distribution was acquired at the 11th hour by Kinaxia in a deal completed just

before the company failed. The purchase sees the group take on all 170 employees and the company’s business and assets. Knights of Old, KNP Logistics Group, Steve Porter Transport and Merlin Supply Chain Solutions are all in administration.

FRP Advisory said: “With the

Lloyd Fraser Group and its parent company Barbican Capital have slammed Close Brothers and Close Invoice Finance for triggering the administration of the haulier in a move it claims was “wholly unnecessary” and the result of “bullying” and “spiteful” tactics.

Birmingham-based Lloyd Fraser Group was placed into administration by its banker Close Brothers. The group, which specialises in the milk, fashion, recruitment and warehousing sectors, employs over 700 staff across 16 depots and operates a fleet of 400 vehicles.

BULK BUY: South Coast Logistics has taken delivery of five new Volvo FM 460 6x2 tractor units. The vehicles join an 85-strong fleet and will operate primarily in the south of Ireland, typically across the province of Munster, working on bulk ADR assignments. Damien Healy, director at South Coast Logistics, said: “We’ve grown dramatically over the last decade and as a result, our fleet has had to undergo significant transformations. Given our prior experience with Volvos, we have an acute understanding of the exceptional quality and reliability that comes with these new FMs.”

exception of Nelson Distribution, unfortunately the majority of the group’s employees have been made redundant, with a small group being temporarily retained to assist in the winding-down of operations. Regrettably, approximately 730 employees will be made redundant.”

A&R Haulage has joined the Palletforce network, taking on CB postcodes in Cambridge and Saffron Walden, as well as CM postcodes around Stansted.

The Risby-based firm works with trailer operators and freight forwarders in the UK and Europe and offers container unloading and fulfilment services at Felixstowe and Harwich, alongside full- and part-load palletised freight final-leg deliveries.

With roots stretching back to

Anthony Finlayson-Green, group chief executive, insisted he received no warning from the bank: “We were a buoyant company. This is just a very spiteful act, which is crazy and will be challenged in the courts,” he said.

Only the group’s recently launched warehousing business Lloyd Fraser 3pl, which is a separate entity, escaped administration.

1972, A&R now runs a team of around 40 full-time drivers and founder Roger Arnold said joining Palletforce fitted with its growth plans and the demands of its customers.

“In order to meet customer requirements and to help us diversify our offering, we felt it was important to be part of a dedicated network in a crowded market,” said Arnold.

Kinaxia Logistics is looking forward to a strong performance in 2024, after laying the foundations for a consolidated business over the past two years.

The group’s recently published annual results to 31 December 2022 have seen it break through the £200m turnover barrier to deliver £206m

in revenue, up 11.7% on the previous year – an increase of £21m.

Gross profit also rose in the period by 17.4% to £52.2m, up from £44.4m in 2021, while operating profit, before exceptionals, rose strongly from £3m to £13.1m, just short of a £10m increase on 2021. Discounting exceptionals,

the group’s operating profit rose by 12%. However, Kinaxia is predicting a less impressive 2023, as a result of the economic challenges brought on by soaring inflation, fuel price increases and the ongoing war in Ukraine, along with a decision to stick with its pledge to consolidate its business during the year.

Distribution Group (MDG) suffered an almost fourfold fall in pre-tax profit last year, as its core newstrade business continued to be hit by plummeting newspaper and magazine sales and a tough economic environment.

However, the group’s attempts to diversify are bearing fruit, with its latest financial results revealing its largest non-newstrade revenue to date.

Its latest annual results, for the year to 31 December 2022, reveal revenue remaining almost static at £1,268.5m (2021: £1,269.6m) with pre-tax profit plunging to £3.5m (2021: £13.5m).

MDG remained upbeat in its strategic report to the annual results, noting that, despite the difficult market conditions, it has

Williams Haulage Limited has been fined £100,000 after a Hungarian lorry driver fell from a loading bay and fractured his skull, resulting in his death.

The logistics firm, which is based in Cynwyd near Corwen, was fined £100,000 and ordered to pay £8,400 costs after admitting to failing to manage risks posed by the operation of the loading bay.

An HSE investigation into the incident found that a risk assessment that identified the risk from falls and introduced control measures had been carried out, but these had not been used in practice.

■ A tanker driver suffered serious chemical burns after standing in what he thought was a puddle of water at the Grimsby site of Tronox Pigment UK in August 2022. The driver required skin grafts and two toes had to be amputated. Tronox was fined £200,000.

Vehicle transport specialist Glasgow Car Movers has entered administration with all 25 of its staff made redundant.

Established in 1999 in Uddingston, the company regularly transported more than 1,000 vehicles each week across the UK, using a fleet of 28 HGVs operating out of two bases.

According to administrator Interpath Advisory, the company had experienced liquidity pressures, in part due to the impact of the Covid-19 pandemic, coupled with rising costs.

“delivered a robust financial performance”.

MDG’s newstrade division’s revenue fell to £934.2m (2021: £977.3m) during the period, as newspaper and magazine volumes continued to decline. This was exacerbated by the demise of retailer McColls, a major MDG newstrade customer.

Menzies Distribution Services (MDS) delivered better news, with revenue rising by £33.5m (18.7%)

in the period to £212.4m (2021: £178.9m), thanks to a restructuring enabling MDS to tender for larger logistics contracts.

MDG’s Express division also boosted revenue by £8.5m (7.5%) to £121.9m (2021: £113.4m) as a result of new customer wins.

However, turnover in Menzies Parcels, which is part of the Express division, decreased by £3.5m to £19.2m (2021: £22.7m), due to losing a major contract in 2020.

After reviewing their options, the directors resolved to appoint administrators on 12 September.

Interpath added that the business ceased to trade prior to their appointment and, with no prospect of trade resuming, the joint administrators made the company’s 25 employees redundant.

Green Biofuels, the largest UK supplier of hydrotreated vegetable oil (HVO), has collapsed, just 20 months after BP took a 30% stake in the company.

Green Biofuels is understood to have suffered cash flow problems for some time and has appointed Lucy Winterborne, Kristopher Aspin and Alan Hudson of Ernst and Young as its joint administrators.

The collapse of the business has

CONTRACT WIN: Yodel has awarded a five-year tyre management deal to Halfords Commercial Fleet Services. Yodel senior category buyer Holly Jones said: “We are pleased to have agreed this new contract with Halfords. It will ensure that Yodel will receive best-in-class tyre management.” Greg Ward, commercial sales director at Halfords, said: “Yodel operates over 1,700 rigid trucks, tractor units and trailers all over the UK and we’re looking forward to developing a strong partnership.”

raised eyebrows in the market, coming less than two years after BP sunk a significant stake into the company in February 2022.

At the time, BP hailed Green Biofuels as being at the “forefront of HVO supply” in the UK market. adding that the investment was part of its strategy to expand its biofuels portfolio, which also saw the oil giant acquire a 28.57% stake in Gasrec at the end of 2021.

A BP spokeswoman told MT

that Green Biofuels had suffered from “cash flow issues”. She added: “We are a minority shareholder in Green Biofuels and we spent a lot of time and dedicated substantial effort to support them. We will be supporting the administrators in carrying out their statutory duties and assessing all options.”

She added: “We are continuing to supply the company with HVO as they are still trading right now and have customers to supply.”

Carlos Rodrigues (pictured), MD of Renault Trucks UK, has warned HGV fleet operators they will come under increasing customer pressure to switch to zero-emission vehicles, and that now is the time to plan their transition if they haven’t already.

“Irrespective of whether it’s difficult for you, it’s happening,” he said at the RHA Forum for the Future at the Vox in Birmingham. “You are now your customers’ problem. Every major company has now subscribed to the Science Based Targets Initiative (SBTi). That’s 982 companies in the UK, including all the major supermarkets, and

most of them are your customers.

“Some are saying to their shareholders that by 2025, not 2035, they are going to achieve net zero. They’re not waiting for the prime minister. They see zero emissions as a competitive advantage to getting more business.”

Rodrigues also cautioned operators against purchasing diesel trucks in the next buying round, claiming their businesses would be “worthless in 10 years’ time”.

He urged hauliers that have not started their net-zero journey to make plans with their truck supplier and customers and come up with a workable plan.

Senior road transport officials have urged RHA members to help them bring operators to accountant if they suspect them of noncompliance.

DVSA chief executive Loveday Ryder said the organisation was working to build stronger ties with hauliers and asked them to report their peers if they suspected them of breaking the rules. “One of the things I’d like to see more of, and for us to change in our relationship

with operators, would be more people coming forward and telling us about non-compliance,” she said. “That would be a huge culture shift from where we are today. Why isn’t non-compliance as socially unacceptable as drink driving?”

Richard Turfitt, senior traffic commissioner and traffic commissioner for the East of England, agreed: “The important thing to remember is RHA members are

bound by the law and so are we. We can only take action if we have evidence. That action often relies on information being passed to the agency, allowing an investigation to happen.

“Your information can directly assist getting shoddy, undercutting operators out of the system through a public enquiry. I rely on you and I expect that of you. As responsible operators, please help me to do my job on your behalf.”

Martin McTague, national chair of the Federation of Small Businesses, told Forum delegates that the Bank of England’s recent decision to hold interest rates will be “an enormous relief” to SMEs.

However, he went on to slam some of their major customers for “an appalling culture of late payment” that is crippling many hauliers.

“If you’re relying on consumer demand, the hold on interest rates means there’s a sense that we’re seeing some light at the end of the tunnel,”

McTague said. “However, I can’t think of one small business that hasn’t experienced late payment, with big businesses feeling they can abuse their supply chain. More than 50% of SMEs are reporting that late payment is getting worse.

“The major impact is that most small businesses have to double their working capital and then lend it to their customers at zero interest. That can’t be acceptable at a time when they’re struggling to invest. If the government is

serous about helping smaller businesses this is an issue they have to tackle, and tackle now.”

More small businesses are reporting revenue falling than revenue rising, McTague added, with the biggest problems being labour, energy and fuel costs.

“With energy we’re looking at ways firms can blend and extend contract agreements,” he said. “We’re also asking the government to change the VAT threshold and encouraging more apprentice schemes like driver boot camps.”

“When you see how much an electric vehicle is to buy, you might think your customers aren’t going to pay for that,” he said. “But for your customer, transport is just a line in their profit and loss account. So the impact of that isn’t the same for them as it is for you.”

Rodrigues also advised operators that the transition could be achieved in stages. “Understand what can be done and don’t do it all in one go,” he said. “Start with maybe a couple of trucks. We sit with operators, we make it work. So you’re then in a position of strength and bring a solution to your customer.”

The RHA, alongside the RHA Benevolent Fund, launched its Member Assistance Programme (MAP) at the Forum.

The confidential service – which operates 24 hours a day, 365 days a year – is staffed by qualified counsellors and aims to help member employees deal with personal or work-related challenges. The programme is run by PAM Wellbeing.

MAP services include in-the-moment confidential support or guidance regarding any personal issues, as well as short-term counselling delivered via telephone or secure video link.

Cognitive behavioural therapy and other mental health programmes are also available via an app, along with referrals to specialised support for debt and legal problems, bereavement, relationship support and trauma.

Adrian Brabazon (pictured), head of UK fleet solutions at BP, has insisted hydrogen will play a crucial role in the future of long-distance haulage and outlined the company’s plans to roll out 25 refuelling hubs by the end of the decade.

However, he went on to tell Forum delegates that BP’s strategy would also see it continue to invest in traditional fuels.

“We believe diesel will still play a major role but with a tipping point for the UK in the late 2030s,” he said. “Electrification will be the primary source of low-carbon transport. The pathway for hydrogen is a bit further out but it will play a crucial role in long-distance haulage.”

Brabazon added that Germany and China were currently leading the race towards net zero.

“But in the UK there are important programmes like the Zero Emission Road Freight (ZERF) demonstrator programme and

we’re eagerly awaiting the results in the near future,” he said.

“We’ve agreed a deal with Daimler to build 25 hydrogen

refuelling stations here by the end of 2030 and are currently developing a hydrogen hub at a site in Teeside.”

Jacqueline O’Donovan OBE (pictured), MD of O’Donovan Waste Disposal, has accused truck makers and commercial organisations of overlooking SMEs in the drive to zero-emission fleets.

Speaking at the RHA Forum, she said the transition remained “a massive challenge for smaller businesses” but that their calls for industry support had been ignored.

“I don’t think the larger companies or the manufacturers understand the challenges for the SMEs,” she said. “There is no collaboration. We’re forgotten because we’re small fry.

“Manufacturers tell us we need to take it to the customer, and preCovid we probably could. But customers are now only looking at price. They don’t care how I get a tipper or a skip to them as long as it comes. They’re not interested in what’s fuelling it.”

The London-based collection and recycling firm has underlined its commitment to reducing emissions by moving its fleet to HVO, but O’Donovan admitted a weeklong trial of two electric trucks had exposed major problems.

“The first one kept running out of power and the second one came

with its own battery but couldn’t do a day’s work in London,” she said. “And electric vehicles are double the price of diesel.”

She added that another major concern was how to charge the firm’s fleet of 100 HGVs. “How are they going to reach chargers? It’s not going to work,” she said. “Then we’re going to have a massive surge and where we’re located won’t be able to cope with that.”

The company is pinning its long-term hopes on hydrogen, O’Donovan said. However, storage remains a problem under current regulations.

“I think more business people should be in the government,” she concluded. “They could get industry leaders around the table for nothing to produce a standard or regulation that’s fit for purpose.”

Inverness has won £10,000 after hauliers and HGV drivers voted it the UK's kindest town.

The competition, which is a joint effort between the RHA and transport software provider Mandata, was launched in April and has gathered more than 1,000 votes from all around the UK.

The winner was announced at the Forum, with Tamworth coming second and Northampton taking third place.

The competition is part of a wider campaign to improve attitudes towards HGV drivers while raising awareness of the need to improve truck stop facilities across the UK.

Operators looking to switch to zero-emission fleets have been told they will need to present a convincing financial strategy to underwriters and a solid return on investment.

Tom Brown, a director at PMD Business Finance, warned delegates that funding for zero-emission vehicles would be hard to come by in the current climate without a “thoroughly thought-out business plan”.

“Financial institutions will be looking a lot deeper than they would if you wanted to invest in a diesel fleet,” he said. “They’ll look at your internal infrastructure and how you are going to support a net-zero fleet.”

Brown added that a main area of concern to underwriters is a fleet’s residual value. “That’s where the government needs to support investments in zero-emission fleets made by SMEs,” he said. “A funder might take the residual risk but we don’t really know what that is yet.”

Brown advised operators to consult a specialist accountant. “Talk to manufacturers and dealers about the operational impact and start to model that financially,” he added. “Also look at solar panels and LED lighting, the return on investment is a no brainer.”

The Trailblazer Group for Transport and Logistics has worked with the Institute for Apprenticeships and Technical Education to update the supply chain warehouse operative apprenticeship.

The existing apprenticeship dates back to 2016, when the format of standards and end-point assessments was formulated at the same time as the Apprenticeship Levy was introduced. There were some inconsistencies between the original standard and the end-point assessment, which have now been rectified.

The new apprenticeship has been developed over a period of 12 months and was approved by the Institute on 5 September. We are just awaiting final endorsement of the revised funding band by the secretary of state for education. The apprenticeship remains at Level 2 and of 12 months duration.

The new standard has been prepared to reflect the advanced methodologies and digital applications used in a modern warehousing environment.

Within the end-point assessment, the multiple-choice test paper has been replaced by an apprentice portfolio and professional interview. This will demand a greater understanding by the apprentice of the principles of warehousing and the different

processes involved. The observation remains as the other end-point assessment method.

The Trailblazer Group believes the revised apprenticeship and the increased funding band will provide a much more attractive route for developing new warehouse operatives, and should help employers to resolve this skills gap.

The supply chain operator apprenticeship was also accredited in 2016 but strangely it had two options – one for a supply chain operator (traffic office) and the other for a removals operative.

This didn’t seem rational, so the Trailblazer Group has worked with the British Association of Removers and gained agreement from the Institute to split the apprenticeship into two new apprenticeships: traffic operator and removals operative.

We have completed the skills, knowledge and behaviours for these roles and are now developing the end-point assessment methods.

The latest statistics published by the Institute of Apprenticeships and Technical Education reveal that the last full academic year, 2021/22, saw the highest number of starters for the LGV driver apprenticeships, with 2,827 for the Cat C+E appren-

ticeship and 420 for the urban driver (Cat C) apprenticeship.

However, the decrease in the driver shortage has resulted in just 1,125 starters in the Cat C+E apprenticeships in the academic year up to April 2023 and 336 starters for the urban driver apprenticeship over the same period.

Similarly, the number of warehouse operative apprenticeship starters has reduced from an alltime high of 2,504 in 2020/21 to 1,239 in the nine months up to April 2023.

It is hoped that the recent increase in the funding band for the LGV driver Cat C+E apprenticeship from £7,000 to £8,000, the new standard and the increase in the funding band for the warehouse operative apprenticeship from £3,000 to £5,000 will encourage more employers to use this method to bring new talent into the sector and utilise more of their Apprenticeship Levy.

Decarbonisation – are you bored of it yet? With all the pressures of keeping a transport business afloat in these troubled times, 2035 and the first ban on the sale of diesel trucks must seem like a lifetime away.

to a lack of fast charging capacity means that two or maybe three battery vehicles will be needed to replace one double- or sometimes triple-shifted diesel.

The newspaper for transport operators

To contact us: Tel: 020 8912 +4 digits or email: name.surname@roadtransport.com

Editor Steve Hobson 2161

Head of content Tim Wallace 2158

Steve Hobson Editor Motor TransportWhile politicians scrabble for votes by making announcements to please the “ordinary, everyday people” – remember, we used to be “hard-pressed families” under David Cameron – the real impact of achieving net zero in the supply chain that everyone takes for granted has barely been considered by the government.

The notion that, apart from a few exceptionally hard to electrify specialist applications, battery electric trucks work fine seems to be embedded in the DfT. But it is becoming increasingly obvious that replacing diesel vehicles with battery electric on a like-for-like basis just isn’t going to work.

The huge increase in upfront costs and the inevitable reduction in productivity due

Hydrogen is sometimes presented as the white knight that will ride to the rescue of heavy, long-haul operations, but we have a long way to go before this is a commercially viable option.

So if everyone is bored on decarbonisation, why go on about it?

There is a link between the high-profile failures of some long-established transport companies over the last year and the uncertain future that is facing the whole industry.

Driver shortages and high fuel prices are often cited as factors in these companies’ demise – what it really highlights is a failure to adapt to changing times.

Love it or hate it decarbonisation is coming and is going to lead to changes on an unprecedented scale and pace. Get ready.

In a world where efficient transportation is vital, the driver shortage is a big problem. However, a beacon of hope emerges through technology, with artificial intelligence (AI) poised to revolutionise the transport industry, offering a compelling solution to this persistent challenge.

decision-making algorithms, especially in emergency situations, require transparent solutions.

Events and projects editor Hayley Tayler 2165

Group production manager Isabel Burton

Senior display sales executive Barnaby Goodman-Smith 2128

Event sales Tim George 0755 7677758

Classified and recruitment advertising rtmclassified@roadtransport.com

Sales director Emma Rowland 07780 604075

Divisional director Vic Bunby 2121

MT Awards Katy Moyle 2152

Managing director Andy Salter 2171

Editorial office Road Transport Media, First Floor, Chancery House, St Nicholas Way, Sutton, Surrey SM1 1JB 020 8912 2170

Free copies MT is available free to specified licensed operators under the publisher’s terms of control. For details, email mtsccqueries@roadtransport.com, or call 01772 426705

Subscriptions

RoadTransport@abacusemedia.zendesk.com 020 8955 7034

Motor Transport Subscriptions, Abacus, 107-111 Fleet Street, London EC4A 2AB

Rates UK £156/year. Cheques made payable to Motor Transport. Apply online at mtssubs.com

Jose Lezáun VP of operations, TruckstersFirst, the once-futuristic notion of automated and autonomous vehicles is now a tangible reality that stands to redefine our approach to transportation. Second, AI’s capacity to enhance efficiency is undeniable. AI-powered systems leverage real-time data and predictive analytics to optimise routes, reduce idle time and minimise fuel consumption.

These adaptable systems respond to changing conditions and traffic patterns, resulting in swifter deliveries and fewer delays. The logistical challenges magnified by the driver shortage can be substantially mitigated through AI’s ability to orchestrate complex supply chains. Predictive algorithms forecast demand patterns, facilitating resource allocation efficiency and reducing waste.

While concerns about job displacement are valid, the move towards automation could usher in opportunities for workforce reskilling. Professions such as mechanics, data analysts and AI system supervisors would be in high demand to support and oversee this technology, cultivating a new ecosystem of employment.

Nevertheless, integrating AI is not without its challenges. Regulatory frameworks must evolve to ensure the safe deployment of autonomous vehicles. Ethical considerations concerning

The partnership between AI and the transport industry promises a future where human beings can relinquish repetitive tasks, concentrating instead on higher-order responsibilities that demand creativity and critical thinking. Technology’s goal is not to replace humans but rather to complement and augment their capabilities, fostering a more productive and harmonious collaboration.

Embracing intelligent route planning systems, such as the system we use at Trucksters, is another path towards alleviating the driver shortage. AI-powered relay systems can identify ‘optimal exchange points’ along routes, meaning drivers swap their loads at the most efficient point of their journeys.

In summary, the future of the transport industry is intricately linked to the advancement of AI technology. By addressing the driver shortage and tackling logistical complexities, AI offers the promise of a streamlined, efficient, and sustainable transport network.

As we stand on the brink of this transformation, stakeholders must work collaboratively to ensure a seamless transition, harnessing the power of technology to shape a brighter future for the industry and society at large.

If you would like to contribute to MT’s Viewpoint, email steve.hobson@roadtransport.com

Registered at the Post Office as a newspaper

Published by DVV Media International Ltd

© 2023 DVV Media International Ltd

ISSN 0027-206 X

It’s been five years since the DVSA launched its Earned Recognition (ER) scheme with a promise that the enforcement agency would ‘work with, not against’ compliant operators – and it says its aims are being achieved.

Rolled out in April 2018 following a year-long trial, the DVSA says 10% of the national heavy vehicle fleet is now an ER member. According to figures provided by the agency, this equates to 126 operators, 412 operator licences, 25,841 HGVs and 17,716 PSVs.

ER marked a shift in approach by the agency and it has become one of the most obvious ways in which a haulage operator can prove that they are meeting driver and vehicle standards. By regularly sharing performance information with the DVSA, scheme members’ lorries are less likely to be pulled over at the roadside.

The argument put forward by the DVSA was that if they’re stopping fewer compliant vehicles, then it would free up resources to target its enforcement activities at high-risk, dangerous traffic instead. And, as far as it is concerned, this is exactly what is happening. “The ER scheme takes up less than 0.5% of the DVSA enforcement resource, but the ER team looks after 10% of the fleet,” explains a DVSA spokeswoman. “This frees up the enforcement resource to target the serious and seriously non-compliant. This will continue and develop in a similar way to how we enforce continues to develop and evolve.”

But this upbeat assessment is not shared by one of the industry’s largest trade associations. “From the data we have seen over the past couple of years, it would appear not,” responds Phil Lloyd, head of engineering policy at Logistics UK. “DVSA has checked fewer vehicles at its roadside inspections and undertaken fewer maintenance investigations, and when comparing MoT failure rates to OCRS scores, there has not been much variation.”

For Leicester-based Trucklink EU, having a fleet that glides past roadside officers unimpeded is a bonus, but it is not its primary reason for joining the scheme. The company operates 25 lorries and it became ER accredited in 2022 after making “considerable investments” in updating its systems and technology to meet the standards demanded by the DVSA.

“We never had a lot of stops to start off with,” says Paul Whelan, Trucklink depot manager. “I don’t see that as a commercial benefit. It’s about my team doing the best at what they are doing, to the best of their ability. That’s the bit I like about it, it’s belt and braces. We know we are good at what we do, but it’s good to have someone outside the business checking that and we are not leaving anything to chance.”

But it’s the commercial benefits – or lack of them – that are the sticking point as far as he is concerned, and he believes a lot could be done to make it more attractive. “The DVSA is the official body for transport and yet the government does not dish out contracts to ER operators. Why not?” Whelan asks. “We need to be at the front of the queue! ER is the benchmark.

“I don’t think it helps us gain new business but what it does do is demonstrate that we are as compliant as we can be and that we are being continually monitored on a monthly basis, so it gives us peace of mind. So if we’re talking commercial benefits then no, there’s nothing there at the moment. The general public doesn’t recognise it either, or has never heard of it – why isn’t it being pushed more?”

Trucklink is not alone in wanting improvements in the scheme. The DfT says there has been “considerable feedback” from operators and trade bodies wanting more flexibility in demonstrating their high standards.

As a result, the DfT launched a consultation on relaxing annual testing for ER operators, which it said this

Earned Recognition is now well established with hundreds of operators signed up to the voluntary scheme. But are its aims being achieved and what do hauliers want to see included? Chris Tindall reports

CHECKING THE BENEFITS:

could be achieved “without compromising safety because of the assurance that ER provides”.

The DfT is still analysing the responses to these plans, but not everyone agrees with the idea. “When we carry out maintenance audits, you often see a lot of money being spent on a truck only around the MoT date,” explains Paul Allera, RHA technical director. “Hauliers are waiting until their MoT. ER is not looking at vehicles, it’s looking at processes and procedures. So, if you are not getting a roadside stop and you are having an MoT every two years, how do you know it hasn’t got a mechanical failure?”

ER requires operators to have a DVSA-validated IT system which tells the DVSA is the operators has

missed any vehicle maintenance KPIs every four weeks, so compliance levels are routinely checked remotely.

However, increasing the testing intervals is likely to be backed by ER members. “I support that a lot,” says Whelan. “The vehicles are built to run without being tested continually. If I am having my vehicles inspected every six weeks, do I need them MoT’d every year as well? So I welcome that; this is part of a commercial benefit.”

As long as ER has existed there have been comparisons with the Fleet Operator Recognition Scheme (FORS). Recent moves by the DVSA to encourage clients of logistics operators to specify ER in their tender documents and the development of a specific HS2 module have increased speculation that the scheme is being positioned as a rival to FORS.

But both scheme operators are at pains to express their “uniqueness”.

“The DVSA Earned Recognition scheme is a comprehensive safety and compliance scheme measuring all aspects of requirements in line with the operator licence undertakings,” says a DVSA spokeswoman. “It is the only scheme that monitors key performance indicators (KPIs) relating to drivers’ hours and vehicle maintenance, making it a unique scheme providing assurance that standards are being maintained every month by any operators who hold the ER accreditation.

“We have also developed modules that are sector specific, which can be used as a ‘bolt on’ to the ER accreditation providing unique flexibility for operators. One of our most recent modules, the TfL contractual requirements module, provides ER operators with an alternative to FORS Silver but at a higher level.”

But Geraint Davies, FORS concession director, says: “The fact that FORS examines the full scope of any operation at a granular level sets it apart from other schemes and could even negate the need to complete additional environmental accreditations, as FORS is largely aligned with other standards and accreditations.

“Having been an operator I found myself using much of the FORS documentation to achieve other standards and accreditations. The FORS Professional training portfolio proved especially useful too – something FORS is uniquely positioned to offer.”

But rather than attempting to shout about their differences, Logistics UK says the scheme operators should instead be trying to harmonise their requirements. “There are benefits and issues with any scheme and from our members’ perspective they would like to see parity between these schemes, with one audit being able to fulfil the requirements of other schemes,” says Lloyd.

The DVSA encourages ER operators to apply for delegated examiner status so that they can conduct their own HGV driver testing.

This was not included in the call for evidence exercise relating to heavy vehicle testing carried out last April, but guidance on how any operator can provide driving tests for their employees is available on gov.uk. The agency says ER operators are likely to be judged favourably.

Operators can apply for permission for their employees to provide driving tests for staff if they’re an O-licence holder, or if they’re a police or fire and rescue service. The delegated employee must then complete an initial training course and reach an appropriate standard in the delegated driving examiner theory and practical tests.

The DVSA adds that when deciding if someone can be a delegated examiner, it will take into consideration whether they have picked up any criminal convictions during the previous three years; that they continue to be a “fit and proper person”; whether they reached the appropriate standard in the above tests and training courses; and how much professional development the delegated examiner has done.

To remain an examiner, an employee must carry out 40 tests a year. If they do not carry out any tests for six months the operator must inform the DVSA; the employee is then unable to carry out any more until the agency confirms in writing that the restriction has been lifted.

“DVSA encourages ER bus and haulage operators who have the facilities and the demand for training and testing of their own drivers to consider applying for DVSA delegated examiner status, but it is not a requirement,” says the DVSA spokeswoman. “We already know ER operators work to the highest standards and this service can provide cost savings to their business.”

Logistics UK said it was supportive of the initiative, because self-testing was one of the main benefits sold to ER operators.

TESTING TIMES: The DfT has suggested biennial MoTs as a possible enhancement to the Earned Recognition scheme

ER has been accused of focusing on larger hauliers and being too difficult for smaller operators to join. The DVSA launched a ‘Road to Earned Recognition’ programme, aimed at operators who have held a licence for six months or less, mainly to help new operators avoid costly mistakes that could see them up before their TC. It says 21 applications have been received so far.

“The programme is set around milestones over a two-year period and helps new operators run their business safely and efficiently from day one,” says the DVSA spokeswoman. “The ER scheme is open to operators of any size; 15% of the operators in ER have 10 vehicles or less.”

Not everyone gets on with ER and if the KPIs are not met, the DVSA will terminate their membership. The agency confirms there are 22 operators who no longer hold ER status.

“If operators are having difficulty managing the requirements of the ER scheme, the ER team will work with members to help them get back to consistently meeting KPI scores,” says the spokeswoman. “However, if the operator does not engage with the ER team or continues to not meet ER standards, then removal from the scheme is an option.”

But for those companies that hit their KPIs and are committed to demonstrating compliance, ER is seen as the best that’s currently available. “If someone asked me if I would push for ER if I moved to another company then yes, I would,” confirms Whelan. “It proves to the outside world you are doing a good job and also to my team who are being continually audited.” ■

LOWERING EMISSIONS: Aggregate Industries says its CO2 emissions have reduced by 90% since it switched to using HVO in its tankers

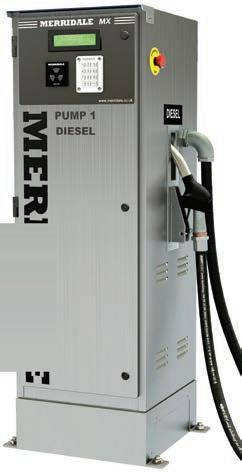

Electric vehicles have had huge amounts of column inches dedicated to them over the past few years, but as things stand a viable, battery-powered bulk haulage tanker has yet to get off the ground.

For this reason, a move to cleaner alternatives is seen as one way forward and hydrotreated vegetable oil (HVO) is emerging as one of the best fossil-free, transitionary fuels available.

It has significant benefits for operators mindful of their carbon footprint. HVO is circular in nature, having started out as a raw material derived from plants, and so HGVs are effectively reusing waste from the food industry. Switching to HVO is also extremely easy as no vehicle modifications are required.

“We see HVO as the way forward for bulk tanker operators as a means to reduce emissions from that particular fleet,” says Chris Ashley, the RHA’s environment lead. However, there are two significant issues with the fuel that its proponents are campaigning for the government to address: price and availability.

SIMPLE SWITCH: Diesel can be replaced by HVO without any vehicle modifications

These stumbling blocks should not be underestimated. Motor Transport spoke to one major bulk tanker haulier, which says the numbers do not add up. “The more you look into it, the more challenges you face trying to replicate what we do now,” the operator, who asked to remain anonymous, says. “We looked at HVO and decided not to use it. You have to look at the economics and weigh it up against what the customer wants to pay. And when

you look at the economics, they don’t stack up.”

Ashley says the RHA is busy trying to convince the government these challenges can be overcome. “There are two things we would say to try and resolve the issues,” he says. “Firstly, the government should unequivocally support its use through its low carbon fuel strategy, which we are still waiting for. Secondly, the price is around 10% to 20% more per litre than diesel, so the government should look to reduce that price per litre by introducing a fuel duty rebate that is linked to emissions reduction.”

Asked whether he thinks the government is listening to the RHA’s calls, Ashley says: “I think the point has landed with the government as to the benefits HVO can bring to the industry, but it has yet to make a decision as to whether it will support its use. We will continue to make the case. I think the government has been, up until now, very committed to the notion of zero emissions as opposed to lower emissions.

“I get that. I understand why they don’t want anything to distract from that. However, we also have to face up to the reality of keeping the economy going. Low emission fuels have a legitimate role going forward.” He adds: “The prime minister has recently said that there has to be a pragmatic and proportionate approach, so lower emissions very much aligns with that.”

These issues have not prevented Suttons Tankers from trialling the fuel’s use, and fleet director Steve Hassall says he is “excited” about the company’s preliminary findings.

Bulk tanker operators are unable to switch to electric power, but some are discovering the benefits of another environmentally friendly fuel. Chris Tindall reports

“We have been exploring various alternative fuels for our tanker operations and decided to start with HVO,” he says. “While we considered several options, including biodiesel and LNG, we found that HVO stood out due to its significant environmental benefits, compatibility with our existing infrastructure, and potential for integration into our operations.

“The decision to trial HVO was based on a comprehensive evaluation of factors such as fuel efficiency, emissions reduction, and overall feasibility, including the requirements of ADR. The potential advantages of HVO made it a compelling choice for our trial,” says Hassall.

“At Suttons, we want to be leading the sustainability agenda with our customers and that is why we undertook this HVO trial independent of any specific customer drive. The fact that we are undertaking this trial and will have accurate, first-hand experience of HVO in our operations is creating a great deal of interest from our customers, who will be able to reduce Scope 3 emissions through the services that Suttons provides.”

He says it is still too early to provide exact figures. However, Suttons believes it has seen an 83% reduction in its carbon emissions as a result of using 100% HVO. “The decision to continue using HVO within our fleet after the trial will depend on a comprehensive analysis of the trial’s outcomes, including economic factors,” Hassall

Industry leaders and environmental campaigners are urging ministers to cut the duty for fuels such as HVO in order to incentivise a move towards low carbon emission fuels.

In a letter to the transport minister Jesse Norman MP, a group of more than 30 signatories warns of the “urgent imperative” to reduce harmful pollutants, with one in 20 deaths across the UK directly attributed to poor air quality.

The coalition, led by fuel supplier Green Biofuels and with the backing of tanker operator Suckling Transport, says the DfT and Treasury should work together to reassess fuel duty schemes and explore tax incentives to encourage fleet managers to transition away from diesel.

Green Biofuels chairman William Tebbit says: “These are fuels you can use while you transition to other forms of fuels, whether that is electricity or hydrogen.

“Emissions out of the tailpipe are substantially lower in nitrous oxides and particulate matter. In addition to that, because they are made from waste and waste residues, they are lower in greenhouse gases.

“In comparison to regular diesel they emit about 90% less greenhouse gases.

“These fuels are more expensive and it seems somewhat bizarre that a far superior fuel in terms of greenhouse gases and emissions is charged with the same duty. That’s not incentivising.”

Tebbit adds: “You are not going to throw away an HGV that has a 10-year lifespan and may have cost £500,000, including the tractor unit and trailer, to replace it with an electric one or a hydrogen one that’s not really available nor performs as well.

“But you can just drop in a clean fuel and keep that piece of technology running for its entire life, hence reducing the amount of carbon from manufacturing as well and a lot of businesses in the UK are now doing that.

“But they are doing it because they know it’s the right thing to do; they are not being financially incentivised.”

says. “We can’t speak for other tanker operators but HVO is the current big opportunity to reduce emissions.

“We can also see opportunities for battery electric vehicles in our fleet over the next five years. The availability of hydrogen-fuelled HGVs that are compatible with hazardous operations is less clear at this stage.” This latter point is important and helps explain why HVO is probably the best currently available alternative fuel for tankers.

Martin Tomlinson, head of media for Volvo Trucks UK & Ireland, says running fleets on HVO brings a lot of advantages, particularly for bulk tanker operations. “It’s a less water- and land-intensive alternative to biodiesel, and its high quality as a fuel means it can be used in any of our latest Euro-6 diesel trucks,” he says. “The main reason that tanker operators will probably stick with HVO is that we can’t currently get ADR certification on an electric or LNG truck, which leaves only that alternative.”

Hassall agrees. “The majority of our operation is delivering hazardous cargos under ADR regulations,” he says. “As a drop-in replacement for fossil diesel, HVO will allow us to reduce emissions while alternatives such as battery electric and hydrogen are not currently available for ADR operations.”

Asked to clarify the certification process, a spokesman for the DVSA says: “The category of dangerous goods carried depends upon the category of vehicle used. Different categories of vehicle must meet differing specifications.

“A vehicle carrying a load classed as ‘explosive’ must be fitted with a compression ignition engine using only liquid fuels with a flash point above 55 degrees Celsius. Engines fuelled by gas and vehicles with an electric power train cannot be used. A vehicle carrying flammable liquids can use an engine powered by LNG, CNG or diesel, but cannot be fitted with an electric power train.”

Simple implementation

Aggregate Industries (AI) is another company using HVO in its tanker operations and as a result it says it has managed to reduce CO2 emissions by 90%. Explaining why it chose the fuel, Matthew Owen, AI supply chain manager within its cement division, says: “It is available now, there is an available network, no engine or vehicle modification is required – it is a drop-in fuel and there is no need for big infrastructure changes.

“We see HVO as very much a transitional fuel. We recognise that we are still burning a liquid fuel but from a responsible sustainable source, certified under the renewable fuels partnership. It is important to us that we have that traceability within the supply chain.”

Owen thinks there will be an bigger uptake of HVO over the next few years as availability increases, and he says AI is aware that many other hauliers are exploring its potential too. “Implementation was simple,” he continues. “We have had positive feedback and comments from drivers, for example, pointing out that there has been no change in driving experience or vehicle performance. Anecdotally, drivers believe there is also a slight improvement in fuel performance.

“HVO is a fuel we aim to continue to use and in our cement division we are looking at bringing more vehicles online over the coming year. Fuelling infrastructure is still an issue. It can limit our ability to completely change

METICULOUS PLANNING: Suttons Tankers evaluated HVO carefully before deciding whether to trial it

at this point, but with good planning and changes like introducing a split fuel tank at our Cauldon Cement Plant [in Staffordshire] it is definitely advantageous.”

The RHA’s Ashley points out that right now, HVO only accounts for around 0.3% of the fuels market. “It’s tiny,” he says. “In our view, one of the stumbling blocks is the lack of government backing to support its use. If the regulatory framework was unequivocal, then it would give suppliers the confidence to increase supply.

“There are a range of options other than HVO. Our position at the RHA is that all those alternatives should be in play to cater for the long-distance conundrum, because electric doesn’t yet cover that business use case.” ■

While the debate still rages over whether hydrogen fuel cells will be required to supplement batteries to power the highest-weight, longestrange zero emissions trucks of the future, German engineering giant Bosch is investing €2.5bn (£2.1bn) in volume production of fuel cells at its Stuttgart-Feuerbach, Homburg and Bamberg factories in Germany as well as in China.

“Here in Stuttgart-Feuerbach, in the plant whose history goes back further than any other Bosch plant, the

Bosch recently held a Tech Day at its Feuerbach factory in Stuttgart to showcase its investment in fuel cell technology. Steve Hobson reports

hydrogen future is about to happen,” says Stefan Hartung, chairman of the board of management. “Bosch knows its way around hydrogen, and Bosch is growing with hydrogen. There can be no climate neutrality without hydrogen.”

While the fuel cell power modules will mainly be built at the 5.4 million sq ft Feuerbach site, which opened in 1910, the Bosch plant in Bamberg will manufacture the core component (the fuel cell stack). Other components such as the electric air compressor and recirculation blower will come from Homburg. At full capacity Feuerbach could produce 5,000 power modules a year.

Power module production will also take place in Chongqing, China, with the components being supplied from a plant in Wuxi.

Bosch is also planning to manufacture stacks for mobile applications at its US plant in Anderson, South Carolina.

There are already around 3,000 people within Bosch working on hydrogen technologies, more than half of them in Europe.

Bosch’s proton exchange membrane (PEM) fuel cells can be used in a range of applications, including industry and domestic heating, but mobility is one of the main target applications. The company predicts that one in five new trucks weighing 6 tonnes or more will use a fuel-cell powertrain by 2030. In battery-electric heavyduty trucks the batteries can weigh up to 9 tonnes, while the batteries in an equivalent fuel-cell truck would weigh around 500kg, according to Bosch, with the fuel cell adding another 500kg.

“Electrical solutions have limitations in transport,” says Hartung. “Heavy trucks need a hydrogen-based solution. It is not either/or – we need both.”

In the UK, hydrogen is not seen as “a panacea” for reaching net zero emissions by 2050 but it could

One of Bosch’s first customers for its fuel cell mobile power module was the Nikola Iveco Europe joint venture launched in 2021. In May 2023 Iveco took over the European JV and an Iveco branded 6x2 fuel cell tractor unit was on show in Stuttgart.

With 2 million km already racked up by 50 vehicles in customer trials in the US and Europe, Nikola plans to launch its Tre truck in the North American market in the third quarter of 2023. The Tre is being built in Coolidge, Arizona, where the power modules will be assembled under licence from Bosch. This business model could be replicated with other truck OEMs.

The Iveco tractor unit was assembled at its Ulm plant in Germany, a manufacturing facility dedicated to building heavy-duty fuel cell trucks. Series production is due to start in Ulm by the end of 2023.

Felix Gebaur, project lead engineer - vehicle validation at Iveco, showed us round the truck, which is clearly production ready rather than a thrown-together prototype.

The 6x2 unit weighs 12 tonnes and uses a steered tag axle to give the required manoeuvrability despite its extra length.

It is fitted with two 200kW motors, two 84kWh 700V battery packs, a twin-stack 200kW fuel cell and five 700-bar hydrogen tanks holding 70kg of hydrogen, enough for a range of at least 800km.

It takes 20 minutes to refuel and if a 700-bar refuelling station is not available it can refuel at 300 bar, although that will halve the range.

become “a big niche” fuel in particular applications, according to the Commons Science and Technology Committee. It argues that hydrogen will have a “specific but limited” role in decarbonising some sectors where electrification is not possible, and as a means of storing energy.

In addition to the fuel-cell powertrain, Bosch is working on a hydrogen internal combustion engine (HICE), using both port and direct injection of hydrogen.

It says this solution is particularly suitable for longhaul heavy vehicles. “A hydrogen engine can do everything a diesel engine does and it is almost carbon neutral,” says Markus Heyn, member of the Bosch board of management and chairman of Bosch Mobility. “It also allows a fast and cost-effective entry into hydrogen-based mobility.”

Similar to a natural gas spark ignition engine, more than 90% of the development and manufacturing

Despite the apparently closed front grille there is a large heat exchanger behind it to cool the fuel cells. The batteries are also actively cooled but use a different circuit.

This example was fitted with large tyres – 315/80s – but production versions will use 315/65s.

Bosch Group revenues were €88.2bn (£75bn) in 2022 and Mobility is its largest business sector, generating almost 60% of sales.

The business sector’s main areas of activity are: injection technology and powertrain peripherals for internal combustion engines; powertrain electrification; vehicle safety systems; driver assistance and automated functions; vehicle-tovehicle and vehicle-to-infrastructure communication; and services for the automotive aftermarket.

Bosch is synonymous with automotive innovations such as electronic engine management, the ESP traction control system and common-rail diesel technology.

The group employs around 421,000 people worldwide.

technologies needed for the HICE already exist – though because hydrogen is a ‘dry’ fuel it does not provide any internal lubrication of the engine’s moving parts.

Bosch expects launch in mid-2024 and “six-figure” unit volumes by 2030.

However, the UK DfT insists HICE vehicles are not truly zero carbon emissions and will be included in the bans on UK sales of new non-zero emissions trucks planned for 2035 and 2040.

There was no discussion of the economies of hydrogen mobility at the Tech Day and, quite apart from the technical challenges, hydrogen is an inefficient use of scarce renewable electricity, is a difficult gas to store and transport and any leakage to the atmosphere causes more global warming than CO2 or methane. The cost of fuel cells is still far higher than batteries.

However, Bosch expects the unit cost to come down as production volumes ramp up and believes that it will be a practical and financially viable solution for high power, long-haul trucks and off-road applications. ■

While Bosch has committed to a hydrogen future, it says prospects for the business depend heavily on the political environment.

Chairman Stefan Hartung believes that Europe must do much more to create a counterweight to the rapid pace of developments in other regions of the world, such as the US.

He has four demands of German and European policymakers.

“First, we have to step up the pace of hydrogen production in the EU,” he says. “Second, global supply chains have to be set up, and third, hydrogen has to be used in all sectors of the economy.” A fourth point, he added, is to quickly set up infrastructure for distributing hydrogen in Europe.

CRITICAL CONCERNS: Bosch chairman Stefan Hartung believes Europe must step up the pace of hydrogen production

“It is blindingly obvious that the government must take the lead here,” Hartung says. “Without hydrogen vehicles there will be no hydrogen filling stations, and vice versa.”

As well as powertrain fuel cells, Bosch’s PEM technology can be used for small self-contained electrolytic production units, preferably powered by renewable electricity. This could be an option for back-to-base operators until a widespread public hydrogen refuelling network is developed.

As well as electricity, making hydrogen requires lots of water – 9kg to make 1kg of hydrogen gas. Bosch also makes the water purification systems that can turn just about any water supply, including sea water, into the ultra pure water needed by the electrolyser.

Its Rexworth division also produces key components for the compressors needed to take the hydrogen gas from 30 bar at the electrolyser to 700 bar for the composite steel and carbon fibre vehicle fuel tanks.

Bosch’s PEM stacks can be packaged into a container with power ratings of 1.5MW to 5MW. A 1.5MW unit can produce 23kg of hydrogen per hour –enough to power a truck for at least 300km. Depending on the relative price of electricity and diesel, Bosch said hydrogen “could soon be no more expensive than other powertrains”.

A fuel cell isn’t much to look at, but it packs a big punch.

The fuel-cell power module made in Feuerbach is the most complex system Bosch has ever developed. It is made up of hundreds of individual parts, and has been carefully designed to fit into the space previously occupied by the truck’s combustion engine.

The actual fuel cells at the heart of the power module are only the size of an envelope, and weigh less than 100g.

Up to 455 fuel cells are combined to make a stack capable of providing electrical output of more than 100kW. A fuel-cell power module uses two stacks delivering over 200kW – enough to power a 40-tonne truck when used in conjunction with a battery pack.

A lot of effort has gone into prolonging the service life of PEM fuel cells to as much as 30,000 hours to increase reliability and minimise operating costs.

Over 1,200m of high-speed laser welding is needed in each stack to make sure they are hydrogen-tight.

Fuel cells work best when operating at around 40% of their installed capacity, when they can be up to 50% efficient.

DOUBLE DELIGHT: The E-Transit has been met with widespread acclaim and scooped multiple industry awards – including MT Clean Fleet Van for the second successive year

Ford was among the first to stand up against the decision of the government to push back the ban on petrol and diesel vehicles from 2030 to 2035, and it’s little wonder as the giant manufacturer has gone all-in on electrification.

Ahead of the official government announcement, Lisa Brankin, Ford UK chair, said: “The auto industry is investing to meet that challenge. Ford has announced a global $50bn commitment to electrification, launching nine electric vehicles (EVs) by 2025. The range is supported by £430m invested in Ford’s UK development and manufacturing facilities, with further funding planned for the 2030 time frame. This is the biggest industry transformation in over a century and the UK 2030 target is a vital catalyst to accelerate Ford into a cleaner future.”

Their multi-award-winning Ford E-Transit has collected almost every single industry accolade since being named MT Clean Fleet Van of the Year last year, and having once again claimed the title this year, it will soon be joined by additional electrified models.

Ford E-Transit Custom will launch next year, followed by an all-electric version of the Ford Transit Courier by the end of 2024. There’s even the sector’s first plug-in hybrid pick-up truck due in 2025, underlining the rapid and expanding portfolio of EVs being rolled out.

Yet the Ford E-Transit will likely remain the most significant electric model for some time. Although the Ford Transit Custom is the UK’s best-selling vehicle, an electrified van will not likely have the same uptake by large fleets as the big electric Transit has seen. With the delayed ban on internal combustion engined vehicles, the appetite from retail customers for E-Transit Custom will also likely be less.

The E-Transit is then, the most important van to launch in a decade and will probably remain the most important vehicle of this decade too.

“The addition of an all-new electric powertrain to the Transit family has been exceptionally well received by fleets,” explains Iain Brooks, Ford Transit product marketing manager.

An electric version of Britain’s best-selling van needs to make a statement and Ford has done exactly that with the E-Transit, making it not only powerful, but with a good range and plenty of body sizes – the Swiss Army knife of vans doesn’t want to lose its reputation for versatility just because it’s got itself some batteries.

Despite its size and powertrain, the E-Transit is the most powerful van on the market with a massive 198kW – the equivalent of 265hp – for the top-rated version with a more restrained 135kW model that still provides 181hp also available. That means the E-Transit will be faster than any other large van (diesel or electric) including rivals like the Renault Master E-Tech, Mercedes-Benz eSprinter and MAXUS eDeliver 9.

Range is claimed to be up to 196 miles from the 68kWh battery and if that’s still not enough for a day’s work it is capable of charging from 15% to 80% in just 34 minutes. In contrast a standard charge from a 11.3kW wall box charger will take eight hours.

The batteries are beneath the chassis and hang down below the vehicle in a reinforced box. This lowers the centre of gravity compared to the diesel van and its rivals, which largely choose to house the batteries between the chassis rails on their large vans.

“E-Transit provides every customer with a comprehensive standard specification, advanced technologies, new connected features and award-winning driver assistance systems to make electrifying their fleets easier and more beneficial than ever before,” Brooks says.

“The vehicle is designed to satisfy a wide range of customer use-cases, with a 68kWh usable battery capacity as standard, providing a competitive range of up to 197 miles WLTP. E-Transit provides customers with a world-class combination of capability and low cost of ownership,” he adds.

The creation of an electric Transit hasn’t been a completely straightforward task, and isn’t merely a case of swapping the engine and gearbox for a motor and batteries. The electrical and mechanical elements of the new E-Transit have had to be made specifically for the

Messing with an icon always brings with it an extra level of scrutiny. The Ford E-Transit is proof that change is nothing to be frightened of

new van and include a completely changed rear axle and suspension.

The E-Transit is based on the Transit’s rear-wheel-drive platform with its electric motor contained within the rear axle. Its size, however, means that the traditional leaf springs for the rear suspension were not possible, so new independent coil springs had to be created. As a result, not only has the ride quality improved but the overall driving experience too.

The E-Transit is instantly fast and completely effortless in the way it builds speed. While this will undoubtedly be a concern for fleet managers worried about their drivers racing their E-Transits at every opportunity, it does help when running with a full payload and will also be useful for towing.

The heavy battery pack can be seen hanging beneath the chassis on the E-Transit and is encased in a toughened steel box. The exceptionally low down weight means the van clings to the road, improving the ride quality. It’s also much quieter than previous iterations – and not just because it is electric. With the motor in the rear, well away from the driver, the E-Transit is the quietest of all the electric vans on the market.

The downside of its rear-wheel-drive configuration is that the rear loading height is around 200mm higher than a front-wheel-drive Transit van. Given that the E-Transit has found a home on courier fleets including Amazon, it does represent a lot of vertical mileage for the unfortunate drivers climbing in and out at every stop.

On the inside, the Transit is largely unchanged from the diesel van with the exception of a 12in touchscreen borrowed from the Mustang Mach-E, which is the centrepiece of the new cabin.

It runs Ford’s SYNC 4 connectivity system providing infotainment and navigation, as well as access to a new range of connected features including an intelligent range predictor that factors in traffic and weather conditions. Customers also benefit from a lifetime subscription to FordPass Pro or the Ford Pro telematics packages and access to the Blue Oval Charging Network for a year.

“Ford looked at the entire eco-structure of driving and utilising EVs and offers end-to-end Ford Pro solutions

including software, charging, service and financing to help customers optimise the E-Transit’s productivity and performance,” Brooks says.

“Ford Pro’s FordLiive connected uptime system also promises to transform the productivity of commercial vehicle customers. This uses real-time vehicle data to connect customers and vehicles with dealers and Ford Pro expertise, delivering fewer breakdowns, fewer timeconsuming trips to dealers and faster workshop repairs. In addition to delivering vehicle health alerts directly to customers via Ford Pro software, the FordLiive Vehicle Uptime System also enables Transit Centre workshops to use customer vehicle data to reduce turnaround times via faster diagnosis, proactive parts ordering, and scheduling support to increase workshop bay availability.”

One element that will likely increase uptake compared to many of its rivals is that the E-Transit will be available in multiple sizes, with 25 different models that include short, medium and long wheelbase vans, as well as three GVWs of 3.5-tonnes, 3.9-tonnes or 4.25-tonnes. Load volumes are up to 15.1cu m and its maximum payload is 1,758kg for a panel van and 2,090kg for a chassis cab. Safety systems have also been improved, with a new Reverse Brake Assist as well as a 360-degree camera giving a birds-eye view of the surrounding area.

Together with the connected software solutions provided by Ford Pro, functional working equipment like Pro Power Onboard for powering tools, and an as yet unmatched range, the E-Transit continues to lead the way for clean light commercial vehicles. ■

SHAPE SHIFTER: Ford has been mindful of the Transit’s reputation for versatility, offering the electric version in a range of body sizes

JUICY COUTURE: the top-rated 198kW E-Transit is the most powerful electric van on the market. With a range of almost 200 miles and a fast-charging option, the E-Transit offers ample performance for most fleet operations

The Volvo FM has been delighting drivers and operators alike since it first appeared on the market 25 years ago, and the latest generation is no exception

Competition between manufacturers in the fleet sector is more intense than ever, particularly in the 44-tonne tractor unit market, all manufacturers having raised their game considerably in the past decade or so. Which makes it all the more difficult for the judges to choose a winner in the Fleet Truck of the Year category. Overall levels of performance, economy, reliability and driver comfort are higher than ever, and finding clear advantages for one product over another is quite a task. But one characteristic that does hold true is consistency, particularly over different generations of a particular manufacturer’s product lines.

This year’s Fleet Truck of the Year winner excels in this area. The current Volvo FM tractor unit is the latest generation of a long line of fleet specification models that date back over 55 years, to when the Swedish manufacturer first entered the UK truck market with the then-revolutionary F86 range.

It introduced new levels of performance, economy, reliability and driver comfort to a market dominated by domestic manufacturers, whose products were, in the main, dated and not fit for the UK’s rapidly changing road transport industry. This somewhat diminutive truck enabled Volvo to go from being a minor player to leading the tractor unit market in just five years.

It also led to the development of subsequent models that were aimed at the same sector of the market. Each generation surpassed the outgoing range in virtually

every key area, but held true to the original concept of a flexible range that could handle multiple applications and still offer a low overall cost of ownership. The F7 replaced the F86, which in turn was replaced by the FL7/10/12; the FM range was introduced in the late 1990s.

The FM was a departure from previous fleet specification ranges, in that it shared the basic cab shell, chassis and most of the driveline with the bigger FH. This modular approach to the Volvo heavy truck range brought numerous advantages for both operators and maintenance providers, and improved the efficiency of the production process and support services. Also, drivers were able to benefit from a common control layout, potentially higher levels of specification and greater comfort.

When the first version of the FM was introduced in 1998, it had been anticipated for some time and the market was ready for the new model. Volvo offered three different engines, and the option of a high-roof Globetrotter cab on the relatively low-mounted FM. The secondgeneration appeared in 2001, mirroring the enhancements introduced on the FH range and with further refinement of the driveline.

There were upgrades in 2005 and 2010, and an extensive facelift in 2013. This included improved cab interiors and exteriors and other engine and driveline updates. Volvo also launched the heavy-duty FMX range at the same time; aimed at the construction industry and other tough applications, it broadened the appeal of the complete range.

The third and current version of the FM, also based on the latest FH range, was launched in 2020. It offers improved vision, cab interior space and ride and handling. Drivers and operators have welcomed the new model, and it has raised Volvo’s profile in the fleet sector.

The striking new cab design is a big step forward over the previous range. Cab entry and exit is first rate, while a lower, reprofiled engine tunnel makes it far easier to get across to the passenger side and access the bunk in sleeper cab versions. Internal and external storage is excellent, the driving position is superb and the control layout makes it easy for drivers to get comfortable and quickly become familiar with the truck. This has long been a Volvo hallmark, particularly with the lowermounted fleet specification models, with well-laid-out controls that are close to hand and easy to use.

The use of a lowered version of the taller FH cab brings much-improved vision compared with the previous FM, and large areas of glass with a low window line and

reprofiled dash give clear sight lines in almost every direction. While Volvo has yet to replace mirrors with camera technology, the existing mirror layout gives a wide spread of rearward vision while virtually eliminating blind spots.

The FM cab range is extensive, with both day and standard sleepers available with a flat roof for car transporters and other specialist applications. A high roof Globetrotter version is available with one or two bunks, along with a factory-built crew cab for municipal applications.

A huge range of cab trim, equipment and specification options is available, and the more basic trim aimed at the toughest of applications is still very comfortable. At the other end of the spectrum, an FM can be specified to a very high level, matching that offered with the top versions of the bigger FH.

All versions meet the strict Swedish crash impact regulations. Volvo has fitted airbags in trucks for over 30 years, and has incorporated numerous safety features in its vehicles for generations. This now extends to measures safeguarding other road users, including frontal protection, energy absorbing areas and the myriad of electronic safety systems that are part of modern truck design. Advanced monitoring using vehicle telemetry enables both operators and workshops to closely watch a truck’s performance. Volvo offers a wide range of service and maintenance contracts, which can be tailored to meet individual requirements.

The FM range is available with diesel, gas or fully electric drivelines, and all versions are standard production models built in the same factories on the same fully integrated production lines. This means that the same levels of build quality, service support and parts availability is offered, regardless of the choice of power unit or drive system.

Both the 11- and 13-litre Euro-6 step E diesel engines are offered in the FM. The 11-litre comes with ratings

between 330hp and 460hp and the 13-litre between 420hp and 500hp. Both produce high levels of torque over a wide rev range and give impressive fuel economy. All use non-cooled EGR and SCR, which reduce emissions to the lowest possible levels, and can run on normal diesel, biodiesel and HVO without modification. Both capacity power units have standard exhaust brakes and the optional VEB+ engine brake to aid retardation on descents. Volvo’s advanced I-Shift transmissions provide a smooth drive and good overall efficiency and performance.

Gas-powered versions of the 13-litre engine are offered at 420hp ,460hp and 500hp, running on LNG or renewable biogas. These HPDI engines use a small amount of diesel to initiate combustion and AdBlue to reduce emissions.