4 minute read

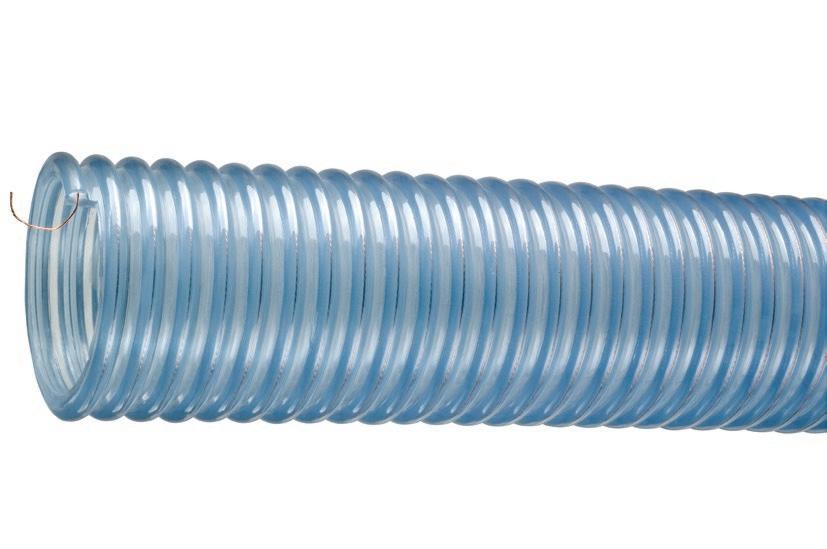

2001™ Series Hose

from Kuriyama Tigerflex Hoses Catalog Ducting Food Grade Material Handling Liquid Suction Hose Warehouse

2001™ Series

Heavy Duty Food Grade Polyurethane Lined Material Handling Hose With Grounding Wire

General Applications:

• Food grade material handling – heavy duty abrasive • Material handling – heavy duty abrasive • Pharmaceutical product transfer • Plastic processing equipment • Pneumatic conveying equipment Construction: PVC cover with polyurethane liner, rigid PVC helix and grounding wire.

Service Temperature Range:

• Extra Thick Abrasion Resistant Polyurethane

Liner – Designed for dry applications where severe abrasion is a factor. Provides for longer hose life and lower operating costs versus rubber or PVC hoses. • Food Grade Materials – Hose Cover complies with applicable FDA (03) requirements. Hose Liner (Product

Contact Surface) complies with applicable FDA(04) requirements and USDA(12) requirements. • Phthalate Free

Nominal Specifications

• Grounding Wire – Multi-strand wire helps prevent the build-up of static electricity for added safety and to help keep material flowing smoothly. It’s embedded within the rigid helix to prevent contamination of transferred materials. • Transparent Construction – “See-the-flow.” Allows for visual confirmation of material flow. • Convoluted Outer Cover – Provides increased hose flexibility. • Oil Resistant Polyurethane Liner – Resists most animal and petroleum based oils.

Series Number ID OD

Working Pressure (psi)

Vacuum Rating Hg (in)

Min. Bending Radius at 68°F (in) Standard Length (ft)

Weight (in) (mm) (in) (mm) 68°F 104°F 68°F 104°F (lbs/ft)

2001–150 1-1/2 38.1 1.88 47.8 50 25 Full 28 6 60 0.48 2001–200 2 50.8 2.44 62.0 40 20 Full 28 7 60 0.67 2001–250 2-1/2 63.5 3.12 77.2 40 20 Full 28 8 60 0.92 2001–300 3 76.2 3.70 94.1 40 20 Full 28 9 60 1.35 2001–400 4 101.6 4.80 122.0 35 18 Full 28 15 60/20 2.17 2001–500 5 127.0 5.81 147.6 35 18 28 25 23 60/20 2.77 2001–600 6 152.4 6.93 176.0 30 15 28 25 26 60/20 3.90 2001–700 7 178.8 8.08 205.2 30 15 28 25 30 60/20 5.20 2001–800 8 203.2 9.28 235.8 30 15 28 25 36 20 6.65

NOTE: Service life may vary depending on operating conditions and type of material being conveyed. NOTE: For details of the following compliances, refer to footnotes listed on page 63.

*Actual service temperature range is application dependent.

CAUTION: This product is designed to dissipate static electricity when the embedded grounding wire is physically extracted and securely connected to ground, through the fitting or by other means. BSE/TSE(02) , FDA(03) , FDA(04) , Phthalate Free(10) , RoHS(11) , USDA(12)

Features and Advantages:

• Superior Static Protection! – A properly grounded

Voltbuster™ hose will not retain an electrostatic charge sufficient to create a propagating brush discharge. Hose material, using the embedded grounding wire, shows a charge decay time constant of < 1 second, based on independent lab testing. • Food Grade Materials – Hose tube complies with

FDA(05) requirements. Grounding wire embedded in external helix to prevent material contamination.

Nominal Specifications

NEW LENGTH& SIZE

VOLT™ Series

General Applications:

• Bulk truck and railcar unloading • Fly ash collection • Food grade material handling –heavy duty abrasive • Material handling – heavy duty abrasive • Milling machine scrap recovery • Pharmaceutical product transfer • Plastic processing equipment • Pneumatic conveying equipment Construction: Static dissipative polyurethane tube, rigid helix and grounding wire (patent pending).

Service Temperature Range:

-40°F (-40°C) to +150°F (+65°C)*

• Extra Thick Abrasion Resistant Single-Ply

Polyurethane Tube – Provides for longer hose life and lower operating costs versus rubber or PVC hoses. • Transparent Construction – “See-the-flow”. Allows for visual confirmation of material flow. • “Cold-Flex” Materials – Hose remains flexible in sub-zero temperatures. • Easy Slide Helix – Rigid helix design protects hose tube from wear; allows hose to slide easily over rough surfaces. Easy to handle. • Phthalate Free

Series Number ID OD

Working Pressure (psi) Vacuum Rating Hg (in) Min. Bending Radius at 68°F (in) Standard Length (ft)

Weight (in) (mm) (in) (mm) 68°F 104°F 68°F 104°F (lbs/ft)

VOLT150 1-1/2 38.1 1.87 47.5 40 20 Full 28 2 100/60 0.31 VOLT200 2 51.1 2.52 63.9 40 20 Full 28 6 100/60 0.61 VOLT250 2-1/2 63.5 2.96 75.2 40 20 Full 28 7 100 0.76 VOLT300 3 76.2 3.60 91.4 40 20 Full 28 9 100/60/20 0.91 VOLT400 4 101.6 4.69 121.0 35 17 28 25 12 100/60/20 1.70 VOLT500 5 127.0 5.75 146.8 35 17 28 25 14 60/20 2.13 VOLT600 6 153.4 6.81 173.2 30 15 25 20 16 60/20 2.53 VOLT800 8 203.5 8.76 223.3 30 15 25 20 18 20 3.30 VOLT1000 10 255.5 11.04 280.5 25 10 22 16 25 20 4.99

NOTE: Service life may vary depending on operating conditions and type of material being conveyed. NOTE: For details of the following compliances, refer to footnotes listed on page 63.

*Actual service temperature range is application dependent.

CAUTION: This product is designed to dissipate static electricity when the embedded grounding wire is physically extracted and securely connected to ground, through the fitting or by other means. BSE/TSE(02) , FDA(05) , Phthalate Free(10) , RoHS(11)