Who's who in the NASC: officers, council, committee chairs, regional chairs, and NASC office staff. For full committee listings see p50.

David Brown lays out his ambitions and plans for his presidency. A key focus is on the insistence by main contractors to use NASC Members.

The latest round-up of news, plans and developments from the NASC. Includes new publications and a focus on the updated SG4:22.

Showcasing the best entries to the 2022 NASC Awards. Categories include Project, Innovation, Apprentice of the Year, and the President's Award.

NASC committee and CISRS listings.

A comprehensive listing of full NASC members organised by head office as well as A-Z regional information. Also includes new category members.

A very warm welcome to all our members and regular readers, and in particular to readers of Construction Management magazine, which is again kindly circulating the NASC 2023 Yearbook and directory with its November/ December 2022 issue.

Firstly I’d like to thank all of our contributors, and all the NASC members who have participated in the work of our amazing standing committees during 2022. Their involvement helps to make the NASC a well-respected organisation, held in high regard throughout the industry.

An array of regular features, reviews, news, and essential member information awaits, and I would draw your attention straightaway to the excellent project news section commencing on page 18, which features an array of entries for the keenly anticipated NASC 2022 Awards.

As we approach the end of 2022 we can also reflect on the achievements of Lynn Way (Chris Sedgeman Scaffolding Ltd) whose extended Presidency will draw to a close at the NASC AGM on 18 November. Seldom has an organisation had to stand up and be counted in the way which NASC was required to do when faced by the ravages of Covid from 2020 to 2022.

Under Lynn’s direction, and drawing upon her involvement as a director of Build UK and a member of the CLC Senior Advisory Group, the NASC was able to dispense excellent practical guidance and advice to its members. This enabled many businesses to navigate these turbulent waters and not only stay afloat, but

also participate fully in the work of a resurgent construction sector. Not only has Lynn been the first ever woman NASC President, she has also presided over a significant period of change, as NASC has looked to reform from within during the last 12 months. The confederation has engaged the services of a professional marketing agency to gauge the nature of its offering, and is now taking steps to improve its operation.

Additional membership categories have been created during 2022. These categories are now beginning to make their mark. Services and Ancillary Products (SAP) members have been a welcome sight at recent rounds of NASC regional meetings. Greater engagement is now being sought with stakeholder organisations within the NASC Information membership category, whose numbers have grown very rapidly in a short period of time, now exceeding 100.

If I tell you any more I will spoil the fun, so please read on for yourselves, and I’d urge you to start with a very interesting, informative, and personal article by our incoming President David Brown, who sets out his objectives for the next two years on page 8.

In conclusion I would like to thank the resilient NASC staff, and those members who have again given freely of their time during 2022. Member involvement is critical to ensure the continued refinement, development, and revision of industry guidance which assists all those who work in the scaffolding sector. For that we thank them warmly.

It is with great honour that I write this as the new President of the NASC. I am excited by the changes and the reenergising of the NASC and I can’t wait to get started.

My career began as a trainee QS for a main contractor at 17 years old. Some years later via a degree and contractor experience, my dad – who was part owner of IBN Scaffold Access Ltd – gave me a temporary role as a QS, which became permanent. Following a recent management buyout of IBN Scaffold Access Ltd, I have, with Camela Marshal, Paul Bennett and Karl Farrand, taken over ownership of the company.

My journey with the NASC started in 2012 when I joined the Contracts Committee eventually becoming the Chair. The NASC has shown me that it doesn’t matter who you are, what member company you work for or what size company you represent, the NASC is open and accessible to all.

The NASC is a vibrant organisation bursting at the seams with passion and knowledge of the industry. But it can’t stand still: we must keep improving. The NASC conducted a full business review and has relaunched the NASC charter and published the NASC business development plan.

We’ve listened to our members, clients and prospective members to ensure the NASC is relevant for today’s construction industry.

Under my presidency it will better represent NASC member’s needs,

“THE NASC HAS SHOWN ME THAT IT DOESN’T MATTER WHO YOU ARE, WHAT MEMBER COMPANY YOU WORK FOR OR WHAT SIZE COMPANY YOU REPRESENT, THE NASC IS OPEN AND ACCESSIBLE TO ALL”

promote NASC-only status from main contractors and clients and also work towards tackling the labour shortage.

Scaffolding is a fantastic sector of the construction industry to work in. We need to tell people and be proud of membership.

My predecessor, Lynn Way, has done a fantastic job as NASC President; the drive and dedication she has shown over her three-year term has been amazing to witness. Her achievements with Build UK and also the work she did during the COVID 19 pandemic have left the NASC in a better position within the industry than when she started.

I know I can count on her support during my term and I look to having the opportunity of continuing to work with Lynn.

We must recruit new starters into the industry. We rely on new blood coming into scaffolding to keep this amazing trade going. In order to do this, the NASC is about to embark on an ambitious plan to provide training grants for members. NASC is to provide grants not only to incentivise new entrants into our Industry but to also ensure that training and development is encouraged throughout the Industry.

Training is front and foremost of the NASCs objectives and these grants enable members to maintain and further develop a highly trained and skilled workforce.

The NASC appreciates the difficulty in trading in this industry currently and has no intention of making it even harder by putting obstacles in

members way that impact on their business.

Net Zero Carbon is approaching and all businesses must have this in place by 2050. NASC will be offering help and support to members in order to achieve this.

We recently issued guidance note SE1:22 which explains net zero carbon. We will continue to provide guidance and access to training to help members better prepare their businesses for this.

The NASC eportal is going to be further developed to ensure that NASC members have full access to all NASC guidance notes and TG20 as well as new releases such as TG1:22 Temporary Edge Protection.

One area I am extremely passionate about is main contractors insisting

on only using NASC Member companies. Over recent years this criteria from main contractors has changed and we need to get back to this.

My message to main contractors is:

NASC training grants will be made available to members

l Do you want to employ scaffolding contractors who help produce the industry guidance and set the standard for the scaffolding industry?

l Do you want to employ the scaffolding contractors who, year after year, are reducing their accident statistics and improving the scaffolding industry?

l Do you want safe and compliant companies working on your projects?

By employing a NASC member company you get this as a minimum.

Our NASC member companies are great at what they do and are recognised for the talent of their teams and the projects they undertake. That is why I will be championing “NASC Members only”. With the support of the NASC staff we will be contacting main contractors, local authorities and government to ensure this is re-established.

I look forward to being your NASC President and with your support

I know we will continue to make scaffolding a fantastic industry to work in.

“WE MUST RECRUIT NEW STARTERS INTO THE INDUSTRY. WE RELY ON NEW BLOOD COMING INTO SCAFFOLDING TO KEEP THIS AMAZING TRADE GOING”

and Safety Management (MIIRSM), incorporated member of the Institute of Builders (ICIOB) and Associate member of the Institute of Environmental Management (AIEMA).

“I’m very excited to take on the role,” Kearney said. “I’ve seen how the NASC works – and the good it does for its members and the industry as a whole – from my time on the H&S Committee. It’s an absolute honour to join the UK’s premier scaffolding trade body.”

Robin James, NASC managing director, said: “We are delighted to welcome Steve into the NASC

executive team fold. His experience and enthusiasm is unparalleled. Additionally, we have long admired his work ethic and commitment to pushing the industry forward. He will be a great addition to the team.”

The NASC has strengthened its team of in-house scaffolding experts with the appointment of Steve Kearney as health & safety manager.

Kearney will work closely with the NASC’s Health and Safety Committee to further improve safety standards across the industry. He will also be on hand to answer questions from NASC Information members.

Kearney has served on the NASC Health & Safety Committee since 2012 and brings with him more than 40 years’ experience in the scaffolding industry. He has held a variety of roles including scaffolder, H&S manager and HSEQ director of TRAD Group. He is a chartered member of the Institute of Occupational Health and Safety (CMIOSH), member of the International Institute of Risk

More than 100 organisations have taken up the NASC’s Information membership offering since it was relaunched earlier this year.

The free membership has been well received by organisations across the construction industry, from major tier 1 contractors and local authorities to H&S consultants and bodies such as the Chartered Association of Building Engineers (CABE) and the Association of Construction Quality Professionals.

These members enjoy discounted rates on all NASC guidance and direct access to the NASC’s inhouse H&S and technical advisors.

They also receive member bulletins, made up of topical, informative and educational scaffolding updates.

The NASC now boasts seven membership categories: Contractor

membership; Supplier membership Information membership. Design, Training and Services & Ancillary Products. This new trio of memberships has seen a surge in new members during 2022.

Jamie McGuire, membership manager, said: “It’s been great to see so many new ‘service’ members come on board this year. Businesses in these categories have all recognised the NASC’s unique ability to put them in touch with their target audiences; established and successful scaffolding contractors.

“For our part, we’re taking a more involved stance, helping these members build closer relationships with NASC Contractor members, in various ways: from face-to-face meetings to monthly e-shots and editorial in the NASC’s in-house magazine, Scaffolding Matters.”

“

I’VE SEEN HOW THE NASC WORKS – AND THE GOOD IT DOES FOR ITS MEMBERS AND THE INDUSTRY AS A WHOLE"

Eight new titles have been added to the NASC Guidance library this year.

In total, there are 100+ NASC titles available for purchase via the NASC’s online shop. These are split into a number of categories, including Health & Safety, Technical, Contractual, Asset Protection, Product Purchasing and Sustainability and Environmental Issues. This comprehensive reference library is constantly reviewed and updated to ensure titles are up-todate and fit-for-purpose. All guidance can be accessed digitally by taking out an NASC ePortal subscription.

For a free NASC Guidance Index visit www.nasc.org.uk

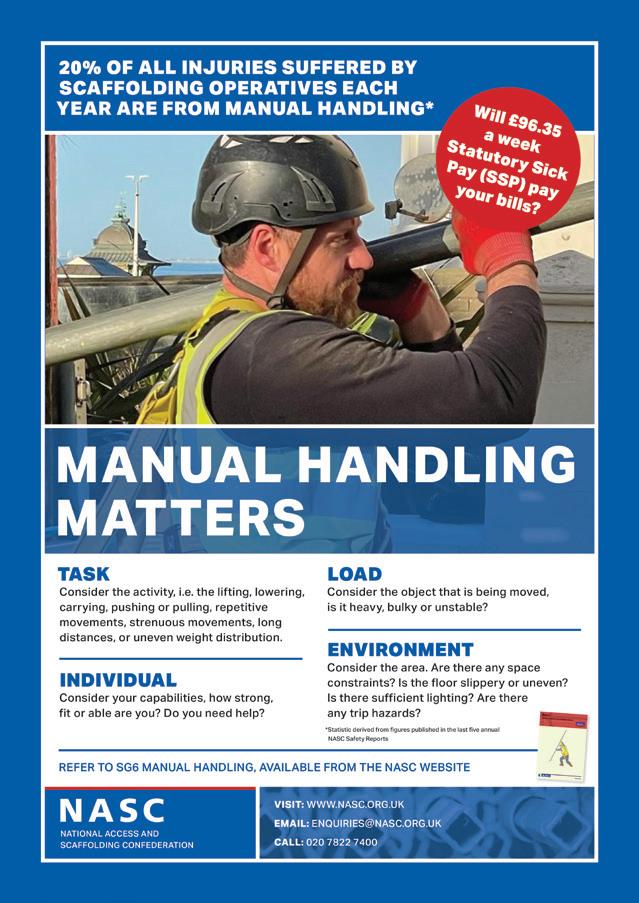

SG6:22 Management of Manual Handling in the Scaffolding Industr y Helps assess the risks posed by lifting, carrying and team manual handling activities.

SG42:22 Working Over or Near Water Provides safety measures for scaffolding work carried out over / near water (including on, adjacent to or over water) where potential hazards exist.

SG43:22 Lone Working in Scaffolding

Provides simple, practical and cost effective measures which employers can use to help prevent and manage the risks - such as violence to lone workers.

SG45:22 Management of Scaffolding Operations to BS 5975:2019

A brief, simple and concise guide to assist scaffolding contractors and others involved with the delivery and management of temporary works.

TG6:22 Care and Maintenance of Scaffold Boards

Provides guidance on the inspection, care and maintenance of scaffold boards to maximise their operational service life.

TG23:22 Prefabricated Beams

Provides best practice and outlines technical, practical and safety information relating to prefabricated beams and their use.

TG26:22 Galvanic Corrosion of Aluminium Tubes and Prefabricated Beams

As aluminium couplers are not readily available, aluminium tube and beams are invariably connected with steel couplers and joint pins. Unfortunately, when two dissimilar metals such as aluminium and steel are in contact, a phenomenon known as ‘galvanic corrosion’ can occur where the corrosion of one of the metals, in this case aluminium, can be greatly accelerated. In severe cases this could seriously affect the integrity of the scaffold structure.

SE1:22 Becoming Net Zero Carbon Provides useful and accessible guidance about ways to reduce carbon footprint and work towards net zero. It includes a glossary and FAQ, quick wins, potential longerterm opportunities, grants and incentives, a draft policy statement and useful links.

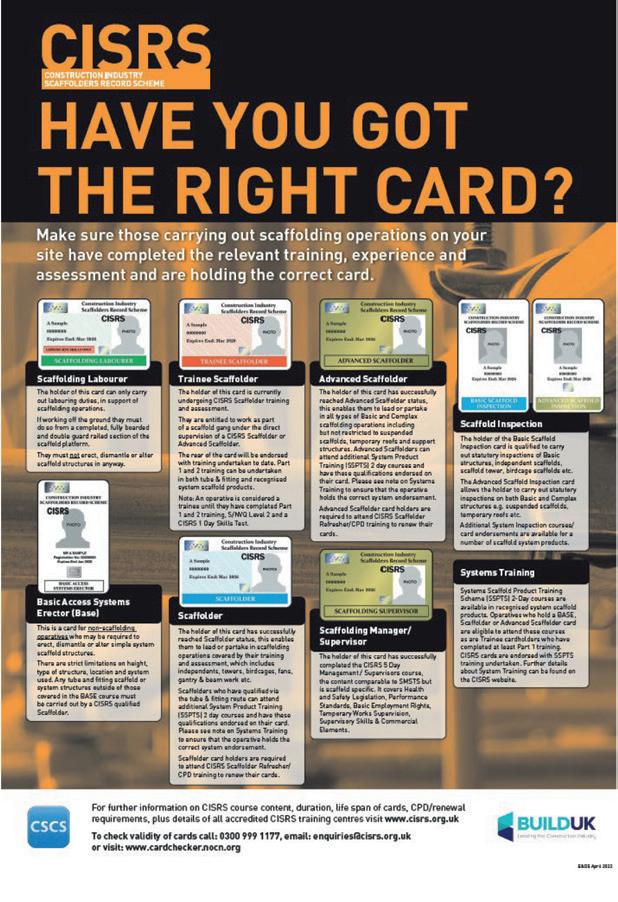

CISRS has issued an updated ‘Have You Got the Right Card?’ information poster aimed at helping site managers and contractors check that operatives, manager/supervisors and inspectors of scaffolding hold CISRS cards endorsing the correct qualifications and experience.

It is hoped that this resource will assist in their responsibility of keeping each site compliant and safe.

To obtain a new poster please email enquiries@cisrs.org.uk

The NASC has produced two safety-focused posters aimed at increasing awareness of the two most common causes of injuries to NASC member scaffolding operatives: manual handling and slips and trips on the same level. For free copies of these posters please email enquiries@nasc.org.uk

The NASC has published its 2022 Safety Report, which contains NASC Contractor member accident statistics and analysis relating to the 2021 calendar year.

There were 91 incidents recorded by 237 NASC Contractor members during 2021. While that represents a slight year-on-year rise, it shows that members continue to operate to exceptionally high safety standards.

Assuming the incidents happened to 91 separate individuals, that means 15,529 or the 15,620 operatives employed by the NASC as a whole – equating to 99.4% - went through 2021 incident free.

What’s more, the data shows that 181 NASC Contractor

members, 76% of the total, had zero incidents during 2021.

Alan Harris, NASC Health and Safety Committee Chair, said: “The NASC has witnessed significant reductions in slips, trips and falls and material handling following NASC training and guidance focus. We continue to work with our membership across all age groups in the areas of manual handling and safe working at height to reduce injury reports further.

“With an increase in smaller businesses joining, the NASC is committed to safeguarding the areas of induction and safety training as key performance indicators for all NASC membership.”

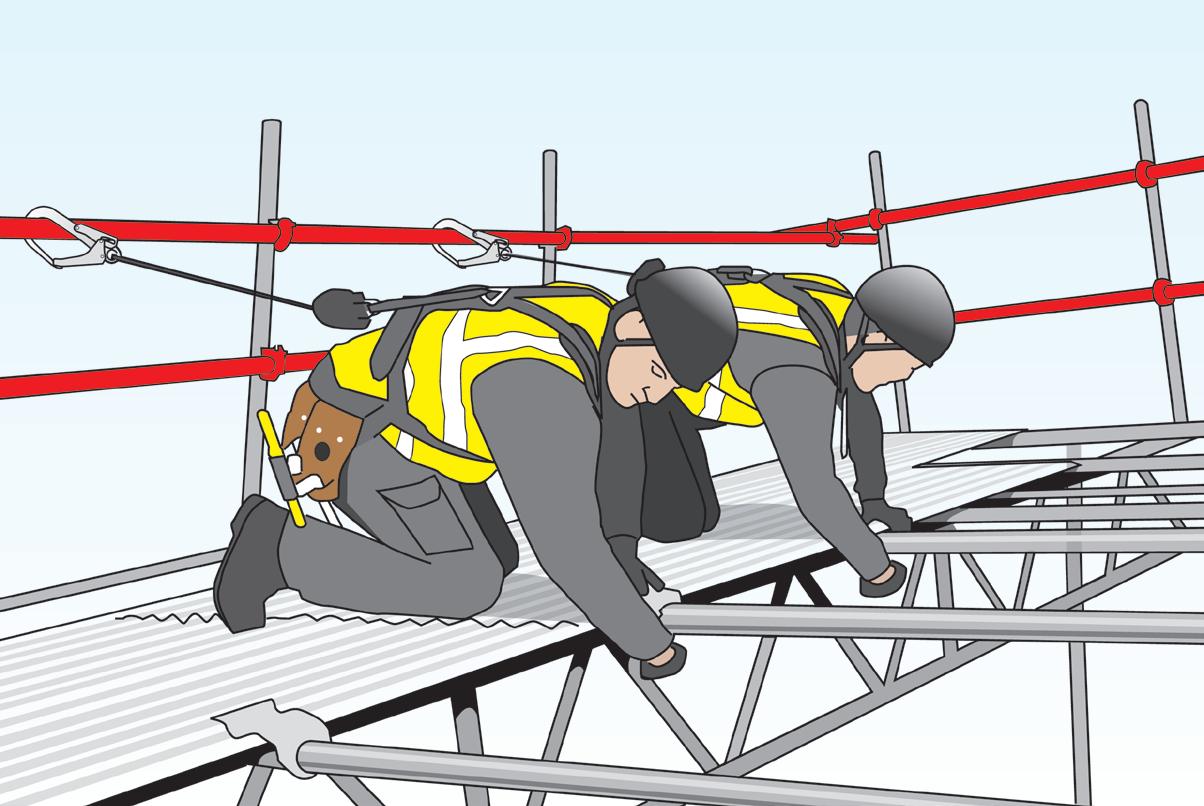

SG4:22 was released earlier this year, replacing SG4:15. SG4 is one of the NASC’s core guidance notes. It illustrates current preventative and protective measures which represent good industry practice when establishing safe systems of work to prevent and protect against falls from height during scaffolding operations.

The guidance was updated to ensure it remains current and reflects the needs of, not only NASC membership, but the wider access and scaffolding industry.

The review ensures the guidance features methods of work and equipment that reflects current industry good practice. The working party has considered accident learning, legal cases, enforcement action, good industry practices and new technology for fall prevention and protection.

To ensure the guidance remains current, obsolete products and methods of working that are no longer in common use have been removed. New sections have been introduced or further guidance

provided to protect scaffolders and support employers in establishing safe systems of work. Additional case studies have also been used. Some of the new additions to SG4 include:

l Embracing technology

l Fragile surfaces

l System scaffolding

l Working with beams

l Temporary roofs

How has accident learning influenced this revision of SG4? Sadly, we are still seeing fatalities and life-changing injuries in our trade as a result of falls from height. Many of these tragic accidents are avoidable. As a result of fatal accidents to non-NASC scaffolders since the last revision, new specific guidance has been added for working on traditional temporary roofs erected in situation and working on or near fragile surfaces.

How has SG4 changed the industry?

SG4 has played a significant part in changing the culture of the industry and raising the standards of safety. The accident statistics within the NASC membership speak for themselves: an 87% reduction in the number of falls since 1999 despite

an increase of nearly 50% in the number scaffolders working for our members.

You don’t have to look very far to see examples of unsafe practice. So, as an industry we can’t rest on our laurels and the confederation and other industry stakeholders, like the Construction Industry Scaffolders Record Scheme (CISRS), still need to keep promoting good practice.

Our clients now have a heightened awareness of scaffolding industry good practice through the publication of guidance such as SG4 and often play a major part in changing attitudes towards unacceptable risk-taking by scaffolders.

The marketplace for scaffolding contractors who ignore good practice is gradually getting smaller. And as a business owner the frustrations of losing work to competition that cuts every corner in the book is still a factor but is getting fewer.

I would encourage anyone who is involved in scaffolding activities – from scaffolding contractors through to H&S consultants, principal contractors and beyond –to familiarise themselves with SG4:22 and ensure scaffolders in their charge are working to this guidance at all times.

NASC member: Enigma Industrial Services Main contractor: ISG

Cameron House, located on Loch Lomond, is a Scottish five-star resort and formerly a 17th-century mansion. The hotel suffered extensive fire

damage in December 2017, and the building became structurally unsafe. Primary contractor ISG appointed Enigma as the sole provider of temporary access on-site throughout the complex restoration project. Various tube and fitting and Kwikstage scaffold configurations were erected around the hotel exterior and interior to permit safe access for multiple

trades to complete the extensive works programme schedule.

The scaffold around the historic hotel was fully encapsulated with a temporary roof, and propping scaffolds were implemented to support loads. To install the temporary roof with a clear span and no central supports, Enigma’s engineering team used the existing façade retention scaffold to provide roof support. This also limited the required tie positions to leave minimal trace of temporary access upon completion of the works.

Additionally, a birdcage scaffold was implemented across the entire ceiling area of the leisure centre facility utilising 1.0m deep alloy truss beams to reduce the amount of scaffold legs built from groundlevel and allow unrestricted access,

THE SCAFFOLD AROUND THE HISTORIC HOTEL WAS FULLY ENCAPSULATED WITH A TEMPORARY ROOF AND PROPPING SCAFFOLDS WERE IMPLEMENTED TO SUPPORT LOADSCameron House, a five star hotel on Loch Lomond

to install ducting and internal infrastructure. Enigma also erected a fully encapsulated scaffold structure incorporating an integrated mast climber loading bay and temporary roof to assist the client with constructing the new hotel extension by providing unrestricted access on all elevations.

NASC member: Bilfinger UK Main contractor: Respol Sinopec Resources UK

Bilfinger UK was tasked to deliver safe access to the underside of an oil rig to remove and replace the underdeck oily drains pipework. Different options were considered but three access solutions were chosen with an engineering review carried out on each.

Deciding that FlexBeam was the safest fit-for-purpose solution, Bilfinger partnered with Layher UK’s technical team and designed the world’s first underdeck scaffolding system using FlexBeam to provide safe access. Using Layher’s aluminium scaffolding FlexBeam

reduced construction time by 40% when compared with traditional conventional tube and fitting scaffolding.

The access system was installed six days ahead of the initial estimation and 15 days ahead of the time estimated if utilising tube and fitting scaffolding. This equates to 246 work hours ahead of schedule and 601 work hours ahead of what would have been required if using traditional tube and fitting scaffolding, providing a labour saving of around £30,000.

Scaffolding for access to underside of oil rig

NASC

Industrial services specialist KAEFER is responsible for providing access solutions at Hinkley Point C, as well as delivering the containment liner coatings and surface protection for concrete in the internal building

rooms of both nuclear reactors, and supplying high grade steel ducting for the nuclear island HVAC systems.

The client needed to weld an equipment hatch onto the nuclear island inner containment liner at Hinkley Point C. The hatch was originally intended to be installed prior to the 47m wide ring being lifted into position but doing so would have delayed a critical element and major

project milestone of the build project which was the lift and installation of the liner ring into position.

KAEFER’s solution was to erect a Layher system scaffold suspended independent that was to be erected 270m away from the reactor unit at ground level and then to lift that into position by crane.

The main difficulty was that the equipment hatch was 35m in the air and within the reactor area there were ongoing, critical concrete installation activities taking place 24/7, these activities could not be disrupted.

The decision was made to erect the supporting scaffold within the equipment hatch in situ but to do so we also needed to reduce the working at height risks and therefore a loading platform was erected onto a steel gantry at ground level and craned into position.

Our innovative design allowed for critical path works on site to be replanned, and the continuous concrete works were also able to progress; this also allowed for early installation of the liner, a significant milestone for the client.

The HMS Victory is an extremely complex shape that required a 3D survey and 3D design. PHD’s in-house design team were able to create a fantastic 3D concept which helped them to design out any risks and also showed the client what the scheme would look like before it was built.

The HMS Victory, one of the world’s best-loved ships and national treasures, is embarking on a hugely significant conservation milestone as the ship’s rotten outer shell is removed and replaced with new oak. Repairs will be made to the ship’s structural framework, and she will be fully re-rigged, in a process lasting 10 to 15 years and costing £35 million. For this work to be carried out the ship needed to be fully enclosed by temporary scaffolding.

The scaffold structure to enable the renovation works is a combination of temporary roof protection, semi-enclosed visitor experience, working access platforms and enclosed loading bays. The temporary roof is also a further combination of Layher and Dessa systems to accommodate the ship’s existing infrastructure and mast retaining cables, whilst they remain in position during Stage 1 works.

HMS Victory is embarking on a major repair project

Redricks Lakes appointed the Connect Events Team for its addition of the Mega Slide to the Aqua Splash Park. The slide is a 10-metre-tall tower with three different levels, all individually designed to achieve the correct trajectory into the water for their given starting height.

Due the shallow depth of the water at the edge of the lake, Connect had to cantilever the kickers out over the water and adjust the kicker angles/ heights to ensure that there was enough water depth where people would enter the water.

Connect’s SHEQ team and regional operations manager carefully risk assessed the project and detailed calculations were prepared to create a self-supporting structure to form the slide. Collaboration between Connect’s operatives and the other parties involved on the project, they were able to successfully construct Europe’s biggest Mega Slide.

A number of revisions were needed after the slide was first tested to ensure that distance and trajectory worked effectively.

Chris Sedgeman Scaffolding was contracted to provide scaffolding to enable access to all elevations of the steel framed headgear of the victory shaft for an inspection. Once this was complete, the client requested that a full containment scaffold be constructed to give access for grit blasting, removal and replacing of steel and painting of the structure.

Following extensive consultation with Raptor scaffold design and consultancy, Chris Sedgeman was able to build a fully encapsulated scaffold structure utilising the inspection scaffold already standing on site.

Chris Sedgeman was then requested to provide Internal scaffolds inside the main shaft of the headgear which meant that access to all of the steel structure was enabled. This included a crash deck that was built under the cage that was previously used to transport the miners to the lower levels.

All works were complicated by the location of the site. Geevor is situated on the West Penwith coast and is exposed to the ferocity of the Atlantic Ocean.

The requirement to minimalise the use of physical ties contact points to enable the works was also a cause for careful consideration but was overcome by utilising the steel stainless bolts used to attach the timber façade to the existing structure and band and plate couplers and attaching tubes.

Situated in Manchester city centre and dating back to 1873, the Printworks once housed the largest printing press in Europe. In 1999, a £110m conversion was carried out to transform the establishment into a 365,0002ft multi-entertainment complex lodging an assortment of venues from 25 independent business to a 23-screen cinema.

Connolly Scaffolding was contracted to provide scaffolding solutions to enable a complete external and internal refurbishment and an installation of a 900m2 digital ceiling.

On the exterior, system scaffolding was required to assist in the external renovations and to allow new signage to be craned to its new position on the roof.

The interior consisted of a specialised combination of scaffolding types. In addition to system scaffolding, a series of traditional tube and fitting towers linked with bridging beam scaffolding across two levels has also enabled us to effectively negotiate the time frame restrictions and to efficiently fulfil the client’s brief of which demanded minimal scaffolding at ground level.

The use of tube and fitting scaffolding at street level enabled Connolly to construct scaffolding that fits with the uneven contour of the courtyard below but also allows unhindered access to the pedestrianised street.

The restraints placed on the working parameters, location, logistics, and design has meant that the Printworks project has tested Connolly Scaffolding like no other project.

“ALL WORKS WERE COMPLICATED BY THE LOCATION OF THE SITE, GEEVOR IS ON THE WEST PENWITH COAST AND EXPOSED TO THE FEROCITY OF THE ATLANTIC OCEAN"Manchester entertainment mecca, The Printworks

NASC member: JDC Scaffolding

Main contractor: McLaughlin & Harvey

The Annexe Building was built between 1886 and 1899 and comprises of two main buildings; the Red House, which was one of the first cold stores in the world, and the triangular Fish Market.

JDC was contracted to enable restoration works to make the building safe, clean the external masonry, replace internal timbers, replace the roof coverings and alter the internal layouts. Scaffolding works comprised external independent scaffolds, temporary roofs, bridged birdcages to the existing arcades, full-length access to the existing roof lanterns and

temporary bracing and supports to the existing trusses.

The project highlighted JDC’s design capabilities and the depth of its engineering knowledge. The design development was an intense process and carried out in difficult communication circumstances during a pandemic with a very large design team – often with many different ideas.

The parameters for both vertical and horizontal loadings, set out in many areas looked unachievable, but with time, thought and with the knowledge of the management team most issues were solved.

National

NASC member: Liddiard Scaffolding

Main contractor: Brymor Contractors

Liddiard Scaffolding was awarded the contract to erect scaffolding to several areas of the building which required extensive roof repair works.

The scaffolding solution required proved to be the most technically challenging project that Liddiard has undertaken to date. There is a roof span of 40m that required a temporary roof scaffold and a duo pitched roof. All of this had to be completed with no physical ties on one elevation, as these were not permitted. Extensive design work had to be carried out involving hours of work and time with Liddiard’s foreman and design engineers.

All works had to be complete whilst the building was in full occupation by researchers and also in use by students from the University of Southampton, who are partnered with the Centre. The building and use thereof are very sensitive and all works had to be carried out with this in mind. Half of the building was also quayside and presented many further health & safety issues to overcome.

NASC member: LTC Specialist Scaffolding

Main contractor: Nevada Construction

LTC Specialist Scaffolding was requested to erect a temporary roof nearly 200ft long over an existing flat roof. There was no room surrounding or nearby the building to lay out the roof system to crane into position as the building is surrounded by access roads. LTC therefore had to erect the system roof in situ. The team installed cantilever sections to install the roof covering as they were unable to use a scissor lift to pull the sliding roof system through the tracking.

The challenges were all about access and maintaining a safe environment for the campus/building users while achieving a programme of works acceptable to the main contractor and their client.

The project highlights the problemsolving approach of LTC’s business whilst continuing to maintain a high level of safety for its operatives.

University challenge: temporary roof at Exeter University

“THE

NASC member: Apex Scaffolding (Exeter)

Main contractor: Daedalus for the National Trust

This Scheduled monument was built in 1868 to house a Cornish Beam Engine to pump out the water and ventilate the shafts buried deep under Dartmoor to extract products like zinc, copper, arsenic, and silver. Since closing, the engine house has stood out as a beacon beside one of the main routes through Dartmoor.

The scope of works was a full refurbishment of the building, stabilising, and repointing the whole building. This included the chimney which not only projected an extra 8m above the main building, it also was over a metre out of plumb. The client

required all the works to be weather protected so Apex enlisted Optima Designs of Bristol to design a splitlevel temporary roof to fully enclose the whole working area.

This allowed full working access to all areas, including the inside faces. A birdcage scaffold filling the building meant that through ties were used instead of physically tying into the protected masonry.

Once the scaffold was handed over, it was not the end of the problems, the only thing predictable about Dartmoor weather is its unpredictability. This proved to be the case with this job. Not only did it snow, but the scaffold also had to withstand Storm Eunice. Neither of which proved to have any effect on the excellently designed and built scaffolding.

NASC

Main contractor: Bell Group

Scaffolding was required to enable works to carry out window replacement, roofing works and concrete repairs to the exterior of Parkstone House, a building used to home NHS staff.

Phase 3 required a solution to provide access above a fragile flat roof covering the hospital library. The conventional solution would have been to penetrate the flat roof and erect supporting towers within the library and beam between the towers to enable the erection of 13 lifts of scaffolding above.

The normal method in this scenario would have meant the closing of the library and removal of the flooring to create a foundation to support the significant leg loads, at the same time as weather proofing the building and making good afterward. But this would have proved costly, highly disruptive and hugely inconvenient for all parties.

Ideal Scaffolding (Southern) Ltd came up with a proposal to anchor all scaffolding to the building by creating a series of cantilevers bolted to the facade with no grounded legs. The purpose was to spread the load evenly across the building using shear plates bolted to the wall. The total load was to be distributed over 20 shear plates per lift x two bolts per plate x 11 levels = 220 plates and 440 bolts in total.

Main contractor: Story Contracting

Swaithe Viaduct had suffered from years of neglect, resulting in line speeds being reduced and ultimately the need for repair.

The bridge is a 10-span structure with extremely limited access to eight of the spans. Infrastructure Site Services (ISS) provided birdcage and encapsulation, underslung and cantilevered scaffolds as well as providing access from the ground, an external walkway and loading bays.

The project presented ISS with a number of challenges including unstable ground conditions, the client’s requirement for a Niko track to be incorporated to the full length of the walkway – overcome by ISS’s bespoke bogey and runway system, and a change in hanging detail owing to badly corroded steelwork.

This project stands out for the work involved in erecting complex scaffolds to a bridge that is “on the skew” throughout.

“THE NORMAL METHOD WOULD HAVE MEANT CLOSING THE LIBRARY AND REMOVAL OF THE FLOORING BUT THIS WOULD HAVE PROVED COSTLY, HIGHLY DISRUPTIVE AND INCONVENIENT FOR ALL PARTIES"Poole library (above left) and Swathe viaduct (below)

NASC member: Malvern Scaffolding Main contractor: Worcester Cathedral

Malvern Scaffolding was entrusted to provide a scaffolding solution that would protect the cathedral’s priceless artifacts and books from water ingress during the roof replacement.

In addition to the library roof refurbishment, the Cathedral was keen to maximise the amount of work they could get done in this difficult to access area. Whilst the scaffold was in place but still working within the timescale & budget, they needed access to the Transept & Nave Roofs for repairs.

With the temporary roof in place additional scaffolds were going to

increase the overall loadings, but using the Haki system and edge protection, Malvern managed to reduce the loading enough to make it work.

Scaffolding systems erected included the temporary roof, a Haki stair access tower, Haki loading area with 750 beamed walk-way, Nico track system with trolled, independent access and support scaffolds and Haki double width walkways.

The project required problem solving, working under pressure to a tight budget and timescale, organisation and design management.

Malvern used Haki system on Worcester Cathedral Library

NASC member: SAY Scaffolding Main contractor: Simpsons (York)

SAY Scaffolding was awarded the contract for access and protection scaffolding for the Hull Maritime Museum restoration project.

Working closely with the client at tender stage, helping and explaining all possibilities with designing the scaffolds to meet their requirements and budget, SAY explained ways to erect the scaffold as to not put any loading onto the roof structure.

It also worked with the client on ways to reduce the cost of the scaffolding contract by erecting one of the three temporary roof scaffolds at a time, dismantling it and re-erecting it to the next roof in phases to follow in line with their works.

Challenges that were presented during this project included the risk to the public so close to the site during the delivery of scaffolding

materials. SAY ensured that appropriate delivery times were adhered to where the public was less likely to be at risk and used the banksman on site during the delivery process so that if members of the public were in the area, they would be aware of moving vehicles and hazardous zones.

Another challenge was at tender stage, looking at how to erect the high-level scaffolds with temporary roofs without the scaffold sitting on the existing roof structure. SAY overcame this challenge by designing the scaffold to use multiple scaffold beams to span across areas of the roof for scaffolds to be built from.

NASC member: TR Scaffolding (Bristol) Main contractor: National Highways

The M5 J11 Golden Valley junction features a gyratory system which comprises two bridges over the motorway. Both bridges required extensive concrete repairs.

The repairs required hydro demolition which uses large quantities of high pressure water to remove redundant concrete around the existing reinforcement bars and cages. National Highways required an access solution which encapsulated the work area to stop the egress of debris and also contain all water. This latter requirement was a challenge: the entire working platform would need to be water proofed, which included a temporary seal between bridge and scaffold.

There were a lot of design constraints:, the scaffold could not protrude below the soffit of the bridge; the support scaffold on the deck needed to be positioned to avoid areas of verge strengthening; plant needed to pass down the centre of the bridge; and the entire structure needed to encapsulate hydro demolition debris.

The single cantilever design concept quickly evolved and

indicative leg loads and kentledge requirements were determined to enable bridge engineers to confirm if the existing bridge had sufficient capacity to support the temporary works.

National Highways believes the scaffold is the first ever scaffold to have successfully permitted hydro demolition activity over the top of a live motorway.

NASC member: Shield Services Group Main contractor: Tilbury Douglas

Prince Charles Hospital is a major framework scheme to renovate the hospital site, which includes a significant asbestos abatement programme, described by the principal contractor, Tilbury Douglas Ltd, as: "The largest asbestos removal project in Wales and possibly the UK”.

Prince Charles Hospital has seen the erection and dismantling of multiple complex structures to provide suitable access for the safe removal of asbestos products. This project has had 23 designs, 17 design amendments and 21 individual RAMS

documents, most have which have been revised multiple times for Scaffolding Operations.

The Prince Charles Hospital project has raised many challenges beyond those typically associated with scaffolds of this type.

Bespoke scaffolds for asbestos removal have the requirement to minimise tolerances and service gaps to help ensure an airtight enclosure can be erected and not breached during the operation.

Most projects of this nature occur in obscure or discrete locations removed from public view or exposure. However, at Prince Charles Hospital, the scaffolds were erected at a live site, often with members of the public adjacent or below. In some cases, patients were undergoing treatment in rooms next door or behind the walls being worked on.

The focus of the NASC President’s Award is chosen by the NASC President, shining a spotlight on member achievements against their Presidential objectives.

This year, incoming NASC President David Brown recognised member efforts to work in more environmentally-friendly and sustainable ways.

and maintaining environmental standards.

Additionally, Tubes is reducing its use of natural resources through the adoption of e-forms and iPhone apps rather than paper alternatives, and through purchasing 100% sustainably sourced timber.

JFE Attridge Scaffolding Services Co Ltd has also invested in electric vehicles and forms. The company’s yard-based vehicles are now operating using HVO (Hydrogenated vegetable oil) fuel and carried out successful HVO trials on its commercial vehicles over 3.5 tonnes.

Planting trees, installing solar panels and Net Zero ambitions are among sustainabilily measures taken by members

Liddiard Scaffolding Ltd has planted 3,700 Christmas trees at its plantation in Liss, Hampshire, as a way of offsetting some of its carbon footprint. It has pledged to plant at least 500 trees every year. The company’s vehicles have also been fitted with engines that meet Euro VI Standards and it has placed an order for its first electric car.

Prior to 2021, Tubes Scaffolding Ltd produced a carbon emissions report which reviewed vehicle fuel, electricity and waste disposal. At the start of 2022, the company developed an environmental action plan to meet key targets: reducing carbon emissions, use of fuel and scaffolding materials through reuse and recycling all by five per cent by 2025.

Tubes is also working towards ISO 14001 Environmental Management certification to ensure it is achieving

Existing solar panels have been used to provide electric vehicle charge points and a wood chipper and wood silo have been introduced to enable a biomass boiler to be supplemented with scrap boards/split sole boards and damaged timber pallets. All employees have also attended an environmental awareness course.

GKR Scaffolding Ltd became the first scaffolding specialist in the UK to become carbon neutral. The company commissioned Engie to conduct a full external audit of its carbon footprint and put in place a roadmap to become Net Zero Carbon by December 2023.

GKR identified that the majority of its emissions are classed as Scope 1 Emissions, which means that 295 tCO2e (83% of their total emissions) were derived directly from operations on-site and through their logistics. Furthermore, 63% of GKR’s carbon emissions were attributed to its fleet of lorries. To counter this, GKR now uses HVO fuel on the whole HGV fleet.

To reduce Scope 2 Emissions, which include the indirect emissions from purchased power, GKR switched to renewable electricity in its offices and facilities.

Being certified as Carbon Neutral in line with PAS 2060 recognises the significant reduction GKR has made in Scope 1 and 2 Emissions, with the remaining 93 tCO2e balanced by offsets.

The Innovation of the Year category showcases NASC members’ new products and processes, developed and implemented to increase safety and efficiencies.

Benchmark Scaffolding Ltd has expanded its mobile Benchmark App, adding work instructions for additional works. The signed proposed works will go straight to main office, the principal contractor will then sign in agreement, all communication taking place digitally and recorded.

Benchmark has also added harness inspections to the App system, meaning all harnesses are inspected and signed by the inspector every month with no paperwork involved.

Lyndon SGB introduced QuickDeck to the UK market this year. It is a suspended access system designed to improve productivity and safety, reduce cost and save time. It provides a flush suspended working platform effectively providing a factory floor environment in the air.

One of the big advantages of the system is how the framework is

progressively erected. Once a starter platform is formed each subsequent bay framework is erected directly adjacent to the existing platform and then swung out and rotated into position and locked off before being decked out and guardrails fitted.

Layher’s Twixbeam provides contractors with a light but high load bearing beam with no welded profiles. The product integrates with existing Layher Allround & Flexbeam systems and offer multiple uses in construction/street-work scaffolding, industrial scaffolding and falsework formwork scaffolding, as well as heavy duty suspension technique.

StepUp Scaffolding UK’s GuardAid Tool, a scaffold positioning tool, enables scaffold configurations to be erected without the risk of fall from height. The erection process ensures that the permanent guardrail is fitted before the platform is installed, and before the scaffolder ascends to the next working lift. The use of GuardAid Tool also ensures the scaffold structure is automatically braced.

PHD Modular Access Services Ltd has developed a modified version of the Minecraft game to attract the next generation. Using bespoke assets it enabled modified elements within the game to build structures that resemble scaffolding. The result was toured around schools to great success.

Altrad UK developed an e-learning module format linked to a learning management system. It removed the reliance on trainer-led, classroombased training which reduces cost, time and loss of productivity. The bespoke learner-lead, e-learning modular content is offered via a gamified, learning experience platform easily scheduled around any downtime.

Ideal Scaffolding (Southern) Ltd’s Ideal Cantilever eliminates traditional grounded standards and relies on the integrity of the building façade for all vertical and horizontal support.

It can be used to negate traditional beam-work spans and associated issues surrounding heavy duty tower foundations. It could be introduced to any area or level of the façade, using powered access, at any frequency, given each decked lift is selfsupporting.

EVOTOP is the new and improved modular façade scaffolding system from PERI. It is an evolution of the PERI UP Easy system, which was one of the first façade system scaffolds to integrate the advanced guardrail feature in 2016.

With EVOTOP, PERI can offer customers solutions for all bay lengths, widths, and load classes, as it has the strength of a frame system and the flexibility of a modular system.

The NASC continues to recognise the efforts and achievements of the next generation of scaffolding industry employees through its Apprentice of the Year category. This year’s entries showed that technical and non-technical apprentices of all backgrounds and experiences are embarking on careers in the scaffolding industry.

Below: Louie Peebles

Louie Peebles, JMAC Scaffolding Ltd is a bright young man who gained good exam results. With a range of apprenticeships open to him, he chose scaffolding because he wanted to be able to use his natural skills for problem-solving and wanted to work in an industry where people were dedicated and committed to working hard. Louie always takes feedback on board positively. If he makes a mistake, he corrects it and takes the learning on board.

Mason Gill, SRK Scaffolding has exceptional time keeping and recorded zero sickness during his time as an apprentice at Hinkley Point C. He always attends work and safety briefings, offers suggestions, and listens to advice.

Throughout his scaffolding training, Mason has succeeded many challenges that has come his way, the positive feedback from Weston College and his colleagues have come with high praise.

Lee Benson is an enthusiastic and hardworking member of the Lyndon SGB team that doesn’t give up until the job is done. He will always offer his help to anyone struggling as he thoroughly believes in teamwork.

His colleague Trenai Munnings has shown maturity beyond his years and is always well spoken, respectful, polite and above all else helpful. Trenai committed to the apprenticeship programme and assured his manager that he could fit this in alongside being a part time carer for his mother. Trenai’s determination to make this work in the face of adversity is testament to his ambition, character and resilience.

Above: Lee Benson

Below: Mason Gill

Bottom: Trenai Munnings

Jack Greenway hasn’t had a single unauthorised day off work since joining Star Scaffolding Ltd through the NASC Kickstart Scheme. He has never been late, despite catching a bus and a train every day to be at the yard for 7am each morning, and always comes into the office smiling.

He takes a huge amount of pride in everything he does, from taking great care with his tool belt and belongings, to ensuring the wagon is properly strapped up in the morning.

According to Ideal Scaffolding (Southern) Ltd, what makes Leo Simpson stand out is his enthusiastic approach to scaffolding and his certainty that this is the profession for him.

He has demonstrated a great aptitude for scaffolding and working within a team and already after a relatively short period of time has progressed to a level one would expect of someone with far more experience within the industry.

Connect Scaffolding Ltd has entered a trio of apprentices into this year’s NASC Awards. Despite only being 23 years old, Jordan Allen has a manner about him that displays his mature attitude and commands respect from his peers. No matter the job, his site supervisor knows he can rely on Jordan to complete it to a very high standard, always complying to Health & Safety procedures.

Jordan has become a valuable member of the team and his reputation precedes him - Site Supervisors regularly ask for him to be a part of their site team, as his hard work makes a huge difference to the standards of work produced.

Luke Westcott’s fantastic attitude and eagerness to learn has made him stand out from the crowd. No matter the job, he always gives 100%, has a great can-do attitude and his hard work makes a huge difference to the standards of work produced. Every Site Supervisor is more than

happy to have him on their site as he takes instruction very well, has excellent timekeeping and will often go out of his way to ensure the job runs smoothly, sometimes driving up to an hour out of his way in the morning to collect a transit loaded with materials for site.

Alex Burgess’ attitude towards health and safety has impressed clients and his peers alike and he has become a valuable member of the team. He is consistently praised by his colleagues; his attitude to learning makes him stand out and he is a pleasure to work alongside. Alex shows an eagerness to learn and is always interested in going above and beyond, whether that is listening and learning from his chargehand or completing external training courses.

Sarah Klieve (chair) High Peak Scaffolding Ltd

Phil Hinch Brand Energy & Infrastructure Services UK Ltd T/A Lyndon SGB

Gary Coote CCS Scaffolding Ltd

Mike Wright Millcroft Services PLC

Danny Dwyer PHD Modular Access Services Ltd

Anthony Houghton Shield Environmental Services Ltd

Kate Thomson Thomson Scaffolding Ltd

Chris Hilton Vision Scaffolding Solutions Ltd

Steve Fellows (chair) Malvern Scaffolding Ltd

Lynn Way Chris Sedgeman Scaffolding Ltd

Rachel Dalby (J Mac Safety Systems Ltd)

Sean Pike Layher Ltd

Lydia Chard Star Scaffolding Ltd

Mike Burr (chair) LTC Group 87

Andy Gaynor Allied Scaffolding Ltd

William Somerville Altrad Services UK

James Lewis Brogan Group Ltd

Lynn Way Chris Sedgeman Scaffolding Ltd

Aled Hughes CITB

Lester Brown HAKI Ltd

Sean Pike Layher Ltd

Phil Hinch Brand Energy & Infrastructure Services UK Ltd T/A Lyndon SGB

Dan Wilson Mar Scaffolding Ltd

David Mosley NASC/CISRS

Henry Annafi NASC

Sean Johnston NETA Training Group

Rick Statham Safety & Access Ltd

Tony Gibbs Simian Risk Management Ltd

Lydia Chard Star Scaffolding Ltd

Amanda Riding Training 2000 Ltd

Meurig Thomas Unite the Union

Wayne Connolly (chair) Connolly Scaffolding Ltd

David Anderson Allen & Foxworthy Ltd

Mark Davenport Auditor

Ian Fyall Auditor

Alastair O’May Auditor

Paul Turner Auditor

Kevin Ward Auditor

Darren Maratty Interlink Scaffolding Ltd

Ronnie Charters JR Scaffold Services Ltd

Mike Lloyd LTC Scaffolding Ltd

Phil Heffernan Scaffold Erection Services Ltd

Matthew Cousins (chair) Apex Scaffolding (Exeter) Ltd

Trevor Clarke Amber Scaffolding Ltd

Lynn Way Chris Sedgeman Scaffolding Ltd

Andy Thomas H&H Contract

Scaffolding Ltd

David Brown IBN Scaffold Access Ltd

Wendy Bradley Joint Taxation Committee

Darren Hayward Millcroft Services plc

Ian Fyall Simian Risk Management Ltd

Mark Chard Star Scaffolding Ltd

HIRE, SALES & MANUFACTURING

Sean Pike (chair) Layher Ltd

Sarah Wilson (vice chair) Gilray Plant Ltd

Chris Viney Afix Group UK Ltd

Joachim Gundersen Alustar AS UK

Richard L’Herroux AT-PAC Ltd

Gary Pinkney BD Pinkney & Co Ltd

Steve Masters Brisko Scaffolding Ltd

Tommy Ross CCB Scaffolding Supplies

Alan Scott Enigma Industrial Services Ltd

Matt Shore Forgeco Ltd

Mark Clifford Generation (UK) Limited T/A ALTRAD Generation

Matt Johnson George Roberts (NW) Ltd

Gary McCulloch Haki Ltd

Phil Marks PCP Gratings Ltd

Alasdair Stables Peri Ltd

Tom Steele PSB Sales Ltd

Jerry Watts (Auditor) QSI Ltd

Jeff Wood Ramsteel Tubes Ltd

Grant Norfolk Rotamead Ltd

Knud Pedersen Step Up Scaffolding UK Ltd

Tony Mills St Helens Plant Ltd

Alan Slater TRAD Hire & Sales

Ashleigh Grainger Trademagic Ltd

Gary Griffiths UK System Scaffold Hire Ltd

Anton van Dooren van Thiel United UK Ltd

Ryan Clegg Bilfinger Salamis UK Ltd

Priscila Escobar HAKI Ltd

Ivik Masek 48.3 Scaffold Design Ltd

Steve Prower Actavo (UK) Ltd

Tony Jenkins Altrad Dessa

Jason Black Brand Energy Infrastructure Services UK Ltd T/A Lyndon SGB

Colin Murphy Cape Industrial Services Ltd

Martin Nicholas Chris Sedgeman Scaffolding Ltd

Matt Shore Forgeco Ltd

Wayne Lovelock Formula Scaffolding Ltd

Ricky Mair Highland Temporary Works

Jan Andresen HSE

Martyn Ostcliffe HSE)

Nick Geddes Layher Ltd

Matthew Brewin Lindway Scaffolding Ltd

Ian Nicoll Nicoll Reid Associates

Russ Marlow Optima Scaffold Designs LLP

Charles Stratford Peri Ltd

Ray Kellard Scaffold Designs Ltd

Stuart Salmon TR Scaffolding (Bristol) Ltd

Stephen Corden Wood Group Industrial Services Ltd

Alan Harris (chair) Pro-Fix Access Ltd

David Anderson Allen & Foxworthy Ltd

Peter Booth Benchmark Scaffolding Ltd

Ryan Clegg Bilfinger Salamis UK Ltd

Mark Collinson Brand Energy & Infrastructure Services UK Ltd T/A Lyndon SGB

Pat Walsh Altrad Services Ltd

Roy Rogers Enigma Industrial Services Ltd

Jo-Anne Michael HSE

Adrian Rooney Midland Scaffolding Services Ltd

David Mosley NASC/CISRS

Steven Kearney NASC

Rick Statham Safety & Access Ltd

Simon Hughes Simian Risk Management Ltd

Kate Thomson Thomson Scaffolding Ltd

James Attridge (chair) JFE Attridge

Scaffolding Services Co Ltd

AIS Survivex

Aberdeen 0844 8001810 www.aisgroup.co.uk

All Access Training Services Glasgow 0141 8822555 www.allaccesstraining.co.uk

ASET International Oil & Gas Training Academy Aberdeen 01224 896196 www.aset.co.uk

CITB NI Co. Antrim 02890 825 466 www.citbcsni.org.uk

Enigma Industrial Services Ltd Renfrewshire 07484 929072 www.enigma-is.com

Excel Training International Paisley Tel. 0141 416 9865 www.etihealthandsafety.com

HAKI Ltd Kinross, 01827 282 525 (Option 4) www.haki.co.uk

National Construction College Renfrewshire 0344 9944433 www.citb.co.uk/training

NORTH EAST

AIS Survivex

North Shields 0844 8001810 www.aisgroup.co.uk

NETA Training Group

Middlesborough 01642 616 936 www.neta.co.uk

NETA Training Group Stockton-on-Tees 01642 616 936 www.neta.co.uk

Safety and Access Ltd

Stallingborough 01469 552848 www.safetyaccess.co.uk

NORTH WEST

3B Training Blackburn 0330 912 0650 www.3btraining.com

Fulcrum Scaffold Safety & Training Ltd Flintshire 0161 706 0345 www.fulcrumscaffoldsafety.com

Lawsons Training Ltd Workington 01946 833313 www.lawsontraining.co.uk

Simian – CIST Anglesey 0345 602 2418 www.simian-risk.com Simian Warrington 0345 6022418 www.simian-skill.com

Total People Manchester 0161 674 7822

Training 2000 Blackburn 01254 54659 www.training2000.co.uk

YORKSHIRE

3B Training Doncaster 0330 912 0650 www.3btraining.com

MIDLANDS

Construction College Midlands 01922 663600 www.constructioncollege.co.uk

Safety & Access Ltd Nottingham 0115 979 4523 www.safetyaccess.co.uk

Simian Aspects Training Ltd Coventry 0345 602 2418 www.simian-risk.com

EAST ANGLIA

Britannia Safety & Training Wymondham Tel. 0800 019016/01953 606100 www.britanniaits.com

National Construction College Kings Lynn Tel: 0344 9944433 www.citb.co.uk/training

SOUTH EAST

CHSG – Construction Health &Safety Group Chertsey 01932 561 871/563 121 www.chsg.co.uk Layher Ltd Letchworth 01462 475 100 www.layher.co.uk

National Construction College (South) Erith, Kent 0344 9944433 www.citb.co.uk/training PERI Ltd Brentwood 01788 861600 www.peri.ltd.uk Safety Services (UK) Ltd Oxfordshire Tel 0845 4025050 www.safetyservices.co.uk

Simian - Carshalton College 0345 6022418 www.simian-skill.com

Simian Waltham Forest 0345 602 2418 www.simian-risk.com

SOUTH

CWIC Scaffolding Academy Swansea 01792 482022 www.cwicscaffoldingacademy. co.uk

LTC Training Services Ltd Plymouth 01752 485303 www.ltctrainingservices.co.uk

LTC Training Services Ltd Cullompton, Devon 01884 664224 www.ltctrainingservices.co.uk

Simian – Weston College Weston-Super-Mare www.simian-skill.com