8 minute read

electric power safety course

SESSION ONE

Electric Power Safety Excellence course

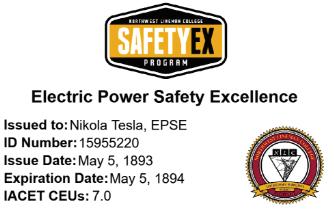

The Electric Power Safety Excellence course walks safety professionals through some basics of power delivery work. Students will learn about several topics including the electrical grid, rigging practices, and working in elevated positions. Students will also experience basic line work with tasks such as operating equipment, using line tools, and examining electrical devices. The capstone project for this course involves a mock job site observation using new found power delivery understanding. Trainees who successfully complete this course will be able to designate themselves as EPSE certified.

KNOWLEDGE (ACADEMIC SUBJECTS)

ELECTRICAL GRID

Electrical Grid combines basic electrical theory with discussions on today's electrical systems. This topic addresses voltage, current, resistance, and how they interact with each other in electrical circuits. As the learner begins to understand how electricity behaves, the content shifts toward conductors, insulators, materials, and electrical equipment (transformers, regulators, etc.). This enhances the learner's knowledge of why power lines are constructed the way they are and how electricity affects work practices.

ROPES AND TENSIONS

This topic starts with knots, types of ropes, slings, shackles, etc. The learners will explain how rigging practices are dictated by working load limits, knot efficiencies, and sling configurations. Learners will be able to define the bight and identify areas on the job where workers must avoid the line of fire. Inspection and removal of defective rigging equipment is also discussed in this topic.

PERSONAL PROTECTIVE EQUIPMENT

The Personal Protective Equipment section takes a detailed look into the common protective equipment on a power delivery job site. This not only looks at work gloves, safety glasses, hard hats, etc., it will also include a look at fire retardant clothing requirements, rubber gloves and sleeves, and more. Inspecting and maintaining PPE will be constantly reinforced throughout the course.

THE CAPACITY MODEL™

This topic takes on safety philosophy from a different outlook. It teaches learners to look at the work site during the stages of job hazard analysis with the capacity to fail perspective. If workers build capacity to fail into their work plans, more emphasis is placed on special precautions so that hazards are addressed before they become accidents. It also teaches the use of the Energy Wheel in job briefings.

SKILL (LAB AND FIELD COMPETENCIES)

PERSONAL PROTECTIVE EQUIPMENT

This hands-on training is designed to teach the learner about the use, care, and storage of personal protective equipment. Inspection of fall protection equipment, rubber insulating gloves, and other types of PPE are taught during this topic.

ROPES AND TENSIONS

This topic is intended to set up various scenarios that involve creative rigging practices, such as job sites where access is limited. Parted blocks, slings, ropes, and capstans will be used to simulate pole setting, transformer installation, and more to raise awareness of strains and tensions on the work site. The Capacity Model is reinforced by teaching the learner where the line of fire exists when rigging equipment fails. Learners will even be able to experience simple tasks such as changing out a dead-end with a hoist and a grip, tensioning a down guy, and more.

DIGGER DERRICK SAFETY

There are lots of situations that affect safety on the work site where a digger derrick is used. There are multitudes of little details that can turn into big safety issues that can only be shown by setting up this equipment and operating it in an instruction, not production, environment. Trainees will learn about three points of contact when boarding the vehicle, hydraulic fluid and pressures, load angle charts, critical components, and other tips about operating the equipment to help keep workers safe.

ELECTRICAL DEVICES

This hands-on instruction augments the Electrical Grid subject. As learners begin to identify the pieces and parts in the classroom (reclosers, capacitors, regulators, etc.), they can actually get a close-up view of this equipment in NLC’s state-of-the-art lab building. Learners will be able to see how a regulator’s taps adjust, how a capacitor operates, cut-out operations, etc., which emphasizes why these pieces of equipment are important to the electrical system.

TRANSFORMER BASICS

The transformer is the most utilized piece of equipment on the electrical system as it allows voltages to be transformed to consumable levels. One of the most common mistakes that lineworkers make is just taking a simple continuity check on the transformer before it leaves the yard. In addition to testing a transformer, learners will be able to see how a transformer supplies voltage to a residence. This training will occur in NLC’s stationary Transbanker Lab.

BEHAVIOR (DEMONSTRATING SUCCESSFUL BEHAVIOR)

PROGRESS CHECK

The Progress Check is an end-of-week discussion that occurs between the individual learner and the instructor. The learner’s performance as it relates to the three phases of education is the topic of discussion; a document showing performance drives the discussion and is reviewed with the learner.

PRACTICUM

JOB SITE OBSERVATIONS

This portion of the program occurs in between Session 1 and Session 2. Practicum, by definition, is a practical section of course study, and in this case, will be completed through job site observations. Each participant in the program will be required to conduct no fewer than five job site field observations and prepare a summary presentation on his or her experience. This will give the participant a chance to process what was learned in Session 1, relate the information to what he or she is seeing during the observations, and deliver a safety presentation to classmates at the beginning of Session 2.

SESSION two

KNOWLEDGE (ACADEMIC SUBJECTS)

SAFETY PRESENTATION

This is the conclusion to the Job-Site Observation Practicum that occurs between Session 1 and Session 2. Each participant will be required to present an 8-10 minute presentation to the group that summarizes what the participant observed in five field observations. This presentation must also include a safety training based on the observations. At a minimum, the presentation must relate to the subject matter learned in Session 1, but may also spark discussions on other safety-related topics.

WORKING IN ELEVATED POSITIONS

It is important to note that trainees will not be expected to climb and perform work in elevated positions during this training. Instead, learners will be exposed to the different types of equipment and the requirements to use them based on the task at hand. Lineworkers commonly find themselves relying on a combination of work positioning systems and personal fall arrest systems while performing a single task. We will look at those scenarios and discuss compliance with the fall protection rules.

OSHA ELECTRIC TRANSMISSION AND DISTRIBUTION (ET&D) 10-HOUR COURSE

This subject is the most recognized version of the OSHA for Construction course in the industry. It has been designed and developed specifically for power delivery workers and explains in detail what OSHA says about specific work practices. This subject is taught by an authorized OSHA ET&D trainer, and participants will also earn the ET&D Course Completion Card.

WORKING ON LINES AND EQUIPMENT

This subject teaches the learner about the two methods of working on lines and equipment: de-energized and energized. Classroom lecture and application exercises are used to educate on the theories behind effective bonding and grounding, including ground sources, fault current levels, and hazardous sources of electrical energy that can still exist on a de-energized line. In addition, the use of rubber protective equipment and live-line tools when working lines and equipment energized will be discussed. Participants will be educated on the principles of insulate, isolate, protection from the second point of contact, and live-line bare-hand concepts.

SKILL (LAB AND FIELD COMPETENCIES)

WORKING ON LINES AND EQUIPMENT – GROUNDING AND BONDING EXERCISES

Using NLC’s low training line in the yard, learners will be able to experience the process of installing and removing grounds, in both EPZ and Bracket configurations. The trainees will also learn how to set up an EPZ from a bucket, as well as ground a padmount transformer. The process will reinforce the process of identify, disconnect, test, ground, and clean so that trainees can explain why it’s important to prove lines de-energized before work can begin.

HOT STICKS AND ATTACHMENTS

If work is to be performed on those circuits while the line is energized, the crew must decide whether or not the tasks can be performed with rubber gloves and hot boards, or if the job should be done using hot sticks. California’s Title 8 Rules state that rubber gloving cannot be performed directly from the pole for systems operating above 7,500 volts, and the maximum system voltage that can be rubber gloved overall is 21,000 volts. Therefore, the hot stick method is still a viable option. Learners will learn how to use a telescoping stick and will experience a variety of other simple tasks using hot sticks. By doing so, they will be able to explain how minimum approach distance applies when using sticks, and how the second point of contact affects the work.

WORKING ON LINES AND EQUIPMENT – RUBBER GLOVES AND COVER-UP STRATEGIES

Customers do not like power outages, so lineworkers must be able to perform energized work. Lineworkers must learn the proper way to apply the three main principles of rubber glove work: insulate, isolate, and protect from the second point of contact. These principles will be defined, and hands-on training in the yard will reinforce these principles. Trainees will use rubber gloves and sleeves to apply line hose and blankets to the low lines in the training yard. The sequence of application and removal will be taught in addition to covering items of different potential within the immediate work space.

MOCK JOB SITE OBSERVATIONS

Field training is always occurring at NLC’s campus, which presents the opportunity for learners to conduct a work site observation. They will be expected to view the event from start to finish, which includes participation in the job briefing, the work process, and the post job activities. During this observation, the learners will be completing job observation worksheets so that they can document their findings during the work process. Upon conclusion of this, they will present their findings to the rest of the group in the classroom.

BEHAVIOR (DEMONSTRATING SUCCESSFUL BEHAVIOR)

FINAL EVALUATION

This is similar to the Progress Check but is the final performance-based discussion with the individual learner. Phases (knowledge, behavior, and skill) of the educational model are covered during a one-on-one conference between the trainer and the trainee.