36 minute read

STRAIN OTM

grown by VERANO

G-WAGON IS A CROSS BETWEEN G6-JET FUEL AND GHOST TRAIN HAZE BY VERANO, AND I THINK MOST OF MARYLAND HAS JUMPED ON THE G-WAGON!

Bringing a mellow good mood, this daily driver of a strain has 20% THCA and a relatively even distribution between terpinolene, myrcene, pinene, caryophyllene and limonene.

Together this forms a synergy between the quintessential indica and sativa profiles, delivering a mellow potency that really allows this flower to shine as a maintenance strain throughout the day.

Now we all have our own ailments and various strategies for using our Cannabis products to accomplish our goals, and a maintenance strain is an often overlooked and undervalued tool that is nevertheless essential to a patient’s endeavors.

Many of us seek out profiles that specifically target a certain symptomology or promise access to a specific state of mind, which in turn leads us to hunting around for the various niche flowers across the market that match our needs. This is very fun and of course essential to the process of developing a Cannabis treatment regimen, but this can often be a difficult task to do efficiently.

This is where the G-Wagon pulls in - bringing a profile just subtle and versatile enough to touch on just about every type of symptom a Cannabis patient might encounter - with enough THC to do the trick, but not enough to impede the tasks of the day.

G-Wagon is a pleasantly mild and earthy smoke that can be puffed on all day to get through those moments when life might start to overwhelm you.

We often forget that stress is one of the most detrimental forces acting on our health, making a maintenance strain like G-Wagon invaluable. And I have seen many a Marylander turn to the G-Wagon for a break in the day.

Terpinolene tops off the profile, which ensures a decent amount of energy to keep the myrcene in check. Now, .29% myrcene is not enough to cross the threshold into couch lock land, but will absolutely synergize with the caryophyllene to provide a smidge of pain relief and additional anti-inflammation. The limonene and beta-pinene help keep the spirits up and the mind focused, as this profile entourages into an allpurpose, daily driver toke.

Able to gently touch all your needs, the G-Wagon is truly a flower for the coronavirus quarantine.

You can use it to endure the days of isolation, as well as combine it with your other more niche profiles to snowball their effects to new heights of relief.

Whether used as a reinforcement flower or a maintenance toke, Verano’s G-Wagon is the steady strain to keep you keeping on. Don’t forget to treat your stress and stay safe out there! Thanks again to Verano for providing the medicine we need to help us get through these trying times. 20% THCA .47% THC .08% A-PINENE .127% B-PINENE .291% MYRCENE .09% OCIMENE .342% TERPINOLENE .123% LIMONENE .043% LINALOOL .159% CARYOPHYLLENE .034% CARENE .037% HUMULENE

1 PROPAGATION/PLANTING 2 PLANT CARE 3 HARVEST 4 DRY + CURE 5 TRIMMING 6 PRE-ROLL MANUFACTURE 7 BHO & CO2 EXTRACTION 8 SOLVENTLESS EXTRACTION 9 EDIBLE PRODUCTION 10 TESTING THE PRODUCTS 11 PACKAGING & FULFILLMENT 12 EDUCATION & CONSUMPTION

Seed to $ale

For most of its modern history as a medicine and recreational consumable, Cannabis remained shrouded in mystery. Patients and stoners alike found vague answers to prying questions: What strain is this? Not sure - the guy called it Purple Princess. How high will this brownie get me? One will get you pretty high, two will get you really high. Where did this come from? BC, I think. Wait, no - Humboldt? Every step from behind Prohibition’s curtain offers clearer answers. Now, with two thirds of the United States employing some form of legalization or decriminalization, tracking systems and testing requirements have made it possible to follow - and track - a product from the geneticist who bred the seed all the way to the joint in a patient’s hand.

For more than a year, our editorial staff has been working closely with Oregon breeder Hermetic Genetics, cultivator Urban Pharms and distributor The Sweet Life, in order to track a locally bred strain from seed to consumption. It has taken a monumental amount of work and logistical wizardry to bring you the story package you see here. So heat up your banger, pop your gummy or spark up your joint, and give some love to the people that make it all possible.

1Propagation and Planting

Our story begins with seeds bred by Oregon-based breeder Hermetic Genetics and popped by Seth Marsh, owner and founder of of Urban Pharms. The seeds spend 12-24 hours in a high moisture environment - wet paper towels in plastic bags in this case - which cracks the seeds open and begins the life cycle for the plant. The seed and its protruding taproot are then gently placed into four inch soil plugs, where they’ll reside for their infancy and toddler stages of life. Once they’re a few weeks old and about six inches tall, the plugs are removed from trays, planted into one gallon pots and transferred to the greenhouse to grow. After a couple weeks vegging in the greenhouse, they spend about a week living outside the greenhouse to begin becoming accli- mated to the outdoor environment before being transplanted into custom made, 360 gallon pots for later vegging and flower.

2Plant Care Upkeep and maintenance are abso- lutely critical to growing a successful crop. There are dozens of different techniques, but clipping fan leaves and interior nodes, and supporting a plant with trellis netting are two of the most widely practiced forms of maintenance. Clipping fan leaves and interior nodes promotes airflow and helps defend against the development of powdery mildew. Plant upkeep has less agreed upon methodology, with essentially every grower implementing a slightly different strategy to keep their plants healthy and happy. These days, one of the most commonly practiced forms of plant upkeep is integrated pest management, which is the practice of implementing human-safe and ecosystem-friend- ly methods of pest prevention, instead of using offthe-shelf pesticides. Ladybugs are natural predators that feed on both aphids and mites - two pests that love to munch Cannabis.

3Harvest During Fall harvest season, when the leaves are changing and the Cannabis flowers have ripened into plump, chunky buds, life on the farm buzzes with an energy that can be best described as organized chaos. Dozens of seasonal workers descend on the property, where towering 12- to16-foot Cannabis trees are chopped down, deleafed, quartered, bucked and prepped to be hung to dry. It’s a sight to behold - the hum of activity, the positive energy and the exhilarating rush of bringing down thousands of pounds of flower as part of a well-oiled operational machine. At Urban Pharms, the teams constantly move the plants from one stage to another assembly line style, each step in the process fitting together efficiently like the gears of a clock. Harvest is, by far, the most labor-intensive stage in the life cycle of a Cannabis plant, and everything needs to happen within a narrow window of time to ensure peak quality for the resulting product.

4Drying &Curing Executing a proper dry and cure might be the most important step in growing a Cannabis plant. Dry too fast and your volatile (and highly desirable) terpenes dissipate, leaving you with buds that smell like hay. Beginning your cure with too much moisture left in the buds can cause mold and ruin a perfectly good harvest. Most commonly after harvest, branches are chopped from the plants and hung in a temperature and humidity controlled environment for 7-10 days before being moved into the curing steps of the process. Urban Pharms built a brand new 8,000 square foot drying and curing facility in 2019 - no small investment and a testament to the importance of this step in the process. During the curing process, bags are ‘burped’ in order to release evaporating moisture and off-gas CO2. This step is one of the keys to finishing quality flower.

5Trimming Trimming generally occurs twice for outdoor plants. First, immediately at harvest, large fan leaves are removed either by hand or by machine - depending on the size of the crop. Then, after drying, the plants are ready to be more finely manicured and are cleaned up with more precise trim machines, by hand, and sometimes both. Generally speaking on scaled farms, the second step occurs only for buds headed to market and not destined for pre-rolls or processing, as the cost of trimming is a significant portion of a farm’s annual overhead. This important step helps bridge the gap between a plant in a field and a finely manicured, purchase-ready product at a dispensary.

6Rolling Deep Generating thousands of prerolls per day for statewide distribution takes a lot more than a Diamond hand grinder and a pack of RAW king size papers. Flower is milled to a fine grind - often using industrial machinery - before being loaded into joint-packing equipment. The industry standard cone-filler is the Futurola Knockbox - some of which can handle up to 300 pre-rolls at a time. One of the biggest challenges of this step in the process is ensuring that operators successfully fill each cone precisely to the desired level. At this scale, being a fraction of a gram off the mark adds up quickly.

7BHO & CO2 Extraction The art of solvent based extraction has come a long way since backyard blasting, but the end goal and fundamentals of the procedure remain the same: to extract the highly valued cannabinoids and terpenoids using a combination of precisely dialed pressure and temperature. In solvent based extraction, such as butane (BHO) and supercritical CO2 methods, a solvent is put in contact with the flower, drawing out the beneficial compounds. The resulting oil can be further refined using ethanol distillation and is often clarified through winterization, during which fats and waxes are removed using a combination of ethanol and sub-zero temperatures. Cartridge manufacturers have traditionally favored refined solvent based extraction, as it often results in clearer oils, which offer ‘shelf appeal’ for case-cruising consumers.

8Solventless Extraction Solventless extraction relies on purely mechanical methods. Rosin, hash, dry sift - these comprise the old school. They keep more of the plant’s overall profile intact, as they’re not winterized or distilled - the fats and waxes stay in the mix. Current trends in developed markets are showing that what’s old is new again - connoisseurs increasingly prefer solventless to solvent based extracts.

9Edible Production Differing types of extracts are added to edibles at various stages of production, depending on the product. Some manufacturers use ethanol extracted FECO - which contains a significant amount of plant matter, and offers an extremely strong flavor profile and heavy, medicated effects. Most edible producers currently serving the market use nearly pure cannabinoid distillate or isolate, as these showcase little to no flavor or aroma - though they sacrifice full spectrum efficacy in the process. Dialing in the process of adding extract to edibles is of paramount importance - batches undergo rigorous testing to ensure that each serving is dosed properly. Just a fraction of a milligram off, and a producer can lose hundreds - if not thousands - of dollars to product loss.

10 Testing The Products After cultivation and before consumption comes the most intricate and expensive stage in the entire process: testing. This is the step that separates the pro from the amateur, in terms of consumer confidence. Samples are sent to testing labs after any stage in the process where the product may end up in a consumer’s hand: after cultivation, after extraction and after extract is added to edibles. Each stage gets a separate test, which is undoubtedly costly. At the lab, scientists employ methods such as high-performance liquid chromatography to identify and measure the compounds in the plant or product’s chemical composition. This tells producers, regulators and consumers exactly what is in the product. All legal states require cannabinoid, pesticide and moisture testing. Some states also require terpene and heavy metals testing at an additional expense. Savvy producers in states where this additional testing is optional often choose to add these tests for greater transparency and marketability.

11 Packaging & Fulfillment Product is packaged and custom printed batch specific labels are affixed to each sales unit before the products are locked in the vault to await delivery. Each product can be traced all the way back to the seed using the state’s tracking system. Next, inventory managers update the state tracking system as products are secured for delivery to retailers. One of the keys to a robust market is a well maintained relationship between the sales representatives, drivers and retailers. This relationship determines the product mix available to customers, and if the brands and retailers aren’t talking to one another, consumers miss out.

12 Education & Consumption Budtenders spend time educating their customers, finding the best products to suit each individual situation. Like the distributor-retailer dynamic, the budtender-customer relationship determines the quality of the overall experience. So, now you’ve purchased your Cannabis - the best part. After arriving safely home, you open the childproof packaging. Whether you’re binge-watching Netflix, recording the next great album or tending to your own garden, one thing’s for sure - it took an army of people and a mountain of effort to bring you this experience. Savor the moment. And tip your budtender.

PLANT PEOPLE

CANBY, OR Grower

MAX WHITE | AROMA CANNABIS DIRECTOR OF CULTIVATION AND CO-FOUNDER Interview by Tom Bowers @PropagateConsultants

How long have you been cultivating Cannabis?

At the age of 12, I suffered an eye injury leaving me blind and with a condition ironically called chronic glaucoma. I became a medical marijuana patient in 1999 at the age of 16-years-old and immediately began growing for myself and other patients. I’m the ripe age of 37 today and there hasn’t been a year in which I wasn’t cultivating Cannabis.

How would you describe your approach to Cannabis cultivation at Aroma? How does it differ from other growing experiences you had in the past?

When I started in the good ol’ Oregon Medical Marijuana Program (OMMP) days, it was a vastly different arena. Prices were double or more what they are today. I had one employee - me. I didn’t have to pay attention to operating costs or budgets because let’s face it, the margins were glorious. I only had up to 48 plants at one time, so I could give the ladies names if I liked.

As far as techniques and grow styles, I did it all growing up. I grew in outdoor fields, greenhouses, attics, basements, warehouses. The first grow I ever did was in the corner of our family room growing up. At 16-years-old, my dad helped me build an 8x8 plywood box. I threw a 1000- watt China hat fixture in there and torched my crop - learned and moved on.

Today I find myself behind a computer screen a lot more. With my team, we watch numbers and data constantly. We prepare budgets and projections. The recreational market was a tough start. It has been a crash course in running a business as efficiently as possible. Naturally with scaling up into a more commercial approach, some of the personal intimate touches do not pencil in any longer, but I can say quality is still the main focus.

What is the most challenging part of running a Cannabis cultivation facility?

Learning to run a business. Whether you are selling kind nugs, shoes, cars or cheeseburgers, it’s all the same in regard to running a business. I don’t have any formal business education or degree. I was a simple Oregon dope grower with a drive to succeed. Learning to work with governing agencies, the county permitting process and the tax man has taken some practice - but a good challenge is always healthy and rewarding.

What advice do you have for cultivators (professional and amateur)?

Be open to learning more than one way of doing things. Ask a lot of questions from a wide circle of professionals. If you can, join community groups or volunteer in a field of desired expertise. Become a good networker! I love the phrase “your network is your net worth” because it is absolutely true. Today, when I don’t know the answer, I do know somebody that does. And they are happy to share that knowledge with me, as I am happy sharing with somebody else in need.

LOS ANGELES, CA Compliance Officer

You were previously a vital part of the operation at House of Cultivar in Seattle, then you moved to California for a new role. What does

a Compliance Officer do? I see that all our actions are tracked and traced from seed to production to nursery to manufacturing, distribution and retail. If that’s tough to stomach, an easier way to explain it is I’m a detail coordinator for compliant actions within the facility. Basically, what the Bureau of Cannabis Control wants is someone who is there to avoid product diversion and ensure product safety.

Having to deal with said governing body for Cannabis, what do you do to make your job

enjoyable? It is great going back to a facility and seeing that the company is taking the appropriate measures that I incorporated. The fact is that people generally do what they want, but there are fiery hoops to jump through, so it makes my job enjoyable to see this function from the black market to a compliant market.

Where do you see the regulatory aspect of

Cannabis heading? The biggest issue right now we need to get resolved is banking. We have no banking in California. Other states have implemented financial security for the industry, but unless we go with some crazy, random Russian bank, we’re hung out to dry. We make a lot of money for the state and they need to take care of us. We are really scrutinized and our money is just as good as someone who is not playing the game as well, but they are a federally legal industry like insurance or liquor.

What is your preferred way to wind down after spending your day as the last line of defense

against the pot police? (Giggles) I love going for a walk with the dogs, smoking a joint, and taking a good minute to appreciate where I am in life and that I’m a part on this revolution, because this is a time in history that is never going to happen again. This makes me want to go to work the next day.

ANCHORAGE, AK Trimmer

CHRIS CLARK | CODE GREEN Interview by Mike Ricker @RickerDJ

You have a trimming company which is unique to the Alaska Cannabis industry. What prompted you to start a business trimming flower for other

companies? I saw a need. There were a lot of farms doing everything right, but when the time came to handle the product, either the task was too overwhelming for them or the other options weren’t viable. So, that’s when I trained up a group of people and set a basic standard for the whole procedure. I have to say that there was a company before me, but in my opinion, they were ripping off growers and I just saw a much better way to do it.

What is your trade secret to making a successful

business out of trimming? Consistency. I know what I want to see when I go into a store. I know how I think bud should look. When the person taking in the product at a store sees 100 eighths that all look the same, I know we’ve done our job right.

Why is trimming a noble profession? I honestly believe that trimmers can make or break a product. You can do everything right on the grow end, but if your product isn’t handled properly at the end of the day, it can end up looking like shit - you know?

If you handed off your earbuds to the person next to you right now in the middle of a trimming sesh,

what would they hear? They’d be getting into some Mike Love or Nahko Bear. That’s Nahko and Medicine for the People.

Since you’re in Alaska, have you ever considered opening a beard trimming company, and if so, would you consider trimming a Bearded Lorax?

I’ll trim anything you put in front of me, brother (laughs).

A grateful look behind the scenes with a member of the Cannabis industry responsible for each step of the Seed to $ale process...

IRVINE, CA Lab Technician

MIKE TUNIS & ADAM FLOYD THINK20 LABS Interview by Wyatt Early @ErrlyWyatt

What is the process a bud or concentrate takes from entering to exiting the lab?

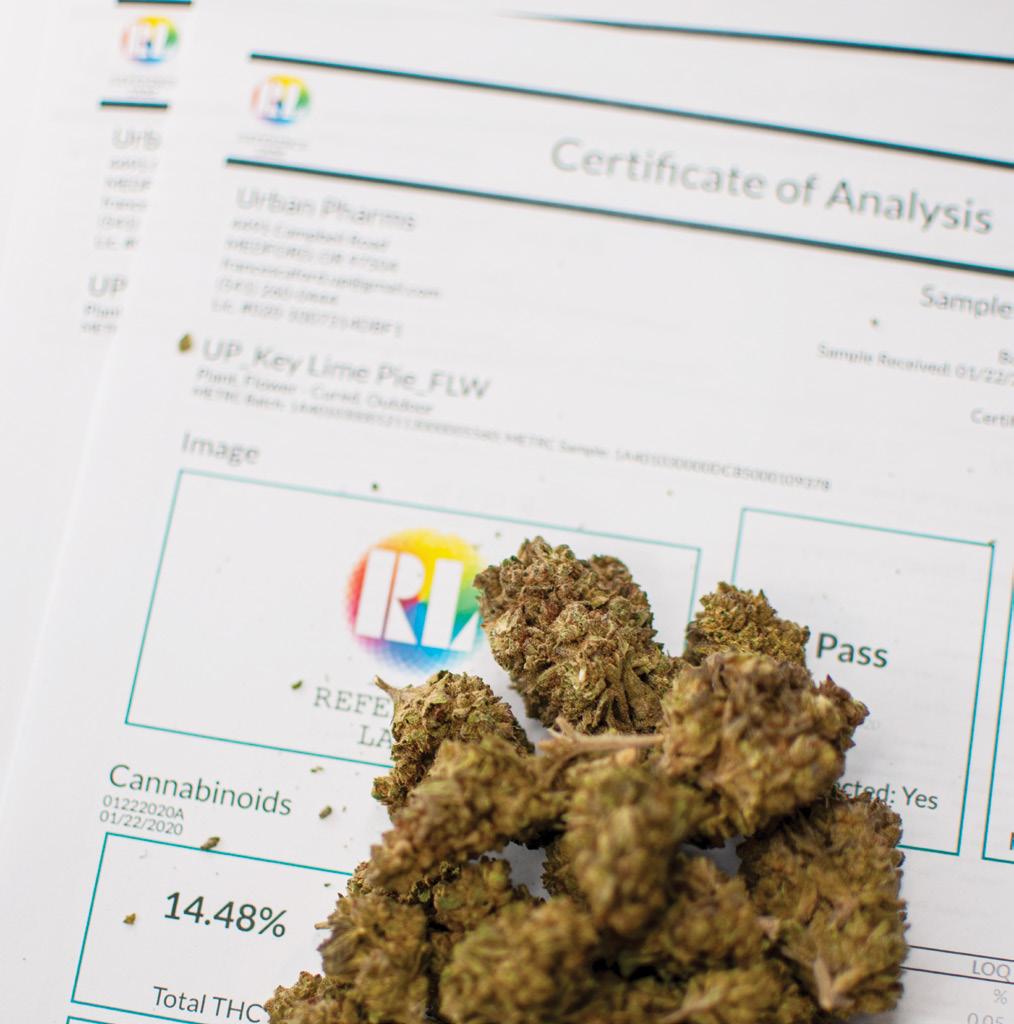

When a sample enters our laboratory it is first weighed, received and accessioned into Metrc and our internal tracking system. Then the sample makes its way over to our photography lightbox, where we take high-resolution images of the sample and its packaging to be displayed on the certificate of analysis.

For a full panel regulatory compliance sample, the first analysis conducted is the foreign material inspection. Here, we inspect the sample under a digital microscope, looking for adulterants such as dirt, mold, insects, fibers, hairs, etc.

Once the foreign material inspection is concluded, the sample is then homogenized - the process of making the sample uniform throughout, so that any sub-sample taken from the homogenized sample will be representative of the entire sample.

Proper homogenization is especially important when it comes to testing Cannabis flowers, primarily because they are very inhomogeneous - with the largest percentage of cannabinoids residing in the trichomes and the lowest amount coming from the leaves and stems.

Once all the analyses required for a sample are completed, the compiled data package is reviewed by senior lab personnel to verify values are correct and that all the analytical instrumentation quality control checks are within specifications pursuant to internal and external acceptance criteria.

Following this final quality assurance check, the certificate of analysis is uploaded to Metrc, the BCC, and released to the distributor who submitted the sample for testing.

EUGENE, OR Extraction Lab ProcessingManager

REGIS PHILBURN | ECHO ELECTUARY Interview by Amanda Day @Terpodactyl_Media

Dealing with the plant up-close must provide a unique perspective. What have you learned about Cannabis through your

processes? For the purpose of extraction, we seek out different traits such as unique terpene profiles, specific trichome morphology and lower THC to terpene ratios. There has been some breeding done specifically for extraction strains, but we hope to see this develop further in coming years into two distinct subtypes of varietals, similar to wine and table grapes.

What qualities do you look for in extraction source material?

Complex and unique terpene profiles, and clean growing practices and down to earth people/companies are essential factors in choosing our grow partners. Within our own grow we feel that organic sungrown Cannabis produces some of the most complex terpene profiles, but we also enjoy the range of flavor and repeatable results that come with the tight environmental control of indoor gardening. Cannabis enthusiasts are always looking for the next hot strain, so it is important to be aware of, and cater to, new strain trends.

Echo Electuary has been a staple of the Oregon market since before recreational legalization. What procedures have you utilized to provide your customers with consistent products?

We have developed our own methods for flash freezing using dry ice (CO2) and/or liquid nitrogen, in order to best preserve the ‘live’ terpene profile. In our extraction process, we utilize sub-zero temperatures, passive recovery, and precision flow control to achieve a variety of different hydrocarbon extract consistencies. Every batch goes through our dewax/winterization process to remove lipids and other unwanted components. Cleaning is an integral function of making consistent extracts and we rigorously clean our equipment and purify our solvents between batches to keep the extracts pure and free of cross-contamination.

Modern consumers have many options when it comes to dab products. Do you have a favorite type of extract? What do you en

joy about that form or consistency? I enjoy variety and could never be satisfied with just one consistency or type of extract, but in general, I prefer consistencies such as budder (badder) because of its well-balanced THC to terpene ratio, and its ease of use. Homogeneous extracts like budder tend to dab more evenly, with the THC and terpenes vaporizing simultaneously, which is the best all around effect for me personally. I am enamored by well-grown THCA crystals and enjoy vaporizing those as well, usually towards the end of the day.

FREDERICK, MD Packaging Manager

NIKIA HARRISTON | GLEAF Interview by Wyatt Early @ErrlyWyatt

What is your daily life like as a packaging manager?

Once we get the buds from harvest that have been manicured and trimmed, we start the packaging process.So, we start off with 10 pound batches and my team will package as much as they can from those batches into 3.5 gram drams. Depending on how light or heavy the different strains’ buds are, it can be anywhere from two to five pounds per batch going into eighths. We use a packaging machine we call Bimba, which funnels large amounts of Cannabis into small and precise amounts.

After being packaged, we place the containers into boxes of 224 grams (half of a pound). Each box must be labeled by hand with strain name, cannabinoid profile

and terpene profile. To account for this Cannabis being prepared to go to a dispensary, each box must be entered into Metrc. Then we can seal everything up and place them on the shelves for specific dispensaries to receive them.

What is left from that batch is called small bud, which is used for pre-rolls. All of our trim is sent to the lab to be

processed into all of the concentrates we make. We have a Futurola grinder to grind the buds, and use a Futurola machine to make pre-rolled joints and phillys. We have a ‘travel sheet’ that shows us which employee completed which process in packaging our products, for accountability and quality control. We track every single gram that leaves our facility, from seed to sale in the Metrc system. Whether it’s fresh bud, product that dropped on the floor, green waste or anything else, everything must be accounted for.

CHRISTA DANTINI

Selling Cannabis takes patience and the ability to read individuals. How did you build this expertise?

I have been in retail my entire life, since I was old enough to work at the age of 16. And I’m a people person. I’m more about building relationships with the individual than I am with getting the sale, and when you do that you get a keen ear to listen, which leads you to find what they are really looking for. Then figuring out what they need is super simple. When people feel that you are naturally interested in them, you create relationships that last.

You have children. Does selling Cannabis some

times feel like negotiating with your kids? It used to back when I was selling shittier products (laughs). But now that I sell the best brands in the Cannabis market, it’s easy - at least in my opinion. The people who were assholes back in the day, giving me the runaround, are now wanting to do business and are more flexible, which is kinda cool.

What is the most gratifying part of being in this

business, compared to doing retail? I think people are really chill and kind overall in this industry. For me, having the flexibility to be a mom and take care of kids and still smash out work is everything. And I love Cannabis. It has so many healing properties and it’s so much more than just a recreational thing. I feel good about what I’m doing at the end of the day.

How do you feel about the new Trolls

movie? I haven’t seen the new Trolls movie (laughs again). I think it’s the only one I haven’t seen yet.

ELLICOTT CITY, MD Store Buyer

BRANDON COLEMAN | GREENHOUSE WELLNESS Interview by Wyatt Early @ErrlyWyatt

What do you do as a buyer for a dispensary? As a buyer, you are tasked with many responsibilities outside of purchasing Cannabis for your store. To start, I am always keeping track of the inventory of the store in an effort to keep stocks high. I base my buying decisions on a variety of factors. Sometimes it’s feedback from patients wanting more of a certain product or producer, and my relationships with producers helps me do just that. Patients give me feedback routinely, sometimes multiple times daily - everyone has their favorites and wants to be able to buy them.

How do you decide what products to buy? When it comes to flower and concentrates, I have personally used a vast majority of the products I bring in. I spend a majority of my time managing relationships between myself, growers, processors and patients. Almost everyone uses a different wholesale platform to showcase their product. The biggest systems used are Leaf Trade and LeafLink, as well as individual email blasts with certificates of analysis.

Why does a dispensary need a buyer? Not every dispensary has a singular person set as the buyer. A lot of times the owner of the dispensary will be buying the products for the store. I have autonomy to make buying decisions without approval from anyone, which I believe gives me a leg up. Combining all of these factors into a patient facing brand/dispensary is really what wraps up my job.

Continued from p. 37

PLANT PEOPLE

COCKEYSVILLE, MD Patient Consultant

DR. ALEX DIX | KIP CANNABIS DOCTOR OF PHARMACY, B.S. CHEMISTRY Interview by Wyatt Early @ErrlyWyatt

When a patient comes in for a consultation, whether new or old to Cannabis, I always introduce them to our handbook and a few key concepts within that are crucial for them to understand. The handbook contains various basic topics about medicine, the endocannabinoid system, plant components, dosage forms of Cannabis, pharmacogenetics and a journal they utilize for their personal experience.

We will begin the healing process by locking in their goals. Are they aiming to relieve pain? Sleep throughout the night? Sense happiness? Leave pharmaceuticals in the past? Regardless, once the goals are established, we then dive into the educational scope of Cannabis. With its multiple active ingredients/compounds - cannabinoids - and its terpene properties, the various patient goals are achievable due to the unique structure of the plant. I emphasize drifting away from buying decisions simply based on sativa or indica. Trust the terpenes - they enhance the psychoactive components in Cannabis. The active ingredients and terpenes present in each strain allow for the potential to better target the release of specific neurotransmitters in our nervous system that regulate many processes within our body.

Shortly following, we discuss dosing. Each patient starts with the smallest possible dose first, ensuring sufficient time to yield the full effect. Once analyzed, we can decide if more or less is needed. Different products have different optimal doses and we work together to find the most suitable, safe and convenient method for that person. It may fluctuate, but the journal allows for record keeping and efficient modification, if needed.

The journal at the back of our handbook contains three sections: type, cannabinoid/terpene profile, and a number scale. The type section contains information about the method of ingestion - inhalation, sublingual, topical - dosage form, and information about the provider. Usually for the terpene profile/cannabinoid section it’s best to rip the label off or write down required information. The number scale is used before each dosage and after to assess the effect of each medication and its alignment with the patient’s goals. Additionally, the journal contains space for information regarding the time taken and technique - bowl, inhaled for three seconds, exhaled for two. Overall, the journal contains beneficial information to manage symptoms, track progress and modify accordingly. It’s important for our patients to understand how products relate to the learning points crafted in our handbook. This influences more knowledge and in turn confidence about the medicine regularly consumed.

PALMER, AK Budtender

SHELBY SWANSON | MATANUSKA CANNABIS COMPANY Interview by Mike Ricker @RickerDJ

Budtending is a profession. Where did you gain your expertise before entering the Cannabis industry?

In Alaska we have vertical integration, so I first began as a trimmer for the Matanuska Cannabis Company before coming on as a budtender. Before that I was in the service industry for a long time as a janitor, and worked at the post office and elementary schools. I like working with people and I felt like I’m more comfortable in this type of environment than being in a type that is, how do you put it…normal?

Where do you see the Cannabis industry heading in

Alaska? What amazes me most is the amount of people in the community who use Cannabis as medicine, as opposed to recreationally. Especially with the virus going on, being considered essential business, I see this having a ripple effect in the community - but I’m not sure if it will improve anything moving forward with federal legalization. We don’t really know what it’s going to take to change the laws, so we just keep on doing what we’re doing, which is presenting Cannabis in a positive light. The fact that we are essential business is a great move in the right direction.

If you were to run for the Governor’s seat in Alaska, what would be your main selling point for getting

elected? Oh man (laughs). I don’t know if it would be any one thing, but more like just changing the goal posts. I would rather take care of everybody in our community to make sure they are all provided for before giving big tax credits and free money to the oil industry. There are people out here who are really struggling to even make it to the next day. Our leaders tend to forget about the small people.

What strain would you recommend to a melancholy moose, if one were to mosey into the shop one day?

Ooooh, the Honey Banana by Althea’s Morning Bear. It’s a nice sweet indica that isn’t too dense, so you don’t have to grind it and you can just pack it into a bowl and hit it there.

AMBER VAUGHN |TERPENE TRANSIT Interview by Mike Ricker @RickerDJ

Distribution is an integral part of a moving society. What is different about doing it in the Cannabis industry compared to making deliveries

for a company like Amazon Prime? I think it always boils down to the regulatory nature of what we do, in always having to remain compliant. And we do it with a smile! Comparatively speaking, the big difference is delivery schedules. With a big company like Amazon, you know you’re going to get your delivery sometime before 8:00 PM tomorrow. For us, every store, every situation is a little unique, so being flexible and being able to adapt to each store’s unique quirks is a challenge. But we are not just robots, either. It’s important to us to create a pleasant experience because we know that customer service is the name of the game. So, that is an area that we truly feel differentiates us from the corporate drop and go delivery services. We create relationships, we network, we make friends.

Are you worried about contracting COVID-19 by

having contact with numerous people daily? It is a concern and the best we can do is the best for ourselves. As long as people are doing their due diligence to prevent it, we are happy to be out on the road making this happen. We provide gallons of ISO, gloves and masks, follow protocol to sanitize every day, and everything is UV lighted every day. We just go above and beyond for the prevention of COVID.

Has anything noteworthy happened on a delivery that you

would like to entertain us with? The first year that we started, we got pulled over by the state patrol and we told him we had 1,000 pounds of Cannabis in the back. We asked him if he wanted to see it and his response was, “I want to see it, but I don’t want to go through it.” Then he took a photo of it, which I assume he sent to all his buddies, then sent us on our way.

What is your preferred method for transiting terpenes into

your body? Dabs all day. Except when it’s time to drive, of course.

SEATTLE, WA CreativeDirector

MATTHEW MIKULSKI | CHATTER CREATIVE Interview by Mike Ricker @RickerDJ

You were a sponsored skateboarder in your younger days.

Where is the creative correlation between the two? I’ve always been influenced by Thrasher Magazine and TransWorld, so a lot of my inspiration comes from the wheels, the skateboards and the graphics - that old school look and feel. Everything that Powell and Peralta was doing, Steve Caballero, Bones Brigade, Tony Hawk, that whole crew.

I know there is something special about marketing Cannabis compared

to ordinary brands. What is it? Cannabis is different - wide audience - so you can’t really hone in on one particular person because everybody’s different. So you have to cast a wide net. Keeping my designs simple and clean is important. I’m always thinking about the 21-year-old to the 75-year-old person, male and female. So, the challenge is not having one particular person you’re designing for. Another thing worth mentioning is 11 years ago when I started Chatter Creative; a lot of corporate clients were shunning me for taking Cannabis clients and it feels like some of them are coming around. And even with aunts and uncles, there is a degree of acceptance you can feel more and more of. The perception of Cannabis is changing and it’s cool.

Could you ever work in another field now that you’ve realized your dream of being in the Cannabis game?

I’ll always be a designer. I love to illustrate, so if I wasn’t dealing with brands and marketing, I would probably shift into illustration. In fact, I could see myself doing children’s books.

Three easy ways to infuse your favorite cooking methods with a little Cannabis!

You may be stuck at home or you may be at work, but I know you are being careful and keeping your distance. It’s hard, sometimes sad and sometimes scary - often both. This month, instead of celebrating berries and asparagus, I am offering three basic recipes that you can make and keep in the fridge or pantry, and infuse at will. I always have these three items ready to go.

ONE OUNCE TOP QUALITY SHAKE, DECARBOXYLATED CANNA-FLOUR

1. Place the Cannabis in the bowl of a food processor or in freshly cleaned coffee grinder.

Not a method I use often, canna-flour involves baking with the actual plant. This means more of that Cannabis flavor than you would get from the other infusions. But, it also means less steps! Canna-flour works for baking if it comprises no more than 20% of the recipe.

When baking with canna-flour, keep the oven at 340°F or below. For recipes that call for 350°F, just lower to 340°F and cook a few minutes longer. Ramp up the spices a bit and there should be no harsh taste of Cannabis.

2. Process the Cannabis until it becomes a very fine powder.

3. Store in an airtight container until ready to use. 4. To use, replace up to ¼ the amount of flour in a recipe with Cannabis flour. Sift together the prepared Cannabis powder with the flour for even distribution. For flavor and consistency, try to stay at or below the ¼ substitution rule.

THESE THREE DRINKS will keep you high and happy while waiting for Spring. Well, waiting for 4/20. It can be a long wait - may these recipes help pass the time.

The syrup can be added to smoothies, ice pops, granitas, and other tasty spring treats,

SIMPLE CANNA-SYRUP - 3 CUPS FILTERED WATER - 3 CUPS FINE GRANULATED SUGAR - 3 TABLESPOONS VEGETABLE GLYCERIN - ½ OUNCE FINELY CHOPPED AND DECARBOXYLATED CANNABIS

1. In a large saucepot bring water to a boil. Add the sugar and stir until dissolved. 2. Add the Cannabis, cover, and reduce heat to a simmer. Cook for 30 minutes. 3. Reduce the heat to low, whisk in the glycerin, and simmer for 10 minutes. 4. Remove from the heat and allow to cool for 20 minutes. 5. Place the cheesecloth or fine strainer above a heatproof bowl and carefully pour the syrup into the bowl. 6. Strain the Cannabis from the syrup and pour into a container. 7. Once you allow the syrup to cool at room temperature, cover and store in the fridge for up to three months.

CANNA-CREAM

2 CUPS HEAVY CREAM 2 TABLESPOONS VEGETABLE GLYCERIN ½ OUNCE FINELY CHOPPED, DECARBOXYLATED CANNABIS

1. In a double boiler or a medium bowl on top of a saucepan with water, heat the cream. 2. Add the Cannabis and glycerin, whisk like crazy, and gently simmer for one hour.

3. Carefully pour the mixture through a fine mesh strainer lined with cheesecloth.

4. Allow to cool at room temperature for 20 minutes before covering and refrigerating. Keeps for about a week in the fridge, depending on the state of your heavy cream.