WORKING TOGETHER

GENESEO CLUB

DOUBLES DOWN ON SHOW DISPLAYS

DOUBLES DOWN ON SHOW DISPLAYS

Are

•

•

•

•

•

Early wind energy devices, powered by batteries, brought radio (and more) to the farm.

Landon Hall Group Editor

Leslie C. McManus Senior Editor

Christine Stoner Associate Editor

Terry Price Art Director

Baylie Koch Advertising Coordinator

Web and Digital Content

Tonya Olson Digital Content Manager

Advertising Director

Brenda Escalante escalante@ogdenpubs.com

Display Advertising (800)678-5779; adinfo@ogdenpubs.com

Classified Advertising (866)848-5346; fcmclassifieds@ogdenpubs.com

Newsstand: Bob Cucciniello; (785) 274-4401

Customer Care: (866) 624-9388

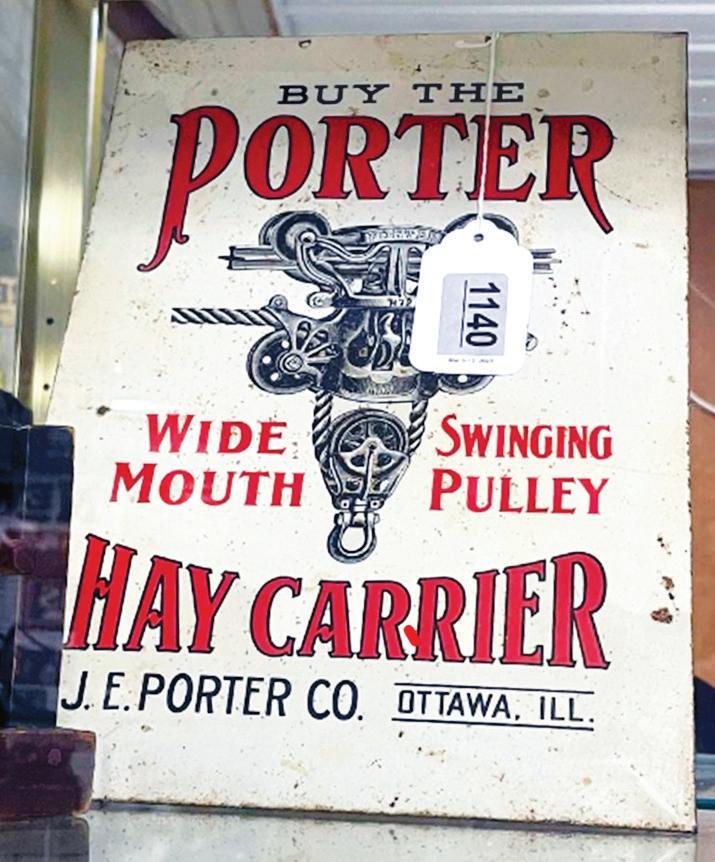

Seen a sign like this one? Unless you were tracking a mid-March auction, you’ve probably never laid eyes on one. But no one would blame you for hustling out to the barn to see if there’s something like it tucked away somewhere, because this one just sold for $19,000.

Events like this always summon up the same image in my brain: a bunch of old timers in rockers, whiling away a pleasant afternoon on a front porch somewhere in heaven. The crew I’m picturing today farmed in the early 1900s and saw the evolution of barn equipment that may or may not have come soon enough to spare their backs the worst of the labor-intensive process of getting hay into the mow.

Bill Uhler Publisher

Cherilyn Olmsted Circulation & Marketing Director

Bob Cucciniello Newsstand & Production Director

Bob Legault Sales Director

Andrew Perkins Director of Events & Business Development

Tim Swietek Information Technology Director

Ross Hammond Finance & Accounting Director

Farm Collector (ISSN 1522-3523), May 2023, Vol. 25, Issue 10. Farm Collector is published monthly by Ogden Publications Inc., 1503 SW 42nd St., Topeka, KS 66609-1265. Periodicals Postage Paid at Topeka, KS and additional mailing offices.

POSTMASTER: Send address changes to Ogden Publications, Inc., 1503 SW 42nd St., Topeka, KS 66609-1265. For subscription inquiries call (866) 624-9388. Outside the U.S. and Canada, call (785) 274-4366; fax: (785) 274-4305.

Subscribers: If the Post Office alerts us that your magazine is undeliverable, we have no further obligation unless we receive a corrected address within two years.

© 2023 Ogden Publications Inc. Printed in the U.S.A.

In accordance with standard industry practice, we may rent, exchange, or sell to third parties mailing address information you provide us when ordering a subscription to our print publication.

If you would like to opt out of any data exchange, rental, or sale, you may do so by contacting us via email at customerservice@ogdenpubs.com. You may also call 866624-9388 and ask to speak to a customer service operator.

These are people who only grudgingly exchanged hard, cold cash for, well, anything. They built their own homes, they raised their own food, they fixed what broke. The value of a good hay carrier, though, was immediately apparent to all.

There is a significant spread between the price of a hay carrier 110 years ago and a sign selling today for $19,000. It is the kind of gap that would likely test an aversion to cursing. “Durn,” one old boy might say, as others share glances, eyes narrowed in amazement over such a price paid for a sign (selling hay carriers!) that didn’t even light up. “Cain’t figger it,” another mutters.

The past, they say, is a foreign country. They do things differently there.

The future is equally inconceivable. That’s why our sheds, basements and closets are full to overflowing. When all we have to do is live long enough to convert junk into treasure, there’s little incentive to run a tight ship. Clean out that old shed? Better think twice. You might just be sitting on a gold mine!

WhenInternational Harvester debuted the TD24 in 1947, it quickly claimed the title of not only being "America’s most powerful crawler tractor" but also the world’s largest!

A versatile, heavy-duty bulldozer, it was designed to tackle any big job — from pipe-laying and construction to mining and logging. In fact, its revered reputation in the redwood logging industry would ultimately earn the massive machine its notable nickname — “Big Red.”

The TD-24 was also more modernized than even its closest competitors. Weighing in at 20 tons and powered by a new 180-hp, 6-cylinder diesel engine, its innovative 4-speed syncromesh transmission offered faster cycling and unprecedented finger-tip control.

The TD-24 is now faithfully replicated in precision-engineered die-cast metal.

Manufactured by SpecCast and presented by Hamilton in very limited quantities, the “1:25-Scale International Harvester TD-24” is a giant of power and pull — measuring an impressive 9 inches long! Authentic features include an adjustable clutch and rear winch ... fully rotating metal tracks ... official logos ... and more!

Reserve yours now for just four payments of $52.49*; only your first installment will be billed prior to shipment. Your 100% satisfaction is guaranteed — or your money back! Reply today!

America’s most powerful crawler tractor breaks ground once again in an incredibly detailed 1:25-scale die-cast replica!High-gloss paint scheme with official logos Adjustable, cable-operated dozer blade Rotating all-metal tracks

I bought this truck in 2008 after seeing an ad in your great magazine. It came from a farm in Ontario, Oregon. I’m always very happy to renew.

I got this water motor pump at an auction a few years ago. It was built by National Regulator Co., Chicago and New York, and patented in 1912. I have seen a few water motors. One was used in the basement of an old house to pump cistern water to the second-floor bathroom. I wonder what other uses they had. Are there any other water motor collectors out there? Also, I would like a source for 4-inch leathers for the pistons.

Bob Farris, Rochelle, Illinois; (815) 384-3715

I found this old corn sheller thrown out beside my neighbor’s barn. I would like to restore it, but unfortunately, there is not enough of the wood left to tell what it originally looked like. If anyone has any information on this sheller, or pictures, I would appreciate copies.

Gerald Rice, 960 Howard Hall Rd., Franklin, KY 42134; (270)647-1387; email: garice1952@gmail.com

Frank A. Haines, (also known as MRZIP)

In the December 2022 issue of Farm Collector, Janet Marchiniak asked for help identifying a steam engine. The photo shows an early 1900s Aultman & Taylor steam traction engine, 60hp on the belt and 20hp pulling with its drawbar. It was the largest of that series.

We own and operate one identical to it at our Yamhill County Heritage Center here in McMinnville, Oregon. Ours is completely restored and operates and looks like new. It is a well-designed and -built machine for 1912. Yes, your engine looks familiar: Ours is identical, except for the headlight.

Frank Schurman, restoration volunteer, Yamhill County Historical Society & Museums

Editor’s note: Thanks, Frank: We appreciate feedback from folks like you!

At Eastern Washington Agricultural Museum (EWAM) shows and events in Pomeroy, Washington, the Treasure Trailer is a popular feature. Donations of old, farm-related items (including yard art) are loaded on a trailer but are not tagged with prices. A potential buyer steps up to the trailer and makes an offer on an item. If the EWAM volunteer manning the trailer smiles, the piece is sold. If the volunteer does not smile, the potential buyer is welcome to make a higher offer. Proceeds support the museum, and unsold items return home with the person who brought them.

On Page 4 of the March 2023 issue of Farm Collector, Derrell Schapner from the Hancock County Ag Museum inquired about the colors of the Easy Way hay loader. This photo shows a restored 1938 New Idea hay loader.

I think Derrell is right about the wooden parts being red. I also think that manufacturers wanted to keep consistent with what they considered to be their iconic colors, so the colors of the hay loader probably remained the same throughout production.

My parents milked a few cows back in the day when I was a “snot-nosed kid”! The barn cats got some in their bowl in the barn, plus some to lick off when they got squirted.

Most was taken to the house (if the cow didn’t step in the bucket) and run through the cream separator. The separated milk was used for the family to drink; beats grocery store milk now days. What we didn’t use at meals, the pigs got.

The cream that Mom didn’t use to make butter was put in the cream can and then taken to town and sold at the creamery.

I vividly remember one trip to town with the full cream can. We lived about 16 miles out. The road was quite rutted and slippery. The old car got in one of those ruts and jerked around and dumped the full cream can over! Not only did it make a mess to clean up, we had no cream to sell, so we turned around and went home and made do with what we had until we went to town the next week or month or whenever!

David Ruark, Pomeroy, WashingtonJoseph Stirling, the son of Jared and Marta Stirling, Menno, South Dakota, is this month’s featured artist. “We recently picked up our latest restoration project, a Cockshutt 30,” says his dad. “Later that week, while painting with his sister, he decided to paint a picture of it. He loves Farm Collector, and Sprouts is his favorite feature.” Joseph will receive a Farm Collector T-shirt: Congratulations, Joseph!

Have a budding artist in your family? Send your kids’ or grandkids’ farm-related artwork to Farm Collector, and we’ll send a T-shirt to the monthly winner. Send submissions to Farm Collector, 1503 SW 42nd St., Topeka, KS 66609-1265. Please include the artist’s name, age and hometown and a recent photograph. A release form will be sent to the parents of each artist whose work is selected for publication; the release must be signed and returned to Farm Collector before the artist’s photo can be published. For more information, contact us at editor@ farmcollector.com.

Joseph Stirling with his painting –and the Cockshutt 30 that inspired it (before restoration).

The genius of pioneer inventors can confound us. Countless contraptions that revolutionized farming in the 19th and early 20th centuries have become contemporary curiosities, or even mysteries. Here are

Answers to the May 2023 items will appear in the July 2023 issue. Answers for new items in this issue must be received by May 5, 2023.

A. Tool is factory-made; no markings.

B. Tool is shown in collapsed position. A lever inside expands the three sides. Measures 12-1/4 inches tall; 10 inches diameter. No markings.

C. Tool measures 9 inches long. Folds three different ways. Cast into tool: Armelee’s PAT. MCH 6 88.

D. No description given.

E. Tool measures 8-1/2 inches long. Marked W.H. Anderson & Son, Detroit, Mich.

F. Tool measures 7-3/4 inches long. No markings. Rope not authentic to the age of the tool.

6 May 2023

Send prints to Farm Collector, 1503 SW 42nd St., Topeka, KS 66609. Send digital images to editor@farmcollector.com.

Photos should be taken in a well-lit area against a plain background. Include dimensions and any markings on the piece. We cannot guarantee every photo will be published, nor can we respond to inquiries regarding when photos will be published. No photos will be returned. Digital photos should be sent as .jpgs at a minimum of 300 dpi.

To identify an item: Send answers (with your name and address) to Farm Collector, 1503 SW 42nd St., Topeka, KS 66609. Email responses may be sent to editor@farmcollector.com.

Answers for new items shown in this issue must be received by May 5, 2023.

Farm Collector

Farm Collector

Leather worker’s tool. Identified by Don Snyder, Decatur, Ill.; Nick Caldiero, Afton, N.Y.; Robert Scholz, Elmo, Mo.; Rick Hall, St. Peters, Mo.; John Wilding, Hermann, Mo.; Robert J. Smith, Craigmont, Idaho; and Stan Wegner, Park City, Mt. “This is a leather worker’s embossing tool called a creaser,” Nick says. “It is often called a saddler’s

maker C.S. Osborne & Co., Newark, N.J., who also produced the leatherworker’s draw gauge shown What is it? Collector Columbus, Kan

produced the leatherworker’s draw gauge shown

B. Hangers for barn carrier track. Identified by Bill Reedy, Brandon, Iowa; David Ruark, Pomeroy, Wash.; Ralph Hurlburt, Raymond, S.D.; Gary Froiland, Stewartville, Minn.; Mark Williams, Pandora, Ohio; Abe D. Mast, Millersburg, Ohio; Rudy Beachy, Readstown, Wis.; and John P. Hermann, Columbia City, Ind. “These open-eyed track hangers are used and Minn.;

E. A tooth from a combine’s spike tooth cylinder. Identified by Rick Borland, Carrollton, Ohio; Bryan Burrell, Fairview, Okla.; Larry Kinnison, Bucklin, Mo.; Bernie Hermans, Milbank, S.D.; Bill Reedy; David Ruark; Terry Yexley, Moore Haven, Fla.; John Wilding; Walter Piontkowski, Goodells, Mich.; Ralph Wilton; Ralph Buettner, Cold Spring, Minn.; Jim Bolt, Corsica, S.D.; Bruce Granger, West Concord, Minn.; Abe Mast; Donald Gibson, Scranton, Iowa; Duane Bjerketvedt, Hennning, Minn.; Harold Kaufman; Stanley Cross, Lamar, Neb.; Robert Kahle, Belle Plaine, Minn.; Wendell Schwab, Venus, Pa.; Ray Armstrong, Roanoke, Ill.; Homer Kreider, Lebanon, Pa.; John O. Drivdahl, Denton, Mt.; Robert Burns, Heyworth, Robert J. Smith; and Jayden Stoddard. submitted by Robert Braton, Barnesville, Minn.

Denton, Mt.; Robert Burns, Heyworth,

GLENN CRAIG LIVING ESTATE JD COLLECTION

ELKTON, Michigan 48731

GLENN CRAIG AT 94 WILL SELL HIS LIFETIME JD TRACTOR COLLECTION & MORE AT A LIVE/SIMULCAST AUCTION HELD AT THE RESIDENCE LOCATED 5 MILES NORTH OF ELKTON, MI. ON ELKTON RD. THEN EAST 2 ½ MILES ON FILION RD. AND ¼ NORTH TO 3672 SOULETOWN RD. (HURON COUNTY, MICHIGAN)

WEDNESDAY JUNE 14, 2023 @ 10:00 AM EST. ONSITE

HI-QUALITY AUCTION, VERY WELL-KEPT COLLECTION. THE CRAIG FAMILY FARMS IS KNOWN FOR BEING METICULOUS OPERATORS

Come away with me, Lucille, in my merry Oldsmobile.” These words, from a popular song written in 1905 by Gus Edwards and Vincent Bryan, reflect the sudden popularity of the little curved-dash Oldsmobile, the first car in America to be produced in large (for the times) numbers.

Yet, the long-running Oldsmobile line came to an end when the last Oldsmobile rolled off the assembly line in April 2004, at the same Lansing, Michigan, plant where they were built for nearly 100 years. While that event caused a stir in the press, most reports failed to mention that Ransom E. Olds, the company’s founder, left his mark on the farm as well as the American road, with products ranging from stationary gasoline engines to his famous automobiles.

Ransom Eli Olds was born in Geneva, Ohio, in June 1864, the youngest son of blacksmith and farmer Pliny Olds. “Ranny” took care of his father’s horses – but hated the smell and the chores – and loved to work in the blacksmith shop.

In 1880, Pliny Olds moved his family to Lansing where he and his eldest son, Wallace, started the P.F. Olds & Son company to build steam engines and repair machinery. Young Ransom worked at the factory as a machinist and also kept the books, while he dreamed of building a selfpropelled vehicle.

By 1887, Ransom bought out his brother’s share and assembled a three-wheeled vehicle powered by a 1hp Olds-made steam engine. Although it ran, the car was badly underpowered and Ransom tinkered with it for

a couple of years. His father told someone at the time, “Ranse thinks he can put an engine in a buggy and make the contraption carry him over the roads. If he doesn’t get killed in his fool undertaking, I’ll be satisfied.”

In about 1891, Ransom patented his first gasoline engine, the first of a long line of Olds engines: a singlecylinder vertical engine with hot-tube ignition. In about 1903, S.S. Morton of York, Pennsylvania, patented a heavy traction engine running gear upon which nearly any gas engine could be mounted for power. Some suggest that Olds adapted his “Olds Safety Gas & Vapor Engines” to the Morton Traction Truck and may even have sold a few as Olds “tractors.”

Olds founded the prosperous Olds Engine Works, building a second and better steam car in 1892 and introducing a 5hp, 1-cylinder gasoline-powered car in 1896. He drove the new gas-powered vehicle around Lansing and attracted lots of attention. It was truly the start of many innovations that Ransom spawned.

In 1897, Ransom finally pulled together enough capital from Lansing businessmen to start a firm called Olds Motor Vehicle Co. Only a few cars were built during the first two years, but after an 1899 merger of the Olds Gasoline Engine Works and the Motor Vehicle Co.

into the Olds Motor Works – with $500,000 in capital – cars started to roll off the line.

One story says that Ransom had only $400 of his own money in the Olds Motor Works. The major investor was Samuel Latta Smith, who was named company president, while Ransom was vice president and general manager. Smith insisted that a new factory be built in Detroit. The new plant, the first in the world designed for automobile manufacturing, was completed in early 1900, and production began shortly thereafter.

The first cars sold for $2,823 or $1,250, depending upon which source you believe. Yet, business didn’t immediately boom. In fact, Ransom described his disappointment with the lagging venture, “We thought we had quite a car, but we soon found out that it was too complicated for the public. That first year we lost $80,000.”

Ransom redesigned his car and came up with a small, one-cylinder runabout that weighed 700 pounds and only cost $650. “My whole idea ... was to have the operation so simple that anyone could run it,” Olds said. The “Merry Oldsmobile” caught on immediately and sold like hotcakes. However, on March 9, 1901,

disaster struck when the Olds factory burned to the ground. James J. Brady, a timekeeper, was able to push one car out of the burning building – the only thing that was saved. As the only pattern available, Olds concentrated all production on the little curved-dash runabout and soon moved part of the plant back to Lansing.

Production soon skyrocketed, despite the tragedy. The company built 425 runabouts in 1901, 2,500 in 1902, 4,000 in 1903 and 5,508 in 1904, far surpassing the numbers of any single car model built up to that time (even Fords).

Olds wanted to keep making a small, inexpensive car, but Sam Smith’s two sons wanted the prestige of a highpriced luxury model to sell to their rich friends. Since Smith was the majority stockholder, the big car faction prevailed. As a result, Ransom retired with a pocketful of money in 1904.

R.E. OLDS DEVELOPS A TRACTOR CUSTOM-MADE FOR USE IN FLORIDA

In 1913, Ransom Olds bought 37,541 acres of ground on the northern shore of Tampa Bay and started a town. Originally named R.E. Olds-On-The-Bay, the awkward name was later changed to Oldsmar. Olds intended his city for working people and had his engineers lay it out with wide, tree-lined streets leading from the bay to downtown.

There was a lot of vegetable farming around the Oldsmar area and Olds decided the neighboring farmers needed a locally built tractor to work the fields. Around the end of World War I, Olds organized the Oldsmar Tractor Co. and built a factory in Oldsmar.

The Oldsmar garden tractor was a small machine weighing 1,270 pounds and powered by a 1-cylinder engine with a 5-inch bore and a 5 1/2-inch stroke. The Oldsmar’s engine was mounted low between the two cast iron drive wheels with angle iron lugs. The operator sat on a lightweight, two-wheeled sulky behind the machine and steered with a horizontal steering wheel connected to a simple curved rack-and-pinion. A small, single-plow bottom with a rolling coulter is mounted ahead of the operator and just beneath the steering mechanism. According to C.H. Wendel’s book Encyclopedia of American Farm Tractors, the tractor sold for $375 in 1920.

Apparently, land clearing was a problem

because the regular plows of the day couldn’t easily break tough palmetto roots. According to one account, those pesky plants even defied a dozer blade. Since the little Oldsmar tractor couldn’t tackle the roots, Ransom located a stronger machine built by the Kardell Tractor & Truck Co., of St. Louis, Missouri, and bought the firm.

Kardell built the 20-32 Kardell “Four-in-One” tractor with a big Waukesha engine, as well as a smaller “Utility 10-20.” – Sam Moore

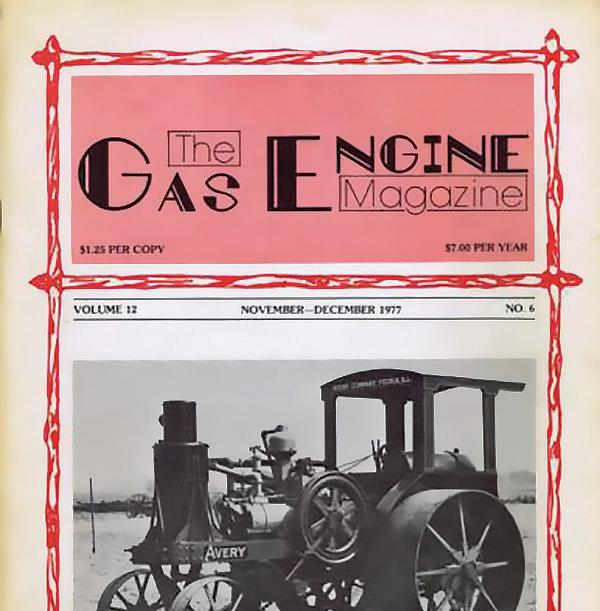

For more information about R.E. Olds and his Oldsmar experiment, see the June 2004 issue of Gas Engine Magazine.

And it’s out with the Olds

Ransom wasn’t out of business for long, and was testing a new car by October 1904. Unable to use his name, Ransom used his initials to name the REO Motor Car Co. The firm built cars until 1936, after which the focus was on trucks until White Motor Co. bought the company in 1957.

Meanwhile, the Smiths continued to build expensive luxury cars, and Oldsmobile sold fewer and fewer of the pricey autos. Only 1,600 were sold in 1906, 1,200 in 1907 and 1,055 in 1908. At that time, William Durant was busily buying up car and accessory plants for his new General Motors Corp., and he snapped up the financially ailing Olds Motor Works on September 12, 1908, for about $17,000 in cash and $3 million worth of company stock.

Oldsmobile quickly became a cornerstone of GM, positioning itself in the center of the automaker’s line-up, with Chevrolet and Pontiac making up the low-priced end and Buick and Cadillac at the high end.

For more than 100 years, the Oldsmobile car has stood for reliability and value. During its more than 90 years with GM, Oldsmobile was known as a builder of high-quality cars, with buyers getting a lot of luxury for relatively little cost. The Oldsmobile was an industry trendsetter as well, and intro-

duced the first chrome-plated trim in 1926, the HydraMatic transmission in 1940, the high-compression engine “Rocket 88” of 1949 and the front-wheel-drive 1966 Toronado.

Roughly 20 years ago, GM decided that it “just couldn’t find a way” to make the Oldsmobile profitable and phased out the line. The last Oldsmobile, an Alero, rolled off the assembly line on Thursday, April 29, 2004. It’s funny, the Oldsmobile 76s, 88s and 98s looked different than most other cars, and GM sold a bunch. Yet, the firm fails when its cars are called Aleros, Intrigues, Bravadas or Silhouettes, and only a dedicated student of the automobile can tell an Oldsmobile from the other identical cars on the market. And GM wonders why they didn’t sell better.

Regardless of that sad end to a venerable company, the lasting impression that R.E. Olds left on America will never fade. FC

To learn more about R.E. Olds and his contribution to American farming and transportation, visit the R.E. Olds Transportation Museum, 240 Museum Dr., Lansing, MI 48933; (517) 372-0529; www.reoldsmuseum.org.

Sam Moore is a longtime Farm Collector columnist. This column originally appeared in the August 2004 issue.

& much more

Zach & Ashley Northway

235 Oak Street, Le Mars, Iowa 51031

(712) 490-5596 • info@flywheel-supply.com website: www.flywheel-supply.com

Over

Wico EK, AH, H1, H4, F4, F6 Coils, points, condensers, Service & Much More. We also supply parts for many other brands.

GASKETS: postage paid

wheel & rear axle brackets $122.13

same kit w/ 2x 9inch & 2x 12inch wheels $304

International LA/LB Cart $216

COILS & MAG PARTS: postage included

Authentic period correct wood case buzz coil $94.50

Authentic wood case single spark coil, great for models $91.93

Low tension coils $94.50

72 Maytag Coil Eismann $124

WE ALSO CARRY PARTS FOR:

We now own & produce the steel stamped mufflers formerly made by Minzel & Elroy of MN!

All gaskets are made in OUR shop, hi quality!

International LA/LB 1.5-2.5hp $35.3 & 3-5hp $38.08 International M 1.5-3hp spark plug & igniter $35.3 Maytag 92 Single & 72 Twin (Not paper gaskets) $15.75 Maytag Upright & 82 $15.75

Briggs 5’s/6’s $21.11

Briggs FH/FI $16.25

Briggs Model B $22.68

Briggs WM/WMB/WI $21.23

Fairbanks ZD $28.27

Lauson (Some gaskets, call)

Johnson Iron Horse 400 & 500 $21.23

Maytag 92/72 ball muffler on hose $56.51

Maytag Upright muffler $42.45

Maytag LeClair for 72 $63.67

John Deere 1.5HP $79.68

ENGINE MUFFLERS: postage paid

All sizes in stock and ship same day!

Custom sizes available, call.

MP=male pipe thread

FP=female pipe thread

International LA/LB 1.5-2.5hp 3/4”MP $29

International LA/LB 3-5hp 1”MP $31

Fairbanks-Morse 1.5hp 1”MP $53

Fairbanks-Morse 3hp 1.5”MP $59.43

Fairbanks-Morse 6hp 2”MP $70.71

Fairbanks-Morse Headless 1.25”MP $50.94

Universal Round Ball

5 inch ball 3/4” or 1” FP $51

10 inch ball 1.25”, 1.5”, 2” FP $65

Stover / Round ball

6 inch ball 3/4” or 1” MP $53

7 inch ball 1”, 1.25”, 1.5” MP $61

Cone / like associated 5.75 inch cone 1”,1.25” MP $63

7 inch cone 1.25”,1.5” MP $64

5.75 inch cone w/ round front 3/4”, 1” MP $55

For more than 100 years, the Oldsmobile car has stood for reliability and value. During its more than 90 years with GM, Oldsmobile was known as a builder of high-quality cars, with buyers getting a lot of luxury for relatively little cost.

The Farm Collector Show Directory is the No. 1 source for the most current and complete show information. This guide has all the information you need for all the antique farm equipment shows in 2023. Each year, the directory features hundreds of pages of event listings and advertisements for tractor and engine shows, swap meets, auctions, threshing bees, and more than 1,000 events featured from coast to coast –and Canada!

In addition, the 2023 Farm Collector Show Directory features our unique S.T.E.A.M Ranking Scale that helps categorize what each show will feature to help attendees choose which shows they want to attend!

Wholesale pricing is also available for resellers. For wholesale prices and ordering, please contact a customer care representative at (866) 624-9388

Item #11758

$16.95

Promo code: MFCPANZ2

For international orders, please call for shipping rates.

Call us toll-free at (866)624-9388 or order online at FarmCollectorShowDirectory.com

For Canada and other foreign orders, please call (785) 274-4366.

Looking for a working show that doesn’t feel like a forced march?

Check out the Antique Engine & Tractor Assn. (AE-TA) in Geneseo, Illinois. Occupying a compact footprint on showgrounds 8 miles north of Geneseo, the club’s annual working farm show in mid-September presents a dizzying array of demonstrations in an easily walkable space.

Established in 1959, the group held shows at several locations before settling in on a 40-acre site donated in 2009 by Hillsdale residents June and Bill Cole in memory of their son, Kevin. The next year, the AE-TA was open for business with a new timber-frame barn, restroom and shower facilities, and a corncrib, sawmill and windmill moved from the club’s previous grounds.

Gearing up for their 62nd annual show this September, the club prioritizes education. “Education of the public, especially the younger generation, is extremely important to us. When this organization started, over 30 percent of the population was on farms. Today, it’s 2-3 percent. Many families are reaching three or four generations away from the farm,” says AE-TA board member Phil Jordan. “Our goal is to educate those generations on how our food was produced and reached the dinner table, along with an understanding of the intense labor it took for their fathers, grandfathers and great-grandfathers to produce that food.”

At the club’s 2022 working farm show, educational demonstrations showcased the blacksmith, sawmill, threshing, horse farming, cane press, plowing, baling and field work. Corn was picked (by hand and mechanically), husked, shelled and put in the crib. An old potato digger turned up a plot of spuds and broomcorn was used to make brooms.

The show feature (John Deere) offered an outstanding display of well restored tractors, including more than a few rare and unusual pieces. A daily parade of tractors and equipment included an informative and entertaining commentary. Inside a beautiful timber-frame barn, a rare Dain tractor

On the far side of the train tracks, a field of corn was a hive of activity, as operators of old mounted, pull-type

and self-propelled pickers mowed down the rows. A vintage manure spreader rolled through a field; horses pulled plows through rich black dirt. In the background, justhusked ears of corn bounced off a bangboard.

Tom Hitzhusen, Geneseo, watched equipment move through the club’s corn field with more than casual attention. Retired from a career in engineering at Deere & Co., he’s been the club’s farmer for the past 15 years, raising 25 acres of corn and 10 acres of beans at the showgrounds. “That gives us enough to demonstrate hand-picking, pull-type pickers and combines,” he says. “And sometimes we have horse-drawn pickers.”

Planting corn that will be harvested by old iron requires a convoluted mental calculation. “The equipment that will harvest this crop was built for 75-bushel corn,” Tom says. “It can’t pick a high-yield crop. And this corn has been bred to stand well. The old pickers can’t get an ear off.” Accordingly, the crop is sprayed two weeks before the show to kill the plant, which also helps when the field is plowed after the show.

For Tom, it is a conundrum. “How can I drop yields? I’m a farmer at heart. I was born to get the highest yield we can,” he says. “But here, we plant wide rows, hold the population down, use an early yield corn and control the amount of nitrogen we put on.”

“Always keep your elbow in. Always be looking three ears ahead. Never look for the wagon.” After giving a corn husking demonstration at the Geneseo show, Dick Humes, Little York, Illinois, rattles of the fundamentals of picking corn by hand. He should know: He’s won his age group in the Illinois state husking competition several times and is a two-time national champion.

His success may be genetic. “I started competing in 1988,” he says. “My dad was a good picker, and after he died, his friends said I should give it a try.” A committed competitor, he trains fairly regularly for an hour a night, a couple times a week.

With more than three decades’ experience in husking contests, Dick does his best to keep the farm country tradition alive. He’s served

Above: A 1973 International 966 with an International 2PR pulltype picker last built in 1970 operated by Garrett Schoonover, Argo, Iowa. Pat Miller, Dixon, Ill., owns the tractor and picker. “Even my dad doesn’t remember picking ear corn,” Pat says. “He was born in 1958 and they weren’t running mounted or pull-type pickers. Back then, a 38-inch row would be common.”

as a coach for three champions in youth divisions, including third-generation picker John Kane, Smithshire, Illinois. “In his first year of picking, he won the nationals,” Dick says.

The McCormick 91 combine Pat Miller was watching on an auction in the spring of 2022 wasn’t bringing much. “The PTO slide was stuck and most of the chains were loose,” he says. “It had been sitting outside and there were bird nests in the elevator.” But it was just what the Dixon, Illinois, man was looking for.

“I’ve been collecting old tractors and restoring tractors in 4-H and FFA since I was 9. We probably have 100 in our museum,” he says. “But what is a tractor without something to pull?”

The McCormick is a perfect fit for Pat’s collection of 10 or 12 antique pickers and combines. “I’ve farmed my whole life and was driving tractors since I can remember,” he says. “But I’ve never done this before, collecting combines and pickers. I grew up with a radio and air conditioning in the cab, but I just like to save old stuff. It’s fun.

“The old pickers and combines, I’ve really seen them take off the last few years,” Pat adds. “There are more and more corn-picking shows, and there’s a lot of action on Facebook. Now they’re starting to bring more: You can’t just sneak in and get one cheap.”

Garrett Schoonover, Argo, Iowa, routinely operates Pat’s International 966 and International 2PR picker. “You just hook on to the wagon, pick a row and try to go straight,” he says.

Nearby, Clint Dixon, Reynolds, Illinois, coaxed a vintage hammer mill to life. Faster and more efficient than burr mills and feed grinders, hammer mills were an immediate hit when they came on the market in the 1920s.

Manufactured by Sears, Roebuck & Co. in the 1940s or ’50s, Clint’s mill features stationary hammers and three progressively smaller screens. It could be used to grind cobs, stalks and hay. Clint and his wife, Martie, demonstrate the mill to grind cobs and use the output as mulch.

The mill is adjustable to the speed of the engine or power unit; Clint generally runs it at 540rpm on his 1951 Dodge Power Wagon. The mill was engineered for 3,100 belt feet/minute.

Launched late in 1945 (possibly inspired by the success of the Willys), the Power Wagon was conceived as an allpurpose farm vehicle. But the market was lukewarm, primarily because of the price. “At $2,000, it was kind of out of reach for the average farmer trying to get out of horses and mules,” Clint says. “It cost almost as much as a 1947 Chrysler Imperial.”

Clint’s Power Wagon is outfitted with the rig’s original 9.00x16 military tires. “They weren’t really popular until the government started using them in World War II,” Clint says. “When Dodge started building these trucks, they used the military tires because there really was no other option to get through mud or snow.”

Clint drives the Power Wagon to nearby shows, but he doesn’t get in a hurry. “It will only go 55mph on a good

Above: Clint Dixon’s 1951 Dodge Power Wagon. Power Wagons were produced as late as 1968; roughly 50,000 were produced.

Far right: Clint’s PTOpowered hammer mill has eight speed adjustments.

Right: Martie and Clint Dixon.

day,” he says. “And that’s okay, because it helps us slow down and enjoy life.”

Producing a throaty roar, a John Deere 550 grain dryer dating to the late 1950s/early 1960s made an unusual display. Donated to the AE-TA by Tom Tygrett, Roseville, Illinois, the batch dryer was designed to support a two-row combine.

“It wouldn’t be able to keep up with modern combines,” Tom says. “It could handle 550 bushels at 10 points moisture removal in about three hours, or about 1,000 bushels a day. It’d normally run on LP. You’d just fill it up and let it run.”

Weighing in at 6,350 pounds, the dryer took 16 minutes to load and 16 minutes to unload. It was filled via a conveyor at the bottom; the dried grain was augered out from the top. Tom kept it on “recirculate” mode during the show.

Back when the John Deere unit came out, he says, most farmers didn’t have storage space for a lot of ear corn. “Then everything took off,” he says. “Grain elevators and continuous corn dryers really came on.”

Bill Zimmerman, Edelstein, Illinois, was hunting for a Ford Model A car when he stumbled onto a rusting hulk of a tractor behind a barn. “I didn’t know what it was,” he says. Ironically, he wasn’t

Left: Bill and Angela Zimmerman with the Thieman tractor, which can be seen on display at the Wheels O’ Time Museum, Dunlap, Ill. Bill estimates that perhaps 500-1,000 Thieman tractors were built.

Below: Early Thiemans’ drive chains were open. Those on later models were enclosed, protecting them from dust and dirt.

completely off-course from his original mission. The tractor – a Thieman kit tractor – had a Ford Model A engine and transmission.

Bill restored cars, not tractors. Still, the rough but complete Thieman hooked him. Produced by Thieman Harvester Co., Albert City, Iowa, the kits were available from the 1930s until about 1942, when American manufacturing output was redirected to the war effort. Buyers provided the engine, drive shaft and rear axle to complete the kit.

Restoration was as straightforward as the tractor itself. “Basically, they just took several pieces of iron and created a tractor,” he says. “There was that big tube; everything else was flat plate. I probably sanded it 10 times. There wasn’t much more you could shine up.”

Steel-wheeled Thiemans are legendary for having a rough ride. This one is on rubber, but the ride quality is little improved. “It’s a fairly light tractor at about 2,000 pounds,” Bill says. “You couldn’t plow with it, but you could use it to cultivate or pull a wagon.”

The Thieman is a crowd pleaser. “When I took it to the 2010 Farm Heritage Days in Wyoming, Illinois,” he says, “it won the award for rustiest tractor.” A year later, after restoration was complete, Bill and the Thieman returned to Farm Heritage Days. “That time it won the award for the shiniest tractor,” he says. FC

At Geneseo, friendly volunteers driving golf carts trolled the gate area at the end of the day, offering attendees a ride to their cars.

For more information: The 62nd annual Antique Engine & Tractor Working Show – featuring International Harvester – will be held Sept. 15-17, 2023, at the showgrounds located at 13451 IL Hwy. 92, 8 miles north of Geneseo, Illinois. Contact: Phil Jordan, (309) 314-5000; email: pm.jordan2591@gmail.com; www.ae-ta.com

Leslie C. McManus is the senior editor of Farm Collector. Contact her at Lmcmanus@ogdenpubs.com.

Whether you’re new to ploughing and need to know the basics for farm work, or are looking to compete in ploughing matches, this handbook is a complete and authoritative guide. This updated second edition includes the current rules for international match ploughing, the scoring system, and ploughing organizations throughout the world. Among the 200 illustrations there are over 150 color photographs specially commissioned to show in detail good practices as well as faults and how to correct them.

By Larry Scheckel

By Larry Scheckel

Farmers have come a long way from the time of the flail and the threshing floor, but the goal has never changed: Separate the oats grain from its stalk. Threshing day on Labor Day, September 5, 2022, brought back a lot of memories from my youth in the 1940s and ’50s on the 238-acre Scheckel farm outside of Seneca, in the heart of Crawford County, Wisconsin.

Fortunately, there is a place to relive those youthful days. It’s on the Monsignor Michael Gorman farm off Highway 171 between Boaz and Rolling Ground, on the western side of Richland County. The 250-acre farm has been in the Gorman family since 1857, handed down through generations of Irish immigrants. It’s located in the Driftless Area, among God’s most beautiful creations.

Monsignor Michael Gorman has been pastor of St. Charles Borromeo’s Church in Chippewa Falls and St. Peter the Apostle Church in Tilden since 2016. Born in Richland Center and raised on the family farm, Monsignor Gorman attended Akan Central Grade School, high school at Richland Center, then St. Francis de Sales College Seminary in Milwaukee and St. Paul

Seminary in St. Paul, Minnesota. He was ordained a Catholic priest in May 1980. He began his priestly duties as associate pastor at St. John the Baptist in Marshfield, then Blessed Sacrament in La Crosse. He studied Canon Law in Rome from 1984-1986.

Monsignor Gorman has held several pivotal posts in the Diocese of La Crosse: Bishop’s secretary, master of ceremonies, director of Catholic Cemeteries, chancellor, moderator of the Curia, director of the Office of Sacred Worship, parochial administrator of 20

Farm CollectorSt. Leo Parish in West Salem and St. Mary Parish in Bangor, pastor of the Annunciation of the Blessed Virgin Mary Parish in Viroqua, Latin instructor at Aquinas High School, rector of St. Joseph the Workman Cathedral in La Crosse, moderator of the Curia a second time, and vicar general.

He is the sixth priest from St. Philip’s parish at Rolling Ground. Eight religious sisters also came out of the St. Philip’s parish. Monsignor Gorman was named prelate of honor by Pope Benedict XVI on October 31, 2012. Yet, with all those duties and responsibilities, Monsignor Gorman remains a farmer at heart.

There can be no threshing day unless there are oats shocks to thresh. To that end, a bunch of us met on August 10 at the O’Kane farm near St. Philip Church at Rolling Ground to cut and shock 2 acres of oats raised by parishioner Mark Burbach. Rolling Ground puts us in Crawford County, a few miles south of Soldiers Grove.

Monsignor Gorman’s 1936 McCormick-Deering grain binder is pulled by a 1941 Farmall H tractor. It’s truly amazing how those mid-20th century machines have held up. Some will soon be 100 years old. I was always intrigued by the knotter on those grain binders. As a kid, I tried to figure out the knotter, but it operated much too quickly. Frankly, it’s still a mystery to me.

We can thank Cyrus McCormick for inventing the reaper and John Appleby for developing the knotter. That combo increased grain production by a factor of 30. That big bull wheel on the binder runs the whole machine: the sickle, the reel, the three canvases, the binding mechanism, the knotter and the bundle discharge. It didn’t take long for us six guys to get the shocking done. It’s a satisfying sight, indeed, to view a field of standing oats shocks.

There’s something else you need to have on threshing day: a threshing dinner. In 2022, it was held at St. Philip Church located about 1 mile east of Rolling Ground off Highway 171. It’s a beautiful edifice, built in 1909.

Monsignor Gorman’s sister, Mary, and her friends prepare and serve a sumptuous potluck dinner at noon for 50-60 people. The desserts are to die for! The threshing dinner and threshing day has been an annual event for nearly 50 years.

I hark back to my early childhood days on the farm when the threshing ring came around to the Scheckel farm. I do believe those farm wives tried to outdo each other in the lavish meals provided for hungry threshers.

Once the threshers’ dinner is concluded, the entourage motors east off

the ridge and into the valley below, some 6 miles to the Gorman farmstead. The good Monsignor had the 1948 McCormick-Deering 28-inchcylinder thresher leveled and belted up to a 1952 Allis Chalmers WD tractor, with all zerks greased. A half dozen men gather around the machinery while spectators view the scene on a higher shaded grassy knoll.

The first wagon load of bundles is pulled into place. Monsignor opens the throttle of the WD with puffs of black smoke wafting skyward. The pulley is engaged and the big beast of a McCormick-Deering thresher arises from the dead, coming to life as the first bundles are tossed onto the feeder chute, the big claw teeth rhythmically gulping for oats bundles.

Soon, a constant yellow plume of straw and chaff from the blower pipe is set against the azure blue Wisconsin sky. Bundle after bundle, the behemoth thresher does its job, all eight belts and five chains working together to remove the oats grain from its stalk.

Monsignor climbs up the steps on the side of the thresher. Threshed oats go up an elevator on the side of the big machine and are dumped in a receiver bucket or weigher. The bucket is counterbalanced by a weight. When full, the bucket opens and dumps the grain into an auger that takes it to a waiting dump box wagon.

At the same time, the dumping bucket operates a geared counter that keeps track of the number of bushels threshed. Two dumping trips of the bucket is one bushel of oats. The counter has three “windows” and operates like the counters used to monitor residential electricity use. Yes, everything is working fine, and Monsignor Gorman retraces his steps to alight on the ground.

He opens the large, galvanized hinged door by the blower fan and inspects a handful of the debris, checking for any kernels that might be escaping up the blower pipe instead of going up the elevator, counted and loaded into the grain bin by an auger.

Threshing complete, the machine must be “put to bed.” The big straw pipe is telescoped to its shortest length. A large gear is turned so the straw pipe is atop and parallel with the thresher, then gently lowered by gearing it to its cradle. The long drive belt reaching from tractor to thresher is removed from the tractor’s pulley and laid out on the ground. A crank on the thresher rolls up the belt and it is secured on the side of the thresher.

The grain auger is removed from the grain bin, swung around and secured by a clamp. The hinged front feeder gate is unfastened and tucked under. The tractor can now back up to the thresher, which is pinned to the tractor for transport to the machine shed where it will be stored until next year.

These threshing machines are a marvel of engineering, perfected over decades of trial and error. The thresher was the largest piece of machinery on the farm and too expensive for most farmers, hence the threshing ring, which traveled from farm to farm.

The threshing machine goes into the machine shed and the New Holland baler, powered by an International 544 tractor, comes out. The crew forks the straw pile into windrows and Monsignor, tractor and baler make circles.

The power take-off is the primary method of transferring power from a tractor to any pulled machine or attached implement. The concept is nearly 100 years old. When PTOs became standard on farm machines in the 1940s and 1950s, the number of accidents increased because loose clothing was sometimes pulled onto the shaft, resulting in bone fractures and loss of limbs, and sometimes ensuring a closed casket.

The Gorman 268 New Holland Hayliner baler is another example of ingenious farm machinery design. These balers were made between 1964 and 1968. It is a marvel to watch the Ujoints, the massive flywheel, the big plunger, the knotters and the belt thrower. The straw bale is squeezed between two wide belts that toss the bale into the trailing wagon. The mechanism allows the farmer to bale hay

Above: Monsignor Gorman’s farm has been in his family for 165 years.

alone, without a worker on the wagon to stack the bales.

With oats in the gravity wagon and bales on a flatbed wagon, the baler is returned to the machine shed. Both wagons are hooked to a pickup truck and oats and straw are returned to the farm from whence they came. Labor Day threshing is done for another year. We give thanks to St. Isadore, the patron saint of farmers. A task which was hard work when we were growing up

has now become a nostalgic pleasure.

Wisconsin Rolling Ground

From start to finish, Peter Rooke’s revised, easy-to-follow narrative will impress and educate both new and experienced hobbyists with exhaustive coverage of the process. In 112 pages, Rooke meticulously leads you through stripping and rebuilding each component of the engine, from bearings to cylinder heads to ignition. Tips along the way cover everything from repairing damaged threads to removing rust and zinc plating.

#5463 $19.95 $15.96

A follow-up to his highly regarded first book (pictured above), this newest gas engine restoration guide from veteran vintage engine restorer Peter Rooke offers a wealth of information for both the new and experienced engine hobbyist. Drawing from his experience repairing and restoring gas engines, Rooke shares the tips and techniques he’s acquired to aid engine restorers in almost every facet of the restoration process.

#7949 $19.95 $15.96

In this comprehensive addition to Motorbooks’ Complete Book Series, tractor historian Robert Pripps provides an amply illustrated, detailed and complete account of Ford tractors, from the earliest Fordsons to the Ford-Fergusons, the Ford N Series, and the Ford “World” tractors manufactured into the 1970s. The only book offering comprehensive coverage of the breadth of collectible Ford tractors, The Complete Book of Classic Ford Tractors is a must-have volume for every tractor enthusiast’s library.

#11212 $45.00 $38.25

In this comprehensive and readable book, tractor expert Jonathan Whitlam tells the story of the development of International Harvester from its North American roots in the 1900s. The book covers developments from the early combustion-engine machines to the merger with Case in 1985 and ownership by Fiat in 1999.

#10907 $24.95 $21.95

Farm Machinery is the definitive book on the current theory and practice of farm mechanization for students and farmers. First published in 1979, the sixth edition incorporates much new text and 280 previously unseen, color photographs illustrating the steady flow of developments in farm mechanization that have taken place over the past decade. Chapters discuss tractors, cultivation and drilling equipment, crop care, harvest machinery, and other equipment found on the farm.

#11627 $34.95 $29.71

As the third volume in author Peter D. Simpson’s Ultimate Tractor series, this 206-page book dives into all the high horsepower, four-wheel-drive articulated machines currently produced worldwide while adding a unique look at rubber track machines, both articulated and rigid framed. Included is company history, and technical specifications, and an abundance of wonderful, full-color photography. #11831 $55.00 $46.75

In Farmall 100 Years, award-winning tractor author, photographer, and historian Randy Leffingwell and prolific tractor historian Robert N. Pripps offer a richly illustrated and detailed book that captures the full story of the iconic tractors. Beautiful photos and rare historical images accompany in-depth analyses of milestone tractors. The engaging text examines engineering developments, their historical context, and key figures. #11801 $50.00 $45.00

Handy Farm Devices, Second Edition, is as useful and pertinent for homesteaders and small-scale farmers today as it was when it was first published nearly 100 years ago. A wealth of labor- and money-saving projects fills this century-old guide to low-tech property maintenance along with easy-tofollow instructions and practical illustrations.

#10715 $14.95 $13.45

With more than 2,000 black-and-white illustrations and clear, practical instructions given by expert handyman and blacksmith Paul N. Hasluck, Metalworking offers everything you need to know to turn a chunk of metal into a useful and well-crafted product. This ultimate, do-it-yourself guide to metalworking is ideal for all handymen, handywomen, and industry professionals — amateur and seasoned alike! #5453 $17.95 $15.95

Internal Fire is the captivating history of the internal combustion engine and the creative individuals who brought it to life. From gunpowder to diesel, the development of these early powerhouses has been recorded from all sides. The influences of new technologies, patents, and obtainable fuels, as well as a growing understanding of the very nature of heat, are all explored.

#11824 $39.95 $33.96

How to Restore Tractor Magnetos is the essential guide to farm tractor electrical systems and offers the tractor restorer all the information needed to restore, repair, and diagnose magnetos. Authored by the late Neil Yerigan, who was a master of working with vintage electronics, the book comprehensively covers how magnetos function as well as how to troubleshoot and repair common problems.

#6384 $24.95 $21.21

VOLUME 1: FIELDWORK

America’s Rural Yesterday transports the reader to another time, when life moved slower and family and community was important. More than 100 photos by famed photographer J.C. Allen show fieldwork, including planting, tilling, harvesting, and more. Also included are shots of threshing, corn shelling, milling, and haystacking. Horses, mules, oxen, vintage tractors, and steam engines provided the power back when rural life was the norm.

#7554 $24.95 $21.95

VOLUME 2: BARN & FARMYARD

Volume 2 of America’s Rural Yesterday includes photos of farmwork performed in dairy, poultry, and hog barns, as well as the wide variety of tasks performed in the barnyard: ensilaging, stock feeding and watering, haymow loading, threshing, corn grinding, butchering, collecting eggs, root cellaring, and much more.

#7555 $24.95 $21.95

VOLUME 3: AT HOME & IN TOWN

This book, the third in the three-volume series, showcases what people did when they weren’t working in the fields, barns, or farmyards in the 1920s-1940s. More than 120 photos show rural families in their kitchens, parlors, and dining rooms. There are photos of going to town and spending time at the library, grocery, general store, school, doctor’s office, and more.

#7556 $24.95 $21.95

VOLUME 4: EARLY TRACTORS

The fourth installment in this series of books using J.C. Allen photos to illustrate how rural life in the first half of the last century, America’s Rural Yesterday Volume IV: Early Tractors, takes the reader back to when these machines were brand new additions to the farmer’s fleet. Featuring over 250 photos from tractors working in farm fields and barnyards from the first half of the 20th century, this book is a must-have for any fan of early tractors and agricultural history.

#11921 $24.95 $21.95

AMERICA’S RURAL YESTERDAY 4-VOLUME SET

Have the entire collection of America’s Rural Yesterday Volume 1, 2, 3, and the newly published volume 4 for one discounted price.

#11938 $99.80 $84.99

Like Henry Ford, Herbert Austin had farming roots. Both brought motoring to the masses and both attempted to take the physical drudgery out of farming by introducing mechanization. This book tells the fascinating and largely untold story of the tractors made by one of Britain’s biggest car makers, and also looks at other uses of Austin engines in the Austin Champ and Gipsy.

#10909 $22.95 $19.99

This closely-researched, highly-illustrated history tells the story of the remarkable David Brown Ltd., one of the largest tractor producers in England during the 20th century. Author Stuart Gibbard interviewed many of the surviving engineers, designers, and other staff involved in the development and marketing of David Brown’s products. Altogether, this is essential reading for anyone interested in English industrial history or tractor history as a whole. This is the first in a trilogy profiling David Brown and its products.

#11625 $48.95 $42.95

In the second installment of this trilogy, Stuart Gibbard tells the story of arguably the most significant period in David Brown Ltd. history. In this period the company became a serious contender on the global market, subsequently establishing their new motto of “mechanizing the world’s farms.” Many of the illustrations have been taken directly from David Brown’s archives and never before seen by the public, making this the perfect read for those interested in the evolution of the tractor industry.

#11626 $54.95 $49.95

AUSTIN TRACTORS

THE DAVID BROWN TRACTOR STORY: PART ONE 1936-1946

THE DAVID BROWN TRACTOR STORY: PART TWO AGRICULTURAL TRACTORS 1949-1964

AUSTIN TRACTORS

THE DAVID BROWN TRACTOR STORY: PART ONE 1936-1946

THE DAVID BROWN TRACTOR STORY: PART TWO AGRICULTURAL TRACTORS 1949-1964

HOW TO RESTORE FARMALL TRACTORS

How to Restore Farmall Tractors walks you through the complete restoration of your red machine, from disassembly to engine rebuild, electrics, painting, and final detailing. Packed with hundreds of helpful step-by-step photographs, proven tips and techniques, and money-saving advice from restorers who know what works, this will be the only guide you need to restore your favorite red tractor.

#10564 $32.99 $29.99

DIESEL’S ENGINE

This book is a fantastic resource for serious fans of engine evolution and a great read as well. If you are interested in how the combustion engine came to be, this work by C. Lyle Cummins Jr. is vital reading. Cummins covers in dramatic detail the entire sweep of Rudolf Diesel’s original ideas and uses black and white photos and period line drawings to further transport you into Diesel’s world. #11825 $75.00 $64.99

THE COMPLETE BOOK OF JOHN DEERE TRACTORS: THE FIRST 100 YEARS

This fact-packed volume takes you through dozens of John Deere farm models, beginning with the 1892 Waterloo Boy and ending with the game-changing New Generation and Generation II lines. Illustrated with incredible color photography and period advertising, this is an essential edition for the library of any Deere fanatic.

#10151 $45.00 $38.25

Explore how the invention and evolution of agricultural technology transformed the farmer’s day-to-day life in Machine Marvels: Revolutionary Red Tractors. The book takes you on a journey that begins in 1830, exploring the pivotal tractors and harvesting machines built by Case IH and their heritage brands. Each piece of equipment comes to life with rich historical and beautiful contemporary photographs of the machine, accompanied by an engrossing narrative and detailed graphics that illustrate the history, mechanics, engineering, and physics of these ground-breaking tractors. For ages 8-12. #11827 $29.95 $27.95

To order, call toll-free 1-866-624-9388 (outside the United States and for customer service, call 785-274-4366) or go to

YEARS OF FARM TRACTORS

Seventy Years of Farm Tractors traces the evolution of the farm tractor. Covering a total of 100 manufacturers in alphabetic order, author Brian Bell gives a history of each company and its major models. Illustrated with a wealth of photographs and extracts from sales literature, this informative text provides a complete overview perfect for any tractor enthusiast.

#10040 $27.99 $25.99

This book fully describes every part of a farm engine and boiler, giving complete directions for the safe and economical management of both. Included are chapters on farm engine economy (with special attention to traction and gasoline farm engines) and a chapter on the science of successful threshing. The book abounds with precision artwork and cutaway illustrations showing the different parts of a boiler and engine, and nearly every make of traction engine.

#8263 $12.95 $10.95

FARM MECHANICS: THE ORIGINAL

1922 EDITION

An essential agricultural text originally published in 1922, Farm Mechanics is a detailed but easy to understand manual outlining all the important aspects of working the land. This guide is both a historical reference for those interested in the history of agriculture and a commonsense tool that outlines essential agricultural skills. #9282 $12.95 $10.95

OILY HANDS AND THE SMELL OF DIESEL: TALES OF A FORD DEALER ENGINEER IN THE 1960S

Oily Hands and the Smell of Diesel provides a view that no book has before — the inside story of the agricultural machinery repair trade. First employed as an apprentice, then moving his way up to an engineer, David Harris gives an entertaining, informative personal account of his time at a Ford main tractor dealership.

#11624 $24.95 $21.21

The Old Threshers organization at Mount Pleasant, Iowa, stores my Rotary Reaper combine on an International Harvester Farmall F-20. I did not get around to checking it out in 2020, as there was no show that year. So, in July 2021, I went down to look at it. One rear tire on the F-20 had a history of a slow leak, but this time it was completely flat.

In early August, I took an air compressor down and pumped it up the day before the Mount Pleasant crew began pulling machines out of storage in preparation for display at the upcoming show. The next day, my son-in-law, Larry Gugel, called to say the tire was flat before the tractor was pulled out. He and Norm Bushart found an air compressor so it could be moved and parked.

Ten days before the show, my son, Eric, and I went down with a pickup load of tools, his air compressor and a lot of hose. The combine is semi-mounted on the right side of the F-20. Of course, the flat tire was on the right side of the tractor and the combine. That meant the combine had to be demounted and propped up. Then the tractor could be rolled back, keeping the bin somewhat stabilized.

There is a subframe under the combine unit. The central part of this tube frame is a 3-inch pipe. On the outer end of the pipe is a tandem-wheel arrangement designed to make the combine ride more smoothly. The front wheel on this was originally turned by a rod from the tractor’s front wheels. I replaced that with a caster wheel.

The other end of the 3-inch pipe had a flat plate welded on it with seven 3/4-inch holes drilled in it. There is a subframe of 3-inch pipe under the center line of the F-20 starting in back of the front wheels and going past the drawbar. Ahead of the rear wheel, welded to the center pipe at right angles, was a 3-inch pipe that had an iron plate welded to it that matched up to a plate on the combine. There are also a couple 3/4-inch angle truss rods that help contain the stress.

The two flat iron plates were bolted together with seven 5/8inch bolts to tie the tractor and combine unit together. The slides on the U-joints would not come apart, so we unbolted the right-angle gear box (we had gotten the sliding shaft off the back of the gear box), so we could leave the gear box with the combine unit when we moved the tractor away.

We put blocks under the inside of the combine and under the header. For some time, we put up with the tipping bin, before finally putting an angle block to the F-20 frame to level it up when we got ready to bolt the two iron plates together.

Then we could proceed with the handyman jack to get the tractor weight off the tire and get the valve core out to get the air completely out of the tube. Any of you who have ever worked on a stiff, 50-year-old, dried-out, hard rubber tire, to get it off the bead to drop it in the drop center of the rim, will know what an aggravating job it is. Those guys who bust and fix tires sure earn their wages.

After a few “under your breath” remarks (as my dad said, some of those machinery designers needed to have their heads examined), we finally got one side of the tire over the rim and pulled out the tube. It was a 38-inch tube in a 36-inch tire but it had no wrinkles. We even took the time to clean off the rim, checking it out and getting the rust and dirt out of it. At some time, there had been calcium chloride in the tires, so the rim was really rusty. We hammered on it and wire-brushed it. We found the hole in the tube and got it patched.

Then we went in search of a water tank so we could check for additional leaks. Norm Bushart hauled us around in his golf cart until we found a slough under a bicycle trail bridge with enough water to dip the tube in (there were no additional leaks). Then we began the process of prying and beating

that tire back on without pinching the tube. We aired up the tire and put some soap suds around the valve stem to check for leaks. There were still no leaks, so the tire was reinstalled on the tractor.

To remount the combine, we parked the pickup ahead of the combine and used a come-along to pull the F-20 forward to where we could bolt it to the combine. Getting that done took a lot of prying and wrenching. Finally, we got it together like it was supposed to be. We gathered up all our tools, jacks and blocks. In the process, Eric lost the air chuck to his air compressor. After 5 p.m., we headed home, the whole day shot. As we had worked through dinner, we made a stop at the ice cream place and got two milkshakes. They were gone by the time we got a mile west of Mount Pleasant.

Richard Stout lives in Washington, Iowa. He is assisted in his writing endeavors by his granddaughter, Ashley Stout.

From what I have read, Thomas Edison envisioned using direct current (DC) for power. Thankfully, that never came to fruition, as DC does not travel long distances efficiently. Its main use today is in diesel electric locomotives, where it is a good fit.

One day, while I was giving a group of ladies a tour of our museum, an older lady looked up at our Wincharger and said something to the effect that, when she was a kid, they could listen to “The Lone Ranger” after school only if the wind was blowing. If there was no wind, the battery would not stand the strain of the drain. There’d be too little energy left for Dad to hear the evening news with Gabriel Heatter!

The Wincharger pictured here (bottom left, opposite page) was sold to be roofmounted with the express purpose of providing a few amps of 6-volt power, being able to power more than just a radio. Those of us who are old enough can remember the cheery glow coming from the radio, as well as the radio being warm to the touch, in contrast to our transistor units of today, where a little 9-volt battery would last for weeks.

The silver paddles on the unit pictured swing out to prevent over-speeding, acting as “air brakes.” The larger three-

blade unit (bottom right, opposite page) is believed to be from Allied-Jacobs, developed by Mr. Jacobs, an early proponent of wind power. Fortunately, this set of blades was laying in the back of a pickup driven by a fellow who stopped to buy gas at my brother Mike’s station, and Mike bought the blades.

Thinking back, someone many years ago got highline power and had the presence of mind to take the wind generator down, as these blades show very little wear and the paint is intact. On the back side of the blades, close to the hub, are governor weights designed to turn the blades straighter, to avoid overspeeding.

The blades were carefully balanced. One has no weights, the others come to this one. Small red teardrops are several ply thick, in some places three or so, others only one or two. Thus, the unit was well-balanced and would run without vibration.

I offered to pay my brother, but he retorted, “None of your d*** business what I paid! You can have them for the museum!” (Thanks, Mike!)

Delco Light made storage battery generating systems from 1916 to 1947. The most popular was the 32-volt unit, with wind as well as a gas engine to keep the batteries charged. These involved 16 2-volt batteries (top left, opposite page) and required keeping the batteries “topped up” with distilled water often if used hard.

In our travels as well drillers, we often find items of interest. The piece shown was, at one time, a large wind generator, as indicated by the size of the tail. This would have produced a fair amount of energy. So it goes. FC

Jim and Joan Lacey operate Little Village Farm, a museum of farm collectibles housed in 10 buildings at their home near Dell Rapids, S.D. Contact them at (605) 428-5979.

J 19th Annual American Farm Heritage Museum Farm Heritage Days. July 28-30 Greenvile, IL. Features: Prairie tractors & Oddballs and Orphans, and Sideshaft & Economy engines. Directions: 1395 Museum Ave, zip code 62246; I-70 exit 45, 45 miles east of St. Louis, turn south off interstate and make first left onto Museum Avenue. Contact: Brent Adkins, 217-8364180; email: amheritagemuseum@yahoo.com Steve Loos, 618-667-9140. www.americanheritagemuseum.org Facebook: American Farm Heritage Museum.

52nd Annual Sandwich Early Day Engine & Tractor Show. June 23-24, 2023. Featuring Haish built engines (Appleton, Chanticleer, & Great Western), Rock Island IHC Tractors. Sandwich Tracor Ride June 23rd. Sandwich Fairgrounds, 1401 Suydam Rd., Sandwich, IL. Show info: Ryan 815-354-5549. Look us up on Facebook Sandwich Early Day Engine Club. Email - sandwichengineclub@yahoo.com, sandwichengineclub.com

Michigan Flywheelers Museum's Swap Meet and Flea Market. Friday, June 9th and Saturday, June 10th, 2023. South Haven, MI. Interested in selling? Registration starts Thursday, June 8th. No political items/weapons allowed. Call 269639-2010 or go to www.michiganflywheelers. org for more info.

Antique Farm Equipment days our 22nd annual show. Friday May 5th & Saturday May 6th 2023 - Wayne County Regional Fair Grounds, Goldsboro, NC. Admission Free. 8:00am - 5:00pm both days. Sponsored by: Eastern Carolina Vintage Farm Equipment Club. Food and Drink

Available Saturday only. Saturday events: Parade of Power 10:00am, Silent Auction, items donated new & old to support our FFA Scholarship Program: Antique Tractors, Hit & Miss Engines and Farm Equipment on display. Vendors with items for sale. For more show information call Kenneth Price 919-398-2649 - email Mac Kornegay at maccfs@yahoo.com or call 919222-6554.

LATHROP’S 45TH ANNUAL ANTIQUE CAR, TRACTOR & ENGINE SHOW

Largest russeLL sawmiLL in OperatiOn

JUNE 15-18, 2023

PARADE OF POWER

FRI & SAT-4 PM & SUN- 1:00 PM

FEATURE TRACTORS FIRST TRACTOR CRUISE

THUR. MORNING

HEATH HISEL 816-812-0858

TRACTOR

FOR INFORMATION ON TRACTOR PULL Gary & Mary Olsen 15187 Nickel Ave. Altamont, MO. 660-367-2330 660-334-0733 (cell)

Not Responsible for Accidents or Theft FOR SHOW INFORMATION CONTACT

Jim Plowman, Lathrop, MO. 816-528-3511 or 816-896-5546 Cell VISIT OUR WEBSITE AT www.lathropantique.com

INDIANA’S JOHNSON COUNTY ANTIQUE MACHINERY ASSN.

JUNE 15-18, 2023

FEATURING : OLIVER, HART PARR CO-OP, COCKSHUTT & BLACKHAWK TRACTORS & EQUIPMENT, CANADIAN BUILT GAS ENGINES, ANTIQUE TRUCKS & CARS

Vendors/Flea Market/Swap Meet /General Info/Equipment: Dwayne Hansford ............(317) 512-0493

FRIDAY: Tractorcade

DAILY: Parades, Flea Market, Crafts, Children’s Activities & Pedal Pulls, Live Entertainment, Sawmill, Wheat Threshing/Baling, Rock Crushing, Combining, Tractor Pulls, Field Demos, Train Rides, Hill’s Fort and Lil’ Red Barn Museum Displays. Fun for the whole family!

CONTACTS: General Info ...............................618-664-9733 Vendors ............618-882-8535 or 618-664-9733 Camping .....................................217-825-8412 Tractorcade ................................618-910-2669

FOR INFORMATION CONTACT: Rick Custer, President (304)229-2101 (evenings)

Flea Markets: Jessica Frye (540) 327-0579

Heflin (540) 514-5854 Tractor Pull: Charlie Gray (540)533-8827

COST: Classified ads are $1.35 per word with a 20 word minimum. For photo with your ad, enclose $25 per photo. For classified display ads –those with special borders or type – call Terri Keitel at Farm Collector, 800-678-5779. Classified display ads are $65 per column inch (color). Bold words only $2 per word.

CLASSIFIED COMBO SPECIAL

Place your ad in both farm collectible publications – Gas Engine Magazine and Farm Collector – for $2.25 per word. Save up to 22 cents per word with double the exposure!

SEND PAYMENT TO: Farm Collector, Attn: Advertising, 1503 S.W. 42nd St., Topeka, KS 66609.

IMPORTANT! Don’t forget to indicate ad classification and mark with “For Sale” or “Wanted.” Classifications appear below. Please write neatly. We reserve the right to edit your ad for consistency and clarity, and may reject any ad.

JOHN DEERE MAIN BEARINGS FOR ALL 2-CYLINDER ENGINES! 100% Manufactured in the U.S.A. Made like the originals! Center Cam Bearings, Center Main Bearings and Rod Bearings Made-to-order / special I.D. & O.D.s /Installation & machining available. MANITOWOC MOTOR MACHINING & PARTS, INC. www.motormachining.com / toll free 1-800666-9129

PAYMENT POLICY: Ads must be prepaid by check in U.S. funds, or charged to MasterCard, VISA, Discover or American Express credit card. Remember to include your name and address, and/or phone number in the word count.

MAIL YOUR AD TO: FARM COLLECTOR MAGAZINE 1503 SW 42ND STREET TOPEKA, KS 66609 classifieds@FarmCollector.com

Ads received after the deadline will be held over for the next issue unless indicated otherwise.

PLEASE NOTE THE DEADLINES BELOW FOR THE NEXT FOUR ISSUES.

ISSUE

June 23

July 23

August 23

September 23

DEADLINE

April 3 2023

May 1 2023

June 1 2023

July 5 2023

Farm Collector may refuse to publish any advertisement at any time, according to our discretion. However, we are dedicated to providing our readers with the broadest range of alternatives possible. We believe our readers are generally intelligent, and trust them to exercise their own good judgment when choosing whether to patronize our advertisers. We cannot verify all claims made by advertisers. Please consider any advertiser’s claims carefully before buying.

– Bill Uhler, Publisher, Farm CollectorPurchase online at Amazon.com or send check for $26 to Linda Laird, 1432 S. San Luis, Green Valley AZ 85614

Volume IV of The History of Old Time Farm Implement Companies and the Wrenches they issued is ready. The book contains 283 pages, pictures over 700 new wrenches and the history of 117 new companies. The supplement has over 6800 part numbers matched to the company that issued the wrench. To order, send a check for $60 to P. T. Rathbone, 6767 Pershall Road, Marsing, ID 83639. rluckystarranch@ gmail.com The price includes postage, other countries please call 208-896-4478 for a quote. Volume I is available for $80, Vol II & III, $55 each. Vol I, II & III, for

3 books for sale of collected thoughts and rural humor.

Behind the Muffler $20

Behind the Fence $30

Behind the Motometer $10

Total of 300 pages. All 3 for $50. Mail check to Bob Frey, 104 Snyders Rd., Phillipsburg, NJ 08865

www.FarmCollector.com

HORSELESS CARRIAGE Replica: Use riding lawnmower motor, transmission and differential. 26” wheels, 52” wide, 82” long and 36” wide seat for two. 1” square steel tube frame, centrifugal clutch, 8-10 MPH speed, 5-8 hp engine. Twenty pages computer-drawn detailed plans, parts supply and photos. Plans $20 each model. Check or money order. Jimmy Woods, P.O. Box 216, Coker, AL 35452; 205-339-8138.

Carburetor, Water Pump Rebuilding, 6 Month Warranty. Farmers Service Incorporated. 8:30 a.m. to 5:30 p.m. EST; 330-482-4180; www.farmersserviceinc.com DECAL (800)286-2171 www.tractordecal.com

Wanted: Looking for old hit-and-miss gas engines to buy. 614-306-0908 or gasenginetom@hotmail.com

Wanted: Always buying hit-and-miss flywheel gas engines, big or small, one or whole collection. 419789-1159 or jon@sideshaft.com (OH)

FOR SALE: McCormic-Deering threshing machine like new, stored inside. 28 inch cyl, 46 inch sep, Machine # NO D82706 North Dakota---701-320-1825

Life size aluminum grizzly bear $2,500. Great for farm or business display. Delivery possible. 785-488-5150

1948 or 1949 McCormick Deering 28 inch threshing machine on rubber - 28 inch. Always shedded with all belts. Call Ronn at 702-606-2020 or 702-862-9492.

Downsizing my Collection: JD 4 bottom Gang Plow with 3 lift handles, very good condition. MM Moline Plow sugar beet lifters. JD Sulky Plow. JD Hit-N-Miss engines Type E. JD No. 12 Pull Type - combine. Contact: Jim Neuwirth 308-225-1967. Scottsbluff, NE. Lots of others, just ask.

Any type, no tooling or minimum for most gaskets. Free online quotations. www.gasketstogo.com

New and used JD two cylinder parts. Specializing in H, M, MT, 40,420, 430, GP, 800 and 801 3-points & parts. Also: See my eBay store for specials and NOS parts. Many reproduction parts. Dave Cook Tractor Parts, 715-373-2092. Morning calls are Best.

Tractor Manuals and Literature. Large selection available. Jim Robinett, 5141 Kimball Rd, Ontario, OR; 97914. E-mail: tractrmnul@aol.com. 206-713-3441.

duckcall1961@yahoo.com

Quarterly “Bang Board” newsletter. Corn History Informational Books Available Find us on Facebook

Spur, helical and worm gears. Pinion and spline shafts. Made to specs or duplicate original. Elmridge Machine & Gear, 94 Fairview Rd, Lititz PA 17543 717664-1079

TURBOCHARGER KITS ANTIQUE GAS TRACTORS FARMALL M, SUPER M 400 450. W9 600-650. FARMALL H, SUPER H, 300-350. INTERNATIONAL 460-806, FARM KIT AND 4 BARREL PULLING KITS. ALLIS CHALMERS WC-WD45. OLIVER 77-881650. Oliver diesel. MASSEY HARRIS 44-444. KEYSTONE TURBO LLC, 2128 DAYTON-SMICKSBURG ROAD,SMICKSBURG PA16256 814-257-8506 duddy1@windstream.com keystoneturbollc.com

Next Generation Magneto Repair, 3rd generation, Dave Temple 856 Willow Brook St. N.E. Owatonna MN, 55060; 507-339-1470.

Steering cylinder repair.New replacement parts manufactured by us. Case-200,300,400,500 series tractors. Ford-700,800,900 series tractors. New pistons, rods, seals and cylinders. Bob Hunter, Pioneer Hydraulics, 5807 E Hayward Rd, Waukomis, Okla.73773. bhunter772@gmail.com, 580-603-0063.

Carr's Repair: We got you Covered! Restore those powerhouses back to original! New IH sleeves & piston kits for IH 9, IH 6 and IH MD,450D, W-9- 650 series gas and diesel tractors and John Deere, D and R piston kits, 720and 830 Diesel kits. Int'l Falls, MN No Sunday calls. Ph 807 487 2548, www. carrsrepairvintageparts.com

For Sale: Grade One plow handles, $50 per pair, postpaid. Beverly Egbers, 326 County Road 24, Hooper, NE 68031; 402-567-2588.

Obsolete water pump? Let me rebuild yours. Mark, 623-205-4482; waterpumprebuilder@gmail.com

Personalized, Magnetic, Weatherproof Display Signs Perfect for Antique Tractor Parades and Shows! Visit www.TheBadgeFactory.com or call 410-239-3368 to order. Take 10% Off with Promo Code: COLLECTOR

www.magneto-repair.com

Looking for old hit miss engines, parts, models and/or entire collections. 614-3060908 or gasenginetom@hotmail.com. (OH)

Wanted: "Want to buy Chase Manufacturing Company, Mason City, Iowa made engines and advertising "My registry of Chase Mfg. Co. engines contains engines: 9, 49, 52, 96, 101, 599, and 805 as of June, 2021. Email: rogerwhite57@ gmail.com. WY

Wanted: Rebuilder of Blacksmith Forge Bellows for Museum. 563-946-2023 (IA)

Like to buy any type of old farm equipment, one piece or whole collection, salesman samples, country store, corn shellers, anything farm related, advertising signs, old wood signs. Leave message 574-304-4587

e history of Deere & Company is several stories at once. John Deere’s Company - Volume 1: From the Steel Plow to the Tractor 1837-1927 is the story of rural and small-town America from the time eastern farmers began moving into the Midwest in the early 1800s, through the American industrial revolution of the late 19th century and up to the creation of the rst John Deere tractors.