2 minute read

Case #3

By: Tyler Hendricks, DDS

A 64-year-old male presented to the OU AEGD program with a chief complaint of “I need to get my teeth out and get dentures.” The patient presents with a complex medical history significant for 50 pack-year smoking history, Type II diabetes, history of heart attack and stroke, spinal disc degeneration, and fibromyalgia. Clinical findings showed that the patient had numerous grossly carious teeth with periodontal mobility ranging from class I to III, classifying him with a periodontitis stage IV, grade C diagnosis. Radiographic findings reflected the clinical diagnoses as well as multiple teeth with periapical radiolucencies.

Advertisement

After completion of a comprehensive exam and review of the treatment options, the patient decided on full-mouth extractions, placement of two mandibular implants, and a maxillary conventional denture with a mandibular 2-implant overdenture as his final restorations.

The denture fabrication process requires multiple appointments, which results in a significant amount of chair time. Digital dentistry has allowed this process to be somewhat streamlined to decrease treatment time for patients. This patient’s treatment was completed using a digital workflow for his record-taking and TrueDent 3D printed, monolithic, class II acrylic resin dentures.

Due to the patient’s complex medical history, his treatment was phased and sequenced accordingly. His maxillary and mandibular teeth were extracted in two separate appointments. Atraumatic extractions were completed with careful attention to preservation of the buccal plate. Two immediate mandibular implants were placed and primary stability was achieved.

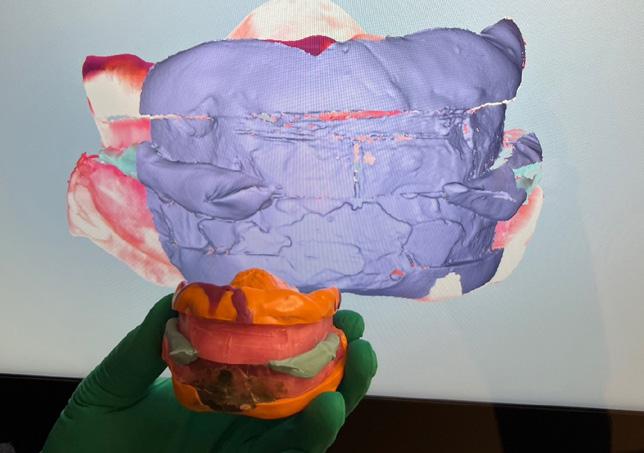

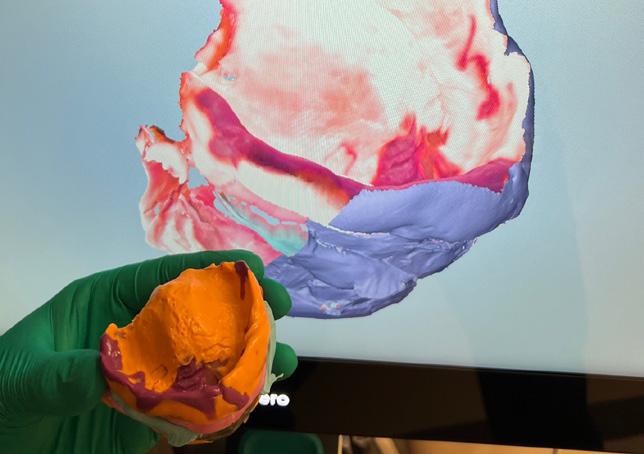

After twelve weeks of healing, the patient was ready for his final restorations. His denture records were completed in a single visit. During this appointment, diagnostic records were made. Alginate impressions were made and poured Snapstone to fabricate custom trays with wax rims. These custom trays were then used to make a PVS wash impression, and wax rims were shaped to establish proper OVD. A digital scanner was used to record the impressions and to digitize his records. The intaglio and cameo surfaces of both impressions, the borders, and the bite at established OVD was scanned. This allows the laboratory to be able to accurately model the patient’s anatomy and can have the TrueDent 3D denture fit with precision. The records were electronically sent to the lab for printing of his dentures (Figure 1, 2).

Digitizing the records allows future flexibility to be able to reprint dentures with any adjustments needed at lower cost and conveniently quick compared to remaking dentures from scratch in the future if they were to break.

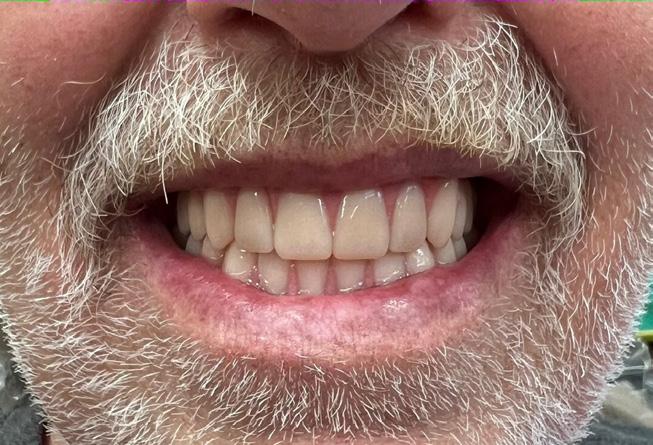

The TrueDent 3D printed dentures were delivered (Figure 3, 4) with proper extensions, stability, and retention. The mandibular implant locators were then luted chairside using Unifast Trad acrylic resin to finalize his lower overdenture. Adjustments to the dentures were made as needed, along with appropriate recall and follow up.

Digital dentistry is changing the way dentistry is practiced, and implementing a digital workflow can save not only chair time, but streamlines and eases appointments for the clinician, the patient, and the laboratory.

About The Author

Dr. Tyler Hendricks is originally from Saginaw, Michigan. He received his bachelors degree in Human Biology from Michigan State University with a minor in Sociology. He received his doctorate from The University of Michigan School of Dentistry in 2022. After completion of the AEGD residency at OU College of Dentistry, he will be an associate in a private practice located back in his home state of Michigan. Go Green!"