6 minute read

Beyond the End of the Road

How Spiers New Technology recycles and repurposes 'spent' EV batteries

by JoMarie Ramsey

At the heart of modern electric vehicles (EV) are lithium-ion batteries. But what happens when they've outlived their initial use?

Spiers New Technology, recently acquired by Cox Automotive EV Battery Solutions, is a trailblazing recycling facility located right here in Norman/Oklahoma/South Oklahoma City, and it's at the forefront of answering that question.

“It's a common misperception that once an EV battery's life ends, it's useless,” said Tyler Helps, director of business development at Spiers. “Our mission is to extend the economic life of these battery packs. They make up about 40% of an EV's cost, and it's essential for the vehicle's residual value.”

Over the past two years, electric vehicles have rapidly gained popularity, and their availability in the market has increased from 2% to 5% of all cars, Helps said. However, the rise in popularity of EVs has raised questions about its viability and posed challenges. The commitment to the entire EV battery life cycle is at the heart of Spiers New Technology's mission. Unlike conventional vehicles that run on fossil fuels, EVs rely on massive lithium-ion batteries. While these batteries have a substantial first lifespan, they don’t last forever, Helps said.

If improperly handled, these batteries pose environmental hazards. Spiers, however, offers a comprehensive solution that tackles this issue head-on. Their cutting-edge process involves recycling, storage and logistics management, focusing on extending the first life of EV batteries.

“There’s a phrase, reduce, reuse, recycle, that often gets used around sustainability projects, and that’s what we’re doing here,” Helps said. “Once an EV battery has failed, companies send us the batteries. If the battery is viable, we repair it so it can be reused in another vehicle.”

Reuse

Once their efficiency drops below a certain point for vehicular use, employees at Spiers extend their first life, maximizing the use of these batteries before they're considered for recycling. The recycling and repurposing process is thorough. A battery first undergoes rigorous tests. If it passes, it’s primed for reuse in another vehicle, Helps said.

For every Original Equipment Manufacturer (OEM), like Chevrolet and Ford, there are specific standards dictating how batteries are produced and tested, Helps said. These standards often mirror rigorous evaluations that batteries undergo during their initial creation. To cater to these diverse requirements, Spiers has crafted a refined system.

“Each of the production lines we have is distinctly organized by its respective OEM,” said Matthew Ellis, a senior sales engineer with Cox Automotive EV Battery Solutions. “This meticulous segregation ensures that recycled batteries from different manufacturers don't compromise on quality or performance.”

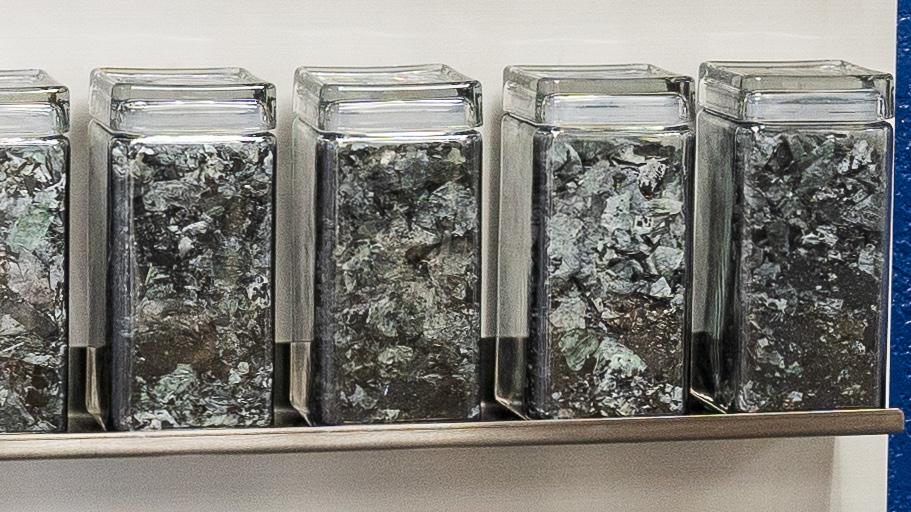

Once a battery can no longer be put back into a vehicle, these batteries undergo a transformative process. Batteries undergo a refining procedure, extracting key components like nickel, lithium and cobalt. The outcome is known as ‘black mass', Ellis said.

“Think of it like the pancake mix ‘Bisquick,’” Helps noted, “It's everything you need to make a battery cell. Add a bit of water, shake, and voila!”

These are then reintroduced into production, reducing the need for raw materials required for a new battery. Notably, the black mass produced by Spiers remains domestic.

“It's used in the production of U.S. lithium-ion batteries,” Ellis said. “Essentially, vehicles in the United States will potentially run on batteries recycled right here.”

The potential for recycling goes beyond just EVs. Batteries that no longer function in cars might still have potential for other applications.

Recycle

“A vehicle requires a lot of power, but once a battery can't provide that, it can still serve in residential or commercial settings,” Ellis said. “Basically, any setting other than a vehicle.”

The second life energy storage system (ESS) is a fascinating application on the horizon. As our electric grid ages, we need more stable, smart grids, and these systems provide that stability, Helps said.

“Energy companies have to design their entire infrastructure to handle that peak power requirement,” said Daniel Lofland, OEC’s energy efficiency solutions specialist. “If every commercial entity only used a steady amount of power, the infrastructure costs would be significantly lower. But, when sudden spikes in demand occur, it stresses the grid.”

By using an ESS, companies can store excess energy during off-peak hours and then deploy it during high-demand periods, effectively smoothing out their energy consumption, Helps said. This reduces the strain on the grid and ensures that the company doesn't hit those high peak usage times, which would drive up their energy bills.

“Think of it as a buffer or reservoir that evens out the flow of energy, similar to how a dam regulates the flow of water,” Ellis said.

Furthermore, as the demand for renewable energy sources like solar and wind increases, the role of energy storage systems becomes even more crucial. These energy sources are intermittent, meaning there might be times when there's an overproduction of energy (on a sunny or windy day) and times when there's hardly any production at all (on a cloudy or calm day), Helps said.

ESS can store the excess energy produced on productive days and release it during the less productive ones, ensuring a consistent supply In a world increasingly focused on sustainability and efficient energy usage, concepts like these are an exciting solution in the transition to more renewable energy, Helps said.

Moreover, the concept of 'second life' for batteries that Helps and Ellis touched upon is an essential facet of sustainability.

“If every battery that was no longer suitable for vehicle use was discarded immediately,” Helps said, “we would be missing out on a massive opportunity for continued utility.”

By repurposing these batteries for less demanding tasks, Spiers is significantly extending their lifecycle, reducing waste and further driving down the environmental footprint of battery usage. In essence, Spiers is not just solving a problem; it's charting the course for a more sustainable future in transportation. As the world shifts gears towards electrification, companies like Spiers ensure this transition is as smooth, efficient, and environmentally friendly as possible.

As the EV market continues its upward trajectory, the efforts of Spiers New Technology and Cox Automotive Battery Solutions prove that sustainability and innovation can indeed go hand in hand. For every member of the OEC, this narrative offers a glimpse of the brighter, cleaner future on the road ahead.