PROFITABLE PRODUCTION STRATEGIES www.cottonfarming.com ONE GROWER PUBLISHING, LLC DECEMBER 2022 Cotton Represented South Carolina And Georgia Producers Named 2022 Southeastern Farmers Of e Year

The best way to thrive this season is to be ready for the ones that follow. And with proven data and results of PhytoGen® cottonseed, you can be confident your operation is ready to thrive for seasons to come. Learn more at PhytoGen.com.

¹2020 Mississippi State University (MSU) On-Farm Cotton Demonstration Trials. 2PhytoGen® brand PHY 411 W3FE outyielded the best Deltapine variety by 87 lb./A in the MSU Official Variety Trials.

™® Trademarks of Corteva Agriscience and its affiliated companies. The Enlist® weed control system is owned and developed by Corteva Agriscience LLC. © 2022 Corteva. (09/22) BR CAAG2PHYG070

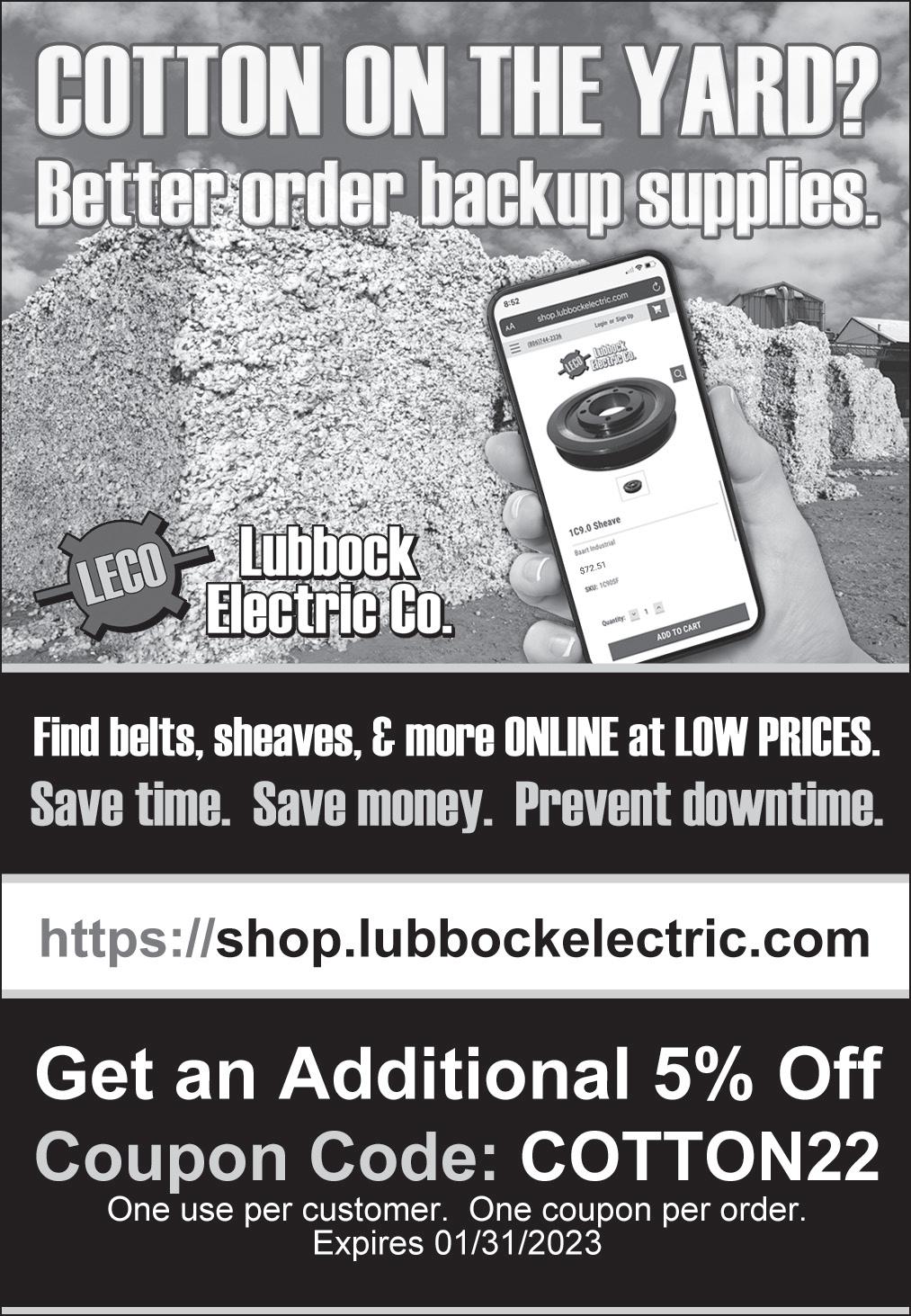

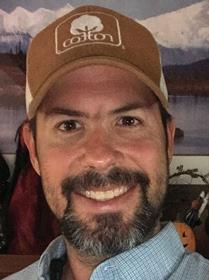

Since 1990, the Swisher/Sunbelt Ag Expo Southeastern Farmer of the Year Award has evolved into the most prestigious honor in the Southeast and nation with 265 agribusiness leaders being honored for their “excellence in agriculture,” according to the Sunbelt Ag Expo. In 2022, cotton farmer Keith Allen was named South Carolina Farmer of the Year, and cotton farmer Scotty Raines was named Georgia Farmer of the Year.

6 WILDLIFE SPECIALIST NAMED

Conservation-minded Texans have a new go-to source — Dr. Jacob Dykes — for science-based information about white-tailed deer and other big game.

17 FAQS ABOUT DRONES

Dr. Steve Li, Auburn University expert, answers frequently asked questions about using drones for pesticide applications in cropping systems.

19 GINNERS MARKETPLACE

ON THE COVER: South Carolina and Georgia cotton producers named 2022 Southeastern Farmers of the Year. Cover photos courtesy of Sunbelt Ag Expo.

in reliability.

Check

more

about the Cotton Ginning Conference at Beltwide. TCGA

COTTON FARMING (ISSN 0746-8385) is published monthly January through December by One Grower Publishing LLC, 875 W. Poplar Ave., Suite 23, Box 305, Collierville, TN 38017. Periodicals postage paid at Memphis, Tennessee, and at additional mailing o ices. POSTMASTER: Send address changes to Omeda Communications, Customer Service Department, P.O. Box 1388, Northbrook, IL 60065-1388 (Phone: 847-559-7578) (Fax: 847-564-9453). Annual subscriptions are $40.

TWITTER: @COTTONFARMING DECEMBER 2022 COTTON FARMING 3

International rates are $55 in Canada/Mexico, $90 in all other countries for air-speeded delivery. Surface delivery not available due to problems

Vol. 66 No. 12

8 Cotton Represented 4 Editor’s Note 5 Cotton’s Agenda 11 Research & Promotion 12 Specialists Speaking 16 Industry News 22 My Turn

FEATURES

industry

the official publication of the ginning

nominations

WEB EXCLUSIVE Arkansas’ 2023 enterprise budgets, an important tool to help farmers plan their next crop season mix, contain changes that reflect some big economic impactors from the current year, said economist and author Breana Watkins. Go to www.cottonfarming.com for this Web Exclusive report. DECEMBER 2022 PROFITABLE PRODUCTION STRATEGIES www.cottonfarming.com DEPARTMENTS & COLUMNS DIGITAL OFFERINGS Keep up with the latest from Cotton Farming by signing up for the monthly E-News at www.cottonfarming.com Facebook: https://www.facebook.com/cottonfarming Twitter: @CottonFarming Instagram: @CottonFarmingMagazine ONE GROWER Supplement to Cotton Farming and Rice Farming Magazines Variety selection State soybean specialists weigh in on decision-making process Look for Soybean South following page 20 in the Southeast and MidSouth editions of Cotton Farming To have industry news and content delivered directly to your inbox, sign up for the monthly e-newsletter at www.soybeansouth.com SUPPLEMENT

out

information

requests

for Ginner of the Year.

Editor’s Note

EDITORIAL/PRODUCTION

Editor-In-Chief

Carroll Smith csmith@onegrower.com

Southeast Editor Amanda Huber ahuber@onegrower.com

Associate Editor Cassidy Nemec cnemec@onegrower.com

Ol’ Man River — The Mighty Mississip’

For most of my childhood, I grew up about 10 miles west of Vidalia, Louisiana, where the Mississippi River bridge crossed over to Natchez, Mississippi. But when I was about 2 years old, we actually lived in Vidalia for a couple years in a little eggplant-colored house close to the levee. Later on, the houses on that side of the street were torn down to make way for the new bridge that was completed in 1988. So, then there were two — eastbound and westbound.

In looking back, Ol’ Man River — the Mighty Mississip’ — has always been an integral part of my life, something I took for granted that would always be there.

I learned to water ski on nearby Lake Concordia and, as a teenager, spent hours on Lake Saint John skiing, tubing and boat riding. Both of these bodies of water are oxbow lakes formed from the Mississippi River.

My mom, sister and brother-in-law owned and operated restaurants in Natchez on Silver Street, which ran right alongside the rolling Mississippi. If patrons showed up at just the right time, they could enjoy a gorgeous sunset along with their evening meal.

During my travels around the Mid-South as an ag journalist, I know exactly where I can cross over the river to move from state to state. Vicksburg, Mississippi, to Tallulah, Louisiana. Hwy. 61 in the Mississippi Delta to Helena, Arkansas. And Greenville, Mississippi, to Lake Village, Arkansas. Of course, there are other connecting bridges, but these are the ones I use the most.

At one time, my parents lived in a house on the bluff on the Mississippi side of the river. You could stand on the upstairs porch and see for miles upstream and downstream. At night, I loved watching the passengers (who looked as small as ants) dance to the band in the upper lit-up ballroom on the fancy paddleboats that passed by. And during the day, it was breathtaking to see the large barges loaded down with crops make their way to New Orleans.

This is a particularly bittersweet memory to me as I observe the toll the drought has taken on this magnificent body of water full of fast-flowing currents moving the crops from field to market. In many places, Ol’ Man River has dried up to what can almost be called a trickle compared to its normally robust power. I pray for rain to help save my old friend and restore its role as the marketing corridor so desperately needed by farmers to cash in on the crops they worked hard to grow. God willing, it will come soon.

Digital Content Editor Katie Guthrie

Art Director

Ashley Kumpe

ADMINISTRATION

Publisher/Vice President

LiaGuthrie (901) 497-3689 lguthrie@onegrower.com

Associate Publisher/Editor-In-Chief CarrollSmith (901) 326-4443

Associate Publisher/Sales Scott Emerson (386) 462-1532 semerson@onegrower.com

Production Manager David Boyd dboyd@onegrower.com

Audience Services Kate Thomas (847) 559-7514

For subscription changes or change of address, call (847) 559-7578 or email cottonfarming@omeda.com

EDITORIAL ADVISORY BOARD

David Burns – North Carolina

David Lynch – South Carolina

Bob McLendon – Georgia

Larkin Martin – Alabama

Mike Sturdivant Jr. – Mississippi Charles Parker – Missouri

Jimmy Hargett – Tennessee

Allen Helms – Arkansas Jay Hardwick – Louisiana

Ronnie Hopper – Texas Ron Rayner – Arizona

John Pucheu – California

If you have comments, please send them to: Cotton Farming Magazine, 7201 Eastern Ave., Germantown, TN 38138.

ACKNOWLEDGEMENT

OF

COOPERATION: Cooperating with COTTON FARMING are various cotton producer organizations across the Cotton Belt. Many representatives of producer organizations serve on COTTON FARMING’s editorial advisory board. Opinions expressed and conclusions reached by contributors are not necessarily those of the cooperating organizations or the editors. All statements, including product claims, are those of the person or organization making the statement or claim. The publisher does not adopt any such statement or claims as its own and any such statement or claim does not necessarily reflect the opinion of the publisher.

Copyright 2022 ©

ASSOCIATED PUBLICATIONS – One Grower Publishing, LLC also publishes RICE FARMING, THE PEANUT GROWER, SOYBEAN SOUTH and CORN SOUTH

4 COTTON FARMING DECEMBER 2022 COTTONFARMING.COM

Carroll Smith Carroll

One Grower Publishing, LLC 875 W. Poplar Ave., Suite 23, Box 305 Collierville, TN 38017 ONE GROWER PUBLISHING, LLC

Lamensdorf PRESIDENT/TREASURER Lia Guthrie PUBLISHER/VICE PRESIDENT

Mike

Cotton’s Agenda

A Functional Forum

The National Cotton Council-coordinated 2023 Beltwide Cotton Conferences (BWCC) will provide research results and other timely information on topics ranging from dicamba usage to drone optimization with the aim of maximizing the production sector’s efficiency, sustainability and profitability.

Who attends this annual event?

■ The BWCC, coordinated by the National Cotton Council, brings together university and USDA researchers, regulatory agencies, Extension personnel/agents, industry sales/support personnel, consultants and producers to exchange information about new products and production/ processing systems that can be tailored to individual farming operations to maximize productivity. Three days of individual reports, panel discussions, hands-on workshops and seminars provide attendees with information they need to help make key cotton production/marketing-related decisions. A diverse program, along with the opportunity to network with peers from across the Cotton Belt, make this conference unique.

program and to housing reservations instructions (cutoff for BWCC room rate is Dec. 19).

How is the programming shaping up?

■ The BWCC’s Cotton Consultants Conference will run from the afternoon of Jan. 10 through the morning of Jan. 11. Topics being considered include updates on ThryvOn™ cotton; herbicide resistance; the U.S. Cotton Trust Protocol®; changes in weather and climate patterns and the impact on crops; regulatory updates and pesticide impacts from the Endangered Species Act; new precision agriculture technologies; retail inventory and supply chain status of fertilizer and chemistries; and dicamba usage.

The BWCC’s 12 cotton technical conferences will provide findings from current research and updates on emerging technology and programs aimed at elevating U.S. cotton production and processing efficiency. Those sessions will meet concurrently beginning the morning of Jan. 11 and concluding by noon on Jan. 12.

For example, the Cotton Sustainability Conference will cover best management practices; industry, brand and retail sustainability goals; market opportunities/downstream perspectives; and new sustainability programs, including the U.S. Cotton Trust Protocol®. The Cotton Agronomy, Physiology and Soil Conference will provide a forum for a discussion of the life processes of cotton plants and interactions among plant and soil variables that affect crop performance and profitability.

Cotton producers, independent crop consultants and students who register before Dec. 14 for the 2023 BWCC on Jan. 10-12 at the New Orleans Marriott in New Orleans, can take advantage of reduced registration fees of $80. After that date, the rate will increase to $100. Those planning to attend are encouraged to register by clicking on the registration tab at the BWCC home page, www.cotton. org/beltwide/. The home page also includes more information, including links to the forum’s final

The Cotton Economics and Marketing Conference includes a session that will explore the market outlook as well as developments in policy and trade. Subsequent sessions, including poster displays, from researchers in industry, government and academia strive to improve understanding of economic and policy-related factors affecting cotton production and downstream industries.

Those with a vested interest in a viable U.S. cotton industry are urged to attend this world-class forum.

TWITTER: @COTTONFARMING DECEMBER 2022 COTTON FARMING 5

Gary Adams is president/CEO of the National Cotton Council of America.

The Beltwide Cotton Conferences provide attendees with information for making key production and marketing related decisions.

Gary Adams

TRAIT STEWARDSHIP RESPONSIBILITIES NOTICE TO FARMERS

Bayer is a member of Excellence Through Stewardship® (ETS). Bayer products are commercialized in accordance with ETS Product Launch Stewardship Guidance, and in compliance with Bayer’s Policy for Commercialization of Biotechnology-Derived Plant Products in Commodity Crops. Commercialized products have been approved for import into key export markets with functioning regulatory systems. Any crop or material produced from this product can only be exported to, or used, processed or sold in countries where all necessary regulatory approvals have been granted. It is a violation of national and international law to move material containing biotech traits across boundaries into nations where import is not permitted. Growers should talk to their grain handler or product purchaser to confirm their buying position for this product.

ALWAYS READ AND FOLLOW PESTICIDE LABEL DIRECTIONS. It is a violation of federal and state law to use any pesticide product other than in accordance with its labeling. NOT ALL formulations of dicamba, glyphosate or glufosinate are approved for in-crop use with XtendFlex® Cotton. ONLY USE FORMULATIONS THAT ARE SPECIFICALLY LABELED FOR SUCH USES AND APPROVED FOR SUCH USE IN THE STATE OF APPLICATION. Contact the U.S. EPA and your state pesticide regulatory agency with any questions about the approval status of dicamba herbicide products for in-crop use with XtendFlex® Cotton. B.t. products may not yet be registered in all states. Check with your representative for the registration status in your state. Products with XtendFlex® Technology contains genes that confer tolerance to glyphosate, glufosinate and dicamba. Glyphosate will kill crops that are not tolerant to glyphosate. Glufosinate will kill crops that are not tolerant to glufosinate. Dicamba will kill crops that are not tolerant to dicamba. Contact your seed brand dealer or refer to the Bayer Technology Use Guide for recommended weed control programs. Insect control technology provided by Vip3A is utilized under license from Syngenta Crop Protection AG. Bollgard®, Respect the Refuge and Cotton Design®, Roundup Ready Flex® and XtendFlex® are registered trademarks of Bayer Group. LibertyLink® and the Water Droplet Design® are registered trademarks of BASF. Agrisure Viptera® is a registered trademark of Syngenta Group Company. Excellence Through Stewardship® is a registered trademark of Excellence Through Stewardship. All other products, company names and trademarks are the property of their respective owners.

White-Tailed Deer And Texas Big Game

Conservation-minded Texans have a new go-to source for science-based information about white-tailed deer and other big game across the state.

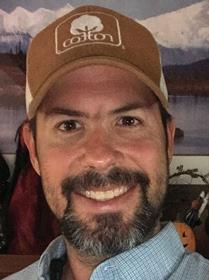

Jacob Dykes, Ph.D., was recently hired as the new statewide wildlife specialist for Texas A&M AgriLife Extension Service and assistant professor in the Department of Rangeland, Wildlife and Fisheries Management in the Texas A&M College of Agriculture and Life Sciences. Dykes, who will be based at the Texas A&M AgriLife Research and Extension Center in Corpus Christi, said his focus will be on white-tailed deer and other big game species, including exotic animals.

“Texas A&M AgriLife hasn’t been very involved with big game across the state, including one of the most popular game species in the nation – white-tailed deer,” he said.

“There are so many questions and such a high demand for science-based information related to their behavior and habitat from a spectrum of stakeholders, including landowners, conservationists and hunters in the various ecoregions of the state.

Cutting-edge Research

game and even exotics,” Rosson said. “Dr. Dykes has hit the ground running and been engaging with stakeholders and every AgriLife Extension agent interested in learning more about big game management. The response has been very positive.”

Big Game Ecology

Dykes said he will concentrate on the interconnections of habitat and the animals and how landowners can influence ecology to improve species productivity based on their stewardship goals.

Integrating technology like tracking collars to study deer movement and monitor behavior can help researchers answer basic ecological questions about the animals, he said. His goal is to produce scientific data that can help formulate and steer land and species management plans that maintain healthy and productive herds.

Dykes looks forward to engaging with property owners and land managers making stewardship decisions. Collaboration with landowners and others will be critical to the program’s success.

Rosson said Dykes’ position will help meet rising demands for information among new landowners. There is also a great interest and demand from landowners looking to manage properties in ways that have long applied to agriculture land valuations and now apply to wildlife.

Before opening a bag of seed, be sure to read, understand and accept the stewardship requirements, including applicable refuge requirements for insect resistance management, for the biotechnology traits expressed in the seed as set forth in the Technology Stewardship Agreement that you sign. By opening and using a bag of seed, you are reaffirming your obliga tion to comply with the most recent stewardship requirements.

Parr Rosson, Ph.D., associate department head for AgriLife Extension in the Department of Rangeland, Wildlife and Fisheries Management, said Dykes is arriving at a critical time for the agency’s ability to provide landowners with expertise that will enhance habitat and wildlife management around the state.

Dykes will help formulate plans and guide landowner management of big game species based on applied science. He will also be conducting cutting-edge research to better understand the needs and behaviors of white-tailed deer and other big game species.

“We felt there was a need in AgriLife Extension based on the demand for knowledge and expertise across the state when it comes to white-tailed deer, Texas big

Listening to questions and concerns from stakeholders will help direct research, Dykes said, and he has plans to help communicate with the public. He hopes to provide a steady stream of information, tips and data related to Texas big game and wildlife improvement opportunities through multiple social media accounts, including Instagram (agrilife. wildlife) and a blog.

“My goal is to make Texas A&M AgriLife the go-to source for reliable information, whether it’s a species-specific or habitat management topic,” he said. “The research we do only has value if it is getting into the hands of people who might want to apply what we learn. Conservation is the common goal, and I am excited to be involved with this program.”

Texas A&M AgriLife provided this article.

6 COTTON FARMING DECEMBER 2022 COTTONFARMING.COM

Dr. Jacob Dykes

Cotton Represented

South Carolina And Georgia Producers Named 2022 Southeastern Farmers Of The Year

Since its inception in 1990, the Swisher/Sunbelt Ag Expo Southeastern Farmer of the Year Award has evolved into the most prestigious honor in the Southeast and nation with 265 outstanding agribusiness leaders being honored for their “excellence in agriculture,” according to the Sunbelt Ag Expo.

The farmers who are considered for this honor grow a number of different crops and raise cattle and other livestock. In 2022, cotton was also wellrepresented by Keith Allen — South Carolina Farmer of the Year — and Scotty Raines — Georgia Farmer of the Year. Following are highlights featuring their families and agricultural operations.

KEITH ALLEN

SOUTH CAROLINA FARMER OF THE YEAR

Betty Allen Farms in Latta, South Carolina, has been in Keith Allen’s family for the nearly 200 proverbial lean and fat years. Growing from a modest holding in 1837 to 3,800 acres today, the farm has experienced everything from near loss at auction in 1917 to two recent 1,000-year floods and drought.

After Allen’s father graduated from Clemson University in

1950, he served his country in Korea only to return home to the driest year on record, with no rainfall until Hurricane Hazel hit in September of 1954. The resulting crippling debt forced him to seek other work as a teacher and then as a full-time Farm Bureau insurance agent just to keep crops in ground.

From his childhood, Allen recalled, “I don’t remember not working on the farm in the summer. I started picking up tobacco leaves at the barn, driving mules, pulling drags, and then plowing with a Super A, then a D-17. When we got a 4230 John Deere, that was something else. There were no cabs in those days, but it was a great way of life, and I was grateful to have those opportunities.”

Allen also went to Clemson University, earning a B.S. degree in 1978 in agricultural mechanization and business. It was a momentous year in which he married his wife, Libby, and built a home with timber from the family property. The two had met as teenagers at a horse show in North Carolina near Libby’s hometown of Rowland. She came from a farming family as well and graduated from North Carolina State University with a degree in Speech Communications and Education.

Today, Betty Allen Farms consists of 3,800 acres currently operated, with 2,980 rented and 820 owned. The cotton crop of 950 acres yielded 1,200lbs/acre; 1,900 acres of soybeans yielded 48 bushels/acre; 600 acres of corn yielded 148 bushels/acre; 250 acres of peanuts yielded 4,000 lbs/acre; and 500 acres of winter wheat yielded 75 bushels/acre.

8 COTTON FARMING DECEMBER 2022 COTTONFARMING.COM COVER STORY

Balancing The Day-To-Day

Allen has updated equipment whenever possible over the years and uses strip till for conservation on most crops and notill on soybeans and corn. He added, “Clemson Extension and Farm Bureau have also been great resources on current agricultural issues and marketing information.”

Most of his corn is sold to a feed mill because the basis is better. He prices some of the cotton himself and puts the rest in the pool with Staplcotn, the oldest and one of the largest cotton marketing cooperatives in the United States. This company specializes in domestic and export marketing, ag financing and cotton warehousing.

Allen says, “I try to figure my cost of production, and when the price is right, I try to forward contract or sell commodities in storage and crops I will produce. Sometimes I use basis contracts when I think the price is rising. I also use the DTN Ag Marketplace app for information and as a trading tool. Purchasing puts and calls on key commodities acts as a hedge to protect the downside of the market and offers potential profit on upswings. Sometimes you get it right, and sometimes you get it wrong; it’s all part of the privilege to make independent decisions about family farming.”

Working with Allen are two full-time employees as well as his nephew, Blake Allen, and his son-in-law, Caleb Miller, who is married to the Keith’s older daughter, Katherine. She earned a doctorate degree in pharmacy and works at a hospital just over the state line in Lumberton, North Carolina. Last December, they presented Keith and Libby with their first grandchild, Allen William Miller.

The Allens also have a younger daughter, Karen, who is autistic but high functioning. She’s a talented artist who works as an art teacher’s aide at the local elementary school.

About his son-in-law, Allen said appreciatively, “He’s taken a leadership role here on the farm and has great technology skills. We plan to do more yield mapping and incorporate that with variable-rate fertilizer applications. Precision agriculture is the future of making inputs more efficient. We’re using grid soil sampling now, but we need to improve on the way we use the data. Technology-dealing sensors that detect plant health will help us more efficiently manage input costs in the future.”

Maintain Perspective

As to overcoming challenges, Allen observed, “Through the years I’ve analyzed productivity and problems with some of the rented land and had to let some go because of wet fields and problems with wild hogs and deer.”

Then, between 2015 and 2018, South Carolina had some of the worst flooding in the state’s history. “Hurricane Joaquin in 2015, Hurricane Matthew in 2016 and Hurricane Florence in 2018 were the worst,” he recalled. “Recovering from them was difficult because we had large losses on cotton and peanuts in 2016 and in 2018 and struggled to cut costs to stay in business.”

Along with using strip till and no-till on his acreage, as well as a no-till drill for more than 30 years, Allen has used the Conservation Reserve Program for quail habitat buffers to increase the quail population. He’s planted tree borders to

reduce runoff and erosion, adding, “I have beehives to help with pollination and use low-drift nozzles when spraying to try to protect off-target weeds or insects. This year I’m also trying some cover crops.”

Libby worked for 30 years as a substitute mail carrier and has been active in special needs issues for children as well as local community fundraisers. She also helps with running parts for equipment and delivering lunches for everyone during harvesting and planting. As Allen said, “She is the rock that keeps me going, and I would be lost without her.”

Reflecting on a successful, 44-year farming career, Allen had this to say: “As a fifth-generation farmer on this land, I look forward to one day handing Betty Allen Farms over to the next generations. This includes my nephew, Blake Allen, and his son, Palmer, and my son-in-law, Caleb Miller, and his son, Allen.”

He added, “But over and above all the operational demands of farming, the most important thing is paying attention to your family. The farm chores will always be waiting and aren’t nearly as important as some memory-making moments the whole family could experience and treasure.”

SCOTTY RAINES

GEORGIA FARMER OF THE YEAR

Scotty Raines didn’t grow up on a farm, but his father kept a large garden at home. His mother, a beautician, had a beauty shop behind their house. Scotty began his agrarian career by selling produce from the garden — tomatoes, squash, cucumbers and corn — to her customers.

He also participated in FFA at Turner High School and, after graduation, became a farm technician with Agratech Seed Research. In 1991, he married Melanie, a girl he’d grown up with, and two years later began farming full-time in partnership with his father-in-law.

Raines said, “I’m very proud of my family. My wife keeps her accounting skills sharp by maintaining the books for three area churches. We are active in First Baptist Church of Tifton. When our oldest daughter, Celie, was in school, she was in the marching band. It was quite a feat because she is hearing impaired. Our second daughter, Christian, is an EMT. She loves helping people, although she battles Lupus and is in pain most of the time. I think this helps her relate to her patients.”

He added, “Her husband, Justin Pate, works full-time on the farm and has a passion for volunteer fireman work. He was just awarded the Turner County Most Responses and Responder of the Year awards. He and Christian have been working on their certification to become foster parents.”

Keeping Up To Date

Raines recalled, “My father-in-law and I originally farmed about 500 acres and eventually expanded to 1,200 acres. I ventured out on my own to purchase 30 beef cows in 1994. During our partnership, we purchased two farms; the remainder of the acres we worked was rented. My wife and mother-in-law were very active in the operation.”

TWITTER: @COTTONFARMING DECEMBER 2022 COTTON FARMING 9

In the spring of 1996, his father-in-law suffered some major health problems, so Raines finished the crop that year. He began farming on his own a year later with 1,000 acres that grew over time to 2,300 acres, with 1,199 acres owned and 1,101 acres rented.

Crop yields at Scotty Raines Farms Partnerships are as follows: 760 acres of cotton yielding 940 (conservatively) lbs/ acre; 385 acres of irrigated peanuts yielding 5,880 lbs/acre; 800 acres of cotton yielding 860 lbs/acre; 200 acres of non-irrigated peanuts yielding 4,760 lbs/acre; 120 acres of corn yielding 219 bushels/acre; and 35 acres of watermelon that yielded well. Raines also owns 27 beef cattle.

In the beginning of his farming career, Raines marketed his own cotton through local gins. He said, “Since I was so busy on the farm, I wasn’t able to do the best job. Joining Staplcotn, a marketing cooperative, was a better solution. It’s a great time-saving and solid way of doing things.

“And because we carefully manage insect pests and harvest in a timely manner, we maximize our cotton quality and therefore receive the best market price possible. I’m proud to say that our farms won a Georgia Cotton Quality Award in Region One in 2021.”

Scotty Raines Farms Partnerships recently purchased a bale picker to allow for faster harvesting and reducing the number of laborers in the field. And they have purchased a precision planter with individual hydraulic down force. This planter helps to get the seed placed at the right depth, even over terraces, and doesn’t overlap seed. The aim is to produce a better, more uniform stand at planting and a better harvest in the fall.

Know When To Step Up

Meeting challenges faced by all farmers is a constant undertaking. For Raines, a major effort has gone into converting dryland production into irrigated production. He has used long-term leases with landowners, purchased irrigated land/ irrigation systems, and updated irrigation systems.

Raines has also had to deal with rising input costs over the years. He explained, “For example, in 1993 we bought a tractor for $35,000. Now that same tractor costs $200,000. We buy fuel in bulk to save money, but now a 7,500–lb. tank might cost $37,000 to fill up. And the prices we get for crops don’t always equal what we paid to plant and nurture them through to harvest. It’s a constant balancing act.”

Of course, one of the most prevalent unknowns is weather. Raines said, “Irrigation helps with drought, but hurricane Irma in 2017 and Michael in 2018 really hit us hard, and we haven’t

fully recovered from those two events when we lost most our crop. Since crop insurance was insufficient to recoup the losses, we were able to do some refinancing to overcome the impact of these natural disasters.”

In the area of environmentally helpful practices, Raines uses variable-rate fertilization of lime, potash and MAP to increase the nutrient efficiency and reduce the potential of oversaturation of unneeded nutrients and fuel wastage. The application is all based on the five-acre grid soil sample taken annually. To protect watersheds and reduce the potential for soil erosion, the farm maintains terraces and waterways.

He noted, “My farm has collaborated with the University of Georgia Extension on research efforts such as soil moisture sensor projects that monitor moisture status and manage water applications. This has greatly reduced the amount of irrigation water used to produce a crop. I also purchase bulk chemical containers to minimize plastic waste. When we do use plastic containers, they are recycled.”

Raines added, “We use conservation tillage methods and winter cover crops, like clover and rye, and now triticale, on the vast majority of acreage. It’s an important tool to help with weed control, improve soil moisture holding capacity, and support the long-term sustainability of our farm.”

The reward of seeing things grow to fruition is still quite real for Raines.

He commented, “We recently needed to plant 140 acres of peanuts on dryland on the north side of our property. The planter sat there for three weeks until the good Lord sent half an inch of rain. The same thing happened recently on the south side of our farm with cotton. We got one inch at almost the last possible moment. That’s when we gladly give thanks for prayers answered.”

Scotty Raines was nominated for Georgia Farmer of the Year by Guy Hancock, University of Georgia Cooperative Extension, Turner County ANR Agent.

“Despite having to overcome numerous adversities in recent years such as tornados, hurricanes (Irma in 2017 and Michael in 2018), and other extreme weather events, Scotty has maintained a strong farming operation and a positive attitude through it all,” Hancock said.

“He is always working towards integrating technology into his farm such as soil moisture sensors, GPS and variable-rate equipment to make the operation more efficient. The Raines family’s resilience and significant investments in agriculture have earned them the respect of those in their community and beyond.”

The Sunbelt Ag Expo contributed this information.

10 COTTON FARMING | DECEMBER 2022 COTTONFARMING.COM

Telling The Story Of U.S. Cotton To Brands And Retailers

The visionary cotton producers who formed the Cotton Research and Promotion Program in the 1960s knew that to stay relevant in our industry they had to come together to tell the story of U.S. cotton.

Over the years, the story of cotton’s advantages over synthetic fibers has evolved, expanded and become multi-faceted with different messages targeting different audiences. One of the most important messages recently has been that U.S. cotton farmers are committed to sustainability and continuous improvement on their farms.

Cotton Incorporated has made an effort this year to support programs and projects that educate key decision makers at major brands and retailers in the supply chain about U.S. cotton production. It has also given U.S. cotton farmers multiple platforms to share their stories.

Cotton Sustainability Summit

In September, The Cotton Board’s Importer Support Program, together with Cotton Incorporated, hosted a Cotton Sustainability Summit in La Jolla, California. The goal of the Summit was to examine sustainability issues from multiple perspectives (growers, retailers, activists, etc.) and to communicate sustainability initiatives that are taking place in the textile supply chain — from producers to brands and retailers.

This type of dialogue is essential for the industry to effectively position cot-

California cotton producer Aaron Barcellos (middle) participated in a panel discussion titled “U.S. Cotton: Setting a New Standard in Sustainability” at the Cotton Sustainability Summit in La Jolla, California.

BY STACEY GORMAN WARREN, ARKANSAS

BY STACEY GORMAN WARREN, ARKANSAS

ton as the fiber of choice for sustainable sourcing programs. Among the 100 Summit participants were representatives from major brands and retailers that are significant users of cotton. Many of them were primarily responsible for their company’s sustainability efforts.

Cotton producers Cannon Michael (California), Aaron Barcellos (California) and Meade Hardwick (Louisiana) attended the summit and presented during panel discussions, sharing information and stories about their experiences as U.S. cotton producers.

Sessions focused on topics such as agricultural practices with a specific emphasis on regenerative farming, impacts of climate change on farming practices, transparency and traceability in the supply chain, the circular economy, and many more issues currently facing fashion-sector decision makers.

“This Summit was a great example of

what the cotton industry can do when there is open and meaningful collaboration,” said Elizabeth King, Cotton Board vice-president of importer relations.

The Cotton Board, Cotton Incorporated, the National Cotton Council and Cotton Council International were all in attendance and unified in their support of the goals of the meeting.

ISP Farm Tours

After a two-year Covid-related hiatus, The Cotton Board’s Importer Support Program was able to host two farm tour events in October. This year’s Importer Farm Tour events included 61 attendees representing companies such as Target, Gildan, Tommy Hilfiger, Walmart, Macy’s, American Eagle Outfitter, and many other major brands and retailers.

Participants flew into Memphis, Tennessee, where they heard from Cotton Incorporated’s team of experts, visited the U.S. Department of Agriculture cotton classing office, and crossed the river into Arkansas to visit a cotton farm and gin.

Arkansas cotton producers Jason Felton and Larry McClendon hosted the tour groups’ farm visits and shared a glimpse into the care they take with their land. Overall, these tours help renew participants’ interest in cotton and leave them with the knowledge to feel good about using cotton, especially U.S. cotton, in their businesses.

Events and programs like the Sustainability Summit and the ISP Farm Tours allow Cotton Incorporated to help bridge the gap between cotton producers and the end-users who are buying their cotton. Impressions and opinions are positively changed when key decision-makers see the innovation, sustainability practices and sophisticated technology that go into producing U.S. cotton — and especially when they hear directly from U.S. cotton producers.

Stacey Gorman is The Cotton Board’s director of communications and may be reached at sgorman@cottonboard.org.

TWITTER: @COTTONFARMING DECEMBER 2022 | COTTON FARMING 11

RESEARCH & PROMOTION

Specialists Speaking

2022 Cotton Crop Recap

ALABAMA Steve M. Brown

I’m ready to sit down. We’ve almost made it to the end of 2022.

My work crew this season consisted of my grad student Sam and me. Like many farmers, we couldn’t find good summer help, so it was just the two of us — except for the day and a half I enlisted my wife as a data recorder. I don’t know how we got it all done.

So, it’s time to spend some reflective moments. Time to kick back and think about the good and not so good of 2022. What did we learn this season? What worked? What didn’t? What might we change for next year and beyond? What is on the list of, “If I had it to do over, I would do this?” These latter things could be or not be reason to change management going forward. Sometimes, “what I should have done differently this year,” could be wrong for 2023 because no two years are ever identical. Each year requires in-season adjustments to new and varied challenges. These adjustments can significantly affect our outcomes.

With recap sheets, record books, field maps, reports and memory, topics such as variety performance, field variations, pest issues, fertility, labor, suppliers and marketing all deserve attention. But also, be thankful you’ve come this far and for those around you with whom and for whom you work and who make it all worthwhile.

I think when all is wrapped at the gin, our crop will be better than expected. Celebrate! cottonbrown@auburn.edu

ARKANSAS Bill Robertson

The 2022 season continues to deliver issues we rarely see in Arkansas. The continued dry fall has harvest progress at perhaps one of the most rapid we’ve ever experienced. We are well ahead of our five-year average as we roll into November.

Good cotton usually picks very well, especially when little rainfall occurs after boll opening. We’re also seeing few weather-related losses, giving us the opportunity to get almost everything the plant produced in the module. Our yield-per-acre values should be higher than expected. This is good news — especially in our current economic situation.

Dry cotton doesn’t pack well and is evident in the fact that most of our round modules are 10% to 15% lighter than we generally see. Our color is great and leaf values are low. The dry weather is a bonus for consultants pulling soil samples and producers getting fields worked up for next year as harvest activities are completed.

Establishing cover crops has been extremely challenging this year. Most expect poor growth at best with covers this fall as our temperatures will likely drop significantly before the moisture we need for good growth arrives. The forecast of a warmer and dryer-than-average fall and winter is falling into place.

The biggest issue most are facing now is the increased percentage of our crop in the discount range for high micronaire. The wonderful weather we had basically the whole month of September matured our top crop more than we may have ever experienced in Arkansas. Between the more mature bolls and delays in initiation of our harvest-aid programs, some varieties are falling in the discount range for high micronaire more than others.

Plans for next year should be falling in place. Issues of input availabilities and input costs appear to be here to stay.

Contact your local county Extension agent for updates on this season’s testing programs and to get details regarding upcoming production meetings. brobertson@uada.edu

ARIZONA Randy Norton

As we wind down the calendar year for 2022, decisions can be made now for the 2023 summer crop growing season. Water availability issues are at the forefront of decision-making factors that will affect the 2023 cotton production year. We’re likely to see another shift downward in cotton acreage for 2023. However, strong prices for both Upland and Pima cotton will tempt growers to plant that undecided acre to a crop of cotton. Time will tell as we proceed into the late winter and early spring.

Whatever the level of cotton planting in the state for 2023, management for efficiency will be critical as always. Decisions can be made now during the winter months that will have an impact on the 2023 cotton season. One of the tasks that can be completed is off-season soil sampling. This is an excellent time to sample soils and have them tested for various nutrient levels that can help you determine fertilizer needs for the coming season.

Recent upward trends in fertilizer prices continue to make nutrient-use efficiency even more critical to maintaining a healthy bottom line in your operation. For example, you might discover that a traditional early season phosphorus (P) application is not needed to maintain optimum crop health because a pre-season soil test revealed soil P levels at well above the five parts per million (ppm) critical level for P in cotton. Residual nitrogen (N) in the soil discovered through soil testing might reveal the ability to trim back on in-season N applications. The alternate scenario is also a possibility where deficiencies in soil test levels may indicate the need to increase fertilizer applications in the coming crop year.

Either way, this information will assist you in determining the right type and amount of fertilizer needed for the 2023 crop. For more information on soil testing, fertilizer recommendations and many other topics, go to the UArizona Extension Crops website at extension.arizona. edu/crops-soils. rnorton@cals.arizona.edu

GEORGIA Camp Hand

Each year presents its share of challenges, and the 2022 growing season was no different. Overall, it seems like the theme in Georgia in 2022 was that it was dry when you needed rain and rained when you’d prefer it be a little on the dry side.

In Tifton, we didn’t have a good rain between April 15 and June 15. Then in August, it started raining and didn’t stop until the second week of September. The untimely rains during boll opening led to a lot of heartburn amongst everyone in the cotton industry because of the plethora of boll rot and hardlock we saw. Personally, I think we had more hardlock than boll rot, and I think more of that wound up in the picker than we thought would. However, yields from April/early May-planted cotton were off a little bit.

As I write this Nov. 4, the yields I’ve been hearing are pretty good. Of course, we’re still all over the board, but when I start hearing numbers over 1,500 lbs. per acre, I think we’ve had a good year. I spoke to a grower today who averaged over 1,300 lbs., and their operation is 100% dryland!! I’d be thrilled if I was that farmer. Quality has been incredible, and that

12 COTTON FARMING | DECEMBER 2022 COTTONFARMING.COM

Specialists Speaking

can be partially attributed to the fantastic harvest weather we’ve had thus far. Only time will tell where we end up because we still have a way to go in terms of harvesting. We likely crossed the halfway mark this week (the week of Halloween).

If I were a grower, I’d start preparing for 2023. I know the current outlook is bleak, but I also know Georgia growers are resilient and committed to growing cotton. Keep an eye out for variety trial results and county meeting dates. Myself and the rest of the cotton team are looking forward to getting out on the road again, talking with you all about this year and preparing for next year. As always, if you ever need anything, your local UGA county Extension agent and specialists are here to help! Don’t hesitate to reach out. camphand@uga.edu

LOUISIANA Matt Foster

Cotton harvest in Louisiana is wrapping up and was around 98% completed as of Nov. 4, which is around 10% greater than our five-year average. We couldn’t have asked for better weather during harvest this year. Hot and dry conditions throughout the growing season and excessive rainfall in August resulted in extremely variable yields throughout the state. Average yields for the state are projected to be around 850 lbs. of lint per acre, which is below the 2021 state average.

According to the U.S. Department of Agriculture Agricultural Marketing Service figures, as of Nov. 4 out of Rayville, 27.4% of the bales received have produced a micronaire value of five or greater. This year’s fiber length, strength and uniformity are averaging 1.15, 30.65 and 81.42, respectively.

Early indications for 2023 are that cotton acres will increase in Louisiana once again. Now is the time to prepare for the 2023 growing season. One of the most important decisions producers make is variety selection. The results from the LSU AgCenter official variety trials and on-farm demonstrations will be available soon at https://www.lsuagcenter.com/ topics/crops/cotton. mfoster@agcenter.lsu.edu

MISSISSIPPI Brian Pieralisi

I appreciate the subtle nuances Mother Nature gives us to set cotton years apart. If we didn’t have the roller coaster ride, all the years would run together, right? 2022 was another year that I will remember, not for the devastating environmental woes, but more for the quiet toll that was taken throughout the year.

In Mississippi, we had the best planting conditions that we’ve experienced in several years. Thrips were heavy as usual, but we had time to deal with this pest while making herbicide applications. Weed control was usual. For the most part, controlling plant height with PGRs was routine due to the drought. Cotton does well during dryer years; however, 2022 was dryer and hotter than “normal,” especially earlier in the season.

Cotton yield was variable across the state. This was no surprise because growth and development varied the entire season, and it was mostly dictated by planting date and environmental conditions. Early cotton didn’t fare well with the hot, dry conditions that we faced late May and June. Plants heights, node counts and fruit retention suffered due to the excessively hot and dry weather. Cotton planted during the second and third week of May capitalized on planting date.

Mother Nature always throws a curve ball, and she threw a sinker during August. After an almost unbearably hot and dry summer, late August produced two weeks of cool, wet weather and heavy rainfall. Depending on your location, wet weather caused yield-reducing boll rot and hardlocked bolls. The severity ranged from minimal to a couple of hundred pounds of lint per acre. Some areas in central Mississippi had devastating yield reductions from back-water flooding. Yields in Mississippi ranged from poor to exceptional with the vast majority falling somewhere above average.

2022 has come and gone for the most part, so it’s time to look toward 2023. Variety selection is paramount when planning for another cotton season. As always, look at multiple-year yield performance for a particular growing region, and don’t put all your eggs in one basket. Check for Mississippi cotton variety performance data at mississippi-crops.com. Happy Holidays! bkp4@msstate.edu

NORTH CAROLINA Keith Edmisten

The cotton crop is probably around 65% harvested as I write this near the end of October. The weather has been mostly dry and allowed for an efficient harvest and good color grades, with 68% of the crop having 31 or better color grades as of Oct. 27. Leaf grades are really good, with the majority of the cotton classed so far between 1 - 3 with very little discounts for extraneous matter (bark and grass etc.) Staple and strength are good with an average of 1.14 and 30.7. The average micronaire is 4.57, but as you would expect with some areas suffering from low, late-season rainfall, about 11.5% of the bales are running high micronaire.

Yields are variable across the state, as is often the situation in North Carolina, with most cotton dependent on rainfall — often spotty thunderstorms. Areas that missed rains in August are reporting below-average to average yields, while areas that received rain in August are seeing surprisingly strong yields. Some growers are actually reporting record yields for their farm. The variability of the crop this year probably puts the overall cotton crop in North Carolina as a little above average in terms of yield and better-than-average fiber quality. keith_edmisten@ncsu.edu

OKLAHOMA Seth Byrd

By the time this issue of Cotton Farming reaches you, it’s likely that most of the 2022 Oklahoma cotton crop is out of the field — hopefully, that is. To say this past season was challenging would be putting it mildly, and while the majority of planting acres never saw a picker or stripper in them, there have been some success stories this year.

There will be some very good, irrigated success stories from the ’22 crop and even some pockets of surprisingly great dryland production. As I write this in early November, it’s too early to draw any general conclusions about fiber quality, but the results of what’s available so far show better values than some feared. Hopefully, this trend will continue and be the start to a better season in 2023. seth.byrd@okstate.edu

TENNESSEE Tyson Raper

We’re at the forefront of another big change in germplasm. I’ve been very impressed with several lines from each of the new tech platforms, and I believe each has several varieties that will fit well within the Mid-South.

Although the number of locations in which we’ve been able to test these varieties is limited, most farms will have several relevant trials with applicable data to review when selecting varieties. As these platforms become more widely available, I would still encourage you to slate a large portion of your acres

to varieties you know.

It can be easy to get caught up in the “new.” The varieties we have now are nothing short of outstanding, and most of these new traits do not provide an inherent increase in yield but instead ease management. Results from some of these trials will hopefully be available by the time you read this; reach out to your local Extension agent or agronomist for more information. traper@utk.edu

TEXAS Ben McKnight

As the 2022 growing season winds down at the time I write this Nov. 4, I’m already looking forward to next year. This year was one of the driest, warmest years on record and led to many challenges for producers in Texas. In many cases, yields were well below average depending on the region of the state. In some regions, like the Coastal Bend, conditions were so dry that cotton failed to emerge in many fields.

As we start to formulate a plan for the 2023 growing season, I would encourage growers to be active with soil testing over the winter months to determine their plant nutrient needs heading into next year. Having an idea of the precise amount of fertilizer inputs needed for a yield goal can assist with minimizing unnecessary costs.

Variety selection for the coming year should also be at the top of the list during the winter months. Variety trial data can provide important information to assist with this decision-making process. The results from the Texas A&M RACE trials will be published online in December, and I encourage growers to take a look at the results from 2022 and previous years to see how certain varieties performed in their respective growing region. Those results can be found at varietytesting.tamu.edu.

The Texas Plant Protection Association Conference is scheduled for Dec. 6-7 at the Brazos Center in Bryan, Texas. The Beltwide Cotton Conferences are scheduled for Jan. 10-12 in New Orleans, Louisiana. I look forward to seeing you at the meetings! bmcknight@tamu.edu

TEXAS Murilo Maeda

Harvest is in full swing as I write this early November. Cool, at times wet, conditions have created challenges in preparing the crop for harvest, but growers keep pushing forward. Yields are lower than initially expected — by as much as 30% for some irrigated fields. However, considering the summer we had, it’s understandable. Thankfully, according to the USDA AMS classing report, fiber quality is good with no major issues as it can often be seen when we have unfavorable conditions during the summer months.

The Lubbock classing office is reporting approximately 47,000 bales classed from 37 gins as of Nov. 3. It averaged 36.74 staple, 1.15 length, 31.44 strength, 80.82 uniformity and 4.19 micronaire. The latest USDA Farm Service Agency crop acreage report from Oct. 3 noted West Texas cotton growers seeded 4.7 million acres in 2022. The split between irrigated and dryland acres is approximately 38% and 62%, respectively.

As of this writing, FSA numbers indicate that as much as 2.95 million acres were failed in the 1N (Northern High Plains) and 1S (Southern High Plains) regions, accounting for almost 63% of the total acres planted. We continue to hear (and see) about more acres being failed, so we still expect an increase in those numbers from the Nov. 9 report. And it may not be until later in the year that we will have anything close to the final numbers for the region.

We continue to wish a safe harvest for those working the long hours to bring the crop in. Movement of large equipment is normal this time of year, so please stay safe out there. mmaeda@ag.tamu.edu

14 COTTON FARMING | DECEMBER 2022 COTTONFARMING.COM

Specialists Speaking

New App On The Horizon

LSU AgCenter Team Receives Grant To Help Farmers Irrigate Efficiently

BY OLIVIA MCCLURE

BY OLIVIA MCCLURE

When drought conditions set in across Louisiana this summer, many farmers resorted to irrigation to try to save their crops. While it helped preserve yields and quality in some cases, the sharp uptick in irrigation raised an alarm among those who monitor water usage in agriculture.

With concerns about the sustainability of water supplies in mind, LSU AgCenter engineer Stacia Davis Conger is leading a team to develop an irrigation decision-making app and outreach campaign aimed at helping farmers mitigate drought risks in an environmentally and economically responsible way. She was awarded a $295,860 grant from the U.S. Department of Agriculture to support the work.

“The long-term goal of this project is to inspire behavioral changes in overall water consumption,” said Conger, who is based at the AgCenter Red River Research Station in Bossier City.

The grant she received is part of a larger effort of the USDA National Institute of Food and Agriculture to “rapidly deploy strategies and fill knowledge and information gaps to protect the nation’s food and agricultural supply chains — from production through consumption — during and after extreme weather and disasters,” according to an announcement from the institute.

Efficient, Site-Specific App Conger, along with co-principal investigators Carol Friedland and Robert Rohli, is working on an app that will provide farmers site-specific irrigation recommendations based on current drought and hydrological conditions. By pinpointing areas of fields that need water most and helping determine the timing of irrigation events, this tool will allow farmers to become more efficient, she said.

Friedland, director of the AgCenter LaHouse Home and Landscape Resource Center, has extensive experience with

mitigating environmental risks such as drought, flood, tornadoes and wind damage.

Rohli, a professor in the LSU College of the Coast and Environment who specializes in climate and weather, is assisting on methods for estimating evapotranspiration, which is a major driver of determining irrigation requirements.

Making the best use of increasingly limited water resources is important.

“Excessive irrigation at unsustainable rates may render water resources as environmentally or economically unavailable,” Conger said.

An Eye On Aquifers

Agriculture is responsible for about 38% of water usage nationally, she said, adding that irrigation has been on the rise in the South for nearly two decades.

In Louisiana, there is growing concern about the long-term viability and quality of aquifers, which supply much of the state with water.

Recent climate trends have exacerbated these issues.

“Louisiana is the most vulnerable U.S. state to extreme weather events due to its high frequency of natural disasters including flood, hail, lightning, tornadoes, drought, extreme heat and extreme cold,” she said.

“Of these hazards, drought is the most expensive risk to Louisiana agriculture, accounting for 95% of projected crop losses by 2050.”

Olivia McClure is associate communications specialist at LSU AgCenter. She may be reached at omcclure@agcenter.lsu.com.

TWITTER: @COTTONFARMING DECEMBER 2022 | COTTON FARMING 15

Young cotton plants emerge from dry, cracked soil.

PHOTO COURTESY OF LSU AGCENTER

“Drought is the most expensive risk to Louisiana agriculture, accounting for 95% of projected crop losses by 2050.”

Americot Announces More

Boots On The Ground

Americot, Inc. has added three new sales team members to the company and announced a leadership promotion.

“As we continue to offer exceptional grower support in the Cotton Belt, we’re growing our team, and I’m extremely happy to introduce Brett, Justin and Levy as the newest members of the sales team. Additionally, I’d like to introduce our latest regional manager, Shane Osborne. Thanks to cotton growers throughout the country, our commitment to providing the highest-quality products and industry-leading customer support remains as strong today as ever,” said Chiree Fields, Americot’s general manager.

Brett Shrader joins Americot as a sales representative. A graduate of the University of Tennessee at Martin, Brett has spent the past 25 years in the cotton industry in roles ranging from crop consultant to agronomist and operations management. He is specialized in precision ag, soil moisture sensory and crop consultation. Brett is based in Cleveland, Mississippi.

Justin Goodman graduated from Abraham Baldwin Agricultural College and has worked in crop consulting and soil science, and managed a commercial cotton gin in South Georgia. He most recently was a project/sales manager for Twin Rivers Land and Timber, a Georgia land and timber company. Justin joins Americot as a sales representative, based in Brooks County, Georgia.

Levy Lord joins Americot as a sales representative, supporting growers in Louisiana as a member of the South Delta region. A graduate of Northeast Louisiana University with a bachelor’s degree in agriculture business, Levy is certified in ag entomology, ag weed control, and ag field soil management and has spent the past 23 years in the fertilizer sales industry. He is based in Baskin, Louisiana.

Americot also announces the promotion of Shane Osborne to regional manager of the Red River Region. He takes over from recently retired Jerry Montgomery. Shane started with Americot in 2017 as a sales representative and agronomic supporter. He graduated from Texas Tech University with a B.S. in agricultural economics and an M.S. in agronomy. Shane is based in Jackson County, Oklahoma.

Industry News

For more information on Americot and its NexGen brand cotton products, call 888-678-SEED (7333) or visit www. americot.com.

U.S. Cotton Trust Protocol Report Reveals Positive News

U.S. Cotton Trust Protocol launched its second annual report, Data Driven. Traceable by Design. A Smarter Cotton Future, which details the program’s results for the 2021/22 crop year. The report at https://report.trustuscotton. org/ reveals growth in Trust Protocol membership across the value chain.

This includes an increase in membership and the number of U.S. cotton acres enrolled, which doubled and now represents 1.1 million acres. The total number of brand and retailer members has grown to 40 and includes Ralph Lauren, J. Crew, Tesco, Levi Strauss & Co., GAP and Old Navy.

The sustainability initiative also welcomed more than 900 supply chain members. The Trust Protocol’s farm-level data reporting shows significant improvements, with producer members demonstrating tangible results across the six key sustainability metrics.

As supply chain membership continues to grow, producer participation is crucial for the program to meet U.S. cotton demand. To learn more or begin the streamlined enrollment process, visit www.TrustUSCotton.org or reach out to the Grower Helpdesk at growers@ trustuscotton.org.

Enrollment Opens For BASF Cotton Producer Clubs

BASF is pleased to announce that cotton club enrollment is now open and could land growers impressive rewards, like a lease on a Ford Super Duty F-350 Lariat truck or a trip to the beach.

The application deadline for FiberMax One Ton Club is Feb. 28, 2023. Printed qualification forms were mailed to FiberMax growers in early November, and applications can also be submitted online (fibermax.com/otc-form).

To qualify for the club, FiberMax One Ton Club growers must produce a minimum of 2,000 pounds of ginned cotton per acre on a minimum of 20 acres planted with 100% FiberMax cotton from Jan. 1 to Dec. 31, 2022.

The application deadline for the

Bright Spot Recorded

In West Texas

Shelly Heinrich, the Cotton Board Southern Plains regional communication manager based in Slaton, Texas, shared this picture of her son, Heath, and her grandson, Field Bessent.

“This photo was taken in southern Lubbock County, Texas,” she said. “The harvest this year is not so big with cotton, but our hearts sure are!

Stoneville Legacy Club is Jan. 15, 2023. Printed qualification forms were mailed to Stoneville growers in early November, and applications can also be submitted online (stoneville.com/lc-form).

To apply for the Stoneville Legacy Club, growers must plant Stoneville cotton on a minimum of 20 acres from Jan. 1 to Dec. 31, 2022.

“There’s no denying that growing cotton is challenging,” says Rachel Walters, Regional Grower & Channel Marketing Manager Seeds, BASF. “It’s a crop unlike any other that takes a grower unlike any other. And it’s this heart and hard work that we can’t wait to celebrate in person through our cotton clubs.”

Learn more about the clubs by visiting fibermax.com/otc, stoneville.com/lc or by contacting your BASF agronomic solutions advisor or agronomic services team member.

16 COTTON FARMING | DECEMBER 2022 COTTONFARMING.COM

FAQ — Using Drones For Pesticide Applications

BY DR. STEVE LI AUBURN UNIVERSITY

BY DR. STEVE LI AUBURN UNIVERSITY

Over past couple of years, we’ve done considerable work with drones and have begun exploring the use of spray drones for applications in cropping systems. Below are several common questions.

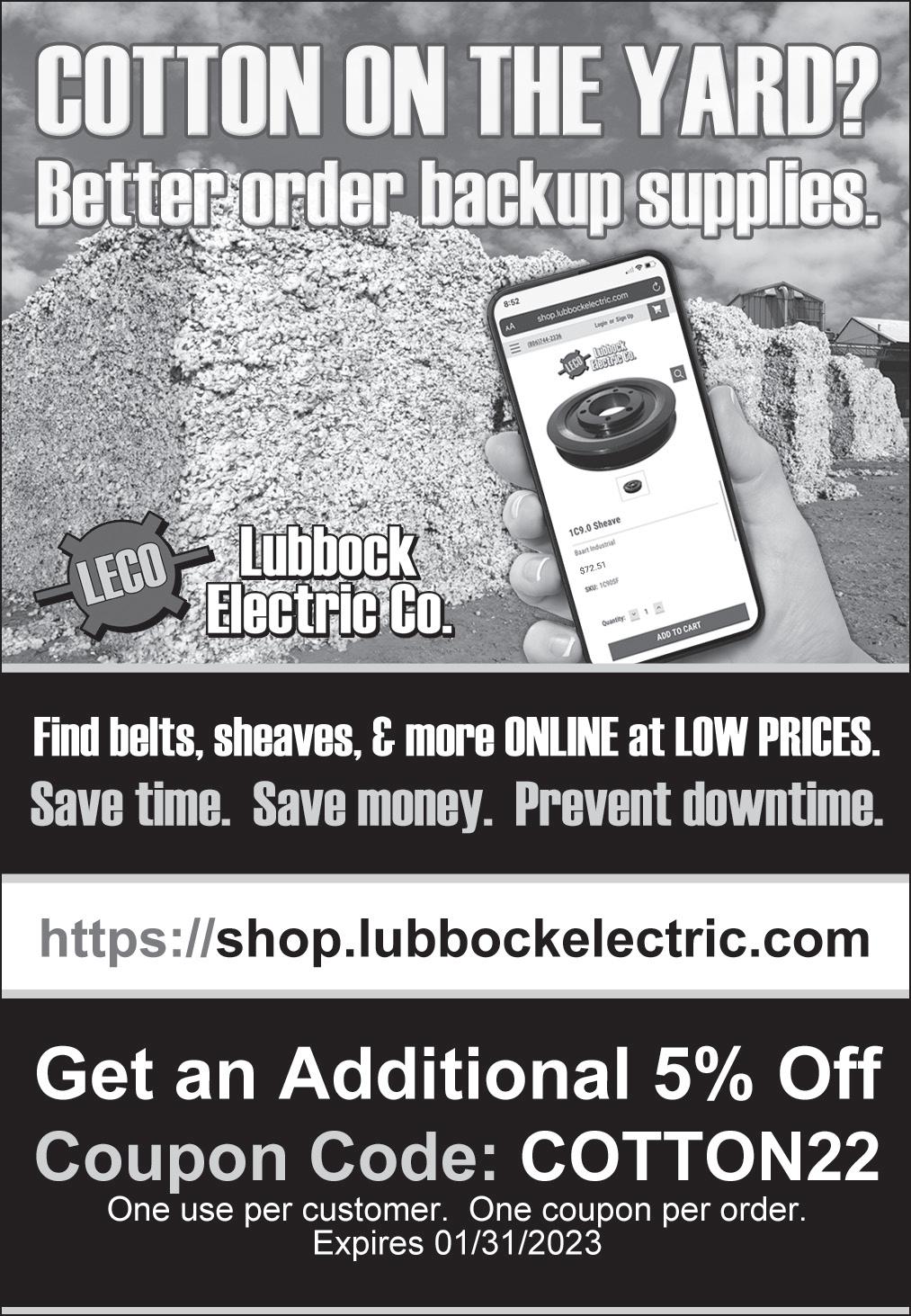

Q. How much do spray drones cost?

For three spray drones, for example, DJI’s flagship spray drone Agras T30, plus all the accessories should be around $90K. A single, well equipped, accessorized drone is about $30K.

Q. How many acres can a drone spray?

It depends on the size of the drone. The largest spray drone with a 30L (7.9 gallon) tank can cover around 25 acres per hour (with ideal field shape and long rows at 2 GPA). You can fly three drones at the same time legally with FAA approval. If spray volume is reduced to 1 GPA, one Agras T30 can cover 6 acres in about 7-8 minutes with a wider spray swath.

Q. Do you need to fly them manually?

Not really unless you switch to manual mode. For most spray jobs, spray drones can follow A-B lines automatically with GPS and RTK guidance. An operator does not need to intervene unless there is a problem. To spray field edges and irregular shapes, manual mode is usually required. The next generation Agras T40 is expected to have a contour mode which allows the sprayer to track around the field automatically.

Q. How long do batteries last?

Not very long, realistically about 8 minutes or so, fully charged with a full spray load.

Q. How long does it take to charge a battery?

Slow charging at 110v requires about 30 minutes per battery, but fast charging at 220V and 50 AMP only 12-15 minutes.

Q. Do batteries require cooling during charging?

It depends. DJI T30’s batteries do not but some other models do require a cooling device during fast charging.

Q. Are spray drones likely to hit trees or other obstacles?

Most of the time, no, because operating systems include collision avoidance radar. However, power lines and other wires present a possible hazard. Be extra careful when operating drones around telephone poles, wires, etc.

Q. Can spray drones follow terrain changes and maintain and spray at a constant altitude?

Yes, spray drones work well over hilly terrain. They have terrain radar to monitor and maintain flight height above the ground/crop canopy.

Q. Are spray drones durable?

Presently, experiences are limited and

there is not a large enough sample size to draw conclusions. Some growers have sprayed over 5,000-10,000 acres with the Agras T30 without major issues.

Propellers need to be replaced once in a while, and ESC, motors, flow meters and pumps are typical parts that often need to be replaced. They do have technical issues similar to any other electronics equipment (both hardware and software), but replacing these parts is usually not very difficult.

Sometimes, locating and procuring new parts can be a problem due to current supply chain issues.

Q. What are the best GPA, altitude and spray swath for spray drones?

This is a complex question because every spray drone is different and every chemical application is different. How to set these parameters depends on chemical properties, spray target and environmental conditions. One approach is to use 10 ft spray height and 20 ft swath. In

TWITTER: @COTTONFARMING DECEMBER 2022 | COTTON FARMING 17

Spray drone demonstration at the East Alabama Crops Tour.

Stillwater. degree in Dr. Banos, California in managepanel of merits conThey high fulltime in agriculcollege or Cotton will Agent of hired Extension and the headquartered at and was Boughen also certified assessment somedegree, assistant and Oklahoma supervised profesand with the limited called meet responsibilities as force. assessment varagencies funding

“My father, Stanley Nemec, was a cotton consultant and the CCOY honoree in 1987. What other career path could I have chosen after walking cotton fields with him since I was 7 years old?

“You have to be ready to roll the minute the sun comes up. I try to educate my growers as to what is going on in their fields. In central Texas, we have to be conservative because of input costs, weather and the challenges of dryland acreage.

“To me, it was a great honor to receive the CCOY award. We, as consultants, work hard to help growers make the best and most economical decisions for their operations. It is a humbling experience to be recognized for it.”

our research we also use a 15 ft height and 25 ft spray swath.

Q. What is required to meet FAA guidelines for using spray drones?

For drones over 55 lb, FAA exemptions include Parts 107 and 137. Some companies have an arrangement (with fees) to allow growers to operate under the company’s Part 137 certificate.

Q. What type of chemicals can be applied with spray drones?

Technically, any chemicals with aerial application labels should be covered for use with spray drones. You should not have mixing problems at the application volumes of 2-3 GPA. Consult product labels for specific information about mixing and application.

Q. Are applications with spray drones subject to drift?

Absolutely, any spray equipment has the potential to create issues with spray drift. This can be particularly troublesome with drones since they are a new type of aerial application. For applications made too high above the spray target or in windy conditions, drift can be particularly bad and can also result in a

loss of the intended spray pattern.

Q. What equipment is needed to facilitate applications with spray drones?

An operational trailer can serve as a base for generators, water and chemicals. These greatly aid in the efficiency of managing applications, particularly in large fields.

Q. Can GPS shape files in tractor systems be used for drone applications?

The answer is it depends. For big open fields without any obstacles in and around the field, shape files should work well. For fields with trees, telephone poles, wires, houses, etc., it is recommended to fly an RGB scouting drone first to generate a precision map.

The spray area can then be drawn on the precision map and exported to the spray drone as shape files. This is the best way to avoid collision. I would not trust satellite images from Google Earth due to the potential for collision. Various objects such as trees and other obstacles in those satellite images may not be current with present conditions.

For more information, contact Dr. Steve Li at 334-707-7370 or steveli@auburn.edu.

Cotton Consultant of the Year sponsored by Cotton Farming

18 COTTON FARMING | DECEMBER 2022 COTTONFARMING.COM

OCTOBER 2020 | COTTON FARMING 11

CCOY

Cotton Consultant of the Year

Mark Nemec

2010 CCOY AWARD RECIPIENT

established 1981

Ginners Marketplace

TCGA Requests Nominations For Ginner Of The Year

Take A Hard Look At Insurance Costs And Safety Culture At The Gin

Now is the time to begin sending in your nomination for the Texas Cotton Ginners’ Association Ginner of the Year. Please consider taking the time to write a nomination letter. This is the highest honor a gin manager can receive by peers in the industry. Guidelines for the selection of Ginner of the Year include:

of the Year, 211 West Bagdad Avenue, Round Rock, TX 786645803.

1. Service to customers by:

a. Quality ginning.

Distractions have become “routine” in our daily lives. Our phones go o , we get text messages and we’re bombarded by the never-ending news cycle. Everything seems to be trying to get our attention, and it’s easy to lose sight of what’s important. Things can sneak up on you, and those are the ones that will jump up and bite you.

b. Ethical business standards. c. Other constructive activities

In the last year or so, we’ve seen huge increases in our costs. As I write this, we’re getting news of the highest inflation in more than a generation… maybe two.

2. Service to all branches of the cotton industry through support and leadership of constructive activities and programs.

3. Other contributions to the people of the community, county and state such as: a. Civic leadership.

While I’m personally seeing some of the things that increased so much ease down a bit, it’s not common for costs that have gone up this much, this fast, to come down or come down very much. We will likely have to learn to live with some of them.

b. Philanthropic work.

The Cost Of Insurance

If you know of someone who deserves this prestigious honor, send us a letter describing his or her attributes. Supporting letters from other industry individuals and organizations are encouraged.

One of the costs that snuck up on many gins in the past year or so is the cost of insurance. Normally, this is a once-a-year expense we get hit with.

The past renewal cycle or two have been more than a bit of sticker shock for many in the ginning industry. Your associa-

Send nomination letters to the TCGA o ice by Dec. 31. Mail the information to the Texas Cotton Ginners’ Association, Ginner

The Texas Cotton Ginners’ Association provided this information.

tions have been aware of this and have brought it to the attention of our memberships. But I think many of us got distracted by the other things going on and have now been hit with the reality that it’s not getting better.

This is a simplified explanation, but insurance companies are going to do what they need to in order to stay in business. They must make money like we do. The companies take our premium and invest it. They pay claims with it, and they expect to have some left over. If losses are low and return on investment is good, you have happy insurance companies. We get stable premiums and competition.

NCGA Beltwide Cotton Conferences Ginning Meeting Schedule

Harrison Ashley, National Cotton Ginners Association executive vice president, has announced the dates and times (central time) for the ginner meetings during the Beltwide Cotton Conferences in New Orleans, Louisiana. They are as follows:

If they have poor investment returns and higher-than-expected cost of claims (read inflation), you have unhappy insurance companies. They may decide to pull out of the market and/or significantly increase rates. This is where we are today.

Tuesday, Jan. 10, 2023: 1:30 – 3:15 p.m., NCGA Safety and Labor Committee Studios 8-9

Your ginners associations and the National Cotton Ginners’ Association have been concerned about this for some time. We need healthy insurers and competition, but we really can only help one side of the insurance problem…losses. NCGA has put together a list of questions to ask yourself, so you can evaluate

Tuesday, Jan. 10, 2023: 3:30 – 5 p.m., NCGA Technology –Air Quality Subcommittee Studios 8-9 Wednesday, Jan. 11, 2023: 8 – 11 a.m., NCGA Technology Committee Galerie 1

PhysicalAddress:225BourneBoulevard•Savannah,Georgia31408-9586USA

MailingAddress:P.O.Box929•Pooler,Georgia31322-0929USA Phone:(912)447-9000•Fax:(912)447-9250

PhysicalAddress:225BourneBoulevard•Savannah,Georgia31408-9586USA MailingAddress:P.O.Box929•Pooler,Georgia31322-0929USA Phone:(912)447-9000•Fax:(912)447-9250

TollFree(USAOnly): 1-800-4LUMMUS (1-800-458-6687)

WebSite:www.lummus.com•E-mail:lummus.sales@lummus.com

TollFree(USAOnly): 1-800-4LUMMUS (1-800-458-6687) WebSite:www.lummus.com•E-mail:lummus.sales@lummus.com

COTTON

TWITTER: @COTTONFARMING DECEMBER 2022 | COTTON FARMING 19

Marketplace

COTTON FARMING IS THE OFFICIAL PUBLICATION OF THE GINNING INDUSTRY.

Cotton Ginners

*****

TWITTER: @COTTONFARMING AUGUST 2022 | COTTON FARMING 19

®

© 2022 Lummus Ag Technology Lummus Ag Technologywants to express its appreciation to our many loyal customers for their continued support and business. With the challenges we face in our industry, we are continually workingto evolve and adapt to changing market conditions and customer needs. Lummusoffersa wide range of products and services, all geared to help your operation be efficient and profitable. Regardless of the project scope, contact Lummus to discuss your goals and needsto ensure your success. Just a short listof items we offer: All-new complete Gin Plants Ginning Machinery (individual machines, stand-alone systems, presses, etc.) Press Consoles and Main Control Consoles Burner and Moisture Unit Gas Train/Controls upgrades Air Monitoring and Fire Detection Kits DGC 2020 Gin and Feeder Controls Gin Dor-Les® and E.E. Dor-Les® Press upgrades 16” diameter Bottom Ram Conversion Hydraulic Tramper/Pusher Conversion Premier™ III Series Hydraulic Pumping Units Press Rebuilds (strain rods, boxes, sills, etc.) Quality OEM Repair Parts UnmatchedTechnical Service The future is bright! Cotton prices have optimism at levels we haven’t seen in a while. A renewed commitment to customer service has Lummus excited for the future – join us as we move forward! © 2022Lummus Corporation

Wednesday, Jan. 11, 2023: 1:30 – 5 p.m., Ginning Conference Studios 2-3

Thursday, Jan. 12, 2023: 8 a.m. to noon, Joint Ginning/Engineering Systems Conference Studios 2-3

Please make plans to attend.

More Details Released About The Cotton Ginning Conference

The Cotton Ginning Conference will take place Jan. 11-12, 2023, during the Beltwide Cotton Conferences. The meetings begin at 1:30 p.m. Wednesday and conclude at noon Thursday at the New Orleans Marriott Hotel in New Orleans, Louisiana.

This technical conference provides a forum for researchers and industry representatives to exchange information on new technology to improve gin operation e iciency and the preservation of fiber quality. Industry issues are addressed by researchers and industry experts covering areas such as innovative management strategies, energy conservation and contamination. They also will discuss environmental regulations compliance, labor law compliance and safety.

A joint session with the Cotton Engineering Systems Conference will include the most recent cotton ginning and harvesting research results. The primary focus is on those related to cotton ginning and harvesting, environmental quality measurements and fiber quality preservation.

Here are a few of the topics and speakers:

2022 U.S. Cotton Quality Update. Robert L Seals, USDA-AMS, Cotton and Tobacco Program.

Cotton Gin Insurance Is in Turmoil; Where Do We Go from Here? Kyle Smith, Triangle Insurance Co.