PROFITABLE PRODUCTION STRATEGIES www.cottonfarming.com ONE GROWER PUBLISHING, LLC MARCH 2023 60-Inch Row Research In Louisiana Cotton Farmer Interest Is A Driving Factor Awards Recognize Mencer And Maeda Patchwork Fixes Can’t Hold California Water

FEATURES

12

BELTWIDE AWARDS

BASF sponsored two prestigious professional awards at the 2023 Beltwide Cotton Conferences: Cotton Marketer and Cotton Specialist of the Year.

14 CA WATER: PATCHWORK FIXES

California Farm Bureau’s Justin Fredrickson comments on the Golden State’s need to bulk up capacity to handle periodic abundance of intense rainfall.

20 GINNERS MARKETPLACE

the official publication of the ginning industry Duncan McCook, TCGA manager of regulatory a airs, discusses OSHA increasing nes and their enforcement guidance.

60-Inch Row Cotton

Grower interest and potential benefits are driving factors for 60-inch row research in Louisiana cotton. There is a lot of crop diversity on many of the state’s farms. Although farmers like to keep cotton in the mix, sometimes it’s difficult to do when the price drops and input costs increase. LSU AgCenter cotton specialist Matt Foster and Northeast Louisiana farmer Darrell VandeVen are looking at an option that may be the answer.

WEB EXCLUSIVE

Steve Stevens, Desha County, Arkansas, cotton farmer, said, “If we use up all the resources we have today, and we don’t leave something for future generations, how is the world going to eat? Go to www.cottonfarming. com for this Web Exclusive report.

ON THE COVER: Darrell and Donnie VandeVen grow 60-inch row cotton in Tensas Parish, Louisiana. Cover photo by Darrell VandeVen.

TWITTER: @COTTONFARMING MARCH 2023 COTTON FARMING 3

COTTON FARMING (ISSN 0746-8385) is published monthly January through December by One Grower Publishing LLC, 875 W. Poplar Ave., Suite 23, Box 305, Collierville, TN 38017. Periodicals postage paid at Memphis, Tennessee, and at additional mailing o ices. POSTMASTER: Send address changes to Omeda Communications, Customer Service Department, P.O. Box 1388, Northbrook, IL 60065-1388 (Phone: 847-559-7578) (Fax: 847-564-9453). Annual subscriptions are $40. International rates are $55 in Canada/Mexico, $90 in all other countries for air-speeded delivery. Surface delivery not available due to problems in reliability.

Vol. 67 No. 3

8 4 Editor’s Note 6 Cotton’s Agenda 7 Industry News 10 Southeast Report 16 Specialists Speaking 22 My Turn

MARCH 2023 PROFITABLE PRODUCTION STRATEGIES www.cottonfarming.com DEPARTMENTS & COLUMNS Management Practices ONE GROWER Supplement to Cotton Farming and The Peanut Grower Magazines Southern Production & Marketing Strategies Look for Corn South following page 12 in the Mid-South and Southeast editions of Cotton Farming .

have industry news and

up

monthly

SUPPLEMENT Building Back Strong TEXAS COTTON ANNUAL TRADE SHOW 30-31, 2023 TEXAS TEXAS COTTON GINNERS' ASSOCIATION Look for the 2023 TCGA Annual Meeting and

Show program following page 12 in the Texas and Oklahoma editions of Cotton Farming

To

content delivered directly to your inbox, sign

for the

e-newsletter at www.cornsouth.com

Trade

Editor’s Note

Carroll Smith

Ready, Get Set, Go!

Growing up in a small Louisiana town, I remember March was the month that sat on the winter side of spring. It was the time of year when you had to stick your head outside in the morning to decide whether to wear a jacket to school that day.

On the warmer days, our junior high PE teacher took us out to the field beside the main building, put us on teams and simulated a track meet of sorts. Most of the events were just foot races since we didn’t have any track equipment, not even starting blocks. Two people — one from each team — lined up, leaned forward a bit with our hands on our knees and waited for the count. Ready, get set, go!

I also remember Shirley Short, the fastest girl in our class. No one could beat her. But we all loved the competition, and I’m sure our teachers enjoyed us getting rid of some of our pent-up adolescent energy.

Ready

In the agricultural community, farmers, consultants, Extension experts and industry personnel find themselves hunched over in the starting blocks this time of year as well.

Get set

Some decisions have already been made, while others are still pending. For example, in the Specialists Speaking department on page 16, North Carolina cotton specialist Guy Collins said, “It’s a great time to start inquiring about seed quality and the North Carolina Department of Agriculture & Consumer Services Cotton Seed Testing Program. Any growers wanting their seed tested should know it’s the grower’s responsibility to ensure the inspectors are notified for testing the grower’s seed.”

And it’s always a good idea to attend winter meetings to hear the presentations and panel discussions that address topics you may still be on the fence about. Discussions often arise, so speak up and ask questions that may help in your decision-making process.

Go!

In most areas of the Cotton Belt, March is not quite go-time. But when the moment is right to crank up the planters, make sure you are ready to make the most out of the 2023 growing season!

EDITORIAL/PRODUCTION

Editor-In-Chief Carroll Smith csmith@onegrower.com

Southeast Editor Amanda Huber ahuber@onegrower.com

Associate Editor Cassidy Nemec cnemec@onegrower.com

Digital Content Editor Katie Guthrie

Art Director Ashley Kumpe

ADMINISTRATION

Publisher/Vice President LiaGuthrie (901) 497-3689 lguthrie@onegrower.com

Associate Publisher/Editor-In-Chief

CarrollSmith (901) 326-4443

Associate Publisher/Sales Scott Emerson (386) 462-1532 semerson@onegrower.com

Production Manager David Boyd dboyd@onegrower.com

Audience Services

Kate Thomas (847) 559-7514

For subscription changes or change of address, call (847) 559-7578 or email cottonfarming@omeda.com

EDITORIAL ADVISORY BOARD

David Burns – North Carolina

David Lynch – South Carolina

Bob McLendon – Georgia

Larkin Martin – Alabama

Mike Sturdivant Jr. – Mississippi

Charles Parker – Missouri

Jimmy Hargett – Tennessee

Allen Helms – Arkansas

Jay Hardwick – Louisiana

Ronnie Hopper – Texas

Ron Rayner – Arizona

John Pucheu – California

ONE GROWER

PUBLISHING, LLC

Mike Lamensdorf PRESIDENT/TREASURER Lia Guthrie PUBLISHER/VICE PRESIDENT

ACKNOWLEDGEMENT OF COOPERATION: Cooperating with COTTON FARMING are various cotton producer organizations across the Cotton Belt. Many representatives of producer organizations serve on COTTON FARMING’s editorial advisory board. Opinions expressed and conclusions reached by contributors are not necessarily those of the cooperating organizations or the editors. All statements, including product claims, are those of the person or organization making the statement or claim. The publisher does not adopt any such statement or claims as its own and any such statement or claim does not necessarily reflect the opinion of the publisher.

Copyright 2023 ©

ASSOCIATED PUBLICATIONS – One Grower Publishing, LLC also publishes RICE FARMING, THE PEANUT GROWER, SOYBEAN SOUTH and CORN SOUTH

If you have comments, please send them to: Cotton Farming Magazine, 7201 Eastern Ave., Germantown, TN 38138.

One Grower Publishing, LLC 875 W. Poplar Ave., Suite 23, Box 305 Collierville, TN 38017

4 COTTON FARMING MARCH 2023 COTTONFARMING.COM

Carroll

IN

ON HIGH YIELDS

A YIELD 50 YEARS IN THE MAKING

Mike Harris had a suspicion that something big was in the making.

In five decades, Harris has seen his fair share of good crops, as well as tough ones. But he witnessed something in 2022 that he never expected to see in Roper, North Carolina: 5-bale/A dryland cotton.

You don’t have to tell Harris that sounds like a stretch — he’d be hard pressed to believe it himself, if he didn’t see it with his own eyes.

“Everyone kept saying, ‘There’s something different about that cotton.’ It was full of bolls, loaded up and bowed out so that you couldn’t see the furrow,” Harris said. “You couldn’t see anything but cotton.”

Like many areas of the Cotton Belt, the North Carolina Blacklands received less-than-average rainfall last season. That makes it even harder to imagine, if it weren’t for the exceptional moisture-holding capacity of the rich Blackland soils. Those fields often make better yields in drier years, assuming a little rain comes at the right times.

“It was a dry year. We had some soybeans that died, and others that really weren’t worth harvesting,” Harris said. “But that cotton got a little rain at just the right time. The good Lord lined everything up. I’ve got to give credit to the soil, the season, our farm crew and Sam.”

Sam Winslow is farm manager at Harris Farms, and he said the 5-bale/A field was the last cotton they planted — on May 20. As the season progressed, people began talking about the crop, but Winslow didn’t think much of it. Until he received the phone call.

“The farm crew called when they got the cotton picker in the field and told me I needed to come out there,” Winslow said. “I rode to the field and just watched them line up round bales. I can tell you this: You’re in good-looking cotton when it’s yielding 2,500 pounds an acre.”

Winslow said they used 80 pounds of nitrogen and planted a new variety for 2022, PhytoGen® brand PHY 411 W3FE. Harris Farms has planted PhytoGen brand varieties for many years, and Winslow said there’s a lot to like about the performance. They also had good yields in 2022 with PhytoGen® brand PHY 400 W3FE and PHY 390 W3FE.

“PhytoGen varieties are generally easily managed plants so you don’t have to apply as much PGR. And I really like the Enlist weed control system — it’s been a key part of our weed control,” Winslow said. “At the end of the day, PhytoGen varieties hold good weight at gin-out.”

Harris said he’s planted PhytoGen brand varieties for many years, relying on the early season vigor to get the crop up fast and accumulate heat units early. A good start helps squeeze what you

can from whatever the season brings.

“You need early vigor to get it up as fast as it can. When it’s soaking up heat units — flowering, squaring, putting on bolls — that’s where your money is,” Harris said. “We like the PhytoGen varieties because they gin out more cotton at the end of the year. That’s what we’re selling, pounds of lint.”

While hitting the 5-bale mark is exciting, Harris said that’s an extraordinary situation, when everything lines up perfectly. He’s more interested in making consistently high yields, season after season, to see what Harris Farms can do in the next 50 years.

“I never imagined this when I formed Harris Farms in 1973,” Harris said. “Every year brings something different. We’ll plant cotton again next year and see what the season brings.”

to glyphosate. © 2023 Corteva

WEIGHING

™ ® Trademarks of Corteva Agriscience and its affiliated companies. The Enlist® weed control system is owned and developed by Corteva Agriscience LLC. Enlist Duo® and Enlist One® herbicides are not registered for sale or use in all states or counties. Contact your state pesticide regulatory agency to determine if a product is registered for sale or use in your area. Enlist Duo and Enlist One herbicides are the only 2,4-D products authorized for use with Enlist crops. Consult Enlist herbicide labels for weed species controlled. Always read and follow label directions. Roundup® and Roundup Ready® are trademarks of Bayer Group. ALWAYS READ AND FOLLOW PESTICIDE LABEL DIRECTIONS. Roundup Ready® technology contains genes that confer tolerance to glyphosate,

Roundup® brand agricultural herbicides. Agricultural herbicides containing glyphosate will kill crops that are not tolerant

an active ingredient in

Mike Harris (left), owner of Harris Farms, and farm manager Sam Winslow stand in a dryland field that made an incredible 5-bale/A yield last season in the North Carolina Blacklands.

Gary Adams

Data That Delivers

Why is Trust Protocol enrollment important?

■ Launched in 2020, the Trust Protocol was designed to set a new standard in making U.S. cotton more sustainably grown. However, producers enrolled in the Trust Protocol can realize another benefit — they are eligible to participate in the Climate Smart Cotton Program, which will provide technical and financial assistance to 1,650 U.S. cotton producers with acres available for Climate Smart practice changes. Another participation benefit is that producers also receive personalized data that can be used to help improve their sustainability efforts and their yields, as well as improve communication with their end customer. That’s important because sustainably grown cotton that is backed by verified data and measurable outcomes is highly sought after by brands and retailers.

Is manufacturer/retailer/brand enrollment strong?

■ The Trust Protocol has welcomed more than 1,100 brand, retailer, mill and manufacturer members, including Levi Strauss & Company, Old Navy, Gap, J. Crew and the most recent to join, American Eagle Outfitters (AEO). As with the others, we were very pleased to see AEO join as it is a leading global specialty retailer offering high-quality, on-trend cotton clothing, accessories and personal care products. Producers’ Trust Protocol membership will support AEO and the growing number of other brand/retailer participants in continued efforts at providing greater transparency. AEO, for example, has set specific goals to achieve carbon neutrality and significantly reduce water use, among other sustainability initiatives.

Is Trust Protocol data confidential?

■ Producers’ entered data is secure and remains confidential, used only in aggregate form. Crop consultants also can be authorized to enter information on a producer’s behalf. Additionally, the John Deere Operations Center can pre-populate up to 40% of the data needed to complete the Fieldprint analysis for those who utilize the platform. Producers can enroll and complete their data entry at https://trustuscotton.org/. Also, 2023 crop enrollment will open the second week of April, and producers should not hesitate to participate. For help enrolling, contact info@trustuscotton.org.

While producer participation in the Trust Protocol has doubled since the program’s pilot year, we need more cotton producers to enroll and complete their 2022 crop data entry before the March 31, 2023, deadline. That way more access to more sustainably grown cotton will be provided to brands and retailers along with science based, data-led assurances consumers can have confidence in — which has been somewhat lacking in the industry to date.

Overall, greater producer participation in the Trust Protocol will increase long-term demand for U.S. cotton. That strategic objective already is being reached as the NCC’s export promotions arm, Cotton Council International, is making U.S. cotton’s global customers very aware of efforts to document U.S. cotton producers’ sustainable strides. For example, participants in CCI’s 40-plus events in 16 of the largest cotton importing countries during 2022 indicated they expect to purchase $4.9 billion worth of U.S. cotton. Bottom line – producers’ Trust Protocol participation is contributing to serious momentum in the world marketplace.

6 COTTON FARMING MARCH 2023 COTTONFARMING.COM

Gary Adams is president/CEO of the National Cotton Council of America and Trust Protocol president.

Trust Protocol participating producers are encouraged to get other cotton producers to enroll their crop(s) in this sustainability initiative.

Cotton’s Agenda

The National Cotton Council strongly encourages its cotton producer members to enroll their 2022 cotton crop in the U.S. Cotton Trust Protocol before the March 31, 2023, deadline.

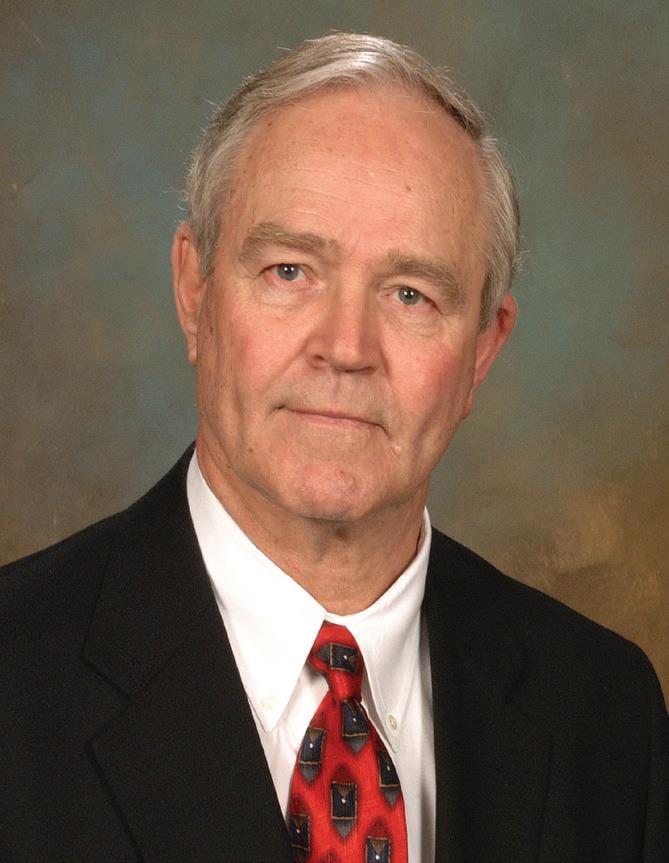

Kenneth Hood Honored With Oscar Johnston

Lifetime Achievement Award

The late Kenneth Hood, a former National Cotton Council vice president, treasurer, vice chairman and chairman, received the Oscar Johnston Lifetime Achievement Award in 2022. He was honored at the National Cotton Council’s 2023 annual meeting held Feb. 10-12 in Dallas, Texas, with outgoing NCC Chairman Ted Schneider presenting the award to Hood’s daughter, Lou Ann Petro.

The annual award, established in 1997, is named for Oscar Johnston, whose vision, genius and tireless efforts were foremost in the shaping and organization of the NCC. The award is presented to an individual who served the cotton industry, through the NCC, over a significant period of his or her active business career. The award also recognizes those who exerted a positive influence on the industry and who demonstrated character and integrity, as well as perseverance and maturation during that service.

Hood, a Mississippi native and Mississippi State University graduate, was active in local, state and national cotton organizations. He served on numerous NCC committees and chaired multiple committees, among them the Farm Program and Economic Policy Committee, Cottonseed Segment Representation Study Committee, its Bale Moisture Task Force, and the Beltwide Cotton Conferences Steering Committee. He continued serving as an advisor to the NCC until his death.

A former Delta Council president and chair of the American Farm Bureau Federation’s cotton committee, he also played a key role in Mississippi’s boll weevil eradication effort.

Hood was a partner in Perthshire Farms in Gunnison, Mississippi. He also was founder and board chairman of InTime, Inc., a precision agriculture consulting firm, was president of Hood Gin Company and Hood Equipment Company, and was a Board member of Staplcotn.

Schneider said Hood had a positive influence on his producer peers through his willingness to embrace cutting-edge technology.

“Kenneth’s willingness to adopt new technology was unmatched as was his eagerness to work with researchers on projects aimed at improving farming efficiency,” Schneider said. “He inspired oth-

ers to do the same.”

In addition, Hood was an active leader in ginner organizations. He was a former president of the National Cotton Ginners Association and the Southern Cotton Ginners Association.

A recipient of the NCC’s Harry S. Baker Award in 2008, Hood was honored over the years with many awards, among them Cotton Farming magazine’s Farmer of the Year, Cotton Grower magazine’s Cotton Achievement Award, Progressive Farmer Magazine’s Man of the Year in Service to Mississippi Agriculture, Farm Progress’ High Cotton Award, Delta Council’s Outstanding Conservation Farmer, Delta Business Journal’s Ag Profile Leadership Award, and the New York Cotton Exchange Cotton Marketer of the Year. He also was ginner of the year for both the Southern Cotton Ginners Association and the National Cotton Ginners Association and recently was selected to Cotton Incorporated’s Cotton Research and Promotion Hall of Fame’s 2022 class.

“Despite these many accolades,” Schneider said, “Kenneth remained humble and was always willing to give of his time whether it was for neighboring producers and researchers or association staffers and journalists. He was an energetic and innovative producer and ginner as well as a tireless servant and leader.”

TRAIT STEWARDSHIP RESPONSIBILITIES NOTICE TO FARMERS

Bayer is a member of Excellence Through Stewardship® (ETS). Bayer products are commercialized in accordance with ETS Product Launch Stewardship Guidance, and in compliance with Bayer’s Policy for Commercialization of Biotechnology-Derived Plant Products in Commodity Crops. Commercialized products have been approved for import into key export markets with functioning regulatory systems. Any crop or material produced from this product can only be exported to, or used, processed or sold in countries where all necessary regulatory approvals have been granted. It is a violation of national and international law to move material containing biotech traits across boundaries into nations where import is not permitted. Growers should talk to their grain handler or product purchaser to confirm their buying position for this product.

ALWAYS READ AND FOLLOW PESTICIDE LABEL DIRECTIONS. It is a violation of federal and state law to use any pesticide product other than in accordance with its labeling. NOT ALL formulations of dicamba, glyphosate or glufosinate are approved for in-crop use with XtendFlex® Cotton. ONLY USE FORMULATIONS THAT ARE SPECIFICALLY LABELED FOR SUCH USES AND APPROVED FOR SUCH USE IN THE STATE OF APPLICATION. Contact the U.S. EPA and your state pesticide regulatory agency with any questions about the approval status of dicamba herbicide products for in-crop use with XtendFlex® Cotton. B.t. products may not yet be registered in all states. Check with your representative for the registration status in your state. Products with XtendFlex® Technology contains genes that confer tolerance to glyphosate, glufosinate and dicamba. Glyphosate will kill crops that are not tolerant to glyphosate. Glufosinate will kill crops that are not tolerant to glufosinate. Dicamba will kill crops that are not tolerant to dicamba. Contact your seed brand dealer or refer to the Bayer Technology Use Guide for recommended weed control programs. Insect control technology provided by Vip3A is utilized under license from Syngenta Crop Protection AG. Bollgard®, Respect the Refuge and Cotton Design®, Roundup Ready Flex® and XtendFlex® are registered trademarks of Bayer Group. LibertyLink® and the Water Droplet Design® are registered trademarks of BASF. Agrisure Viptera® is a registered trademark of Syngenta Group Company. Excellence Through Stewardship® is a registered trademark of Excellence Through Stewardship. All other products, company names and trademarks are the property of their respective owners.

Before opening a bag of seed, be sure to read, understand and accept the stewardship requirements, including applicable refuge requirements for insect resistance management, for the biotechnology traits expressed in the seed as set forth in the Technology Stewardship Agreement that you sign. By opening and using a bag of seed, you are reaffirming your obligation to comply with the most recent stewardship requirements.

TWITTER: @COTTONFARMING MARCH 2023 COTTON FARMING 7 Industry News

Mississippi native Kenneth Hood was posthumously honored with the Oscar Johnston Lifetime Achievement Award at the National Cotton Council’s annual meeting.

60-Inch Row Research In Louisiana Cotton

Grower Interest And Potential Benefits Are Driving Factors

BY CARROLL SMITH EDITOR

BY CARROLL SMITH EDITOR

The agricultural landscape in Louisiana is diverse. Its farmers produce everything from cotton, soybeans, corn, rice and sugarcane to crawfish, peanuts and other commodities.

In areas of the state that predominately raise cotton, a typical rotation includes soybeans and corn. Although farmers like to keep cotton in the mix, sometimes it’s difficult to do when the price drops and input costs increase. One potential solution is to grow cotton on 60-inch rows instead of Louisiana’s popular 38-inch row configuration.

The grower-driven research involving 36- to 72-inch row spacing is ongoing throughout the Cotton Belt with mixed reviews. At the recent Louisiana Agricultural Technology & Management Conference, LSU AgCenter cotton specialist Matt Foster shared his evaluation of 60-inch row spacing in Louisiana cotton.

He said the potential benefits include:

Lower input costs.

Increased drought tolerance.

Lower occurrence of boll rot.

Improved harvest efficiency.

Standardization of equipment with grain crop rotation.

University Research E orts

“The main reason we are looking at it in Louisiana is that growers are interested in equipment standardization with a grain crop rotation,” Foster said. “They want to grow 30-inch soybeans and 30-inch corn.

“I conducted one trial on silt loam soil and noticed that when I applied anything above 60 units of nitrogen, the plants got huge. I also noticed that you have to start spraying the 60-inch rows earlier and more often with plant growth regulators. Once the plants get to a certain size, it’s hard to control them with a PGR.

“The yield trial was done at the Northeast Research Station at St. Joe, Louisiana, on irrigated Sharkey clay soil using five varieties. It was planted a little late, but we kept the seeding rate constant at three seed per foot of row. However, the 38-inch rows were 41,200 seed/A and the 60s were 26,100 seed/A. We kept all inputs the same as far as fertility, pest management and PGRs.”

Foster said he did not see a significant yield difference in

COVER STORY

HANK JONES

row spacing by variety, but he did see a difference among the varieties themselves. With the 60-inch rows, they are trying to see comparable yields, not a huge increase in yields. “It’s promising not to realize a difference,” he said. “This tells you that yield-wise you are not going to see a major drag in going to a 60-inch row.”

The main point is to cut costs where you can to keep cotton profitable. For example, he observed a seed cost savings based on plant population. The savings on the 60-inch rows was $43.12/A.

Foster wrapped up his presentation by pointing out that in addition to looking at benefits, you also must keep in mind the following potential drawbacks:

More prone to lodging, especially with a hurricane.

Delayed maturity.

Potential for weed escapes if plants don’t lap the middles late in the season.

Defoliation could be an issue due to lateness.

Because of increasing farmer interest in the 60-inch row configuration, Foster has more research on tap for the future. Some of the topics he wants to explore include variety performance and production practices, plant mapping in both row spacings and overall economic benefits of 60-inch rows compared to the 38-inch row system.

A Farmer’s Perspective

Darrell VandeVen farms cotton, corn, soybeans and rice with his brother, Donnie, in Tensas Parish, Louisiana. About 70% of their operation is irrigated. After a disappointing year with cotton in 2019, they decided to try something radically different going forward to improve the economics and keep cotton in their rotation.

“We decided to try planting on 60-inch rows — our cotton farming equivalent of a Hail Mary pass,” Darrell said. “We saw an opportunity in a 60-inch-row pattern to address our two biggest hurdles in growing cotton profitably — high cost of production and damage from wet weather in the fall. We also felt we could do some things in the 60-inch system to save a significant amount of money. We could reduce seed and fertilizer and hopefully some early season insecticide applications on a 20-inch band.”

If they could yield the same as they had on their conventional 38-inch rows while spending less money per acre, it might

help cotton remain a viable crop for them. Another benefit the brothers were hoping for was that the 60-inch system in cotton would make it easy to go to 30-inch rows on corn and beans. Before the 2020 season rolled around, they converted their rows to 60 inches and have successfully grown cotton, corn and soybeans in this system for the past three years.

To harvest the 60-inch row cotton, the VandeVens modified their six-row picker and said it did a good job. An added benefit was having more room between the rows to service the picker.

‘Expense Side Of The Ledger’

“There are still things we need to tweak and still trying to learn what works best, but I believe we are more or less there,” Darrell said. “I am convinced it is a good, viable system that will do well, especially in the Lower Delta. When we went into this, we were looking more at the expense side of the ledger. We wanted to make the same cotton but spend less money on it. We have certainly done that. Yield-wise, I am comfortable saying we are not giving up anything, and there may be some situations where we can realize gains.”

The Louisiana farmer said one of their big savings is on seed. They plant 20,000 seed/A compared to most farmers planting about 35,000 seed/A. They have reduced their fertilizer a little bit, and some of the early season insect sprays are going out on a 20-inch band, so they are only spraying onethird of the field.

“We are saving about $60/A on seed, maybe $20/A on fertilizer and about $10/A on each of the two or three banded insect sprays,” Darrell said. “That adds up to $100 to $110 an acre in savings. If you can make the same yield, that money is all to the good.

“I believe it’s a system that ties together the best of everything — 30-inch rows on the grain and 60-inch row cotton,” he added. “You’re benefiting somewhere either in yield or expenses, depending on which crop you are talking about — cotton, corn or soybeans. Most of the farmers around here grow those three crops, and some of my friends got sold on the 60-inch row spacing and are in the process of converting everything.

“To rework all the ground and put it up in rows on a new pattern is a lot to bite off. But I think that over time, we will see more and more interest in it.”

TWITTER: @COTTONFARMING MARCH 2023 COTTON FARMING 9

Darrell VandeVen and his brother, Donnie, farm 60-inch row cotton in Tensas Parish, Louisiana. From just planted on the left to harvest with a modified picker on the right, the brothers are convinced it is a good, viable system that will do well in their rotation.

PHOTOS BY DARRELL VANDEVEN

Thrips In Southeast Cotton Can Be A Problem

If not managed properly, thrips can cause devasting losses to cotton grown in the Southeast. Injury symptoms can range from leaf curling to delays in crop maturity, stand loss and reduced lint. And less lint means less money in producers’ pockets.

“Thrips are a top-five pest in terms of acres treated in every Southeastern state, and they’ve been a priority for Cotton Incorporated-funded research projects every year I’ve been with the company,” said Ryan Kurtz, Vice President of Ag & Environmental Research at Cotton Incorporated.

Research has proven that if thrips aren’t managed timely and properly, a farmer could experience as much as a 400- to 600-pound yield loss. The application of aldicarb insecticide was once the primary option used by cotton producers in the Southeast to reduce thrips, but over the past 20 years, limited availability and the need for specialized equipment has producers primarily using seed treatments, in-furrow liquids and/or foliar sprays.

Control Weeds And Scout

For the past 10 to 12 years, entomologists from the cotton-producing states in the Southeast have worked together to develop practices and recommendations for managing thrips. One of those entomologists, Dr. Sally Taylor from Virginia Tech, has recently joined Cotton Incorporated’s Ag & Environmental Research team.

“We’re lucky to have Sally joining us since Virginia has the highest level of thrips in the Southeast. She brings a wealth of experience and knowledge in thrips management to the team,” said Kurtz.

When asked about her recommendations for battling thrips in the Southeast, Dr. Taylor said, “Seed treatments can provide control of thrips and give an increased lint yield. If you supplement with foliar treatments, you can improve your seedling size and lint yield. The first leaf stage is the time you want to apply a supplemental foliar spray. If you don’t scout your cotton and get on thrips early,

BY MONTY BAIN DADEVILLE, ALABAMA

you could cut into your yield and your profits. So, weed control and scouting for thrips should be a priority.”

Other Thrips Prevention Tools

Another option in thrips prevention is a new biotechnology called ThryvOn™ that was developed by Bayer CropScience. ThryvOn™ started out as a technology to deter tarnished plant bugs. However, as researchers have continued to evaluate the technology, they have found that its true benefit comes in protecting early season cotton from thrips. Unlike other methods, ThryvOn™ Technology is bred into the plant, thus decreasing the need for insecticide applications. It doesn’t cause thrips or plant bugs to die from eating on the

vegetative growths. Instead, it makes the plant less desirable, thus causing a lower population of adults to lay their offspring.

Producers also have access to a “Thrips Infestation Predictor” tool thanks to North Carolina State University’s Climate Office (https://products.climate. ncsu.edu/ag/cottontip/). The Thrips Infestation Predictor for Cotton uses weather data to make predictions of:

Thrips dispersal timing.

Cotton growth affecting seedling susceptibility.

Injury risk that results from thrips dispersal and seedling susceptibility occurring at the same time. Running this tool requires users to enter a planting date and a location. Additionally, users can adjust how many days to run and display model output.

With the real threat of thrips damage in the Southeast, Cotton Incorporated is dedicated to funding research, employing experts and providing tools to growers — all in the hopes of protecting producer profitability. For more information on thrip-related research projects, visit cottoncultivated.cottoninc.com.

Monty Bain is the Cotton Board’s regional communication manager for the Southeast. Email him at mbain@cottonboard.org.

10 COTTON FARMING | MARCH 2023 COTTONFARMING.COM

SOUTHEAST REPORT

Photos of cotton seedlings planted with (top) and without (bottom) an insecticidal seed treatment to control thrips. Note that even with a seed treatment, if plants display thrips injury, and populations are active, a foliar application may be recommended.

WE KNOW ALL ABOUT STRONG STARTS.

EARLY Always read and follow label directions. Stoneville is a registered trademark of BASF. © 2023 BASF Corporation. All rights reserved.

OWN THE

For over 100 years, Stoneville® cotton has gotten out of the ground fast for a strong early stand. And with our Variety Selector Tool, you can see which combination of traits and disease-fighting capabilities will thrive in the conditions you face — giving you a huge advantage early on. Find the variety that’s right for your field at Stoneville-Varieties.com

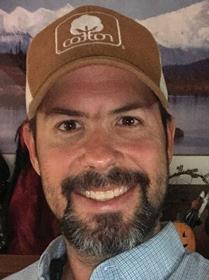

Cotton Marketer, Cotton Specialist Of The Year Honored At Beltwide

At the 2023 Beltwide Cotton Conferences, BASF sponsored two prestigious professional awards: Cotton Marketer and Cotton Specialist of the Year. Arkansas cotton grower Joe Mencer was named Cotton Marketer of the Year and Dr. Murilo Maeda, assistant professor and Extension cotton specialist from Texas A&M University AgriLife Extension, in Lubbock, Texas, was named the 2023 Cotton Specialist of the Year.

Cotton Marketer Of The Year

The Joseph J. O’Neill Cotton Marketer of the Year award presented by ICE Futures (formerly the New York Cotton Exchange) and BASF dates back to 1991.

Joe Mencer is this year’s award winner. Mencer is a third-generation farmer and has been farming since 1979 when he started his operation in Lake Village, Arkansas, with 125 acres of rice on his father and uncle’s land. Mencer had been working for his family since he was old enough to drive the equipment used on their farm. Today, Mencer grows 1,800 acres of cotton, 1,800 acres of rice, 1,000 acres of corn and 2,400 acres of soybeans. He also manages 1,600 acres of timber across Arkansas and Mississippi.

“Mencer has been doing this a long time, and he understands all aspects of the business, which goes beyond just growing the crop itself,” said Jerry Ford, BASF area manager. “Marketing and sharing knowledge of the product, along with the production of the product are a huge part of our industry, a part that Mencer has taken pride in and woven into his business fluidly.”

Mencer runs a family business with the help of his wife and two sons. His younger son runs a trucking company that hauls the cotton and grain for the farm, while his older son has a law degree and assists with all legal matters for the operation. Mencer is also heavily involved in many agriculture boards and committees, including the Arkansas Boll Weevil Board, repre-

senting Arkansas on the National Boll Weevil Board, the USA Rice and Arkansas Rice boards, the Arkansas Ag Council, the local NRCS Board, and the local Farm Bureau Board and Delta ACA Farm Credit Board.

Cotton Specialist Of The Year

Voted on by cotton specialists in the 17 states where cotton is grown, this highly esteemed award is based on several considerations, including exceptional leadership and outstanding industry service.

Dr. Maeda works as a Texas Extension cotton specialist. He has been in the cotton industry his entire life, growing up in Brazil on his family’s cotton farm. Maeda came to the United States in 2010 to pursue his master’s degree in agronomy and crop physiology in 2012 and his doctoral degree in agronomy and crop physiology in 2015 from Texas A&M University. In 2018, he made his debut in Extension. Maeda was the recipient of the 2021 Dr. J. Tom Cothren Outstanding Young Cotton Physiologist Award.

“Along with solid field knowledge, Dr. Maeda also brought an excellent focus in technology, specifically a focus into drone use for producers,” said Kenny Melton, BASF Agronomic Services Manager. “He does a great job bringing West Texas producers into the 21st century and beyond. Not only does he bring the technological knowledge needed to make advancements, but he also does a great job explaining what he is doing and why so producers can have a baseline knowledge as well.”

Maeda recently accepted a full-time position with BASF as its breeding technology manager. Along with his wife and two children, he will be moving back to Brazil to use his focus on drones and the sensing industry to work on BASF’s cotton breeding business in Brazil.

BASF contributed this article.

12 COTTON FARMING | MARCH 2023 COTTONFARMING.COM

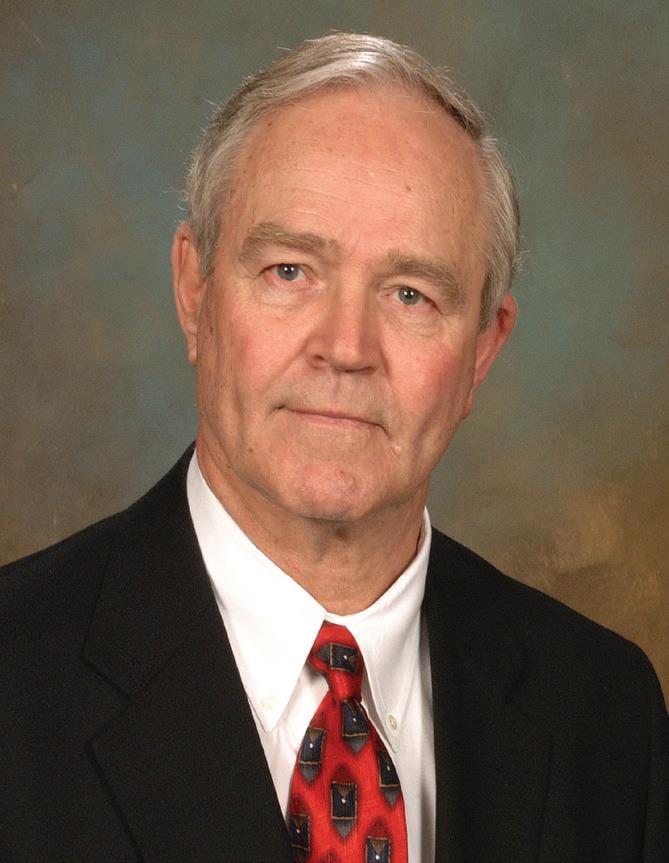

Third-generation Arkansas farmer and Cotton Marketer of the Year Award winner Joe Mencer (left) pictured with O.A. Cleveland, professor emeritus, Agricultural Economics at Mississippi State University.

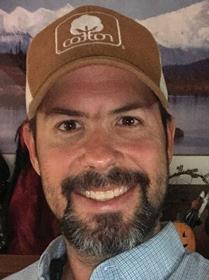

Hunter Frame (left), Virginia Tech and Beltwide Cooperative Extension Cotton Specialists president, joins Dr. Murilo Maeda, Texas Extension cotton specialist — Cotton Specialist of the Year Award winner.

Pest Control With Benefits

Consistency, Earliness Are Advantageous To Cotton Farmers

Sometimes it’s nice to have a few years under your belt to assess if you’re actually on the right track. After all, one good year does not a good decade make. Nor does one bad year. Or one so-so year.

“We had good year in 2022, all things considered,” said Lyle Carraway, a grower in Bishopville, South Carolina. “Cotton and beans turned out pretty good. We didn’t plant corn due to fertilizer costs.”

With everything put to bed for 2022, Carraway said he’s mostly running around burning fuel thinking about what comes next. “There are so many factors to consider,” he said. “Inflation, supply chain issues, pest pressure, weather, emerging technologies. You name it.”

One thing is certain. He’ll be using AgLogic 15GG aldicarb again in 2023. “It’s consistent, saves me time, and if everything goes somewhat as planned, it makes me money.”

Early Season Pest Insurance

Similar to other growers, Carraway uses AgLogic 15GG for thrips and nematode control. But there are other benefits as well. “I like the consistency,” he said.

Since aldicarb (AgLogic 15GG) was reinstated to the market in 2016 after a brief hiatus, that advantage rings true now as much as it has in more than 50 years. In an increasingly complex agricultural environment, performance consistency is a reassuring factor in any aspect of crop production.

Beyond Thrips And Nematodes

“Cotton growers have benefited from the registration of aldicarb in several ways,” said Ron Smith, visiting professor (retired), entomology and plant pathology, Auburn University. “The consistent, highly effective thrips control provided by aldicarb results in farmers not needing to make foliar sprays for thrips. Our observations indicate that cotton treated with aldicarb is less likely to be infested with threshold levels of spider mites.

“This may result from a combination of spider mite control and not making a foliar thrips spray with disruptive chemicals,” Smith continued. “In addition to insect

control, aldicarb also provides suppression of nematodes and has an important fit in nematode-infested fields.”

Thrips and nematode control are two reasons Lynn Hopkins has been using AgLogic on his cotton for the past three years. However, there are other reasons. Hopkins farms in Lee County, South Carolina. “The earliness we get out of the product is definitely an advantage,” he says. “The pest control is the obvious benefit, but getting the crop to jump out of the ground and get going is also a benefit.”

Hopkins applies AgLogic 15GG aldicarb at a rate of 5 lbs. per acre on his cotton. “The early thrips control saves me at least one trip across the field with a sprayer,” he said. “Since I’m a one-man operation, that advantage becomes even more valuable.”

Weather Factors

Weather events over the past few years have made consistency of control even more important. Although thrips and nematodes are the primary reasons for early season use of AgLogic 15GG aldicarb, there is also the anticipation of what might come later. Weather is largely an unknown factor and can impact pest populations long after plant emergence.

In recent years, spring weather and peak thrips populations have been unpredictable according to Scott Graham, assistant professor and Extension specialist, Auburn University.

“In the past two years, wet springs have pushed our planting windows later in many areas,” he said. “This resulted in cotton being planted into the peak thrips pressure window, which is normally expected to be early in the planting season. The Thrips Infestation Predictor Model provides farmers with information on the risk of thrips injury based on planting dates, but sometimes this model is too late to decide on when to use aldicarb or rely on seed treatments alone.”

With planting looming shortly on the horizon, growers are turning their attention from the deer stand to upcoming management challenges. “One of the reasons I like using AgLogic is I don’t have to worry about everything quite as much,” Hopkins said. “That doesn’t mean there isn’t plenty to worry about, but it’s nice to know you can rest a little easier with thrips and nematode control early on.”

TWITTER: @COTTONFARMING MARCH 2023 | COTTON FARMING 13

Brenda Carol submitted this article on behalf of AgLogic.

South Carolina cotton farmer Lyle Carraway said the performance consistency of aldicarb is reassuring to him.

Lynn Hopkins, who farms cotton in Lee County, South Carolina, said early thrips control saves him at least one trip across the field with a sprayer.

Patchwork Fixes Can’t Hold Water Or Serve California

BY JUSTIN FREDRICKSON CALIFORNIA FARM BUREAU

To weather extended and intensifying droughts we have experienced, and that we know are likely just around the bend again, we need to seriously bulk up our capacity to better handle the periodic abundance of intense rainfall, such as last month’s storms.

Updating infrastructure to capture and store excess flows is essential to long-term system resiliency. This can occur through wise land stewardship and regional projects along the way before fast-moving water gets to the bottom of the conveyance system. One major reality, though, is that the big events in California are so flashy, and generate such vast amounts of runoff in so short a time, that the enormous bathtub formed by mountains girding California’s Central Valley inevitably just funnels uncaptured flows through the Sacramento-San Joaquin River Delta and into the Pacific Ocean.

“Water Parking Lot”

Aging 1950s- and 1960s-era state and federal project pumps in the south Delta are capable of skimming off at least a fraction of this water and, in a reasonably good year, sending it south to a water parking lot of sorts: the San Luis Reservoir near Los Banos. From there, state and federal project water, stored from a handful of brief intense winter storms and spring snowmelt, can be later allocated to farmland in the south valley and to millions of residents in Southern California.

However, in recent years first-ever back-to-back zero or near-zero water allocations revealed that this system — built decades ago for another era — has become alarmingly unreliable, and such chronic water scarcity is no longer just a drought-year phenomenon. Seeking to address this problem, California has offered multiple iterations of a proposed Delta conveyance project. A 40-mile underground tunnel is conceived as a means to bypass biological and regulatory issues related to diverting Sacramento River water under or around the Sacramento-San Joaquin Delta estuary. This project has faced environmental lawsuits, planning and permitting hurdles and opposition from water users and communities in the mostly agricultural delta, which relies on freshwater flowing downstream to push back saltwater from the San Francisco Bay.

Though proposed to counteract significant current and future water-supply losses, the delta conveyance plan does not propose to add water above former historic levels of reliability. It also does not address serious emerging stresses on another major California water source: the Colorado River. Another project, the proposed Sites Reservoir, 100 miles north of Sacramento, could add about a half million acre-feet of new supply a year, but that project is years from completion. Desalination and recycled water are other options. Yet, even with all of that, California would still have a large and growing gap in its statewide water portfolio.

Meanwhile, the California State Water Resources Control

Board aggressively continues to push mandated “unimpaired flows” for the Sacramento and San Joaquin rivers in an economically harmful policy that removes millions of acre-feet of water from agricultural use. And the staged rollout of California’s Sustainability Groundwater Management Act is putting a major squeeze on historically groundwater-supported agriculture.

Struggling to fill the enormous California water-supply hole is an emerging patchwork quilt of potential interconnected smaller-scale fixes. These include proposed regional groundwater projects and some intriguing new ideas on ways to safely and cost effectively capture excess delta flows to bank more wet-year supplies in the South Valley. Unfortunately, most such proposals are years away. And existing permitting processes for badly needed groundwater recharge are inefficient, expensive, uncertain and ill suited to capture excess flood flows on a scale needed when water is in abundance.

It leaves us, again, stuck in a zero-sum world, one major flood or drought away from the next major disaster or major missed opportunity for enhancing California’s water supply.

It’s no way to run the 5th largest economy in the world — or stock America’s produce aisles and sustain one of the world’s great food producing regions. The epic flooding this year, on the heels of the last three years of drought, should be an obvious wake-up call. This is what nature has in store for us, and so we need to work with it. We need to match our system to the boombust rhythm of California’s climate to secure our water resources. We need to be bold and envision possibilities instead of limits.

In the face of historic water-supply challenges, California needs to get serious on a viable set of solutions for the entire state. Either that, or we continue our slide down the unproductive path of chronic water shortages, constant conflict and slow economic decline.

14 COTTON FARMING | MARCH 2023 COTTONFARMING.COM COMMENTARY

Floodwaters overflow the Colusa Weir on the Sacramento River on Jan. 12. California’s water infrastructure was ill-equipped to capture abundant rainfall from the atmospheric river storms.

Cotton Flag, U.S.A.

How One South Carolina Farmer Showed His Patriotism Through Harvest

BY CASSIDY NEMEC ASSOCIATE EDITOR

ASouth Carolina farmer used his pent-up creativity in a cotton field — without relying on GPS.

Scott Barfield, a Hartsville, South Carolina, farmer, works for Gill Rogers of Rogers Brothers Farm, one of the largest farms in the state. After being with Gill for over 21 years now, he wanted an outlet for showing his American pride at the end of the 2022 cotton season.

Last spring, Rogers Brothers Farm employees planted 48 acres of cotton on Bishopville, South Carolina, farmland. This farmland, located near Interstate 20, is rented by Rogers for cotton acres. Barfield decided to create what he suspects is the world’s largest American flag to break up the tediousness of picking cotton.

“It’s very monotonous. When we get into the fields, we try to pick them in different ways to break up that monotony,” he said. “I was in one field with our six-row picker. I’d pick six rows, then I’d skip six. After I made five or six passes like that, I was looking back at where I’d already picked and thought, ‘Well, that looks like the stripes of the flag … I wonder if I could make a flag.’”

After discussing his idea that night with

his wife, he committed to it the next day.

“I started jotting down how six rows is about 15 feet so figuring how big the flag was going to be from that. I started going down this rabbit hole of looking up the largest flag in the world. It’s not a full flying flag, but this could be the largest flag in the world.”

Barfield said he went from there and mapped it all out in his head and on paper how he wanted to do it and got the stamp of approval from Gill.

In early December of 2022, after the cotton in the field was ready to be picked, Barfield finished some selective picking to create the stripes of the flag. He then positioned 50 cotton bales to represent the stars of the flag.

“It took about three and a half hours to do the picking and three or four hours to stage the cotton modules,” he said. Barfield was not using GPS, so he “eyeballed” the whole project. The result is a 390 feet tall by 741 feet wide flag.

Barfield comes by his love for farming naturally as his grandfather, great-grandfather and great-uncle were also farmers. He said he has already contemplated what he might do during harvest time this next season.

“I talked to Gill about it and was thinking about reaching out to Guinness to work on another one.”

With big goals and lots of potential ahead, the Rogers Brothers Farm will always have the 2022 cotton crop as one they look back on for years to come. The 2023 cotton harvest in South Carolina is bound to be an exciting one.

TWITTER: @COTTONFARMING MARCH 2023 | COTTON FARMING 15

Scott Barfield, creator of the cotton flag, with his daughter Skylar on the farm.

Last-minute Tips To Get Primed For Planting

NORTH CAROLINA Guy Collins

As I write this Jan. 29, we are preparing for our winter cotton meeting season (aka “the BBQ circuit”), which begins next week. Thankfully, most growers are coming out of another good year for cotton with some reporting record yields, others reporting well-above-average yields and some reporting average or slightly less. Despite noticeably higher input costs, there were plenty of opportunities to book last year’s crop at high prices. When considered along with a “good” year in many places, most growers had another good experience with cotton in 2022, with a positive outlook for cotton in 2023. We have yet to see exactly how expensive this crop will be to produce, but cotton prices have fallen somewhat, so these two things will influence acreage decisions as we approach our planting season.

Although March is well before planting season, it is a great time to start inquiring about seed quality and the NCDA & CS Cotton Seed Testing Program. As seed arrives in North Carolina, the NCDA inspectors will be actively testing seed lots they find. However, the inspectors only collect samples from lots in which they were notified of arrival — or ones that they happen to find. Therefore, any growers wanting their seed tested should know that it is the grower’s responsibility to ensure the inspectors are notified for testing the grower’s seed. This should be done well ahead of planting season, as it is difficult to process seed through the lab in time for planting once we get to mid-April or later.

It is important to remember the difference in official versus service samples, in that official samples must be collected by inspectors from unopened bags or containers. Anyone can collect a service sample from opened bags and submit it for testing, but it holds no merit in any official complaints if one were to arise. It is important to know the difference in the two types of samples — especially for any seed to be treated at the dealer level — if an official sample is desired by the grower. guy_collins@ncsu.edu

TENNESSEE Tyson Raper

Conversations lately have focused on input prices and how to pencil out a profit in the 2023 crop. Over the past several years, I’ve spent quite a bit of time visiting with several people in the industry and testing approaches that might reduce financial risk associated with our crop.

First, I believe several of our mid-maturing varieties perform better when seeding rates are selected to target two plants per row foot on 38-inch rows. This represents a substantial reduction in seed cost, often increases first position fruit retention, reduces PGR needs and lowers first fruiting node relative to thicker stands. Ultra-wide row has generated some press over the past few years. I would argue those on 38-inch to 42-inch row spacing can create the same plant response and similar cost savings observed in the 60-inch to 76-inch spacings by dropping seeding rate in a solid planting scenario.

Second, on most of our silt loam or heavier soils, there may be an opportunity to maintain yields with slightly less nitrogen. In addition to reducing N cost, this reduces needs for PGRs, can increase first position fruit retention low on the plant, supports earliness, reduces disease pressure, increases penetration of insecticides and eases defoliation.

I would challenge you in 2023 to re-evaluate seeding rate and N rate on your operation. I believe you may just find savings on these two inputs domino into greater returns by the end of the season. traper@utk.edu

GEORGIA Camp Hand

It is hard to believe we are getting ready for another growing season. The weather yesterday (Feb. 5) had me itching to plant something, so I planted potatoes and asparagus in my garden. I hope I didn’t jump the gun!

As I look forward to my third crop in this position, I am grateful to be in Georgia working with some of the best county Extension agents and growers in the country.

We are in a much different situation coming into 2023 than we were this time a year ago. Unfortunately, inputs are still high. This time a year ago, December futures for cotton climbed to $1.25 or $1.30 per pound, but now, we are hovering between $0.80 and $0.90 per pound. We are in a tighter spot, and I think there is less room for error this go-round. We need to ensure we are maximizing the inputs we are using and not cutting things that are going to help us out. Big things that come to mind are early season investments that help us in the long run: preemergence residual herbicide, insecticide seed treatments (if not using AgLogic), preplant fertilizer, nematicides, etc. Many of these inputs are vital to our success as cotton producers, and cutting them might save a little bit on the front end and cost us on the back end.

One of the best things I think we can do this time of year is ensure our equipment is ready to go for the upcoming season. It is easy to park a piece of equipment and forget about it until it is needed, but now is the time to make sure everything is tuned up and ready to go. Of course, the most important piece of equipment to growers at the beginning of the season is their planter, so a good run through of that isn’t a bad idea. Drs. Wes Porter and Simer Virk here at UGA have published a row-crop planter checklist to help get your planter tuned up. It can be found here: https://bit.ly/3sMdPpn. To make three-bale cotton, we have to get off to a good start and get a good stand, and I think this resource is helpful with that.

As always, your local UGA county Extension agents and specialists are here to help! Reach out if you have any questions. camphand@uga.edu

MISSOURI Bradley Wilson

Low temperatures in southeast Missouri make me feel like we are still a long way from planting, and this is particularly true as the planting window is generally from late April to late May. Recently, our planting window has been even shorter due to the wet spring conditions in late April.

There are several factors to remember before any potential planting. Variety selection is always important, as variety performance can differ across various soil types in the Bootheel. Making our variety selections early will provide us confidence that we will have our preferred selections at planting.

Another factor to consider is weed management prior to planting. Starting out weed free is essential to a great start, as competition with weeds can reduce stand establishment, growth potential and harbor insect pests following planting. Therefore, pre-plant burndown applications need to be made at least four weeks prior to planting to ensure clean fields.

Early planting is a key component to producing adaquate yields in a short-season environment. However, planting into poor conditions or reduced soil temperatures in an attempt to get the crop in can rob potential yield increases. It is important to remember soil temperatures should be at least 65 degrees Fahrenheit at three to four inches with a positive five-day outlook prior to any potential planting.

16 COTTON FARMING | MARCH 2023 COTTONFARMING.COM

Specialists Speaking

In 2022, we were forced into later planting situations, and an early frost had an impact on several acres. If we are forced into planting late or replant situations in 2023, it may be wise to reduce our nitrogen rates to 80 or 90 pounds to account for the possibility of a shorter season. brwilson@missouri.edu

MISSISSIPPI Brian Pieralisi

As I write this Feb. 3, there is still a lot of uncertainty around 2023 cotton in Mississippi. However, we thrive in a world of uncertainty, which makes this situation somewhat normal. Cotton market prices are lower than last year, input costs remain high and acreage competition between corn and soybean is in favor of the grain crops due to those market prices. Another curve ball to anticipate is Punxsutawney Phil seeing his shadow. If this prediction holds true, and we experience six more weeks of winter, it could compromise some corn acreage.

Now is a good time to finish any tillage practices that were left undone in the fall. Obviously, weather and field conditions limit easy access to tillage this time of year. Also, with more cover-cropped acres in Mississippi, paying close attention to cover crop biomass production could aid in an effective termination. Almost every grower has a different practice and reason for their timing, but knowing what works for your operation and timing it right is key.

Lastly, we did some work in 2022 to rate the number of days of control from preemergence herbicides in the absence of dicamba. Across multiple locations, the top performers were Brake, Caparol, Cotoran, Cotoran + Caporal and Diuron. In 2022 — a dryer year — we saw 28 days of control from these products. Best of luck! bkp4@msstate.edu

ALABAMA Steve M. Brown

At the recent Beltwide Cotton Conference in New Orleans, I had multiple conversations with current and former seed company representatives about the critical importance of seed quality. Obviously, companies are keenly aware of the need for a quality product, but I was pressing the issue.

For producers in the Lower Southeast, the actual cost of seed — that is just the seed, not associated technologies — represents no more than 15% to 20% of the total cost of the bag. The total includes seed, plus technology, plus seed treatment.

Since the mid-1990s, total seed costs in the Lower Southeast have risen 20-fold, from about $35 per bag to more than $700 per bag. Yes, we’ve gained some incredible technologies, but still the seed — that little rocklike kernel coated with Q, Y, Z and with B, W, T, F, E, X traits built in genetically — is the delivery means for the traits. Hundreds of dollars of traits are delivered on a carrier that consumes less than 20% of the cost. That carrier, the seed, NEEDS to be exceptionally good. We pay a BIG price and should receive a quality product that enables predictable, consistent stands.

Seed are a biological product subject to quality variations from the field, gin and seed house as well as in delinting and packaging. Each of these potentially influence seed “performance” in the field. Companies go to great lengths to deliver the best possible product, and while there is no perfect measure or absolute assurance of quality, we currently recognize warm and cool germ data as a good, reasonable estimate.

As an aside, the Extension Cotton Specialists Working Group, which consists of peers from across the Belt, discussed our on-going, Cotton Incorporated-sponsored Seed Quality Project. The efforts led initially by Murilo Maeda of TAMU and now by Camp Hand of UGA, along with work by Lori Unruh Snyder and others at NC State, have increased the focus and understanding of seed quality.

All this to say, Buyer Be Aware. Know what you’ve got. From your supplier, use the seed lot number to obtain data on warm and cool germ, and, if it’s not printed on the bag, seed count per pound. The seed is where it’s at. cottonbrown@auburn.edu

LOUISIANA Matt Foster

With cotton planting just around the corner, now is a great time to review a few, key recommendations to ensure the 2023 season gets off to a great start. In Louisiana, cotton is generally planted mid-April to mid-May, but planting decisions should be based on soil temperature and not the calendar. Early planting is a key component of successful cotton production; however, if planted too early, yield potential can be reduced. Before deciding to plant, it is important to consider factors such as soil temperature and heat units (DD60s).

Soil temperature is the main factor influencing seedling growth rate. Cool soils (below 50 degrees Fahrenheit) can cause chilling injury to germinating plants. Chilling injury can reduce vigor and increase the likelihood of seedling disease issues. Good germination and emergence can be expected once the soil temperature at a four-inch depth is 65 degrees Fahrenheit or greater at 8 a.m. for at least three consecutive days with a good five-day forecast following planting.

Once soil temperature is optimal, it is important to calculate the number of DD60s for the next five days to determine if conditions are optimal for planting. Emergence generally occurs after the accumulation of 50 to 80 DD60s after planting. If the five-day forecast after planting predicts the accumulation of less than 26 DD60s, planting should be postponed. Also, the low temperature for the next five days should remain above 50 degrees Fahrenheit.

Most commercial cotton seed will have at least an 80% germination reported on the seed tag. This is the result of the warm germination test. Field conditions typically are more adverse than laboratory tests, and cool germination test results are a good indicator of seedling vigor. For example, a seed lot with 85% cool germination is more vigorous than one with 65% cool germination. However, if the 65% cool germination lot is planted under ideal conditions, overall germination is likely to be as high as the 85% lot. Conversely, under adverse conditions, the 85% cool germination lot is likely to germinate at a much higher rate than the 65% cool germination lot. Growers are encouraged to request cool germination test results from seed companies.

TWITTER: @COTTONFARMING MARCH 2023 | COTTON FARMING 17

Specialists Speaking

Since the mid-1990s, total seed costs in the Lower Southeast have risen from about $35 per bag to more than $700 per bag. For the price, Alabama specialist Steve M. Brown says we should receive a quality product that enables predictable, consistent stands.

Remember, a cotton seed is a living organism that is used as a delivery mechanism for genetic traits, transgenic technology and even pesticide seed treatments. Care should be taken to preserve and plant high-quality seed to ensure adequate plant stands. Best of luck during the upcoming season. mfoster@agcenter.lsu.edu

TEXAS Ben McKnight

By the time you read this in early March, I anticipate cotton planting in the Lower Rio Grande Valley to be in full swing if weather conditions are favorable. Early to mid-March is also the typical timeframe growers in the Coastal Bend get busy nalizing planting preparations or have already begun getting the cotton crop in the ground with cooperative weather conditions.

As I write this Feb. 3, several regions in Texas have received recent rainfall that has eased drought conditions, but additional precipitation leading up to planting would certainly help get the 2023 crop o to a good start. e current drought monitor map indicates that around 80% of Texas is either abnormally dry or in some form of drought conditions.

As we turn our attention to nalizing plans for the 2023 growing season, I believe it is imperative to have a plan for management and production challenges that we see or know are coming. Depending on the year and growing region, insect pests and disease pressure can vary considerably. One of the constant production challenges we encounter every year is weed pressure. Weed species composition is o en very similar between years in the same eld. We know what weed species are most commonly infesting each production eld and which are particularly troublesome.

With this knowledge, we can start to plan our weed control strategies and herbicide programs going into 2023. Preemergence residual products applied and activated correctly can provide a tremendous amount of value during the early season timeframe when young cotton plants are most vulnerable to yield-robbing competition from weed pests. Additionally, reducing weed populations 70% to 90% with e ective residual programs reduces the pressure we put on our post-emergence products applied later in the season. is strategy is a huge step in the right direction for preserving current technologies and minimizing herbicide resistance issues that may arise in the future.

bmcknight@tamu.edu

ARIZONA Randy Norton

Planting season for 2023 will soon be upon us. In the far southwestern reaches of the state, some cotton will be going in the ground late February and early March. Regardless of the day of the year that planting starts, there are several things to keep in mind when deciding to put seed in the ground.

I had a very wise cotton farmer tell me once that if a grower gets the itch to plant and weather conditions are marginal, his advice is to go out to the eld with the planter and start planting, but don’t put any seed in the hoppers! ere’s a lot of wisdom in waiting for adequate, if not optimum, conditions for planting. e signi cant investment made in planting seed really deserves protection by providing the best opportunity for successful germination and emergence, resulting in a healthy stand of cotton seedlings.

So, what are the conditions that lead to successful stand establishment? e biggest single factor in uencing germination and emergence is soil temperature. Soil temperature measured at planting depth around 8 a.m. in the morning should be above 60 degrees Fahrenheit. Temperatures between 55 and 60 degrees are marginal, and planting into soil with temperatures below 55 degrees Fahrenheit should be completely avoided.

Adequate soil moisture is also critical for germination. e process of seed germination is initiated with the absorption or imbibition of water. Much of the cotton in Arizona is planted into dry soil, and irrigation water is applied to initiate germination. In those instances where cotton is planted into a pre-irrigated soil, placement of seed into moist soil with good seed-to-soil contact is critical for proper germination. is requires a properly prepared seedbed and proper seed placement.

A third factor is the conditions that planted seed experiences in the rst three to ve days a er planting. Adverse weather conditions in those rst few days negatively impacts seedling development and leads to disease and eventual seedling mortality.

In summary, adequate soil temperatures, proper seed placement in moist soil and a favorable three-to- ve day forecast combine for a recipe that will help to ensure a good start to the season with a healthy, uniform cotton stand. For more information on this topic and others, visit our website at extension.arizona.edu/crops-soils. rnorton@cals.arizona.edu

Specialists Speaking

Ginners Marketplace

OSHA Increasing Fines, Increasing Their Enforcement Guidance

Under the current administration, the Occupational Safety and Health Administration has begun to enhance their enforcement e orts. In the fall of 2022, we saw articles explaining how OSHA is working with the Department of Justice to file criminal charges for some very serious OSHA violations. While criminal cases are rare, there has been a lot of publicity around these cases. Go to rb.gy/jiak9w to read more information about them.

Recently, OSHA announced new enforcement guidance encouraging Regional Administrators and Area O ice Administrators to issue more “instance-by-instance citations” and discouraged “grouping” of violations. OSHA sta can now cite certain types of violations as Instance-by-Instance citations when they identify “high gravity” serious violations of OSHA standards specific to falls, trenching, machine guarding, respiratory protection, permit-required confined spaces, lockout tagout and other-than-serious violations of OSHA standards specific to recordkeeping. A decision to use instance-by-instance citations should normally be based on consideration of one or more of the factors listed as follows:

The employer has received a willful, repeat or failure to abate violation within the past five years.

The employer has failed to report a fatality, inpatient hospitalization, amputation or loss of an eye.

The proposed citations are related to a fatality/catastrophe.

The proposed recordkeeping citations are related to injury or illness(es) that occurred as a result of a serious hazard. OSHA also encourages sta not to “group” violations, which was common in the past. They contend citing each item separately will encourage employers to more e ectively comply with the rules. These new guidelines will become e ective March 27.

In addition to the new enforcement guidance, OSHA penalties went up again this year on Jan. 16. The maximum penalty for a Serious violation increased from $14,502 to $15,625 per violation. The maximum penalty for a Willful/Repeated violation increased from $145,027 to $156,259 per violation. The penalty increases are scheduled annually following a 2015 law that requires Federal civil penalties to be adjusted each year.

However, when combined with the new enforcement guidelines, this could significantly increase the penalties an employer may see for a given situation. For example, in the past, OSHA

Cotton Ginners Marketplace 20 COTTON FARMING MARCH 2023 COTTONFARMING.COM

COTTON

COTTON FARMING IS THE OFFICIAL PUBLICATION OF THE GINNING INDUSTRY.

Texas Star Co-op Gin – Wilson, TX Steeper Hoppers with 10-Gauge Steel 50% Larger Square Hydraulic Doors Conversion Kits for Most Seed Houses Call Jim - (972) 381-8899 / cliffgranberrycorp.com ELEVATED SEED HOUSE MINIMIZE SEED BRIDGING • SAFER • FASTER • STRONGER

“We chose the Spee-D-Flow 2.0 because Cliff Granberry Corporation has an excellent reputation and they have been building seed houses for 50 years.”

might issue a small business three or four citations. The fine for each citation would normally be less than the maximum if they had a good history, and the size of the business was considered. With the new guidance, the same situation may now be issued six to eight citations and be combined with the increase in the penalty for each violation. The fines have only gone up approximately 8%. However, if they issue additional citations, the final penalty amount could more than double.

OSHA has recently started hiring additional new inspectors. While OSHA’s sta ing levels significantly decreased during the Covid years, they are re-sta ing, and from their press releases, they intend to increase their inspection sta well above their 2019 levels.

Severe Violator Enforcement Program

In the fall of 2022, OSHA updated the Severe Violator Enforcement Program (SVEP). This program addresses employers who intentionally disregarded the health and safety of their employees. Employers were remanded to this program if it was determined they committed willful, repeated or failure to abate violations. These updates make this program much more stringent. Employers will now be placed in the program if OSHA finds at least two willful or repeated violations or they issue failure to abate notices based on highly serious situations. Also, follow-up inspections must be conducted within one to two years after the final order is issued. There was no time frame for these inspections prior to this update.

To incentivize employers to handle SVEP hazards more quickly, some incentives were revised. The employer will now be eligible to be removed from the SVEP three years after the date that all SVEP hazards have been addressed. Employers can also now have the option to reduce the three-year period on SVEP to two years if they agree to an “enhanced settlement agreement” that involves multiple options, including management leadership, worker participation, hazard identification, assessment, prevention and control as well as others.

In 2017, OSHA required certain employers to electronically enter a summary of accident (OSHA 300A) information into the OSHA Injury Tracking Application (ITA). It is common for OSHA inspectors to request accident logs during inspections; however, this electronic posting now gives inspectors access to this information without a visit to the job site. This information is also posted in a searchable database within OSHA. OSHA has scheduled inspections based strictly upon Days Away Restricted or Transferred (DART) rates calculated from summary accident information. Last summer, OSHA issued guidance to sta to enforce the submission of this electronic information by employers. Recordkeeping violations may now be issued.

Review Safety And Compliance Program

This updated guidance to OSHA sta emphasizes the need for you to re-check the overall safety training program at your facility. Spend some time before operation by reviewing your safety and compliance program. If you do experience an accident at your gin, and have an OSHA inspection, they will be

interviewing your employees to see if they are properly trained and if you are enforcing your safety rules. Inspectors will also want to see documentation.

Be sure you have an initial training session put together for all your employees at the beginning of the season and be sure you have a method of documenting this training. This can be as simple as a sign-in sheet with notes detailing the topics that were covered in the training. Make sure you review safety policies and procedures with facility operational sta . Their participation and “buy in” to your safety program is essential. Time spent with them now before the plant is in operation will pay dividends when the season begins. Providing correct documents and the knowledge and attitude of your plant sta can make a huge di erence with an inspector’s visit.

The new administration has directed OSHA to increase enforcement and stop employers from exposing workers to life-threatening hazards or failing to comply with workplace safety and health requirements. The recently established OSHA goals are to save lives, target employers who put “profit over safety” and create a greater accountability for safety and health. Employers should prepare!

Duncan McCook, TCGA manager of regulatory a airs, contributed this article. Contact him at duncan@tcga.org.

Cotton’s Calendar

March 15: Staplcotn Board Meeting, 214 W Market Street, Greenwood, Mississippi.

March 27: Plains Cotton Growers, Lubbock, Texas.

March 30-31: 2023 TCGA Annual Meeting and Trade Show, Lubbock Memorial Civic Center, Lubbock, Texas.

NORTHERN / LUCUS MACHINE, INC 1116 E SLATON HWY LUBBOCK, TX 79404

FOR SALE: 1 – 158 GIN STAND W/ CONTROLS & 700 FEEDER

MANUFACTURER OF HI- CAPACITY LINT CLEANING SYSTEMS IN 86” TO 110” WIDTHS

NEW 60”, 72”, & 80” OVERSHOT BATTERY CONDENSERS 96” TO 144” INCLINE CLEANERS, STICK MACHINES, & AIR LINE SEPARATORS

HIGH CAPACITY VACUUMS

USED & FACTORY REBUILT GIN MACHINERY

PLASTIC BALING PRESSES

COMPLETE LINE OF REPAIR PARTS FOR MURRAY, MITCHELL, H.E., CONSOLIDATED, CONTINENTAL, MOSS, LUMMUS, HORN, & CMI 806-745-8156

Cotton Ginners Marketplace TWITTER: @COTTONFARMING MARCH 2023 | COTTON FARMING 21

FAX:

NORTHERNLUCUS@YAHOO.COM WWW.NORTHERNLUCUS.COM An informative email summary of your gin’s daily performance. Text 662-809-9730 for an example report

1-800-776-8182

806-745-0564

My Turn

A Grateful Student’s Thank You

About 30 years ago, a 20-something city girl from Massachusetts began spending an inordinate amount of time at the Delta Research and Extension Center picking the brains of Mississippi State University’s Extension specialists. As a young agricultural journalist and a newly minted partner in our Mississippi Delta family farm, I had a lot to learn.