James and Nick Marshall, a father-son team in Baker, Florida, aren’t new to the world of cotton farming. James, setting off on his own in 1972 after seeing his father farm before him, originally began in Jay, Florida, before moving over to the Baker area. They have a primarily dryland, 2,700-acre cotton and peanut farm sitting on sandy-loam soil where 2,000 of those acres are planted in cotton.

See what’s on tap for the 71st Annual Mid-South Farm and Gin Show, scheduled for Feb. 24-25 in Memphis, Tennessee.

Retired cotton physiologist, Dr. Tom Kerby, shares a glimpse of his early life out West, along with highlights of his career in cotton.

the official publication of the ginning industry Locations and tentative dates released for the 2023 Gin Schools. Learn why the round module wrap standard is important.

Hank Jones of Winnsboro, Louisiana, is the 41st recipient of this esteemed award. Read more about him on page 13

Sibei Xia, LSU AgCenter, is developing body-tracking wearable technology. Xia’s hats are designed to have a band that combines functional and cotton yarn to detect temperature without influencing its comfort. Go to www.cottonfarming.com for this Web Exclusive report.

Look for Soybean South following page 24 in the Southeast and MidSouth editions of Cotton Farming.

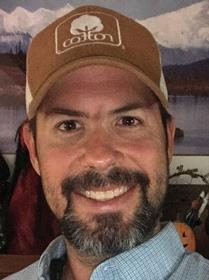

ON THE COVER: From left to right: Maryann, Emery, Nick, James, Helen and Landen Marshall. Cover photo by Colin Hackley.

To have industry news and content delivered directly to your inbox, sign up for the monthly e-newsletter at www.soybeansouth.com .

The Mid-South Farm and Gin Show is celebrating its 71st anniversary in 2023. I don’t remember the beginning of the show, but I recall walking the aisles for many years at different stages of my life. As a kid from rural Louisiana, the idea of going to a big city was overwhelming at best. The only thing that looked familiar to me was the Mississippi River that I grew up next to my entire life. While Dad talked to the people at the booths, I marveled at the big machinery and filled my sack with souvenirs to take home.

Later on, my husband and I farmed in the Delta near Greenwood, Mississippi. The Gin Show was still a big deal, and Memphis was a great adventure. Some years we went by ourselves, and other years we went with a group of farmer friends. We walked the aisles, talked to exhibitors and took in whatever other opportunities were available from year to year. This timing was before the Internet, so if you wanted to know what was going on in the Mid-South ag world, you better show up at the Gin Show.

In the evening, we took in the local cuisine, including Charlie Vergos’ Rendevous, located in an intriguing brick alleyway catty-cornered to the Peabody Hotel. As the establishment’s website says, “In 1948, Charlie Vergos cleaned out a basement below his diner, discovered a coal chute and started a legend. The coal chute gave him a vent for his considerable talent over a grill and allowed him to expand from ham-and-cheese sandwiches to ribs. Today, several thousand people on an average Saturday night pour into our basement and sink their teeth into a slab of what makes Memphis, well, Memphis.” If you have never been there, it’s definitely worth a visit.

During my years as an ag journalist covering the show, the Ag Updates have been a “must attend.” As more educational opportunities have been added, they are front and center as well. A couple of light-hearted memories include the year the guys from Duck Dynasty showed up at an exhibitor’s booth to sign autographs and talk about their upcoming reality TV show. Another year, football legend Terry Bradshaw was hired by an exhibitor to sign autographs and be available for photo ops with Gin Show attendees. Yes, I still have my pic that was taken with Terry!

The Mid-South Farm and Gin Show has a history all its own. It means different things to different people, but everyone holds the memories close to their hearts. Come take a walk through the Renasant Center in Memphis next to the Mighty Mississip’ this February 24-25. You’ll be glad you did.

EDITORIAL/PRODUCTION

Editor-In-Chief

Carroll Smith

csmith@onegrower.com

Southeast Editor Amanda Huber ahuber@onegrower.com

Associate Editor

Cassidy Nemec cnemec@onegrower.com

Digital Content Editor Katie Guthrie

Art Director Ashley Kumpe

ADMINISTRATION

Publisher/Vice President

LiaGuthrie (901) 497-3689 lguthrie@onegrower.com

Associate Publisher/Editor-In-Chief

CarrollSmith (901) 326-4443

Associate Publisher/Sales

Scott Emerson (386) 462-1532 semerson@onegrower.com

Production Manager David Boyd dboyd@onegrower.com

Audience Services

Kate Thomas (847) 559-7514

For subscription changes or change of address, call (847) 559-7578 or email cottonfarming@omeda.com

EDITORIAL ADVISORY BOARD

David Burns – North Carolina

David Lynch – South Carolina

Bob McLendon – Georgia

Larkin Martin – Alabama

Mike Sturdivant Jr. – Mississippi

Charles Parker – Missouri

Jimmy Hargett – Tennessee

Allen Helms – Arkansas

Jay Hardwick – Louisiana

Ronnie Hopper – Texas

Ron Rayner – Arizona

John Pucheu – California

ONE

PUBLISHING, LLC

Mike Lamensdorf PRESIDENT/TREASURER Lia Guthrie PUBLISHER/VICE PRESIDENT

ACKNOWLEDGEMENT OF COOPERATION: Cooperating with COTTON FARMING are various cotton producer organizations across the Cotton Belt. Many representatives of producer organizations serve on COTTON FARMING’s editorial advisory board. Opinions expressed and conclusions reached by contributors are not necessarily those of the cooperating organizations or the editors. All statements, including product claims, are those of the person or organization making the statement or claim. The publisher does not adopt any such statement or claims as its own and any such statement or claim does not necessarily reflect the opinion of the publisher.

Copyright 2023 ©

ASSOCIATED PUBLICATIONS – One Grower Publishing, LLC also publishes RICE FARMING, THE PEANUT GROWER, SOYBEAN SOUTH and CORN SOUTH

If you have comments, please send them to: Cotton Farming Magazine, 7201 Eastern Ave., Germantown, TN 38138.

One Grower Publishing, LLC 875 W. Poplar Ave., Suite 23, Box 305 Collierville, TN 38017

Apush for something better entails a willingness to change. And change opens the door to better-than-expected success.

That’s what happened for producer Stephen Dozier, who farms about 3,500 acres of cotton and peanuts in Georgia. Dozier previously planted cotton varieties with a dicamba-based herbicide system, but he never felt settled with how that fit with his peanut acres.

“I never really liked spraying dicamba because it doesn’t fit well with peanuts. Why would you want to spray something on your cotton that will kill your peanuts? And that goes the other way too,” Dozier said.

In 2021, Dozier planted PhytoGen® brand varieties due to management efficiencies with his peanut crop. PhytoGen® W3FE varieties have the Enlist® cotton trait for labeled applications of Enlist One® and Enlist Duo® herbicides with 2,4-D choline. Peanuts have inherent tolerance to 2,4-Db, a common herbicide used across peanut acres. Because both peanuts and PhytoGen W3FE varieties utilize 2,4-D-based herbicides, there are distinct synergies when planting near one another.

“With PhytoGen W3FE varieties and peanuts, we can spray 2,4-D based products on both crops — it’s a perfect fit.”

Dozier said those benefits made his weed control program more timely and flexible. He recalled one day his peanut sprayer was applying 2,4-Db in a peanut field while his cotton sprayer applied Enlist One in an adjacent field of PhytoGen® brand PHY 443 W3FE. In that situation, he was safe to spray whichever way the wind blew because of compatibility between the surrounding crops.

Another benefit comes with sprayer tank cleanout. If you’re not putting dicamba in your tank for cotton acres, that’s one less thing to worry about when it’s time to make herbicide applications in peanuts. Many growers have found they can use one sprayer for both PhytoGen W3FE varieties and peanuts, eliminating the investment and maintenance of a second spray rig.

“I could definitely use one sprayer for my cotton and peanuts if I wanted to go in that direction,” Dozier said. “Right now, I’m using two sprayers to cover all my acres in a timely manner, but it’s nice not to worry about contamination with dicamba.”

With success in 2021, Dozier planted 100% of his cotton acres to PhytoGen brand varieties in 2022.

He said he was extremely happy with that decision, yielding a triple-digit improvement over the previous year’s farm average. In addition to the benefits with his peanut crop, he also found that PhytoGen offered varieties with protection against the major pests in his area: reniform and root-knot nematodes.

On fields with heavy reniform nematodes, he made several hundred more pounds per acre compared to competitive varieties. He said PHY 443 W3FE and PhytoGen brand PHY 411 W3FE were both excellent yielders, with PHY 411 W3FE better suited to acres with higher fertility and lighter soils.

“The average yield across my farm is higher than it’s ever been,” Dozier said. “When I showed the results to my banker, he said, ‘Wow, what did you do differently this year?’ Planting 100% PhytoGen is one of the best decisions I have made in years, and I will definitely plant 100% PhytoGen again next season.”

read

The National Cotton Council pushed hard for FY23 federal appropriations that would support important research and promotion activities and provide much needed economic relief for U.S. cotton industry members.

■ The NCC submitted its FY23 agriculture appropriations request to the House and Senate appropriations committees. It sought specific funding across USDA’s Agricultural Marketing Service (AMS), Agricultural Research Service (ARS) and the Animal and Plant Health Inspection Service (APHIS).

Through AMS, the NCC requested $4 million in funding to assist in modernizing and upgrading cotton classing laboratories. Increased funding for several initiatives was requested via ARS including for the cotton genetics labs in Florence, South Carolina and College Station, Texas; building renovations at the Southern Plains Agricultural Research Center, also in College Station; and for cotton quality research in New Orleans, Louisiana.

Also requested through APHIS was a $1 million increase for the Cotton Pests Account which funds the ongoing National Boll Weevil Eradication Program. A request of full funding for other important programs, including the Market Access Program and Foreign Market Development Program, Cotton Blue Disease research, and cotton ginning laboratories, was included. The NCC also joined other organizations on a letter to the leadership of the House and Senate agriculture appropriations subcommittees encouraging overall increased funding for federal research, Extension and education.

■ Yes. The NCC publicly lauded House and Senate

appropriations and agriculture committees’ leaders for including this much-needed assistance in the FY23 omnibus spending package that Congress approved and President Biden signed late in 2022. The package included $3.741 billion for disaster relief for ranchers and farmers, including cotton producers. This relief will aid those who suffered losses of revenue, quality or production losses of crops (including crops prevented from planting in 2022), due to droughts, wildfires, hurricanes, floods, derechos, excessive heat, tornadoes, winter storms, freeze, including a polar vortex, smoke exposure and excessive moisture occurring in calendar year 2022.

The package also provides $100 million for USDA to make payments to cotton merchandisers who have experienced economic losses. Also included was $15.45 million for cotton pest management activities, $4 million for USDA’s cotton classing laboratories, and increased funding for ARS cotton genetics and fiber quality research programs.

Among other provisions are those that would 1) provide technical assistance and verification for farmers, ranchers and foresters who participate in voluntary carbon markets; 2) reauthorize legislation that supports a more predictable regulatory process; and 3) extend EPA’s deadline for registration review decisions for all pesticide products until Oct. 1, 2026.

■ The NCC joined numerous other agricultural organizations on crop insurance support letters to Congressional leaders and the Biden Administration urging no harmful changes to the crop insurance program as it “provides predictable, within-budget assistance to farmers.” The NCC will continue advocating for a solid crop insurance program and other sound safety net provisions in the new farm bill. We also continue to support legislation introduced in both the Senate and House that would double funding for the Market Access Program and Foreign Market Development Program.

ACCURACY STEWARDSHIP TOOLS EQUIPMENT FUTURE PERFORMANCE PROFITABILITY SEED PLACEMENT VISIBILITY YIELD MANAGEMENT CROP EMERGENCE SEASONS RELATIONSHIPS SOIL HEALTH WATER USE

Believing in better is a mindset to pursue excellence in everything you do. It’s welcoming opportunities to improve your farm and knowing that your best season is simply a starting point for this season. Precision Planting is for farmers like you who Believe in Better.

Since the turn of the century, Texas farmers and ginners have grown and processed some tremendous cotton crops. Contributing factors to this success include advancements in cotton seed genetics, boll weevil eradication and state-of-theart ginning equipment and facilities. As the 2023 season begins, the groundwork is in place for Texas cotton to build back strong.

To make sure cotton farming and ginning remain a viable part of the state’s economy, the Texas Cotton Ginners’ Association is a vigilant watchdog on issues that could affect our industry.

The TCGA Annual Meeting and Trade Show is one of the largest gatherings of cotton ginning equipment, supplies and affiliated businesses that provide parts or services to the ginning industry. The TCGA Trade Show exhibitors are eager to inform visitors about their products and services related to all things cotton.

Make plans to attend this year’s event as Texas cotton looks forward to building back strong in 2023.

For more information, visit www.tcga.org.

MARCH 30-31, 2023

LUBBOCK, TEXAS

James and Nick Marshall, a father-son team in Baker, Florida, aren’t new to the world of cotton farming. James, setting off on his own in 1972 after seeing his father farm before him, originally began in Jay, Florida, before moving over to the Baker area. They have a primarily dryland, 2,700acre cotton and peanut farm sitting on sandy-loam soil where 2,000 of those acres are planted in cotton.

Marshall Farms is a 100% Deltapine cotton farm, and both James and Nick are members of the New Product Evaluator (NPE) program. They’ve been part of the program since 2009 — NPE’s second year in existence — and have now entered their 14th year as members.

“Here, in our area, we just cannot beat Deltapine,” Nick said after noting their multiple attempts at growing different companies’ varieties.

Four out of the five NPE varieties the Marshalls grew this past

season were Deltapine Bollgard 3 ThryvOn XtendFlex cotton varieties as part of the stewarded groundbreakers program.

“We are very excited about the technology,” Nick said. He added that thrips control was the biggest benefit they’ve seen from ThryvOn. “From the highway, you can tell what fields are ThryvOn and which ones are not; it’s that big of a difference.”

James said they’ve also seen a noticeable difference in fruit setting.

“It seems to start setting fruit a lot earlier because it’s saving the fruit, and that’s beneficial for us. We’re right here in the path of where all the hurricanes like to come, so anytime we can get our crop out earlier, the better,” James said.

In 2022, the Marshalls planted a mix of Deltapine’s DP2020, DP2012, DP2239, DP2141, DP2131 and DP2211 alongside the Class of '23 NPE trial varieties. Three out of the five NPE varieties they planted were recently released as part of the NPE Class of '23.

“Looking forward to those new releases — for two of them,

we would try to get all we can get of them,” Nick said of DP2333 and DP2328.

In splitting up responsibilities on the farm, the Marshalls don’t typically have any set plan since they’re both able to do anything they need to do. Nick said his dad will usually be in the cotton planter in April while he’s in the peanut planter, and they generally try to finish planting around the same time in May — and treat harvest in a similar manner.

As third and fourth generation farmers, James and Nick make use of technology upgrades they’ve added over the years. This includes using John Deere’s highspeed ExactEmerge planter and ExactApply targeted sprayer system, grid sampling, grid spacing and strip tilling. They also invested in a roller picker the first year it became available in 2009.

“That’s made the operation a lot more streamlined,” Nick said, emphasizing its benefit with the current labor situation across the country.

“Pretty much anything new that comes out — we’re quick to try something,” he added.

As far as weeds go, crowfoot grass, morningglory and sicklepod are their biggest culprits. Added insect pressure comes from nearby soybeans and corn, and stinkbugs and thrips remain the major players there.

They spoke on the added benefit from ThryvOn in not having to switch things over to spray thrips during the season as well.

“With peanuts in the mix, there’s always something in the sprayer that doesn’t mesh very well with cotton, or vice versa, so the less I have to be out there and washing chemicals out, that’s much easier on me, too,” Nick said.

Disease isn’t a huge issue for the farm, and the pressure is never high enough where they feel as if they must treat it. There’s some bacterial blight and a little bit of leaf spot due to the humid area they’re in. They attempt to mitigate these potential diseases in their variety selection.

At the end of the season, the Marshalls gin their cotton at Golden Gin in Jay, Florida. With some late rain and a potentially record-setting early freeze, Nick said they still had a good year as far as yields go and great as far as grades go.

Nick noted how, prior to their involvement with NPE, they were a full-season-variety-only farm and used to be hesitant of planting early varieties

“Now, we don’t plant any full-season varieties. It’s all early to mid-season varieties as they seem to have a higher yield potential. These new varieties have got a lot of horsepower, and we’ve been really tickled with them.”

“They’re so good about trying to pinpoint these areas for the variety of cotton. Everything they’ve done has always really been a big help because it always seems like it’s progressing for-

(From left to right) Nick, Landen, Emery and James Marshall stand in their field after the 2022 cotton harvest. The Marshall’s farm is in Baker, Florida, around 30 miles north of Destin, Florida.ward instead of backward,” James said before later adding, “The ThryvOn is just a game changer in our area.”

Progressing forward is nothing new for the area the Marshalls farm by any standard. Being a mere 30 miles north of Destin, Florida, they’ve seen an explosion of people. The population has been encroaching the farm area more and more over the past decade, and the land around them isn’t getting any cheaper.

“It’s getting harder and harder, if you don’t own land, to find land to rent,” James said, including the logic of it being another input cost.

“We’re in a very non-agricultural area where a lot of state forests surround us with their pine trees, so there’s not a lot of land available around here — especially in our county, so we do what we can to keep what we’ve got,” Nick added.

Looking past the storms, the Marshalls discussed some highlights they’ve witnessed on the farm in their lifetimes.

“All of the equipment [upgrades] have helped out with having a lower population [planted] and less chemicals — that’s all a plus,” James said. “We couldn’t grow 2,000 acres of cotton just the two of us if we had to grow it like we did 15 years ago.”

As prevalent as hurricanes are in their area, there’s not much that can be done in preparation of the destructive storms.

When asked how they do their best to prepare, Nick readily affirmed “You don’t.”

“When we get that September or October hurricane, you’re all in at that point,” James said, noting also that crop insurance is their only real protection.

Both James and Nick spoke about the uncertainties that lie with hurricane season, commenting on how one could come in the middle of July or October.

“It does seem like the trend lately has been pushing toward those late-season — late September, early October — ones,” Nick said.

While seemingly dismal, Nick was quick to say how ThryvOn helps in this arena with its early fruiting ability to get the crop out of the field earlier around the end of September now. “That’s a beneficial thing and a very big positive we’re looking at

“From environmental issues, new seed changing the game, new chemicals here and there — it’s fun to get up every day and see what happens this year versus another and the gains we’ve worked toward every year,” Nick said.

with these ThryvOn varieties.

“We can make as good of cotton as anyone in the country; we just have a hard time keeping it on the plant with the humidity here and the late rains and hurricanes,” he said.

Both James and Nick remarked how they keep planting every year, regardless of hurricane potential, and emphasized how they also have their wives’ help as a part of the operation.

“She’s always there,” James said of his wife Helen. “She’s always stacking the round modules as quickly as they hit the ground.”

Nick’s wife Maryann helps as well, and they have two children, Landen and Emery.

As a longtime NPE grower, Nick said one of the beauties of the program is the result of making friends across the Cotton Belt and being able to communicate with them on what varieties they’re liking in their respective areas to tell whether they want to plant those varieties as well.

“Some of the varieties we plant, we never really thought about. We’ll try it, and sometimes we don’t like it; sometimes we do. That’s a lot better than going out there blind and not knowing anything about it.”

“That’s what we’re here for — to test them and see,” James added, noting everyone’s different ideas and thoughts that are shared amongst NPE growers. “Just the little tidbits of information that get passed along — it’s stuff like that that brings us together.”

Nick marveled at the thought of farmers never finding a year that’s the same.

“From environmental issues, new seed changing the game, new chemicals here and there — it’s fun to get up every day and see what happens this year versus another and the gains we’ve worked toward every year.”

“It’s never the same. I know I’m going to see something different today than what I saw yesterday, and I know it’s going to be different than what it was last year,” James said.

“I want to get better. I’m 68 years old don’t know how much longer I can farm, but I wish I could farm another 50 years. I like putting seed in the dirt and watching it grow — that’s what gives me joy, right there.”

Louisiana crop consultant Hank Jones, a perpetual agriculturist, admits to having something close to an obsession with a cotton plant.

“I dabbled in all things ag in Northeast Louisiana,” he says. “However, I always loved spending time in cotton fields looking for insects — although I am nearing the end of the list of those who remember boll weevils and tobacco bollworms. For many of us, getting to work with a crop you are fascinated by and emotionally attached to is just who we are.”

Jones was born to Butch and Martha Ann Jones in Monroe, Louisiana. He graduated from Ouachita Christian School and went on to complete a Bachelor of Science in agronomy from Louisiana Tech University and a Master of Entomology from Louisiana State University. After spending several years in partnership with crop consultants Richard Costello and Ashley Peters, Jones “went solo” in 2016 and established RHJ Ag Services.

“I try to maintain a professional relationship but often find myself more involved or invested with my farmers than just being a consultant,” he says. “I genuinely care for all my farmers and their families. You delight in their successes and mourn the failures. I believe in spending their money like I would my own. I help select varieties, make all pesticide recommendations, even advise with irrigation timing. I offer soil sampling to my clients and make variable-rate prescriptions for fertilizer and growth regulators. I think of consultants as being a Swiss Army Knife. We have to do a little bit of everything.”

The Farmers’ Perspective Jones’s farmer clients have taken note and are appreciative of his efforts.

“I have known Hank for many years through the various roles

I have played involving Louisiana agriculture,” says Jack Dailey, owner of Boeuf Prairie Farm in Franklin Parish, Louisiana. “The industry leadership shown by Hank throughout his career places him in ‘rare air’ among his peers. Whether it has been boll weevil eradication, pesticide issues at the state and federal level, novel sampling techniques or helping to develop young leaders, Hank has always been on the front lines.

“On a more personal level, Hank has become a trusted partner in our farming operation. Our yields have never been better. Hank also devotes his free time to his family, church and local community.”

Ben Guthrie, Panola Co., LTD, in Newelton, Louisiana says, “I have been fortunate over the past several years to have worked very closely with Hank. His dedication to both the industry and our farm has been exceptional. Hank’s work ethic and expertise truly make him an asset to our farming operation and the entire agriculture industry. We have absolute confidence in Hank’s knowledge of agronomy, entomology and current pesticide regulations.

“Agriculture is a costly enterprise with so much at stake. We put our trust wholeheartedly in Hank’s ability to make recommendations that are in our best financial interest. Hank excels

2022 CCOY Hank Jones is joined by his family in a local Louisiana cotton eld. From le are daughter Stella, son Owen, Hank, wife Melanie and daughter Nina.at analyzing a problem and devising a solution. The uncertainties and vagaries involved in raising diversified Southern crops present a considerable challenge to both grower and consultant. I cannot imagine entrusting a better person with my crop and my family’s financial well-being.

“Hank is not only an asset to our business, but he is a valued friend and a true Renaissance man: guitarist, stage actor and meteorologist.”

Kody Beavers, a cotton and grain farmer in Northeast Louisiana, said Jones began consulting for him in 2019 on his cotton, corn and soybeans. He appreciates Jones’s ability to achieve the highest yields while also being economical and environmentally friendly. Beavers says Jones achieves this through an aggressive Integrated Pest Management strategy for each stage of a crop.

“Hank is very thorough in his scouting and leaves no corner unchecked,” he said. “By doing this, he can recommend spray applications based on whether the whole field needs treatment or just a part of it. This is very time consuming, but Hank always knows every intricacy of a field and will ensure we treat accordingly. Hank’s ability to execute a well-thought-out plan ensures that the cotton growers he works for will be successful and continue to thrive in the industry we all love so dearly.”

Although Jones is always thinking of ways to help his farmers be successful, he also includes others in the process. He has had several good scouts through the years and now employs C.J. Smith, who joined RHJ Ag Services in 2019 and is currently enrolled at the University of Louisiana in Monroe studying agricultural business. Jones’s father, who is retired, also helps Smith scout fields.

Jones said some of his best friends are consultants and university personnel with whom he connects daily.

“Whether it’s for information or general conversation, I value having relationships with other consultants and university specialists,” he said. “I was fortunate to have Dr. Rogers Leonard as my major professor in graduate school at LSU. He is now an independent consultant and continues to be a leader in cotton entomology.”

Leonard said Jones has impressed him with his breadth of general knowledge about row-crop farming practices in the Mid-South and his ability to solve real-world producer problems.

“He has considerable experience in general insect, disease and weed management strategies for cotton, soybean, field corn, grain sorghum and rice. Hank has a farming background and understands the current financial burden placed upon producers. He can refine his recommendations based on the economics of a specific situation in consultation with his producers.”

Jones added that knowing the consultants on acres around you helps form a network to toss ideas and information back and forth.

“In this age of differing herbicide technologies, that’s needed more than ever,” he said. “Being a consultant in Louisiana, I’ve been around some of the best ag consultant leaders in our profession. Mr. Ray Young, Mr. Roger Carter, Dr. Grady Coburn and Mr. Harold Lambert were all very gracious to me as a young consultant and set fine examples as leaders. It is also imperative, in my opinion, to form as good a relationship as possible with industry representatives, whether they are from the basic companies or at retail level. I try to implement a teamwork approach with company and dealer representatives, myself and the farmer. If we are in accord, we can accomplish better things for the farmer than working solo.”

Jenny Buller, Syngenta’s Central Louisiana sales representative, said, “We value the opinions of our crop consultants, and Hank is no exception. He does an excellent job of helping us look at new technologies and giving us his honest opinion. Hank is often bouncing ideas around for different scenarios to try and best serve his growers.”

Ryan Rawls (le ), Ronald Rawls, Hank Jones, Neal Rawls and Chad Rawls Louisiana cotton farmers Kody Beavers (le ) and Jack Dailey Ben Guthrie (le ) and Hank Jones Hank Jones pictured in an Australian cotton eldJones graduated from the LSU AgCenter Agricultural Leadership Development Program and said that experience, along with collaborating with other consultants, worked in tandem to lay a foundation in providing confidence and courage to say “yes” to leadership opportunities.

“It’s important to be involved and even more important to be educated enough to form opinions that can be transformed into ideas that move issues from point A to point B,” he said.

Denise Wright, who has served as executive director for the Louisiana Agricultural Consultants Association (LACA) for the past 18 years, said during that time, Jones has been highly visible and proactive in the ag community.

“Hank served as secretary on the LACA Executive Board and works closely with me on annual meeting planning as well as other projects throughout the year,” Wright said. “He is very knowledgeable in agronomics as well as being tech-savvy, which is almost a necessity in these times. Above all this, Hank has shown me how to make a dreary day bright by setting an example and being there no matter what the need is.”

Agriculture can be a tough business, so what keeps Hank Jones motivated to get up every day and do the best job he can for his farmer clients?

“Every growing season is unique,” Jones said. “New fields, new varieties, new technologies, different weather conditions and new folks in the industry give my job a dynamic I would probably not encounter had I chosen another realm in which to work. My relationship with my farmers keeps my batteries charged and always ready to start a new year. However, my love for a cotton plant is something I cannot explain with words. I feel like my child is born when cotton comes up, and I’ve been to a funeral when the stalks are shred. Getting to work with a crop you are fascinated by

1981 Bob Stanford, Flagstaff, Ariz.

1982 Jep Gates, Memphis, Tenn.

1983 Dennis Bouchard, Minter City, Miss.

1984 John Nickelsen, Shafter, Calif.

1985 Dwight Lincoln, Portland, Ark.

1986 Grady Coburn, Cheneyville, La.

1987 Stanley Nemec, Snook, Texas

1988 Robert Moore, Hartsville, S.C.

1989 Curtis Wilhelm, Harlingen, Texas

1990 Mills Rogers, Cleveland, Miss.

1991 Clyde Sartor, Vicksburg, Miss.

1992 John Christian, Raymondville, Texas

1993 Billy McLawhorn, Cove City, N.C.

1994 Dwain Reed, Courtland, Ala.

1995 Barry Aycock, Parma, Mo.

1996 Ray Young, Wisner, La.

1997 Lonnie Bull, Cameron, S.C.

1998 Chuck Farr, Crawfordsville, Ark.

1999 Bob Griffin, Jonesboro, Ark.

2000 Roger Carter, Clayton, La.

2001 Harold Lambert, Innis, La.

2002 Lee Hutchins, Sinton, Texas

2003 Danny Pierce, Princeton, N.C.

2004 Tucker Miller, Drew, Miss.

• Completed a Bachelor of Science in agronomy, Louisiana Tech University. He holds a Master of Entomology from Louisiana State University.

• Started RHJ Ag Services in 2016. In partnership with Richard Costello from 2003-2016 (C&J Ag Consulting). Ashley Peters also was a part of the partnership for several years. Co-owner of a contract research farm with Richard Costello from 2008-2018. All partnerships grew successfully and later allowed each to form their separate businesses.

• Consults on cotton, corn, soybeans, rice, wheat and grain sorghum in eight parishes in Northeast Louisiana.

• Member: Louisiana Agricultural Consultants Association, Louisiana Boll Weevil Eradication Commission, National Alliance of Independent Crop Consultants, National Cotton CouncilCotton Foundation Trustee and Chairman of the Beltwide Consultant’s Conference. Serves as committee member for several clientele advisory teams for LSU AgCenter scientists.

• Graduate of the LSU Ag Center Agricultural Leadership Development Program.

Family Life

Jones was reared in West Carroll Parish in Darnell, Louisiana. He and his wife, Melanie Adreveno Jones, now live in Winnsboro, Louisiana with their children Stella (14), Owen (13), Nina (9) and their pets Hazel “The Dog” Jones and Olaf “The Cat” Jones. They attend Life Church in Winnsboro. His interests and hobbies include checking cotton, playing guitar, community theatre, reading and traveling.

and emotionally attached to may sound obsessive, but for many of us, it’s just who we are. We look forward to being in cotton fields, and suddenly, life comes into balance, and we start acting right again come Spring.”

2005 John Hunter, Lubbock, Texas

2006 Jack Royal, Leary, Ga.

2007 Danny Moore, Marion, Ark.

2008 Ray Young, Wisner, La. (Lifetime Achievement Award)

2009 Joe Townsend, Coahoma, Miss.

2010 Mark Nemec, Waco, Texas

2011 Virgil King, Lexington, Miss.

2012 Tim White, Jonesville, La.

2013 Bob Glodt, Plainview, Texas

2014 Stan Winslow, Belvidere, N.C.

2015 Wes Briggs, Bainbridge, Ga.

2016 Tim Roberts, Dyersburg, Tenn.

2017 Paul Pilsner, Wharton, Texas

2018 Mark Scott, Lubbock, Texas

2019 Eddy Cates, Marion, Ark.

2020 Drake Perrow, Cameron, S.C.

2021 James Todd, Plainview, Texas

Hank Jones: Career & Personal Highlights Hank Jones (right) and his full-time scout, C.J. Smith, who came onboard RHJ Ag Services in 2019. Hank Jones (left) and LSU AgCenter’s Trey Price, assistant professor, and Tyler Towles, assistant professor of entomology.One year ago, in Cotton Farming magazine, each cotton specialist across the belt discussed fine-tuning plans for the 2022 season. Many of us were singing the high input cost blues. Inputs were high, but the cotton price was almost $1 per pound one year ago. The 2023 season stands to be unique in that inputs are still high, but the December 2023 price for cotton is just north of $0.80 as I write this on Jan. 6. So, I’m sure most of us at this point will be singing the blues in this year’s section as well — I hope not actually singing, just figuratively.

Reducing input costs is going to be on the top of everyone’s list this year in terms of planning for the 2023 season. A major thing to consider is that timeliness is key. This applies to all aspects of production. Be timely in planting, weed management, insect management, disease management, fertility, growth management, irrigation, defoliation and harvest.

Make sure these things are done on time and in a manner that it doesn’t have to be redone. This could be a delayed pest management spray that requires a “clean up” application, which would include the cost of more chemical and fuel to conduct. Let’s try to avoid spending money where we don’t have to — I think being timely in production is a major key in doing that.

By the time this is published, we’ll still be doing production meetings (schedule available at ugacotton.com). Come see us while we’re doing our annual road show. We’re looking forward to seeing everyone and hopefully sharing information that will positively impact your operation. As always, your UGA county Extension agent and specialists are here to help! Reach out if you have any questions. camphand@uga.edu

Change happens. In every sphere of life… with family and community, markets and policies; with equipment, labor, tools, technologies, varieties, pests and products. Sooner or later, every segment of life and production is affected by change.

How do you deal with change? In response to various changes, what changes do you make? What do you adopt… or not? How do you adapt and adjust? What practices do you alter? What change do you resist and rather than embrace, take a waitand-see approach?

The winter months typically allow limited field activity but time for meetings, planning and thinking; time to consider and possibly initiate needed change. Not change for change’s sake, but decisions and new steps to improve production and life. cottonbrown@auburn.edu

Mississippi cotton production in 2022 didn’t set any records; however, it was still a good year for most producers across the state. Dry fall weather allowed for an efficient harvest, giving growers time for field preparation for 2023.

Input costs are a primary concern for growers planning to grow cotton. According to agecon.msstate. edu, cotton production costs are projected at near $1,300 per acre in a high-input system and approximately $900 per acre in a lower-input, dryland, non-irrigated system. Given current market prices and seed revenue, each system would require about 1,300 lbs. and 900 lbs. of lint

per acre, respectively, to be in the black in terms of profitability.

After three years of testing three-gene Bt varieties, there’s promise for achieving these yield goals and remaining profitable. Mississippi 2022 cotton variety performance data can be found at Mississippi-crops.com.

The next question to be answered in Mississippi is how many acres of cotton will be sown? It’s a good question because many of the fundamentals point toward a decline in acreage; however, after talking to growers, I don’t think there’ll be a massive drop in acreage — just remaining relatively flat. In 2022, Mississippi harvested 525,000 acres of cotton, and I expect 2023 to be above 500,000 acres.

Finally, as planting season nears and crop mix decisions are made, it’s important to secure a couple of varieties that will perform well for a particular region or environment. I expect 2023 to be like the past with some variability in performance due to the environment. A mix of a few well-placed varieties will allow growers to hedge against whatever Mother Nature is planning. bkp4@msstate.edu

The 2023 Louisiana Agricultural Technology and Management Conference will be held Feb. 8-10 at the Paragon Casino Resort in Marksville, Louisiana. The Louisiana Agricultural Consultants Association sponsors this annual event.

On Feb. 9, afternoon session topics include cotton growth management, ThryvOn cotton and technical updates from industry. On Feb. 10, morning session topics include insect, weed and disease control in cotton, 60-inch row spacing and technical updates from industry.

This is a great event for anyone involved in the cotton industry to attend. I’ve attended this event for over a decade, and I’ve always walked away with valuable and applicable information. For more information, please go to www.laca1.org. mfoster@agcenter.lsu.edu

As I write this the first week of January, drought conditions have eased across the more southerly cotton production regions in Texas. The Lower Rio Grande Valley and Coastal Bend regions have received decent precipitation amounts over the fall and early winter months. A few more rainfall events prior to planting would be icing on the cake for growers in these regions.

Other production regions across the state are still experiencing dry conditions coming out of 2022. The Blackland Prairie, Rolling Plains, High Plains, Winter Garden and South Rolling Plains didn’t catch enough rainfall over the past few months to break extended drought conditions experienced in these regions.

Going into last year, fertilizer prices were on everybody’s radar. It doesn’t appear there’s been much relief in prices going into the 2023 growing season, but there are some things growers can do to avoid spending unnecessary dollars on fertilizer inputs.

If you’ve attended a grower meeting that I’ve presented at this winter, you’ve heard me say that soil testing is perhaps one of the most consistent expenditures that returns value to our growing operations. Prior to making a management decision, I try to gather as much information as

Continued on page 20

Bayer is a member of Excellence Through Stewardship® (ETS). Bayer products are commercialized in accordance with ETS Product Launch Stewardship Guidance, and in compliance with Bayer’s Policy for Commercialization of Biotechnology-Derived Plant Products in Commodity Crops. Commercialized products have been approved for import into key export markets with functioning regulatory systems. Any crop or material produced from this product can only be exported to, or used, processed or sold in countries where all necessary regulatory approvals have been granted. It is a violation of national and international law to move material containing biotech traits across boundaries into nations where import is not permitted. Growers should talk to their grain handler or product purchaser to confirm their buying position for this product.

ALWAYS READ AND FOLLOW PESTICIDE LABEL DIRECTIONS. It is a violation of federal and state law to use any pesticide product other than in accordance with its labeling. NOT ALL formulations of dicamba, glyphosate or glufosinate are approved for in-crop use with XtendFlex® Cotton. ONLY USE FORMULATIONS THAT ARE SPECIFICALLY LABELED FOR SUCH USES AND APPROVED FOR SUCH USE IN THE STATE OF APPLICATION. Contact the U.S. EPA and your state pesticide regulatory agency with any questions about the approval status of dicamba herbicide products for in-crop use with XtendFlex® Cotton. B.t. products may not yet be registered in all states. Check with your representative for the registration status in your state. Products with XtendFlex® Technology contains genes that confer tolerance to glyphosate, glufosinate and dicamba. Glyphosate will kill crops that are not tolerant to glyphosate. Glufosinate will kill crops that are not tolerant to glufosinate. Dicamba will kill crops that are not tolerant to dicamba. Contact your seed brand dealer or refer to the Bayer Technology Use Guide for recommended weed control programs. Insect control technology provided by Vip3A is utilized under license from Syngenta Crop Protection AG. Bollgard®, Respect the Refuge and Cotton Design®, Roundup Ready Flex® and XtendFlex® are registered trademarks of Bayer Group. LibertyLink® and the Water Droplet Design® are registered trademarks of BASF. Agrisure Viptera® is a registered trademark of Syngenta Group Company. Excellence Through Stewardship® is a registered trademark of Excellence Through Stewardship. All other products, company names and trademarks are the property of their respective owners.

The 2023 Mid-South Farm and Gin Show is scheduled for Feb. 24-25, at the Renasant Convention Center, 255 N. Main St. in Memphis, Tennessee. This venue is the former Cook Convention Center.

The 71st annual show features exhibitors from 35 states across the United States and five international countries, displaying new equipment and machinery, cutting-edge technology and a myriad of products and services, representing all major Mid-South crops. The exhibits open at 9 a.m. both Friday and Saturday.

Everyone is invited to attend the Southern Cotton Ginners Association and Foundation Annual Meetings, which begin Thursday, Feb. 23, 1:30 p.m., at the Peabody Hotel.

Dr. Susan Yvonne “Evy” Jaconis, Director of Agricultural and Environmental Research, Cotton Incorporated, and Hank Reichle, President and CEO, Staplcotn, will discuss U.S. cotton’s challenges and new opportunities.

Tim Price, show manager and executive vice president, sponsored by the Southern Cotton Ginners Association, said the event gives attendees an opportunity to take in everything on display on the trade show floors and attend educational seminars on key issues.

Before opening a bag of seed, be sure to read, understand and accept the stewardship requirements, including applicable refuge requirements for insect resistance management, for the biotechnology traits expressed in the seed as set forth in the Technology Stewardship Agreement that you sign. By opening and using a bag of seed, you are reaffirming your obligation to comply with the most recent stewardship requirements.

“Each year, there are opportunities to hear industry expert perspectives,” he said. “There will be Ag Update seminars featuring market outlooks for cotton and grains, as well as an outlook on issues impacting agriculture.”

Price noted agriculture has often had to adapt to a changing landscape, due to weather, regulation, trade issues or geo-political events.

“Regardless of how often we have adapted, we are faced with navigating the change for the best outcomes for our operations,” he said. “This year’s MidSouth Farm and Gin Show will bring it all together in terms of helping attendees

understand the far-reaching impacts of COVID as well as outlooks for the coming year.”

An Ag Update Seminar on Friday, Feb. 24, features Joe Nicosia, Louis-Dreyfus Co., who will provide an outlook on cotton. “Joe’s insights are critical for cotton producers who look to Nicosia for direction on planting and marketing their crop,” Price said.

The Saturday, Feb. 25, Ag Update Seminar features Richard Brock, Brock Associates, who offers an outlook for grains as well as economic policies that may impact agriculture over the next year. Both seminars start at 8:30 a.m. in the Cannon Center.

Additional educational opportunities are planned, including an international trade forum with Agricenter International. More details will be released as they become available.

AgLaunch, which uses a farm-centric innovation platform to bring new ideas into agriculture, is expected to conduct its “Shark Tank”-like workshop where individuals and businesses present their ideas to the AgLaunch panel.

On Saturday, Feb. 25, a special rice marketing educational seminar will be held. The event features Milo Hamilton, co-founder and senior agricultural economist of Firstgrain Inc.

Show closing times are 5 p.m. and 4:30 p.m., Friday and Saturday, respectively. At 9 p.m., Saturday, the popular Jamboree will kick off at the Peabody Hotel Grand Ballroom with music by The Krackerjacks.

See you in Memphis!

For more information, please visit farmandgin show.com or southerncottonginners.org.

The Cotton Board is governed by its membership consisting of both cotton producers and importers. The importers serving on The Cotton Board represent major U.S. brands and retailers — significant downstream cotton users. The producers on The Cotton Board represent their respective states in the U.S. Cotton Belt. Together, these segments of the Board represent a wealth of unique perspectives and insight that help guide The Cotton Research and Promotion Program (the Program).

BY STACEY GORMAN WARREN, ARKANSASDuring its 2022 Annual Meeting, The Cotton Board elected new officers to guide the Program, including Sonja Chapman, to serve as Chairman for the 2022/23 Program year. Chapman, an Importer from New Jersey, is an expert in trade compliance and importing. She currently works as an associate professor at the Fashion Institute of Technology in New York City.

To learn more about Sonja’s unique perspective as an importer leader in the cotton industry, she answered a few questions below.

QWhy is it important for Importers to serve on The Cotton Board?

AWith most of the U.S. cotton crop being sold for export, importers ultimately drive cotton purchases in the international environment. Our businesses are subject to different needs and pressures that drive fiber selection. When importers serve on The Cotton Board, we can provide clear direction on how our business needs are changing and how cotton can position itself to benefit from positive changes and mitigate the negative ones.

QWhat have you learned from the Producer members of the Cotton Board? A

I have learned that farmers are the most optimistic people on earth. And they have to be, considering the level of economic investment they must provide and the risks they take. Like any other business, producers must weigh market, political, environmental and economic conditions as they plan their crops. It’s almost unthinkable that this work can be undone in a day by unfavorable weather events!

QWhat makes you passionate about the cotton industry?

our industry’s environmental impact on the planet, I am enthusiastic about cotton’s position as a natural fiber with biodegradable properties and opportunities for recycling and upcycling.

QWhat is the biggest challenge facing the cotton industry in 2023?

ATraceability and shifting markets constitute a significant challenge for the industry right now. The passage and enforcement of the ban on cotton from China’s Xinjiang region place a substantial burden on importers. Importers who previously purchased finished cotton products from China, or countries like Bangladesh that are reliant on China for fabric production, are already moving to mitigate this risk. Current import statistics show the market share of cotton products is declining rapidly from these countries and that production is expanding in West Asian countries.

To learn more about the cotton importers and producers who serve on The Cotton Board, visit cottonboard.org/our-leader ship.

A

I have always enjoyed the fiber’s comfort, versatility and durability. It really has been the ‘Fabric of our Lives’ for my family and me. Additionally, as we look at ways to reduce

Continued from page 17

possible that will assist me in arriving to my decision. Being active with soil testing on your farm can give you a tremendous amount of information prior to planning a plant nutrient management program going into the 2023 growing season.

Additionally, sampling deeper in the soil pro le to 18 or 24 inches may reveal that you have quite a bit more plant nutrients available to credit toward yield goals than a shallower sample would reveal. e long taproot of a cotton plant has the ability to access plant nutrients at these depths — so long as there are no root-limiting factors present like soil compaction. Get in touch with your local county agent, or visit soiltesting.tamu.edu if you would like to learn more about submitting samples or sampling methods. bmcknight@tamu.edu

is will be my last opportunity to make comments here representing the University of Arkansas System Division of Agriculture. It’s truly humbling to visit with producers that comment how much they enjoy reading our comments every month.

While some things in life are in a constant state of change, some things in farming are always hanging over our heads. Cash margins are nearly always tight, leaving little room for mistakes. ere are many things out of our control, so we must be smart to get the most out of what we can control to establish and maintain yield and quality potential.

Variety selection for yield and quality is an important rst step in establishing our potential. ere are a number of resources available to assist in selecting new varieties. A useful tool is the University Variety Testing Program. Results from the Arkansas Trials conducted by Dr. Fred Bourland may be found at https://arkansas-variety-testing.uark.

edu/. County demonstrations are another good source of information and are included in this report. It’s also appropriate to evaluate variety performance trials from neighboring states in the Mid-South.

Varieties with extreme growth potential, paired with high plant populations and excessive nitrogen, are recipes to make life di cult for both producers and consultants. Avoiding problems is much simpler and o en more pro table than trying to x issues we create.

Other practices to protect yield and quality potential include matching nutrient applications to the crop requirements, utilizing IPM tools to manage pests, ne-tuning irrigation scheduling and using tools like Pipe Planner that can increase e ciency.

Following end-of-season termination guidelines, coupled with variety selection to help ensure we can get a picker in the eld by mid-September, is another important consideration. is will help us to hold onto the yield and quality we’ve worked hard to build all season long while meeting our harvest completion goal of Nov. 1.

Contact your local county Extension agent to obtain information or to get assistance in improving e ciency and pro tability. brobertson@ uada.edu

A new year has come upon us, and while we may still be reeling from the e ects of the 2022 cotton growing season, it’s time to turn our attention to the 2023 season that will be quickly approaching. e cotton Extension production meeting will be held at the Fisher Delta Research and Extension Center on Feb. 9, 2023, from 8:30 a.m. to 12:20 p.m. Registration will begin at 8 a.m. Several speakers will be in attendance to provide research updates and production challenges that may be faced in 2023.

As the topic for these comments is “ ne-tuning for 2023,” we look ahead at what we need to be doing in the next few months to gear up for

the upcoming season. Choosing cotton varieties may be the rst step in the plan as selection can be important for desired yield and ber quality potential. e 2022 cotton small plot OVTs and large plot on-farm county trials can be utilized as a resource for variety selection in 2023. is data can be found at https://moaes.missouri.edu/t-e-jake- sher-deltaresearch-extension-and-education-center/ under cotton variety testing.

Fertilizer input prices are also on the minds of cotton growers for 2023. e rst option that comes to mind is examining soil test nutrient levels prior to planting. at will allow us to make informed management decisions regarding nitrogen, phosphorus and potassium applications in 2023. In closing, we need to sit down and pencil out our plans for cotton management in 2023. If we can help you plan for the 2023 season, please feel free to reach out. brwilson@missouri.edu

Although the 2022 Mid-South cotton crop generally le a pleasant taste in the mouth, price outlook for the crop in early 2023 has turned the taste to slightly bitter. Over the past few years, you’ve read several excellent input-saving strategies outlined by my colleagues in this very column; in my opinion, 2023 looks like a great opportunity to test those out.

All of these should be applied relative to your personal experience, but generally speaking, we can still likely reduce seeding rate, lower applied-nitrogen rate and be slightly more aggressive (mainly earlier) with PGRs. ese cost savings multiply and begin with plants per acre; recall we only need two plants per row foot in the upper Mid-South. Furthermore, we need to make sure we are not pushing the N rate. Selecting a higher-than-needed seeding rate and over applying N will delay maturi-

ty, increase PGR needs and decrease your bottom line.

For those near Jackson, join us for our annual Cotton Focus event on Feb. 8, or check our blog in the coming weeks for additional information on each of these inputs. traper@utk.edu

Variety selection is certainly a major part of ne-tuning plans for the coming season. e cotton OVT yield data and large plot variety data is available on our portal (https://cotton.ces.ncsu.edu/). e OVT ber quality data will be uploaded there once the analysis is completed. e data is also available on our variety selection tool (https://trials.ces.ncsu.edu/cotton/select_trials/).

It’s important to look at balanced data when using the variety selection tool. Balanced means all the varieties are included at all the locations. Due to a glitch in the program, you’ll only get balanced data if you don’t select the large plot Washington - Enlist only and the Stanly – Xtendex-only locations. In general, early maturing varieties didn’t perform as well in 2022 as they did in 2021 due to more drought stress. Selecting varieties with varying maturity can help manage risk.

Growers who really want to ne-tune their cotton production need to think hard about the inputs they are using. Are you getting any value from some of them? is is especially important for inputs that haven’t been tested by unbiased sources. For example, if you’re applying a foliar application, are you applying enough actual fertilizer to increase yields enough to pay for the fuel you’re using to apply the product? e best way to determine if inputs are valuable is to apply them in strips in a eld or two. Otherwise, you’ll likely not have any idea if they’re pro table. keith_edmisten@ncsu.edu

The Gin School is designed to benefit the U.S. cotton ginning industry. Cooperators include the U.S. Department of Agriculture-Agricultural Research Service, the National Cotton Ginners’ Association and its member associations, the National Cotton Council, Cotton Incorporated, gin machinery/ equipment manufacturers and suppliers and select land-grant universities.

Distractions have become “routine” in our daily lives. Our phones go o , we get text messages and we’re bombarded by the never-ending news cycle. Everything seems to be trying to get our attention, and it’s easy to lose sight of what’s important. Things can sneak up on you, and those are the ones that will jump up and bite you.

Tentative dates set for the 2023 sessions appear below.

tions have been aware of this and have brought it to the attention of our memberships. But I think many of us got distracted by the other things going on and have now been hit with the reality that it’s not getting better.

Each level of ginners school coursework is built on the previous level of instruction, with Level I as the foundation. Therefore, the school’s coordinators strongly recommend that beginning students, regardless of gin experience, start with Level I. Levels I, II and III are all two-day courses, therefore students enroll for one level per school.

In the last year or so, we’ve seen huge increases in our costs. As I write this, we’re getting news of the highest inflation in more than a generation… maybe two.

Southwest Ginners School

South Plains Ginning Laboratory

Lubbock, Texas

March 27-29, 2023

While I’m personally seeing some of the things that increased so much ease down a bit, it’s not common for costs that have gone up this much, this fast, to come down or come down very much. We will likely have to learn to live with some of them.

Western Ginners School

Southwestern Cotton Ginning Research Laboratory

Mesilla Park, New Mexico

May 2-4, 2023

Stoneville Ginners School

One of the costs that snuck up on many gins in the past year or so is the cost of insurance. Normally, this is a once-a-year expense we get hit with.

USDA Ginning Research Laboratory

Stoneville, Mississippi

The past renewal cycle or two have been more than a bit of sticker shock for many in the ginning industry. Your associa-

June 6-8, 2023

Level I

• Introduction to Cotton Ginning and Ginning Demonstration.

• Basic Gin Safety.

This is a simplified explanation, but insurance companies are going to do what they need to in order to stay in business. They must make money like we do. The companies take our premium and invest it. They pay claims with it, and they expect to have some left over. If losses are low and return on investment is good, you have happy insurance companies. We get stable premiums and competition.

• Basic Hydraulics.

• Air Utilization.

• Electricity in the Gin.

• Maintenance and Adjustment for Seed Cotton Cleaners, Gin Stands and Lint Cleaners.

If they have poor investment returns and higher-than-expected cost of claims (read inflation), you have unhappy insurance companies. They may decide to pull out of the market and/or significantly increase rates. This is where we are today.

• Maintenance of Auxiliary Components.

• Classing Cotton.

• Moisture Measurement.

• Review of the Cotton Industry.

Your ginners associations and the National Cotton Ginners’ Association have been concerned about this for some time. We need healthy insurers and competition, but we really can only help one side of the insurance problem…losses. NCGA has put together a list of questions to ask yourself, so you can evaluate

• Waste Collection and Disposal.

Lummus Ag Technologywants to express its appreciation to our many loyal customers for their continued support and business. With the challenges we face in our industry, we are continually workingto evolve and adapt to changing market conditions and customer needs.

Lummusoffersa wide range of products and services, all geared to help your operation be efficient and profitable. Regardless of the project scope, contact Lummus to discuss your goals and needsto ensure your success.

Just a short listof items we offer:

All-new complete Gin Plants

Ginning Machinery (individual machines, stand-alone systems, presses, etc.)

Press Consoles and Main Control Consoles

Burner and Moisture Unit Gas Train/Controls upgrades

Air Monitoring and Fire Detection Kits

DGC 2020 Gin and Feeder Controls

Gin Dor-Les® and E.E. Dor-Les® Press upgrades

16” diameter Bottom Ram Conversion

Hydraulic Tramper/Pusher Conversion

Premier™ III Series Hydraulic Pumping Units

Press Rebuilds (strain rods, boxes, sills, etc.)

Quality OEM Repair Parts

UnmatchedTechnical Service

The future is bright! Cotton prices have optimism at levels we haven’t seen in a while. A renewed commitment to customer service has Lummus excited for the future – join us as we move forward!

PhysicalAddress:225BourneBoulevard•Savannah,Georgia31408-9586USA

PhysicalAddress:225BourneBoulevard•Savannah,Georgia31408-9586USA

MailingAddress:P.O.Box929•Pooler,Georgia31322-0929USA

Phone:(912)447-9000•Fax:(912)447-9250

MailingAddress:P.O.Box929•Pooler,Georgia31322-0929USA Phone:(912)447-9000•Fax:(912)447-9250

TollFree(USAOnly): 1-800-4LUMMUS (1-800-458-6687)

TollFree(USAOnly): 1-800-4LUMMUS (1-800-458-6687)

WebSite:www.lummus.com•E-mail:lummus.sales@lummus.com ®

WebSite:www.lummus.com•E-mail:lummus.sales@lummus.com

© 2022 Lummus Ag Technology

© 2022Lummus Corporation

Level II

• Purpose and Operating Principles of Individual Gin Machines.

• E icient Operation, Adjustment and Maintenance of Gin Equipment.

• Pneumatics and Waste Collection.

• Electrical Systems.

• Hydraulic Systems.

• Gin Safety.

• Management Tips.

• Roller Ginning (at the Western School only).

Level III

• Review of Functions of a Ginning System.

• Electrical Systems.

• Air Systems in the Gin.

• Drying and Moisture Restoration Systems.

• Matching Machinery Capacities in the System.

• Seed Cotton Unloading Systems and Management of Seed Cotton Handling Systems.

• Bale Presses and Hydraulic Systems.

• Safety Programs and Labor Regulations.

• Cottonseed Handling Systems.

• Roller Ginning (at the Western School only).

The 2023 Continuing Education schedule is being developed and may be di erent for each of the three schools.

For more information, visit https://www.cotton.org/ncga/ ginschool/index.cfm.

Wrap products will have to meet or exceed three main requirements in order to be approved:

1. Laboratory Testing

a. Specific Sampling Procedures.

b. Specific Material Strength Characteristic Testing.

2. Field Testing

a. Over time – 6-month test period.

b. In hot/moderate/cold environments.

c. In high UV exposure environments.

d. Under repeated exposure to rain, wind, snow, hail, etc.

3. Wrap Color

a. Improve detection using color-imaging systems.

b. Allowable/Recommended Colors:

i. Any color except clear, white, tan, brown or black.

ii. Recommended Color: Pantone 306C.

For questions or to begin testing in order to be on the approved listing, please email wrapstandard@cotton.org.

Feb. 10-12: NCC Annual Meeting, Fairmont Hotel, Dallas, Texas

Feb. 15: PCCA Board, Delegate Body & Marketing Pool Committee Meetings, Lubbock, Texas

Feb. 21: Rolling Plains Cotton Growers Annual Meeting, Taylor County Expo Center, Abilene, Texas

Feb. 23: SCGA Annual Meeting, The Peabody Hotel, Memphis, Tennessee

Feb. 24-25: 71st Mid-South Farm and Gin Show, Renasant Convention Center, Memphis, Tennessee

Feb. 28: Great Plains Cotton Conference, Pratt County 4-H Events Center, Pratt, Kansas

March 6-8: Cotton Board Meeting, Omni-Louisville, Louisville, Kentucky

March 15: Staplcotn Board Meeting, 214 W Market Street, Greenwood, Mississippi

March 16: Calcot Board of Directors Meeting, Zoom Meeting

March 27: Plains Cotton Growers Inc. Board of Directors Meeting, Lubbock, Texas

March 28: Plains Cotton Growers Inc. Annual Meeting, Lubbock, Texas

March 30-31: TCGA Gin Show, Lubbock, Texas

April 14-15: Oklahoma Cotton Council’s Annual Denim Ball, Skirvin Hilton, Oklahoma City, Oklahoma

April 14-15: American Cotton Producers, Hyatt Regency DFW, Dallas, Texas

April 19: PCCA Board & Delegate Body Meetings, Lubbock, Texas

According to the National Cotton Council, protecting the quality of our cotton is more important than ever.

On Feb. 15, 2022, the new voluntary round module wrap standard was approved and published by the American Society of Agricultural and Biological Engineers (ASABE).

This standard protects the industry against inferior wrap products that are beginning to enter the U.S. market and could cause contamination. The standard was developed using measurements from wrap products that perform at levels acceptable to the U.S. cotton industry.

The National Cotton Council will maintain the database of approved wrap products on its website at https://www.cot ton.org/tech/quality/contamfree.cfm.

Producers are urged to only use the approved wrap products, which will greatly reduce the chance for plastic contamination.

May 17: PCCA Board of Directors Meeting, Lubbock, Texas

May 18: Calcot Board of Directors Meeting, Phoenix, Arizona

May 31-June 2: Texas Cotton Association’s 112th Annual Convention, Louisiana Cantera Resort & Spa in San Antonio, Texas

June 4-7: NCPA 2023 Annual Meeting, Westin La Paloma Resort & Spa, Tucson, Arizona

•Brought to you by Cotton Farming magazine, the official publication of the ginning industry

•Keep up with the latest ginning news and calendar of events

•Place classified ads for equipment, sales and help wanted

To advertise, contact Associate Publisher/Sales Scott Emerson 386-462-1532 • semerson@onegrower.com

“We chose this seed house because of its reputation for performance.”

Quito Gin Co., Itta Bena, MS

Steeper Hoppers with 10-Gauge Steel

50% Larger Square Hydraulic Doors

Conversion Kits for Most Seed Houses

NORTHERN / LUCUS MACHINE, INC 1116 E SLATON HWY LUBBOCK, TX 79404

FOR SALE: 1 – 158 GIN STAND W/ CONTROLS & 700 FEEDER

MANUFACTURER OF HI- CAPACITY LINT CLEANING SYSTEMS IN 86” TO 110” WIDTHS

NEW 60”, 72”, & 80” OVERSHOT BATTERY CONDENSERS

96” TO 144” INCLINE CLEANERS, STICK MACHINES, & AIR LINE SEPARATORS

HIGH CAPACITY VACUUMS

USED & FACTORY REBUILT GIN MACHINERY

PLASTIC BALING PRESSES

COMPLETE LINE OF REPAIR PARTS FOR MURRAY, MITCHELL, H.E., CONSOLIDATED, CONTINENTAL, MOSS, LUMMUS, HORN, & CMI

806-745-8156

1-800-776-8182

FAX: 806-745-0564

NORTHERNLUCUS@YAHOO.COM

WWW.NORTHERNLUCUS.COM

Iwas incredibly fortunate to enjoy a career in cotton. I was born in Douglas, Arizona, but moved to Farmington, New Mexico, as a toddler. A small family farm consisted of dairy cows and fruit trees. My parents grew up in the Depression, were hard workers and didn’t want us to be bored. During the school year, there was milking morning and evening, with a few chores thrown in. Summers were long days. We raised our own alfalfa and corn for the dairy cows. Herbicides were not in common use. When we weren’t milking or haying, we were chopping weeds in the corn. There was no time for sports and hobbies, and little time for homework. By the time I graduated from high school, I knew how to work, and I knew I didn’t want to farm as a career. Yet I found I liked seeing a crop grow.

I took my time becoming acquainted with the cotton plant. I served a 27-month mission for my church in Guatemala, El Salvador and Nicaragua, then followed that up with three years in the U.S. Army during the Vietnam war. This gave me time to mature and set in motion a desire to be my best. During this time, I met and married my sweetheart, June (we are now in our 56th year together).

My educational journey started at Brigham Young University with a major in soil chemistry. Two life changing events led me to cotton. I intended to get a Masters in fruit physiology at Utah State. I asked Dr. Laren Robinson (Dept. Chair) for a reference letter, and he replied, “No!” I was shocked. I had the best GPA in the department. Why? After a long pause, he smiled and said, “If you want me to write a letter of recommendation for you to pursue a Ph.D., I’d be happy to, but it will be a waste for you to only get a M.S. degree.”

BYU hosted the Western Collegiate Soils Judging Contest my senior year. The only soil pit where I finished judging early was the one the University of Arizona coach supervised. I won the high individual score at the event. A week later, a detailed description of Dr. Buxton’s research arrived, along with a graduate fellowship offer. Provo, Utah was cold. Logan was even colder. I thought of my mom’s stories of picking cotton. I remembered my

Arizona roots, and June and I changed our plans from fruit physiology to cotton.

My M.S. documented how the cotton plant responds to row spacing, plant density and varieties with a range of leaf shapes. I came up with a system to “map” boll set or fruit shed. It took a page per plant, and my six-year-old daughter was my plant map recorder. Analysis and summary were with a hand calculator. All five of my children were plant mappers at one time. My Ph.D. research used radio-active carbon dioxide in enclosed field chambers to document photosynthesis by different leaves, and where those sugars were translocated. I became very acquainted with cotton in those years.

My career continued at University of California. We improved capacity of plant mapping and tools to summarize results. We documented DD60s for the growth stages. About 1985, we realized we could use in-season measurements (boll retention, height, internode length between the 4th and 5th node below the terminal, and nodes above white flower) to adjust inputs to optimize the remainder of the season. We advanced and applied these concepts during my years with Deltapine. DP555BG/RR would have never made it to market without it. Plant mapping demonstrated right away that it was different. It was a slow starter. Nodes, height and internode distance at early bloom suggested limited growth. Yet three weeks after flowering, even with a good boll load, it didn’t slow down like other varieties. We worked closely with our seed production growers and told them they needed to apply PIX early even though it didn’t appear necessary. They didn’t believe me then but did after the first year.

I was blessed to work with great institutions and associates. My learning to “observe” and “listen” to the cotton plant blessed my career. I was honored to be named a Fellow in the American Society of Agronomy for my research and honored to receive the two big cotton awards (Extension Education and Cotton Physiologist Research). I look back with satisfaction for the years of treasured interactions with researchers in academia and equally with growers and consultants. Cotton is a marvelous plant, and the industry associated with it is the best. I am a blessed man and cherish my memories with so many involved with cotton.

— Dr. Tom Kerby, retired cotton takerby@yahoo.comphysiologistDr. Tom Kerby Cotton Farming’s back page is devoted to telling unusual “farm tales” or timely stories from across the Cotton Belt. Now it’s your turn. If you’ve got an interesting story to tell, send a short summary to csmith@onegrower.com. We look forward to hearing from you.

“June and I changed our plans from fruit physiology to cotton.”

BASF’s cotton portfolio has so much to offer, like herbicide combinations. Pair BASF’s knockdown and high-quality residual for the most complete and trusted in-season weed control. Find the hardest working herbicide combinations for your field at CottonWeedControl.com.

Strong yields are always a point of pride. Even more so when the odds are stacked against you. That’s why cotton growers in the South rely on the advanced genetics and innovative trait technology of Deltapine ® brand cotton — bred, tested and grown to consistently perform year after year.

Find the cotton varieties strong enough for the South at Deltapine.com