is Coming Winter Winter Ice In e Cotton Market Could Start Melting During e 2023 Harvest PROFITABLE PRODUCTION STRATEGIES www.cottonfarming.com ONE GROWER PUBLISHING, LLC JANUARY 2023

The best way to thrive this season is to be ready for the ones that follow. And with proven data and results of PhytoGen® cottonseed, you can be confident your operation is ready to thrive for seasons to come. Learn more at PhytoGen.com.

¹2020 Mississippi State University (MSU) On-Farm Cotton Demonstration Trials. 2PhytoGen® brand PHY 411 W3FE outyielded the best Deltapine variety by 87 lb./A in the MSU Official Variety Trials.

™® Trademarks of Corteva Agriscience and its affiliated companies. The Enlist® weed control system is owned and developed by Corteva Agriscience LLC. © 2022 Corteva. (09/22) BR CAAG2PHYG070

Vol. 67 No. 1

FEATURES

10 SOUTHERN PLAINS REPORT

Cotton Incorporated is working with a program called Quail Forever, which has now expanded its territory to include Texas.

12

VARIETY SELECTION

State cotton specialists discuss the many factors farmers must consider when choosing their varieties for the upcoming season.

20 GINNERS MARKETPLACE

Early days of cotton gins were the rst test of the newly created U.S. patent system and provide background of the initial successful cotton gin factories.

WEB EXCLUSIVE

Advanced textiles sector needs to get in high gear in using natural, biodegradable raw materials. Cotton’s functionality must be explored said Mr. Suresh Kotak, International Cotton Advisory Committee. Go to www. cottonfarming.com for this Web Exclusive report.

Yangxuan Liu, University of Georgia Department of Agricultural and Applied Economics, discusses the potential for wintry conditions in the cotton market during the first three quarters of 2023. She also offers tips to farmers to help navigate this scenario and makes a prediction about when the “winter ice” may start to melt.

Look for Corn South following page 12 in the Mid-South and Southeast editions of Cotton Farming

To have industry news and content delivered directly to your inbox, sign up for the monthly e-newsletter at www.cornsouth.com

DIGITAL

ON THE COVER: A field of cotton stubble covered in snow. Cover photo by Guy Sagi/123RF.

COTTON FARMING (ISSN 0746-8385) is published monthly January through December by One Grower Publishing LLC, 875 W. Poplar Ave., Suite 23, Box 305, Collierville, TN 38017. Periodicals postage paid at Memphis, Tennessee, and at additional mailing o ices. POSTMASTER: Send address changes to Omeda Communications, Customer Service Department, P.O. Box 1388, Northbrook, IL 60065-1388 (Phone: 847-559-7578) (Fax: 847-564-9453). Annual subscriptions are $40. International rates are $55 in Canada/Mexico, $90 in all other countries for air-speeded delivery. Surface delivery not available due to problems in reliability.

TWITTER: @COTTONFARMING JANUARY 2023 COTTON FARMING 3

6

4 Editor’s Note 5 Cotton’s Agenda 10 Southern Plains Report 12 Specialists Speaking 16 Industry News 22 My Turn

Winter Is Coming

the official publication of the ginning industry

PROFITABLE PRODUCTION STRATEGIES

DEPARTMENTS

JANUARY 2023

www.cottonfarming.com

& COLUMNS

.

Planting Tips January 2023 Supplement to Cotton Farming and The Peanut Grower Magazines Southern Production & Marketing Strategies

OFFERINGS Keep up with the latest from Cotton Farming by signing up for the monthly E-News at www.cottonfarming.com

Facebook: https://www.facebook.com/cottonfarming Twitter: @CottonFarming Instagram: @CottonFarmingMagazine

.

. SUPPLEMENT

Editor’s Note

EDITORIAL/PRODUCTION

Editor-In-Chief

Carroll Smith csmith@onegrower.com

Southeast Editor Amanda Huber ahuber@onegrower.com

Associate Editor Cassidy Nemec cnemec@onegrower.com

Icy Factors Set Up Wintry Cotton Market

In football, “icing the kicker” is a ploy the opposing teams’ coaches have used for years in clutch field goal situations. It involves calling a time out either before the kicking team sets up, right after they set up or right before the ball is snapped. The objective is to slow down the momentum and force some downtime for the kicker to reflect on whether he can follow through and put some points on the board.

Although a clutch field goal and an opposing coach are not part of the picture in the world of cotton, several factors are in place in 2023 that may potentially ice the cotton market. According to Yangxuan Liu, University of Georgia economist, this could result in a year of winter for cotton producers. Check out her discussion of these components in the cover story on page 6.

But even though Liu is predicting a wintry market scenario for the first three quarters of the year, she has a more optimistic outlook for the fourth quarter. The Georgia economist also offers some tips worth considering for producers to successfully navigate their way through the 2023 “winter” in cotton farming.

While Liu tackles these cotton marketing aspects, on page 12, our state specialists discuss variety selection, which is one of the most critical decisions producers have to make. Farmers must prepare now to kick off the 2023 season and hopefully go into the fall with a successful crop to gather.

As Arkansas cotton specialist Bill Robertson says, “Each variety has its strengths and weaknesses. The challenge is to identify these characteristics and adjust management strategies to enhance strengths while minimizing weaknesses. Once planted, no amount of effort can make up for a poor decision.”

With an eye on the fourth quarter, Liu says, “the winter ice in the cotton market could start to melt during the cotton harvest in 2023.” If this proves true, producers want to make the best variety selections for their farms to be in a position to take advantage of this forecast later on.

Here’s wishing everyone a happy and prosperous New Year!

Carroll

Digital Content Editor Katie Guthrie

Art Director Ashley Kumpe

ADMINISTRATION

Publisher/Vice President

LiaGuthrie (901) 497-3689 lguthrie@onegrower.com

Associate Publisher/Editor-In-Chief CarrollSmith (901) 326-4443

Associate Publisher/Sales Scott Emerson (386) 462-1532 semerson@onegrower.com

Production Manager David Boyd dboyd@onegrower.com

Audience Services Kate Thomas (847) 559-7514

For subscription changes or change of address, call (847) 559-7578 or email cottonfarming@omeda.com

EDITORIAL ADVISORY BOARD

David Burns – North Carolina

David Lynch – South Carolina

Bob McLendon – Georgia Larkin Martin – Alabama Mike Sturdivant Jr. – Mississippi

Charles Parker – Missouri

Jimmy Hargett – Tennessee

Allen Helms – Arkansas

Jay Hardwick – Louisiana Ronnie Hopper – Texas Ron Rayner – Arizona John Pucheu – California

ACKNOWLEDGEMENT OF COOPERATION: Cooperating with COTTON FARMING are various cotton producer organizations across the Cotton Belt. Many representatives of producer organizations serve on COTTON FARMING’s editorial advisory board. Opinions expressed and conclusions reached by contributors are not necessarily those of the cooperating organizations or the editors. All statements, including product claims, are those of the person or organization making the statement or claim. The publisher does not adopt any such statement or claims as its own and any such statement or claim does not necessarily reflect the opinion of the publisher.

Copyright 2023 ©

ASSOCIATED PUBLICATIONS – One Grower Publishing, LLC also publishes RICE FARMING, THE PEANUT GROWER, SOYBEAN SOUTH and CORN SOUTH

If you have comments, please send them to: Cotton Farming Magazine, 7201 Eastern Ave., Germantown, TN 38138.

4 COTTON FARMING JANUARY 2023 COTTONFARMING.COM

Carroll Smith

Grower Publishing, LLC 875

Ave.,

ONE GROWER PUBLISHING, LLC

PUBLISHER/VICE PRESIDENT

One

W. Poplar

Suite 23, Box 305 Collierville, TN 38017

Mike Lamensdorf PRESIDENT/TREASURER Lia Guthrie

Cotton’s Agenda

Gary Adams

Consistent And Insistent

The National Cotton Council’s voice is steadily persistent on matters that could affect cotton producers’ ability to compete in the global marketplace.

What were some key activities this past year?

■ Cotton flow and marketing activities received a major NCC focus in 2022, including continued testing and comparisons of cotton and polypropylene bale packaging. That included testing of new woven polypropylene bags containing blue color for better detection of this plastic contaminant at gins and mills. Bagging manufacturers are performing additional lamination testing and increasing the quality control checks to make sure these bags fully meet Joint Cotton Industry Bale Packaging Specifications. Another flow activity with potential to enhance our export growth is the NCC Joint Cotton Fungibility Working Group’s efforts at grouping bales with identical qualities that can be interchangeable in the warehouse while retaining individual bale identity/ data. This panel also is investigating techniques to increase warehouse bale selection efficiency for mills to realize higher quality/consistent lint laydowns.

In addition, the NCC’s diligence in working with the Administration and Congress on improvements in the ocean, rail and trucking transportation systems helped avert a rail strike that could have severely compromised the nation’s supply chain and U.S. cotton flow.

The NCC engaged with EPA on multiple rules affecting producers’ viability. Among those were the NCC’s plan to comment on EPA’s final rule to regulate “waters of the United States” that was to be published at the time this column was submitted in mid-December. The NCC had emphasized that losing the Navigable Waters Protection Rule was a step

back and that changing rules every few years would do more environmental harm than good in the long run. Among other regulatory activities was NCC’s submission of comments on EPA proposals affecting plant protection products ranging from organophosates and sulfoxaflor to diruon and dicamba. In comments on the agency’s dicamba risk assessment, for example, the NCC emphasized the product’s importance in managing glyphosate-resistant Palmer amaranth.

NCC and other industry input led USDA to include the Climate Smart Cotton Program in the agency’s Partnership for Climate-Smart Commodities pilot projects. Led by the U.S. Cotton Trust Protocol®, this 5-year pilot will provide technical/financial assistance to more than 1,000 U.S. cotton producers to advance adoption of climate smart practices such as no-till, cover crops and nutrient management on more than a million acres. We also are pleased that 1) more than 600 producers with an estimated 1.1 million acres now have enrolled in the Trust Protocol and 2) participation in the industry’s sustainability initiative is gaining momentum.

How is the NCC involved with farm bill development?

■ We were represented at House and Senate agriculture committees’ hearings in Arkansas, Arizona, California, and Washington DC, during 2022. A newly created NCC Farm Policy Task Force is meeting to develop the industry’s farm bill recommendations. We hope to finalize farm bill priorities in early 2023 and will be communicating with Congressional budget panels in seeking additional resources for an effective farm law.

One priority is NCC’s strong support of a bill introduced in the Senate that would double funding for USDA’s Market Access Program and Foreign Market Development Program. Utilized by Cotton Council International, these two farm law programs are critical to expanding U.S. cotton’s global market access.

TWITTER: @COTTONFARMING JANUARY 2023 COTTON FARMING 5

Gary Adams is president/CEO of the National Cotton Council of America.

Paco Ollerton, an Arizona producer, conveys cotton’s priorities for the next farm bill during a House Agriculture Committee-conducted listening session in Arizona.

is Coming Winter

Navigating The 2023 ‘Winter’ In Cotton Farming

BY YANGXUAN LIU UNIVERSITY OF GEORGIA

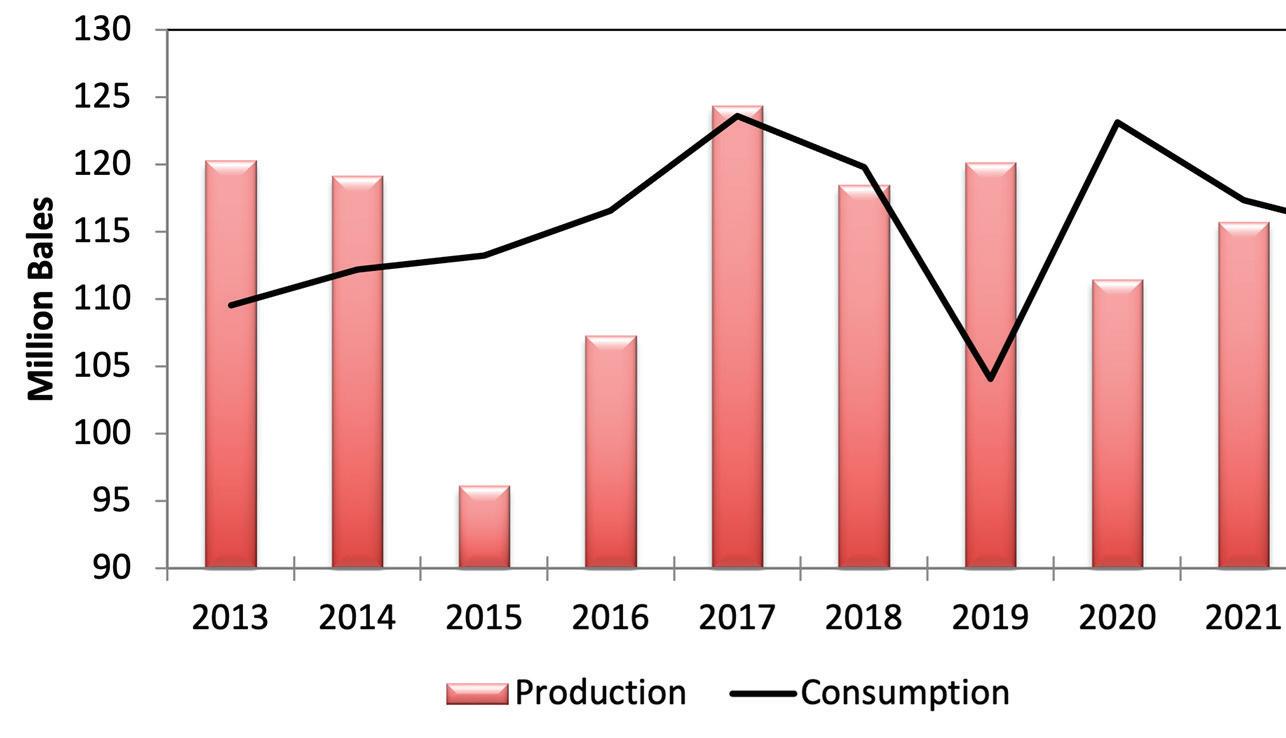

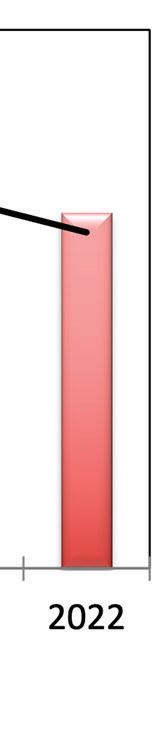

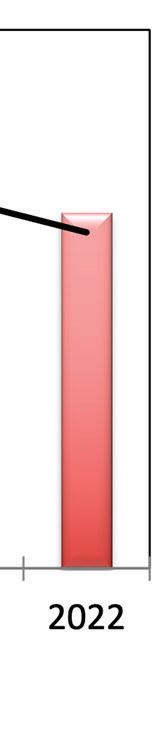

Cotton prices in the year 2022 were like a roller coaster ride, combined with an increase in volatility and the highest price achieved for the past decade (Figure 1). Multiple, rapid rallies in the cotton market were observed in 2022, followed by a quick withdrawal of speculative money. This resulted in an immediate plunge in cotton prices after the rally.

The highest cotton prices for 2022 were achieved May 4 at 149.76 cents per pound, and the lowest cotton prices in 2022 were observed Oct. 31 at 72.26 cents per pound. Several causal factors for the high cotton market volatility in 2022 include: High stock market volatility.

Soaring inflation. Supply chain disruptions. Rising interest rate. Appreciation of the U.S. dollar. Severe drought in the Southwest United States.

Economic Slowdown, Global Cotton Demand

Looking ahead, the year 2023 could be a year of winter for cotton producers. According to the International Monetary Fund, global economic slowdown is expected in 2023 at 2.3%, combined with high inflation worldwide at 6.5%.

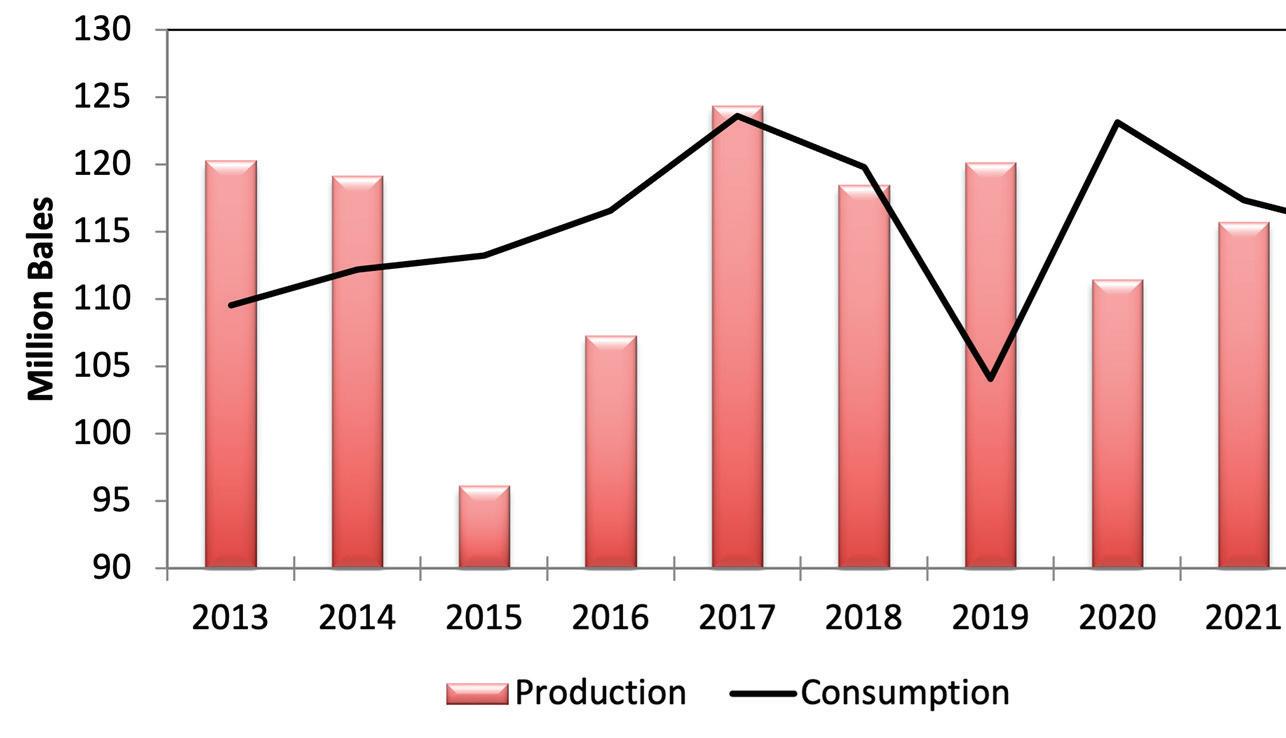

High inflation is depleting the personal saving rate in the United States to a historically low level, with the most recent data at 2.3%. Globally, 2022 cotton production is projected at 116.4 million bales, above the world

6 COTTON FARMING JANUARY 2023 COTTONFARMING.COM

COVER STORY

Yangxuan Liu

Believing in better is a mindset to pursue excellence in everything you do. It’s welcoming opportunities to improve your farm and knowing that your best season is simply a starting point for this season. Precision Planting is for farmers like you who Believe in Better.

24 COTTON FARMING | JULY 2022 COTTONFARMING.COM FOR FARMERS WHO BELIEVE IN BETTER. ACCURACY STEWARDSHIP TOOLS EQUIPMENT FUTURE PERFORMANCE PROFITABILITY SEED PLACEMENT VISIBILITY YIELD MANAGEMENT CROP EMERGENCE SEASONS RELATIONSHIPS SOIL HEALTH WATER USE

Precision Planting® is a registered trademark of Precision Planting LLC. ©2022 Precision Planting LLC.

cotton mill use at 114.9 million bales (Figure 2). The reduction in economic activity and high inflation in 2023 would likely continue to reduce consumer demand for discretionary items — such as textiles and apparel — thus suppressing cotton prices in 2023.

The cotton production profit margin would likely be lower with high input costs and low prices. On a positive note, economic recovery could probably happen during the fourth quarter of 2023, and the winter ice in the cotton market could start to melt during the cotton harvest in 2023.

Source: barchart.com

2. World Cotton Supply and Demand.

U.S. Cotton Supply And Demand

In 2022, the United States planted 13.6 million acres of upland cotton, the highest in three years.

However, in 2022, the U.S. harvested only 7.7 million acres, with the overall U.S. abandonment rate for upland cotton at 43.4%, the highest on record since 1953.

Severe drought conditions hit the largest cotton production regions in the Southwest (Texas, Oklahoma and Kansas), the West (New Mexico) and Delta (Missouri). The abandonment rate for Texas reached 68%. Texas planted 7.9 million acres of cotton in 2022 — by far the largest of any state — representing 58% of total U.S. planted acres.

The November 2022 U.S. Department of Agriculture World Agricultural Supply and Demand Estimates (WASDE) report projected U.S. cotton production at 14.2 million bales for the 2022/2023 marketing year. This is slightly below the U.S. cotton demand — 12.5 million bales of exports and 2.3 million bales of domestic mill use.

In 2022, the national yield level was 856 pounds per acre. U.S. ending stocks are projected at 3 million bales in 2022. The U.S. ending stocks-to-use ratio is forecast at 20.3% for the 2022/23 marketing year.

Interest Rate, U.S. Dollar Appreciation

In response to high inflation, the Federal Reserve increased the federal

funds rate to tamp inflation with its largest rate increase since the 1980s. The Federal Reserve’s commitment to bringing inflation back down to its target of 2% would likely result in a 5% or more interest rate through 2023.

The rising interest rate further accelerated the appreciation of the U.S. dollar. Cotton is a global commodity; on average, over 80% of cotton produced in the United States is exported. The appreciation of the U.S. dollar increases prices paid by foreign consumers and makes U.S. cotton less attractive.

This could result in a further decline in cotton demand from the United States and lower cotton prices for U.S. producers in 2023.

2023 Price Outlook Summary

U.S. cotton acreage and production would be likely to decline in 2023 due to lower relative price expectations with competing crops, such as peanut and

corn. As this is being written on Dec. 5, 2022, December futures prices, CTZ23 (Dec ‘23), for the 2023 cotton crop are currently around 79.62 cents per pound.

The optimistic likely price for cotton in 2023 is 80 to 85 cents per pound or better, and the pessimistic likely price for 2023 is 70 to 75 cents per pound. For planning and budgeting projections, a price of 72 to 78 cents per pound is suggested for 2023.

Higher production costs and greater financial risk in 2023 make it more critical for producers to estimate and control their cost of production. Producers who are not in a marketing pool are encouraged to develop a marketing plan to protect the harvest price, as it is risky to lock in high input prices without a marketing plan for the crop.

Yangxuan Liu is an assistant professor, Department of Agricultural and Applied Economics, University of Georgia.

8 COTTON FARMING JANUARY 2023 COTTONFARMING.COM

Figure 1. Cotton Cash Prices for the Past Decade.

Figure

Source: USDA Foreign Agricultural Service

“The winter ice in the cotton market could start to melt during the cotton harvest in 2023.”

WEIGHING IN

ON NEMATODES

VARIETIES PROVE BIG SUCCESS AGAINST NEMATODES

Nematodes are sneaky pests — too small to see and often the cause of hard-todiagnose yield loss. If you suspect low fertility or drought stress, nematodes could be the root of the problem.

Ron Taylor of Tallapoosa River Farms in Tallassee, Alabama, pinpointed the issue years ago through soil testing, so his challenge wasn’t the diagnosis — it was finding a good solution.

“We know we have nematodes all over the river bottoms that we farm — they’re everywhere,” Taylor said. “We’re dealing with reniform nematodes 90% of the time, but we also have a few root-knot fields. The numbers are high enough to affect our cotton crop, especially under stressful conditions.”

Nematicides and seed treatments never solved the issue, so Taylor was interested when he heard that PhytoGen® cottonseed was planning to launch varieties with built-in resistance to reniform and root-knot nematodes. Several years ago, he worked with his PhytoGen cotton development specialist to plant a trial with an experimental reniform-resistant variety, and he immediately saw a yield increase.

“The cotton came up and you could see the difference all year long. It was 6 inches taller than the susceptible varieties,” Taylor said. “When we defoliated it, you could see it was good cotton, and it was 250 pounds better than the rest of the plot.”

Since that first year, Taylor said he’s seen similar results in his annual on-farm variety trials, but the real proof came in 2022 when he planted PhytoGen® brand PHY 443 W3FE on about 900 acres. The variety is resistant to both reniform and root-knot nematodes, as well as bacterial blight. In 2022, PHY 443 W3FE yielded up to 1,350 lb./A, an excellent yield considering 80% of their ground is dryland.

“In 2022, PHY 443 W3FE performed the same across the farm as it did in the trials,” Taylor said. “I picked one of the most popular competitive varieties side by side, and PHY 443 W3FE beat it by 150 to 200 pounds. I also put PHY 443 W3FE in a competitor’s trial, and it beat everything in that trial.”

NOT JUST FOR NEMATODES

In addition to reniform and root-knot nematode resistance, Taylor said the Enlist® weed control system works well on his farm. When

the Enlist® trait was being launched in PhytoGen® W3FE varieties, he visited demonstrations in Georgia and the Mississippi Delta to learn more about the system. Those visits gave him confidence in the system and Enlist® herbicides.

“We use Enlist One herbicide, Liberty herbicide and glyphosate, and Enlist One is good on weed control,” Taylor said. “I’ve tried spraying dicamba with competitive varieties, but Enlist One cleans out of the tank easier. And you don’t have to worry about volatilization like other products. As long as it hits what you’re spraying, you’re good.”

Planting new varieties with a different herbicide system came with a learning curve, and Taylor said he relies on PhytoGen Cotton Development Specialist Russell Nuti, Ph.D., to answer questions and get insights on varieties. That’s appreciated, and something he believes sets PhytoGen cottonseed apart.

“The big thing with PhytoGen is the dedication of the employees. If I call, they answer; if I need something, they are here. You don’t get that from every company. I have thoroughly enjoyed working with Russell and everyone at PhytoGen. They treat you right.”

™ ® Trademarks of Corteva Agriscience and its affiliated companies. The Enlist® weed control system is owned and developed by Corteva Agriscience LLC. Enlist Duo® and Enlist One® herbicides are not registered for sale or use in all states or counties. Contact your state pesticide regulatory agency to determine if a product is registered for sale or use in your area. Enlist Duo and Enlist One herbicides are the only 2,4-D products authorized for use with Enlist crops. Consult Enlist herbicide labels for weed species controlled. Always read and follow label directions. Roundup® and Roundup Ready® are trademarks of Bayer Group. ALWAYS READ AND FOLLOW PESTICIDE LABEL DIRECTIONS. Roundup Ready® technology contains genes that confer tolerance to glyphosate, an active ingredient in Roundup® brand agricultural herbicides. Agricultural herbicides containing glyphosate will kill crops that are not tolerant to glyphosate. ®Liberty is a registered trademark of BASF. Always read and follow label directions. © 2022 Corteva.

Ron Taylor (second from right) says PhytoGen® brand PHY 443 W3FE has helped him manage reniform nematodes and improve yields by 150 to 200 lb./A compared to a competitor variety on his farm in 2022. A fifth generation farmer, he grows 1,800 acres of cotton in the Tallapoosa River Farms partnership with family members (from left) Mark Taylor, Jody Haggard, Josh Simmons and Brent Timmerman.

™ ® Trademarks of Corteva Agriscience and its affiliated companies. The Enlist® weed control system is owned and developed by Corteva Agriscience LLC. Enlist Duo® and Enlist One® herbicides are not registered for sale or use in all states or counties. Contact your state pesticide regulatory agency to determine if a product is registered for sale or use in your area. Enlist Duo and Enlist One herbicides are the only 2,4-D products authorized for use with Enlist crops. Consult Enlist herbicide labels for weed species controlled. Always read and follow label directions. Roundup® and Roundup Ready® are trademarks of Bayer Group. ALWAYS READ AND FOLLOW PESTICIDE LABEL DIRECTIONS. Roundup Ready® technology contains genes that confer tolerance to glyphosate, an active ingredient in Roundup® brand agricultural herbicides. Agricultural herbicides containing glyphosate will kill crops that are not tolerant to glyphosate. ®Liberty is a registered trademark of BASF. Always read and follow label directions. © 2022 Corteva.

Ron Taylor (second from right) says PhytoGen® brand PHY 443 W3FE has helped him manage reniform nematodes and improve yields by 150 to 200 lb./A compared to a competitor variety on his farm in 2022. A fifth generation farmer, he grows 1,800 acres of cotton in the Tallapoosa River Farms partnership with family members (from left) Mark Taylor, Jody Haggard, Josh Simmons and Brent Timmerman.

Quail Forever Program Expands To Texas

The 2022 Southern Plains cotton crop will be remembered as one of the most challenging seasons in many years. Between the lack of rainfall, excessive heat and high winds, establishing any type of cover crop and viable commodity was difficult. Nonetheless, producers’ stewardship of the soil and land continued regardless of limited yield and revenue.

A year like the one we just had also spotlights under-producing acres within production fields. As the 2023 crop year is approaching, it is a great time to reconsider what to do with those marginal, less profitable acres. One option is to enroll that land in a wildlife conservation program. One program Cotton Incorporated is working with — Quail Forever — has now expanded its territory to include Texas.

BY SHELLEY HEINRICH SLATON, TEXAS

“I am very excited to have Joshua join our Texas Quail Forever team and family,” said Thomas Janke, the Texas State Coordinator for Pheasants Forever Inc. and Quail Forever. “His background in agriculture and passion for conservation is going to help successfully grow our collective efforts towards conservation and sustainability in the Texas Panhandle. This position and opportunity would not be possible without the collaborative support and commitment of our commodity partners.”

New Life For Marginal Acres

New Team Member Onboard

The partnership with Quail Forever integrates agricultural economics, cutting edge geospatial technology and wildlife conservation to deliver profitable producer outcomes with tangible environmental benefits. In November 2022, Quail Forever announced Joshua Michna as the new Texas Precision Ag & Conservation Specialist.

In this position, Michna will help Texas South Plains and Panhandle producers evaluate acres and establish wildlife conservation practices. Using his expertise in precision agriculture technologies and farm production experience, he will guide Texas producers to identify possible biodiverse habitats and practices and assist in enrolling in conservation programs.

By targeting return on investment at a sub-field scale, Michna will help define areas to explore alternative agricultural practices, voluntary conservation programs, cost-share and other funding opportunities to increase profits and success for a producer’s operation. The end goal of this position is to offer habitat-based solutions including soil health, water quality, carbon sequestration and rural economic development while maintaining high farm revenues.

Canadian geese migrate to the West Texas region during the winter months. ey nd refuge in low lying areas and feed from area wheat and rye cover crops.

Creating opportunities for acres to sustain wildlife and add to profitability often appears to be counterintuitive. However, the Quail Forever program, first established in Georgia, has a proven record of success, which is why it has expanded to include Texas. Cotton Incorporated, the United Sorghum Checkoff Program and BASF Agricultural Solutions are key partners in bringing the program to Texas producers.

The goal of the partnership is to make sure that producers have the tools necessary to be successful in creating sustainable conservation habitats for wildlife on marginal acres. “This program is a great opportunity for cotton and sorghum producers in Texas. The collaboration aims to help farmers apply production data and precision ag technologies to identify less profitable acres and create biodiverse habitats,” said Jesse Daystar, Cotton Incorporated’s Chief Sustainability Officer and Vice President.

Michna will work closely with area producers, Quail Forever biologists and chapter representatives and NRCS conservation personnel. For more information about precision agriculture and conservation solutions in Texas, contact Joshua Michna at jmichna@quailforever.org. Joshua will be traveling with me around the South Plains and Panhandle, so we look forward to seeing you on the turnrow.

Shelley Heinrich is the Cotton Board Southern Plains regional communications manager. Email her at sheinrich@cottonboard.org.

SOUTHERN PLAINS REPORT

BASF’s cotton portfolio has so much to offer, like herbicide combinations. Pair BASF’s knockdown and high-quality residual for the most complete and trusted in-season weed control. Find the hardest working herbicide combinations for your field at CottonWeedControl.com.

Engenia® herbicide is a U.S. EPA Restricted Use Pesticide. Every application of Engenia herbicide requires the use of a pH buffering adjuvant such as AEGOS Buffering Technology. Additional state restrictions may apply. Always read and follow label directions. Liberty, Engenia, Outlook, and Zidua are registered trademarks of BASF. © 2023 BASF Corporation. All rights reserved.

Engenia® herbicide is a U.S. EPA Restricted Use Pesticide. Every application of Engenia herbicide requires the use of a pH buffering adjuvant such as AEGOS Buffering Technology. Additional state restrictions may apply. Always read and follow label directions. Liberty, Engenia, Outlook, and Zidua are registered trademarks of BASF. © 2023 BASF Corporation. All rights reserved.

2023 Variety Selection

ARIZONA Randy Norton

Variety selection is probably one of the most important decisions contributing to the success of a cotton crop. As part of our University of Arizona variety testing program, we have observed as much as a bale per acre difference in performance between the highest-yielding variety and the lowest-yielding variety at a given location in a single year. This indicates the potential impact of an improperly selected variety.

Differences in fiber quality have also resulted in premium/discount ranges reaching as high as 5 cents to 6 cents per pound among varieties at a given location. The combination of both lint yield differences and fiber quality differences demonstrate the importance of evaluating cotton variety testing results as part of the decision-making process for variety selection.

New varieties are entering the marketplace each year, and it’s uncommon to have a single variety around for more than four to five years before it’s replaced. New technology and germplasm improvements have driven this turnover in varieties. If you look at beltwide cotton yields over the past 20 years, a clear, positive trend of increasing yield is observed. A lot of this increase is due to new and innovative pest control technologies, but we can’t discount the improvements made in germplasm for both yield and fiber quality.

Due to the high turnover rate of varieties, the decision of variety selection can often be confusing. The University of Arizona conducts an aggressive variety testing program consisting of small and large plot trials conducted across the state from Willcox at 4000-foot elevation to Yuma at just above sea level.

This testing program is funded through various sources including Arizona Cotton Growers state support monies from Cotton Incorporated as well as core funding through Cotton Incorporated. It’s also funded in large part by the seed companies themselves. This testing program evaluates both commercially available varieties and also experimental lines that are being tested prior to commercial release. The results from these trials are published each year and distributed in meetings around the state. They can also be found online at extension.arizona.edu/cropssoils under the cotton variety section.

Another important aspect of variety performance is stability. High performance in a variety over locations and across years is a good indicator of one that will likely do well regardless of year-to-year environmental variation. The more information you can gather about the performance of a variety, from whatever source is available, will help you make an informed decision.

rnorton@cals.arizona.edu

TEXAS Ben McKnight

As I write this Dec. 2, the 2022 growing season is quickly coming to an end, and the 2023 growing season will be here before we know it. As we start to shape up our plans for 2023, I believe it’s important to note that many of the decisions made prior to planting will have a resounding impact on the subsequent management decisions made throughout the upcoming growing season. We have all heard at least a hundred times or more that variety decision is probably the most important decision made all year, but this statement still holds true in many ways.

The varieties that you select to grow for the upcoming year will be the

foundational driving force for other important decisions including weed, disease and insect pest management. The trait packages in modern, commercial cotton varieties can be a valuable tool to protect your crop from yield-robbing pests, but yield potential and fiber quality characteristics should still remain important considerations when making variety decisions as well.

With the number of varieties and trait packages available, arriving at a decision that will impact the remainder of the growing season may seem like a very challenging task. Variety testing results from the RACE trials can offer some insight to growers regarding variety performance within their growing region. Drought conditions severely impacted Texas cotton production in 2022, including many of our on-farm variety trials. Therefore, I always encourage producers to look over the results from previous years to include within their decision-making process. This may help identify varieties with yield stability across different years and growing environments.

By the time you are reading this in January, the results for the South, Central and East Texas RACE trials will be available online at varietytesting.tamu.edu. I hope everyone has a great holiday season, and I look forward to seeing you Jan. 10-12 at the Beltwide Cotton Conferences in New Orleans! bmcknight@tamu.edu

OKLAHOMA Seth Byrd

As we wind down the 2022 cotton season in Oklahoma, plans have already been in the works for weeks to get the 2023 season started. Variety selection is always a hot topic as we near harvest as this is a great opportunity for producers to identify varieties that are strong performers on their farm — as well as make note of the varieties they would like to avoid.

Unfortunately, for many acres in Oklahoma, there was little to be learned this year beyond how varieties handle a drought. While many of our irrigated producers may have had a successful year, relatively speaking, it’s still difficult to make many assumptions regarding variety performance in a year where we experienced extreme conditions for so long.

As we move into a new year with more, new varieties coming and others leaving the market, it will be difficult for many to apply much of what they experienced this year to future variety selection. However, if you have an area that’s more prone to drought conditions, this year may have at least shed some light on what varieties are tougher or more resilient in these conditions. It’s also likely that most producers will make variety decisions well before harvest, but we can still be strategic in placement of varieties.

Coming off what we hope is an outlier year, use your previous experience with varieties to guide your selection and placement decisions in 2023. As I’m sure many of my colleagues will also recommend, find out as much as you can about new varieties, including the various variety trials conducted by universities, private consultants and industry groups close by or in similar production environments.

Request information about the varieties and seed lots, such as seed quality data, to help guide you with placement or determining planting order of varieties in an attempt to target conditions that will help optimize stand establishment based on seed characteristics.

Hopefully the new year will bring better growing conditions for the Oklahoma cotton crop, but since we can’t do much to control the weather, the best way for us to optimize yield potential is still to do everything we can to mitigate risk. Good luck in 2023. seth.byrd@okstate.edu

12 COTTON FARMING | JANUARY 2023 COTTONFARMING.COM

Specialists Speaking

WAKE UP WITH US!

Season four of The Cotton Board’s Cotton & Coffee Zoom series is underway. This series asks the cotton-growing community to wake up with The Cotton Board, and in the time it takes to drink a morning cup of coffee, get an update from the Cotton Research and Promotion Program. This is a great way to see how the assessment dollars collected by The Cotton Board are being spent to increase the demand for and profitability of cotton. Each virtual Zoom session includes a 30-minute presentation and concludes with time for discussion and questions. Cotton & Coffee is held on the third Tuesday of each month at 7:30 am Central. Pre-registration is required, so please visit cottonboard.org/cotton-coffee if you'd like to register and participate.

COTTONBOARD.ORG/COTTON-COFFEE

ARKANSAS Bill Robertson

Plans for 2023 should be falling into place. Variety selection is one of the most important decisions a producer makes. Once planted, no amount of e ort can make up for a poor decision. Many producers have booked their main varieties but may still be evaluating some of the new varieties in new technologies that are worthy of a look. ere are many sources of variety testing results. When selecting varieties for planting, don’t simply choose the top-yielding variety at any single testing location or year — look at the averages of several years and locations. Each variety has its strengths and weaknesses. e challenge is to identify these characteristics and adjust management strategies to enhance strengths while minimizing the weaknesses. e best experience for new varieties is based on rst-hand, on-farm knowledge. Evaluate yield and quality parameters of unbiased testing programs to learn more about new varieties. Plantings of new varieties should be limited to no more than 10% of the farm. Acreage of a variety may be expanded slightly if it performs well the rst year. Consider planting the bulk of the farm to three or four proven varieties of di erent maturities to reduce the risk of weather interactions and to spread harvest timings. Information to assist in variety evaluation may be found at the University of Arkansas System Division of Ag Variety Testing webpage at https://aaes.uada.edu/variety-testing/ for variety testing results from county and o cial variety trials. brobertson@uada.edu

LOUISIANA Matt Foster

One of the most important decisions producers make is variety selection. With numerous transgenic traits currently available, selecting a variety can o entimes be a difcult process. It’s valuable for a producer to have as much information on a variety as possible to make a more informed decision. With proper variety selection, producers increase their chances to be pro table and sustainable. To aid in this process, the LSU AgCenter annually conducts o cial variety trials at the Northeast Research Station in St. Joseph, Macon Ridge Research Station in Winnsboro, Dean Lee Research Station in Alexandria and Red River Research Station in Bossier City. is past year, 41 cotton varieties were evaluated at these locations.

In addition to the o cial cotton variety trials, nine on-farm cotton variety trials were conducted with producers throughout the state. e main objective of these trials is to provide as much information as possible concerning a cotton variety’s performance over a range of soil types, growing conditions and management practices.

As a new growing season approaches, variety selection plays a major role in the planning process. Now is a great time to review the past year’s results. Results of the 2022 LSU AgCenter cotton variety trials are located at https://www.lsuagcenter.com/topics/crops/cotton. Happy New Year, and best of luck during the upcoming season. mfoster@agcenter.lsu.edu

MISSISSIPPI Brian Pieralisi

Variety selection is a di cult decision. It’s just as important as it was last year, and possibly more important moving into 2023. Considering varietal placement for your region or agronomic practices — plus disease packages and herbicide technology — in uences overall management for the entire season. Not to mention, improper variety placement can cost you up to 200 or more pounds of lint per acre.

By the time you read this, 2022 cotton variety performance data for both MSU small plot and on-farm trials will be posted to Mississippi-crops.

View Cotton Farming’s 2023 Seed Variety Guide online at https:// www.cottonfarming.com/cover-story/2023-seed-variety-guide/.

com. At this point, some of the newer varieties have had two or three years of performance history, which helps in making selection decisions. Mississippi State small plot variety trials have evaluated approximately 40 varieties for the past two years under di erent irrigation practices in over nine locations and two regions. I recommend selecting a similar environment in the small plot trials to where you are placing a variety and comparing these varieties to a similar environment in a large plot situation.

Finding a variety with two or more years of performance data is also important in strengthening your decision. Two-year performance data is available for both hill and delta regions in the MSU small plot variety trial publication.

Variety selection decisions are made earlier than in years past. Some farmers are booking seed before variety trials are harvested, which illustrates con dence in a variety’s repeat performance. Supply of certain varieties also caused earlier-than-usual selection decisions. To secure a particular variety, plan early and avoid late selection decisions that could result in poor varietal placement. As always, feel free to contact me with any variety selection questions or comments. Happy New Year! bkp4@msstate.edu

TENNESSEE Tyson Raper

As I write this Dec. 5, the Tennessee small plot and large plot variety testing results are currently being compiled, and we are on track to deliver the nal results several weeks earlier than normal. ere is a considerable amount of statistical power in the trials this year — the ability of the trial to identify di erences in performance between two varieties — but we need to exercise caution while interpreting these results as rainfall patterns in West Tennessee during 2022 varied considerably from location to location.

Fortunately, if you consider the di erent rainfall patterns experienced at each Tennessee location, you’ll have tremendous insight on how to place and manage varieties for the 2023 season. Generally speaking, we saw outstanding performance from the early-mid and mid-maturing varieties. Early maturing varieties performed surprisingly well when planted late, but if planted early in drier conditions, performance su ered. Additionally, the preliminary analysis suggests every company has at least one variety in the top statistical tier.

By the time you read this, our full report and a variety guide will be available on news.utcrops.com or utcrops.com. Don’t hesitate to reach out if you have any questions on placement during 2023 or results from 2022. I hope everyone has a Happy New Year! traper@utk.edu

14 COTTON FARMING | JANUARY 2023 COTTONFARMING.COM

Specialists Speaking

ALABAMA Steve M. Brown

In Alabama, as in most states, we conduct variety trials in multiple locations. The reason is obvious: production areas differ widely in terms of soils, weather trends, pest pressures, etc. We grow cotton in environments as diverse as any state in the Belt except Texas, and as a result, variety performance can differ significantly across our various production regions.

In addition to large-scale on-farm trials scattered across the state, replicated, small-plot “official variety trials” (OVTs) are conducted at Auburn University research locations. In 2022, we added Brewton as a location to bring the OVT sites to six, which includes stations at Belle Mina, Fairhope, Headland, Prattville and Shorter. Altogether, 20 OVT experiments were planted at these research facilities, and 14 on-farm trials were initiated in grower fields.

Yield data can be reviewed at https://aaes.auburn.edu/variety-tests/.

Henry Jordan, AU Variety Testing Manager, in addition to making extraordinary efforts to publish information in a timely and efficient manner, has partnered with Medius Ag to develop the AU Variety Selection Platform. This tool enables an in-depth analysis of variety performance and serves as a collection site for production information, pest ratings, field pictures, weather data and calendar events. As with many sophisticated tools, the more you work with it, the more useful it becomes.

An early review of OVT yield data indicates different top performers by location, which underscores the value of “local” testing. Maybe it’s due to the fact that there are so many entries, but there’s also no absolute standout. We’ve had eras in which the opposite occurred; that is, a single star variety dominated large regions of the county. Most recently, it was DP 1646 B2XF, which still performs well in many trials. For most areas, the current portfolio of varieties offers several competitive but maybe not dominant picks — all the more reason to plant multiple varieties on a farm.

Study the data. Check your selections with the “coffee shop” chatter, but temper what you hear by the source and its credibility. Also, given what happened in West Texas in 2022 and the fact that they typically produce a lot of planting seed, you might want to early order. cottonbrown@ auburn.edu

GEORGIA Camp Hand

Those who know me know I love to be in my garden. I grew up working in my Papaw’s garden with him, and it was then that I knew I wanted to work in the field of agriculture. When my wife and I bought our house in Tifton, there was already a huge garden, which I was thrilled about. Last spring was my second garden here, and as we were on the road doing production meetings, myself and my colleagues found ourselves in garden supply shops pretty frequently.

As we were nearing planting time for potatoes, we walked into a store in Laurens Co., Georgia, and they had lots of options to choose from in terms of potato varieties — some of which I was familiar with and others I was not. I wanted to get the most bang for my buck when selecting a variety, but wanted to make sure I was choosing a variety using accurate information and not just choosing one I was comfortable with. So, I did what I would hope any cotton grower would do in my situation, and called a trusted advisor that I was sure would know more about potato varieties than me – Dr. Steve Brown (that’s right, the Auburn University cotton agronomist). He walked me through the varieties I was thinking about buying and helped me make a final decision.

As we approach the 2023 growing season, many cotton growers will go through the process I just described here. Choosing a cotton

variety is complex, and a lot of things go into that choice. Herbicide traits, insect protection, nematode resistance, maturity, fiber quality and ultimately yield. Make the best decision for your farm with the best information available. UGA has multiple resources to help with that, including the UGA On-Farm Cotton Variety Evaluation Program and the Official Variety Testing Program (swvt.uga.edu). Results from both programs will be discussed at county production meetings in the spring of 2023.

Speaking of which, the schedule for 2023 production meetings is now available at ugacotton.com, and your local UGA county Extension agent has that information as well. We are looking forward to getting back on the road, and as always, if you ever need anything, your local UGA county Extension agent and specialists are here to help! Don’t hesitate to reach out. camphand@uga.edu

NORTH CAROLINA Guy Collins

As I write this Thanksgiving Eve, harvest is coming to a close. Nearly all cotton has been harvested at this point — and a lot of beans, too. Although this year brought its share of challenges, as does every year, we have a lot for which to be thankful. In many areas, we harvested a decent to exceptional crop. This is attributed to summer (July to early August) rains, although sparse, and a “clean” Fall with regard to harvest weather — as well as little to no damage from the tropical storm we experienced. Yields varied, as they always do, but many growers harvested a really good crop with good quality.

By the time this is read, variety selection will probably be on everyone’s mind. Variety selection is, and always has been, one of the most important decisions a grower can make. The day seed is planted, the maximum genetic yield potential has been determined. Beyond planting, it’s up to management and the environment to maximize that yield potential.

When observing the results of last year’s NC On-Farm Cotton Variety Evaluation Program, simply making a small error in variety selection could cost upwards of $170 per acre, which is over a $50 million economic impact statewide. Variety decisions should be made based on replicated trial data, from several locations and years, not just the closest trial to your farm. Making variety decisions based on field-by-field observations can be very dangerous, misleading and costly due to subtle variations in soils, rainfall, planting date, etc.

Planting the majority of your acreage to varieties that have shown consistent performance at or near the top (compared to other varieties in the same trial) over a broad range of environments, years and variables within years (soils, planting dates, tillage systems, etc.) will aid in managing and minimizing risks.

Plant a smaller proportion of your acreage to varieties that have performed well across a broad range of environments but have only been in trials for a year. Plant the smallest fraction of your acreage to brand new varieties that have been in a few trials in a single year when tested experimentally. Planting varieties that have never been tested is the most risky practice. Therefore, it’s not advised to plant many acres to such varieties.

The results of the 2022 NC On-Farm Cotton Variety Evaluation Program, as well as the 2022 NCSU Official Variety Trials, will be shared once it’s available, and results for both programs will be included into the NCSU Cotton Variety Performance Calculator, which can be found at https://trials.ces.ncsu.edu/cotton/select_trials/. The results of both programs will also be covered in our upcoming 2023 Winter Cotton County Meetings.

Check with your local county ag extension agent, or check the NCSU Cotton Portal website at https://cotton.ces.ncsu.edu/ for dates/times of your county meeting. guy_collins@ncsu.edu

TWITTER: @COTTONFARMING JANUARY 2023 | COTTON FARMING 15

Specialists Speaking

TRAIT STEWARDSHIP RESPONSIBILITIES

NOTICE TO FARMERS

Bayer is a member of Excellence Through Stewardship® (ETS). Bayer products are commercialized in accordance with ETS Product Launch Stewardship Guidance, and in compliance with Bayer’s Policy for Commercialization of Biotechnology-Derived Plant Products in Commodity Crops. Commercialized products have been approved for import into key export markets with functioning regulatory systems. Any crop or material produced from this product can only be exported to, or used, processed or sold in countries where all necessary regulatory approvals have been granted. It is a violation of national and international law to move material containing biotech traits across boundaries into nations where import is not permitted. Growers should talk to their grain handler or product purchaser to confirm their buying position for this product.

ALWAYS READ AND FOLLOW PESTICIDE LABEL DIRECTIONS. It is a violation of federal and state law to use any pesticide product other than in accordance with its labeling. NOT ALL formulations of dicamba, glyphosate or glufosinate are approved for in-crop use with XtendFlex® Cotton. ONLY USE FORMULATIONS THAT ARE SPECIFICALLY LABELED FOR SUCH USES AND APPROVED FOR SUCH USE IN THE STATE OF APPLICATION. Contact the U.S. EPA and your state pesticide regulatory agency with any questions about the approval status of dicamba herbicide products for in-crop use with XtendFlex® Cotton. B.t. products may not yet be registered in all states. Check with your representative for the registration status in your state. Products with XtendFlex® Technology contains genes that confer tolerance to glyphosate, glufosinate and dicamba. Glyphosate will kill crops that are not tolerant to glyphosate. Glufosinate will kill crops that are not tolerant to glufosinate. Dicamba will kill crops that are not tolerant to dicamba. Contact your seed brand dealer or refer to the Bayer Technology Use Guide for recommended weed control programs. Insect control technology provided by Vip3A is utilized under license from Syngenta Crop Protection AG. Bollgard®, Respect the Refuge and Cotton Design®, Roundup Ready Flex® and XtendFlex® are registered trademarks of Bayer Group. LibertyLink® and the Water Droplet Design® are registered trademarks of BASF. Agrisure Viptera® is a registered trademark of Syngenta Group Company. Excellence Through Stewardship® is a registered trademark of Excellence Through Stewardship. All other products, company names and trademarks are the property of their respective owners.

Before opening a bag of seed, be sure to read, understand and accept the stewardship requirements, including applicable refuge requirements for insect resistance management, for the biotechnology traits expressed in the seed as set forth in the Technology Stewardship Agreement that you sign. By opening and using a bag of seed, you are reaffirming your obligation to comply with the most recent stewardship requirements.

TFB

Highlights Successes

In Year Of Agricultural Hardships

Texas farmers and ranchers battled the hardships of drought, inflation and high input costs but still led the state’s largest general farm organization to many successes this year, according to Texas Farm Bureau President Russell Boening.

Boening, a full-time farmer and rancher from Wilson County, highlighted several of TFB’s 2022 accomplishments during his annual address to about 1,000 farmers and ranchers gathered in Waco at the organization’s 89th Annual Meeting.

“We persisted and promoted Farm Bureau policy goals in Austin, Washington, D.C., and in the courts. We never stopped fighting,” Boening said. “I use the word ‘we’ when I talk about Farm Bureau. We must focus on our mission. We must focus on what we are about, and we are about being the Voice of Texas Agriculture.”

Boening grows feed grains, cotton and wheat, as well as operates a dairy and a beef cattle operation with his brother and father near Floresville. The fourth-generation farmer was first elected president of Texas Farm Bureau and Affiliated Companies in December 2014.

Boening thanked county Farm Bureaus and leaders for helping TFB achieve its 22nd consecutive year of membership growth. TFB completed the membership year with 538,064 member-families.

He said TFB has been actively advocating that the current safety next for U.S. agriculture must be strengthened.

TFB is promoting the American Farm Bureau Federation’s four overarching priorities for the 2023 Farm Bill, Boening noted. The priorities are maintaining a

robust Farm Bill, maintaining a unified Farm Bill that includes nutrition programs and farm programs together, prioritizing risk management tools that include federal crop insurance and commodity programs, and ensuring adequate USDA staffing and resources to provide technical assistance.

He said farmers and ranchers helped elect members of Congress in November who will support Farm Bureau’s Farm Bill positions.

“I am proud that Texas Farm Bureau stands apart. We believe in dialogue and conversation, rather than anger and controversy,” Boening said. “We have to be smart as a community of farmers and ranchers. We must have a sense of purpose.”

For more information about TFB’s 89th annual meeting, visit texasfarm bureau.org/annualmeeting.

Wildlife Specialist Joins Texas A&M AgriLife Service

Jacob Dykes, Ph.D., was recently hired as the new statewide wildlife specialist for Texas A&M AgriLife Extension Service and assistant professor in the Department of Rangeland, Wildlife and Fisheries Management in the Texas A&M College of Agriculture and Life Sciences.

Dykes, based at the Texas A&M AgriLife Research and Extension Center in Corpus Christi, said his focus will be on white-tailed deer and other big game species, including exotic animals.

“Texas A&M AgriLife hasn’t been very involved with big game across the state, including one of the most popular game

16 COTTON FARMING | JANUARY 2023 COTTONFARMING.COM Industry News

TFB President Russell Boening addresses the audience at the 89th annual meeting in Waco.

A Louisiana cotton farmer says the 2022 CCOY is dedicated and excels at analyzing a problem and devising a solution. “We have absolute confidence in his knowledge of agronomy, entomology and current pesticide regulations. He is a valued friend, and his work ethic makes him an asset to our business.”

Another Louisiana cotton farmer says, “The industry leadership shown by him throughout his career places him in ‘rare air’ among his peers. He has always been on the front lines and has become a trusted partner in our farming operation.”

He is described as highly visible and proactive in the ag industry. He is knowledgeable in agronomics as well as being tech-savvy, which is almost a necessity in these times. He is a devoted husband, father, friend and consultant and is there no matter what the need is.

Cotton Farming

Industry News

species in the nation — white-tailed deer,” he said.

“There are so many questions and such a high demand for science-based information related to their behavior and habitat from a spectrum of stakeholders, including landowners, conservationists and hunters in the various ecoregions of the state."

Listening to questions and concerns from stakeholders will help direct research, Dykes said, and he has plans to communicate with the public. He hopes to provide a steady stream of information, tips and data related to Texas big game and wildlife improvement opportunities through multiple social media accounts, including Instagram (agrilife. wildlife) and a blog.

LSU AgCenter Names Key Director Positions

The LSU AgCenter has named two well-established leaders to research and Extension positions.

Michael Salassi will serve as interim executive associate vice president and director of the Louisiana Agricultural Experiment Station and Tara Smith as interim executive associate vice president and director of the Louisiana Cooperative Extension Service.

In these positions, Salassi and Smith will support the statewide efforts of research and Extension.

Matt Lee, interim vice president for agriculture, said he is working to expand opportunities for research and Extension opportunities with federal agencies and industry partners.

“This change to the AgCenter’s administrative structure will allow for a more comprehensive approach to advance the state’s research and Extension initiatives to the next level and allow us to be laser-focused on providing stakeholders with resources that improve lives,” he said.

Deltapine Launches Class Of

‘23 Cotton Varieties

The Deltapine brand Class of ’23 cotton varieties showcase the move to bring to market high-performing genetics in the newest biotech trait platform — Bollgard 3 ThryvOn Cotton with XtendFlex Technology.

Announced at the annual Deltapine New Product Evaluator (NPE) Summit,

the Deltapine Class of ’23 features two new Bollgard 3 ThryvOn Cotton with XtendFlex Technology varieties along with three new Bollgard 3 XtendFlex cotton varieties.

The Deltapine Class of ’23 also represents a strong native trait package, including a new Bollgard 3 XtendFlex cotton variety with resistance to root-knot nematode and bacterial blight. Four of the new cotton varieties demonstrate resistance to bacterial blight, and all five show moderate tolerance to Verticillium wilt.

“The Deltapine Class of ’23 cotton varieties mark another step forward for the entire cotton industry, both from a new trait platform standpoint and in our continuing efforts to raise the bar on yield and fiber quality expectations in Bollgard 3 XtendFlex cotton varieties offered by the Deltapine brand,” said Eric Best, Deltapine cotton product manager.

The Deltapine Class of ’23 cotton varieties are:

DP 2333 B3XF (tested in NPE as 20R733B3XF) is an impressive mid-maturity Bollgard 3 XtendFlex cotton variety for the Mid-South, Southeast and South Texas markets that showed resistance to bacterial blight and outstanding yield potential in NPE plots. This new cotton variety also showed excellent fiber quality potential and delivered farm-record yield averages for several NPE growers.

DP 2328 B3TXF (tested in NPE as 21R4132B3TXF) is a mid-maturity Bollgard 3 ThryvOn Cotton with XtendFlex Technology variety fitting the Mid-South, Southeast, and Upper Gulf Coast and Brazos Bottom regions of Texas, offering moderate resistance to bacterial blight.

DP 2317 B3TXF (tested in NPE as 21R4127B3TXF) is an early maturity Bollgard 3 ThryvOn Cotton with XtendFlex Technology variety for the Mid-South and Texas markets, offering outstanding fiber quality potential and resistance to bacterial blight.

DP 2335 B3XF (tested in NPE as 21R635B3XF) is a mid-maturity Bollgard 3 XtendFlex cotton variety for West Texas markets with resistance to bacterial blight and moderate tolerance to Verticillium wilt.

DP 2349NR B3XF (tested in NPE as 21R649NRB3XF) is a mid-to-full-maturity Bollgard 3 XtendFlex cotton variety for the Southeast, offering resistance to both root-knot nematodes and bacterial blight.

18 COTTON FARMING | JANUARY 2023 COTTONFARMING.COM

CCOY

Cotton Consultant of the Year established 1981

Cotton Consultant of the Year sponsored by

Who is the man so deserving of these accolades? Look for the big announcement in the February issue of Cotton Farming!

Who is the 2022 Cotton Consultant of the Year?

We work hard at what we do because we know you work hard at what you do. Between our print and digital o erings, Cotton Farming is here for you year-round. www.cottonfarming.com@CottonFarming CottonFarming@CottonFarmingMagazine

Ginners Marketplace

Cotton Gins — The Early Days

The cotton gin’s invention served as the first test of the newly created U.S. patent system. The technical problems of Eli Whitney’s design led to almost immediate modifications that were put into place by other farmers and inventors. The wire teeth on the revolving cylinder, for example, were quickly replaced by a series of circular saws.

The origins of the modification are foggy, but as more gins with these saws were distributed, Whitney claimed that their design was an obvious variation of his own, and thus covered under his patent. Though the courts ruled in Whitney’s favor, countless legal battles ensued due to the shaky nature of Whitney’s patent.

Initial Plans To Operate Gins

Whitney and Phineas Miller, his business partner, had originally decided to produce a large number of gins, install them throughout Georgia and the South, and charge farmers a fee for using the gins. Farmers throughout Georgia resented having to pay what they felt was an exorbitant tax and opted instead to make their own variations of Whitney’s design.

Miller brought lawsuits against the makers of these lifted versions, but because of a loophole in the wording of the 1793 patent act, he and Whitney were unable to win any suits until 1802. In a desperate e ort to make a profit, Whitney and Miller began selling licenses to manufacture the gin, but they failed to make a large return by the time Whitney’s patent expired in 1807.

Though most evidence indicates that Whitney was the sole inventor of the cotton gin, many historians believe he was either aided or preceded by another in the design and invention of the machine. The most widely circulated claim to the invention of the cotton gin has been argued on behalf of Catharine Greene, Whitney’s hostess while in Georgia.

Greene was deeply interested in the solution to the mechanical problems presented by the processing of short-staple cotton, and many have contended that she aided Whitney in the gin’s creation but avoided the connection of her name to the invention. Other historians have credited Hogden Holmes, a Scottish immigrant; Robert Watkins, an Augusta businessman and attorney; and William Longstreet, inventor of the precursor to the sewing machine, with the saws that made the gin a profitable success. All three of these men were issued patents for improvements to the cotton gin by 1796. Most evidence indicates, however, that Whitney did invent the saw gin.

Later Developments

During the 1820s, the first successful cotton gin factories appeared. Before the Civil War (1861-65), the cotton gins they produced were sold primarily to farmers, who would install them on their property and use them to gin their own cotton. After the Civil War, however, farmers were more likely to take their seeded cotton to a ginner, who would remove the seeds for a fee in a method called “custom ginning.”

The factory setting of custom ginning demanded e iciency during the whole ginning process, rather than just of the gin itself, and innovations in ginning began to focus more on the

quantity and speed with which these factories could process cotton.

In the mid-1880s Robert Munger of Texas developed “system ginning,” a process by which seeded cotton was fed continuously into multiple gins stands, from which the fiber was immediately pressed and baled. Munger’s system e ectively ended the era of plantation gins and small cotton-gin makers and merchants.

The modern cotton ginning process has continued in Georgia and the Southeast and can also be found in the major cotton producing areas of the southwestern United States and overseas. Cottonseed oil, one of the by-products of cotton production, is commonly used in potato chips and other processed foods. Some consumers are wary of cottonseed oil in foods, as it contains highly toxic gossypol, and is taken from one of the most chemically intensive crops grown in the United States.

Today, only a few technologically sophisticated firms produce cotton gins based on the designs of specialized engineers. The largest of those companies, the Lummus Corp., located in Savannah, Georgia, has brought short-staple cotton production back to its roots at Mulberry Grove.

This excerpted article, “Cotton Gins,” was authored by Elizabeth Hargrett, New Georgia Encyclopedia.

An informative email summary of your gin’s daily performance.

Cotton Ginners Marketplace 20 COTTON FARMING JANUARY 2023 COTTONFARMING.COM COTTON

COTTON FARMING IS THE OFFICIAL PUBLICATION OF THE GINNING INDUSTRY.

Text 662-809-9730 for an example report

James Marion Prance, the proprietor of a cotton gin in Cobb County, Georgia, sits in front of cotton bales in the early 1900s.

COURTESY OF GEORGIA ARCHIVES

Cotton Ginners Marketplace TWITTER: @COTTONFARMING JANUARY 2023 | COTTON FARMING 21 Steeper Hoppers with 10-Gauge Steel 50% Larger Square Hydraulic Doors Conversion Kits for Most Seed Houses Call Jim - (972) 381-8899 / cliffgranberrycorp.com ELEVATED SEED HOUSE “We really like the safety and the speed of this seed house.” Associated Growers Co-op, Inc., Athens, AL MINIMIZE SEED BRIDGING • SAFER • FASTER • STRONGER NORTHERN / LUCUS MACHINE, INC 1116 E SLATON HWY LUBBOCK, TX 79404 FOR SALE: 1 – 158 GIN STAND W/ CONTROLS & 700 FEEDER MANUFACTURER OF HI- CAPACITY LINT CLEANING SYSTEMS IN 86” TO 110” WIDTHS NEW 60”, 72”, & 80” OVERSHOT BATTERY CONDENSERS 96” TO 144” INCLINE CLEANERS, STICK MACHINES, & AIR LINE SEPARATORS HIGH CAPACITY VACUUMS USED & FACTORY REBUILT GIN MACHINERY PLASTIC BALING PRESSES COMPLETE LINE OF REPAIR PARTS FOR MURRAY, MITCHELL, H.E., CONSOLIDATED, CONTINENTAL, MOSS, LUMMUS, HORN, & CMI 806-745-8156 1-800-776-8182 FAX: 806-745-0564 NORTHERNLUCUS@YAHOO.COM WWW.NORTHERNLUCUS.COM

An Invitation To Take ‘Your Turn’

All of us at Cotton Farming would like to thank everyone who has contributed to the My Turn column through the years. Many of our readers have told us it’s one of their favorite pages in the magazine.

As we embark on a new year, we pause to reflect on last year’s submissions and invite more members of our “cotton family” to tell us their stories. Here are some memorable excerpts from 2022.

January 2022, Cindy Faulkner: “Peanut was 100% house cat, not a barn cat. I took her up the steps of the picker on my shoulder. Then she jumped off and walked over to the door waiting for me to get up the ladder to let her in. The rest is history. She has picked cotton with me for 16 consecutive years.”

February 2022, Eric Best: “I think the challenges of working with cotton in West Texas provided me with an understanding not only of how demanding the crop can be, but also how durable and resilient the growers are. Twenty-five years professionally involved in cotton have been humbling.”

March 2022, Janice Smith: “So, Fred and Sandra had just finished eating a big, hard green peach. They nonchalantly wandered back to the front porch, doing a little eavesdropping as they went. That’s when they heard Uncle Will say, ‘Walter, did you hear about the children who died from eating green peaches?’ Two sets of ears perked straight up, and two hearts skipped a beat.”

April 2022, Dorothy Young: “Guess I better tell you my bestest crop consultant that I have been talking about is Ray Young from Wisner, Louisiana. Come see us. We’d love to feed you country cooking and talk about crop consulting and raising crops on this wonderful land God has entrusted to us.”

May 2022, Neil Joiner: “Wind, rain and house-shaking rumbles of thunder came with that ominous cloud, but late in the day a waning sun peeked through the ethereal quietness that sometimes follows a storm. Delicate fingers of light brushed soft pastels onto a canvas of tranquility.”

June 2022, Anne Boyd: “And, before I could think

of what I wanted to say, I looked around at some of the photographs and memorabilia in my cotton-filled house and thought I would want to include a lot about how cotton has been a major part of my life.”

July 2022, Guy Collins: “I can remember packing cotton in trailers for friends whose fathers grew it. I can also remember when the first module builders showed up. If I remember right, a new one cost between $30,000 to $40,000. My grandfather thought it would be hard for anyone to justify the cost of such a luxury. That’s laughable now.”

August 2022, Vern Crawford: “Driving a car is an integrated endeavor requiring multiple skills, a lifetime of learning, a few hiccups along the way and always the frustration of never getting where you want to go fast enough. It’s almost like Integrated Pest Management.”

September 2022, Steve M. Brown: “Remember the old Maytag washing machine commercials? Because Maytag products were so reliable, they never broke down; consequently, no one ever needed or called the repairman. The worst thing for an Extension professional is to be irrelevant. Not needed. Never called.”

October 2022, Neil Joiner: “I had not mentioned two things for which he is well known — fishing and hunting. Many of us have tales about the ones that got away. William’s stories are about the ones that didn’t.”

November 2022, Dean Fisher: “There was much debate as to whether cloth or paper was better for baby, and also what was best for the environment. We opted for cloth diapers, using a service that picked up, washed at 190° F, and then delivered — still preferring cotton.”

December 2022, Ron Smith: “One of our county agents organized a cotton-picking field day with the local schools. I was the guest speaker and prepared a set of ‘How to hand pick cotton’ rules for the occasion.”

To read these My Turn columns in their entirety, go to www.cottonfarming.com and click on Departments. To submit a My Turn column, please contact Carroll Smith at csmith@onegrower.com or 901-326-4443. We look forward to hearing from you!

– Carroll Smith Editor, Cotton Farming

Cotton Farming’s back page is devoted to telling unusual “farm tales” or timely stories from across the Cotton Belt. Now it’s your turn. If you’ve got an interesting story to tell, send a short summary to csmith@onegrower.com. We look forward to hearing from you.

22 COTTON FARMING | JANUARY 2023 COTTONFARMING.COM My

Turn