PROFITABLE PRODUCTION STRATEGIES www.cottonfarming.com ONE GROWER PUBLISHING, LLC OCTOBER 2023 Idalia’s Impact Be Prepared For Potential Late-Season Adverse Weather Mississippi Cotton Farmer Honored For Job Well Done IN THE PATH OF THE STORM: Clemson And Michelin Study Tire Pressure, Soil Compaction

The best way to succeed this season is to be ready for the ones that follow. And with the proven data and results of PhytoGen® cottonseed, you can be confident your operation is ready to flourish for seasons to come. Learn more about PhytoGen and the Enlist® weed control system at PhytoGen.com.

™® Trademarks of

Agriscience and its

The Enlist® weed control system is owned and developed by

Agriscience LLC. © 2022

(12/22) BR CAAG2PHYG083

Corteva

affiliated companies.

Corteva

Corteva.

OCTOBER 2023

FEATURES

6 CONSERVE KANSAS WATER

Changing climates and weather patterns heighten the need for university research.

10 TIRE PRESSURE RESEARCH

Clemson University and Michelin North America, Inc. researchers explore theory to increase yields in cotton and peanut rotation.

12 MS FARMER HONORED

Mississippi farmer Kendall Garraway honored for row crops and enthusiasm for agriculture. PRODUCTION STRATEGIES www.cottonfarming.com

13 UGA COTTON FIELD DAY

Path Of The Storm

20 GINNERS MARKETPLACE

the official publication of the ginning industry

Module Truck Systems purchases Kimbell Gin Machinery Co., including Diamond K Manufacturing.

WEB EXCLUSIVE

DEPARTMENTS & COLUMNS

8 16 Research & Promotion 17 Specialists Speaking 22 My Turn

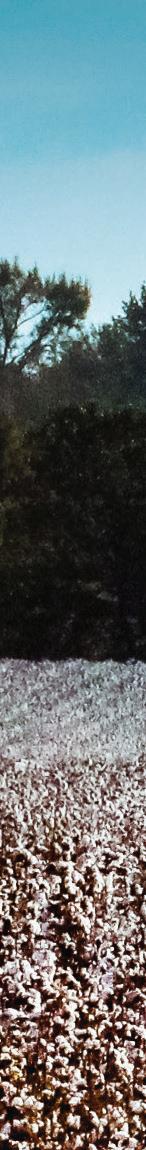

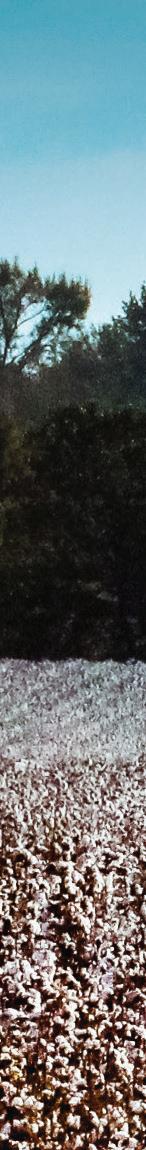

ON THE COVER: Cotton blown over by Hurricane Idalia on Georgia’s Cook and Brooks county line.

Cover photo by Camp Hand.

CelluDot LLC, a startup founded by engineering alumni, will use a $1 million National Science Foundation grant to optimize a nanotechnology product they developed as doctoral students to mitigate herbicide drift in collaboration with the Arkansas Agricultural Experiment Station. Go to www.cottonfarming.com for this Web Exclusive report.

DIGITAL OFFERINGS

Keep

www.cottonfarming.com

Facebook: https://www.facebook.com/cottonfarming

Twitter: @CottonFarming

Instagram: @CottonFarmingMagazine

TWITTER: @COTTONFARMING OCTOBER 2023 COTTON FARMING 3

latest

monthly

sign-up

upper

up with the

from Cotton Farming by signing up for the

E-News at

. Look for the

box in the

right corner of the home page.

COTTON FARMING (ISSN 0746-8385) is published monthly January through December by One Grower Publishing LLC, 875 W. Poplar Ave., Suite 23, Box 305, Collierville, TN 38017. Periodicals postage paid at Memphis, Tennessee, and at additional mailing o ices. POSTMASTER: Send address changes to Omeda Communications, Customer Service Department, P.O. Box 1388, Northbrook, IL 60065-1388 (Phone: 847-559-7578) (Fax: 847-564-9453). Annual subscriptions are $40. International rates are $55 in Canada/Mexico, $90 in all other countries for air-speeded delivery. Surface delivery not available due to problems in reliability.

Vol. 67 No. 10

At the end of August, Hurricane Idalia entered the Gulf of Mexico and slammed into Florida’s Big Bend region as a Category 3 storm. Southeast cotton farmers kept a close eye on the forecast to determine where it would go from there. It was soon obvious that the path included coastal Georgia before moving into South Carolina and eventually North Carolina. Read these firsthand accounts of what happened. 4 Editor’s Note 5 Cotton’s Agenda 14 Industry News

PROFITABLE

Researchers and Extension share experiences with the ryvOn trait and cotton leafroll dwarf virus.

Editor’s Note

Carroll Smith

‘Never Stop Looking For What’s Not There’

“The Magic of Belle Isle” is a movie that explores the role of imagination as a novelist mentors — through example — a young girl who is curious about how to come up with ideas. He tells her, “Never stop looking for what’s not there,” which pairs nicely with American writer William Arthur Ward’s quote, “If you can imagine it, you can achieve it.” Imagination is a powerful tool.

This concept reminds me of many folks in agriculture who are credited with being able to come up with a work-around when faced with a challenge.

For example, Darrell VandeVen, who farms with his brother, Donnie, in north Louisiana, desperately wanted to keep cotton in their crop mix. But in the fall of 2019, they faced the realization that “our cost of production was too high, and the price we usually received was too low for the numbers to pencil out,” Darrell said.

After contemplating their dilemma for a while, the Louisiana farmers decided to try something radically different — planting on 60-inch rows, which was their cotton farming equivalent of a Hail Mary pass. The brothers saved money with their new game plan but also realized they would have to modify some equipment “to further reduce expenses on insecticide and herbicide applications in 2021.” So, by using the power of their imaginations, they appeared to be on the right track.

In Tennessee, cotton consultant Eric Bell said one of his farmers went to skiprow cotton to cut seed and nitrogen costs. The configuration is not for everyone, but the plan he imagined to address these challenges works on his farm.

In this issue of Cotton Farming, North Carolina cotton specialist Guy Collins said there was a lack of data to back up recommendations related to storms and defoliation. He had to keep looking for what was not there. To tackle the challenge, Collins began working on a simulated study to create hurricane force winds and try to quantify what the losses would be for both a stormproof variety and one that’s looser in the burr. In trying to imagine how to make this work, he decided to use leaf blowers and a pressure washer.

“We try to get creative sometimes in our research, and this is one of those times!” he said.

Kudos to everyone in the cotton industry for using their imaginations to solve problems and achieve goals one idea at a time.

EDITORIAL/PRODUCTION

Editor Carroll Smith csmith@onegrower.com

Southeast Editor Amanda Huber ahuber@onegrower.com

Associate Editor Cassidy Nemec cnemec@onegrower.com

Digital Content Editor Katie Guthrie

Art Director Ashley Kumpe

ADMINISTRATION

Publisher/Vice President

Lia Guthrie (901) 497-3689 lguthrie@onegrower.com

Associate Publisher/Editor-In-Chief

Carroll Smith (901) 326-4443

Associate Publisher/Sales

Scott Emerson (386) 462-1532 semerson@onegrower.com

Production Manager David Boyd dboyd@onegrower.com

Audience Services

Kate Thomas (847) 559-7514

For subscription changes or change of address, call (847) 559-7578 or email cottonfarming@omeda.com

EDITORIAL ADVISORY BOARD

David Burns – North Carolina

David Lynch – South Carolina

Bob McLendon – Georgia

Larkin Martin – Alabama

Mike Sturdivant Jr. – Mississippi

Charles Parker – Missouri

Jimmy Hargett – Tennessee

Allen Helms – Arkansas

Jay Hardwick – Louisiana

Ronnie Hopper – Texas

Ron Rayner – Arizona

John Pucheu – California

ONE GROWER PUBLISHING,

LLC

Mike Lamensdorf President/treasurer

Lia Guthrie Publisher/Vice President

ACKNOWLEDGEMENT OF COOPERATION: Cooperating with COTTON FARMING are various cotton producer organizations across the Cotton Belt. Many representatives of producer organizations serve on COTTON FARMING’s editorial advisory board. Opinions expressed and conclusions reached by contributors are not necessarily those of the cooperating organizations or the editors. All statements, including product claims, are those of the person or organization making the statement or claim. The publisher does not adopt any such statement or claims as its own and any such statement or claim does not necessarily reflect the opinion of the publisher.

Copyright 2023 ©

ASSOCIATED PUBLICATIONS – One Grower Publishing, LLC also publishes RICE FARMING, THE PEANUT GROWER, SOYBEAN SOUTH and CORN SOUTH.

If you have comments, please send them to: Cotton Farming Magazine, 7201 Eastern Ave., Germantown, TN 38138.

One Grower Publishing, LLC 875 W. Poplar Ave., Suite 23, Box 305 Collierville, TN 38017

4 COTTON FARMING OCTOBER 2023 COTTONFARMING.COM

Carroll

Cotton’s Agenda

Gary Adams

Enlightening For Efficiency

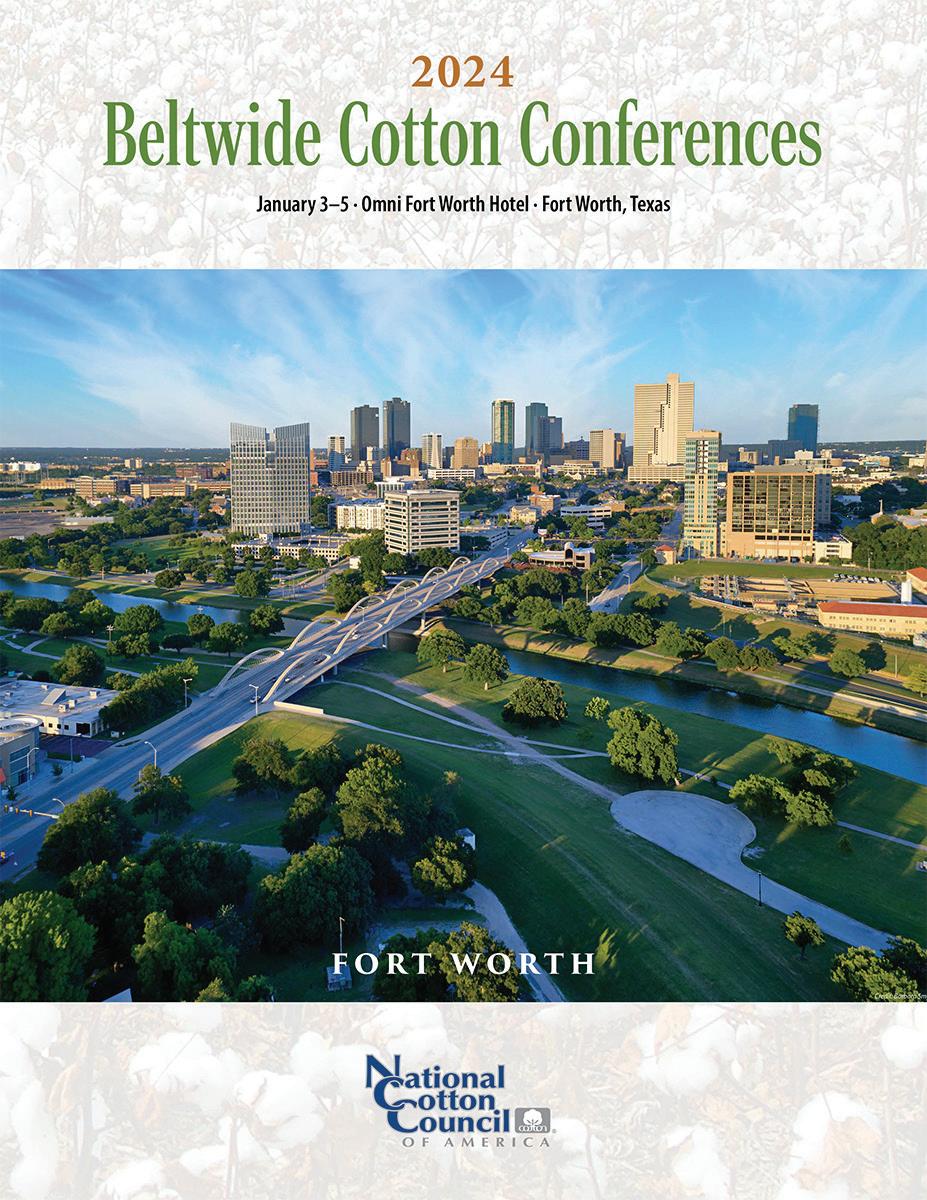

The National Cotton Council-coordinated 2024 Beltwide Cotton Conferences (BWCC) will help industry members make informed decisions aimed at improving productivity, sustainability and profitability.

Who is the event’s audience?

■ The BWCC, coordinated by the National Cotton Council, brings together university and USDA researchers, regulatory agencies, extension personnel/agents, industry sales/support personnel, consultants and producers to exchange information about new products and production/ processing systems that can be tailored to individual farming operations to maximize productivity. Three days of individual reports, panel discussions, and seminars provide attendees with information they need to help make key cotton production/ marketing-related decisions. A diverse program, along with the opportunity to network with peers from across the Cotton Belt, make this conference unique.

Cotton producers, independent crop consultants and students who register before December 18 for the 2024 BWCC on January 3-5 at the Omni Fort Worth in Fort Worth, Texas, can take advantage of reduced registration fees of $80. After that date, the rate will increase to $100. Those planning to attend are encouraged to register by clicking on the registration tab at the BWCC home page, www.cotton.org/beltwide/. That home page also includes links to housing reservations (cutoff for BWCC room rate is December 15), the final program and other useful information.

What’s the programming focus?

■ The BWCC’s Cotton Consultants Conference

will run from the afternoon of January 3 through the morning of January 4. Topics being considered include panel discussions on ThryvOn™ cotton and “See and Spray” technology as well as reports on advancing seed technology and on new varieties and precision agriculture technologies. Also featured will be presentations on the U.S. Cotton Trust Protocol®, agricultural aviation challenges, and regulatory updates, including the Endangered Species Act’s impact on pesticide availability.

The BWCC’s 11 cotton technical conferences will provide findings from current research and updates on emerging technology and programs aimed at elevating U.S. cotton production and processing efficiency. Those sessions will meet concurrently beginning the morning of January 4 and concluding by noon on January 5.

For example, the Cotton Sustainability Conference will cover best management practices; industry, brand and retail sustainability goals; market opportunities/downstream perspectives; and new sustainability programs, including the Trust Protocol. The Cotton Agronomy, Physiology and Soil Conference will provide a forum for a discussion of the life processes of cotton plants and interactions among plant and soil variables that affect crop performance and profitability. The Cotton Economics and Marketing Conference includes a session that will explore the market outlook as well as developments in policy and trade.

Subsequent sessions, including poster displays, from researchers in industry, government and academia strive to improve understanding of economic and policy-related factors affecting cotton production and downstream industries.

Those with a vested interest in a viable U.S. cotton industry are urged to attend this world-class forum.

TWITTER: @COTTONFARMING OCTOBER 2023 COTTON FARMING 5

Gary Adams is president/CEO of the National Cotton Council of America.

Focus On Kansas Water Conservation Changing Climate, Weather Patterns Heighten Need For University Research

BY SHELBY SPREIER KANSAS STATE RESEARCH AND EXTENSION

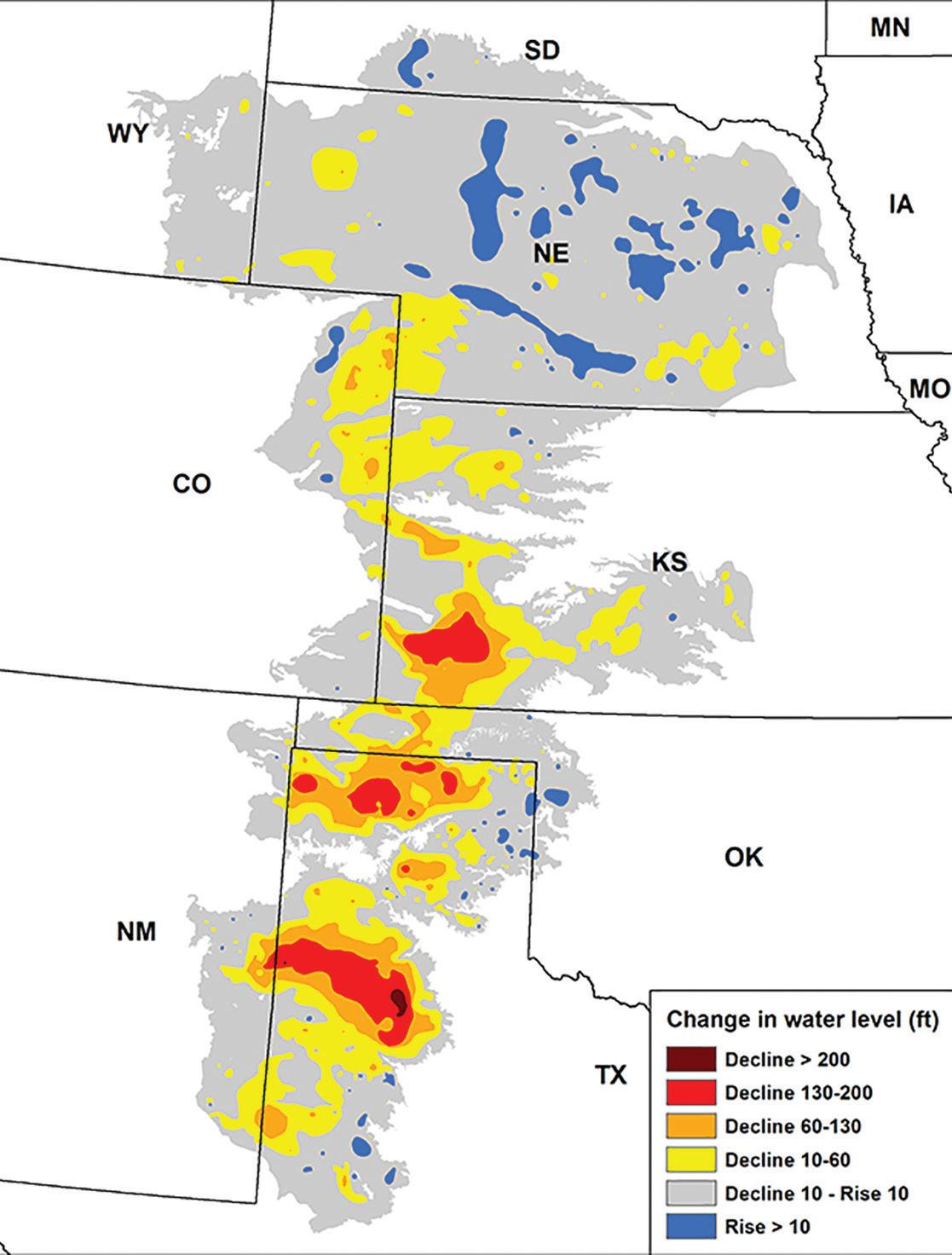

As drought continues to impact farms in many parts of Kansas, a Kansas State University official says researchers are working continually to provide solutions to the state’s water challenges.

Susan Metzger, director of strategic multidisciplinary program development and the director of the Kansas Center for Agricultural Resources and the Environment, calls the university’s work “extensive,” saying it is the product of K-State’s “prominent role in irrigation and water-use research in Kansas.”

“Kansas has about three million acres of irrigated land supporting agriculture,” Metzger said. “We are facing a changing climate that could result in very different weather patterns for our state. It’s critical for us to understand how to conserve our most important natural resource while still using it to benefit our farmers and all those that benefit from Kansas agriculture.”

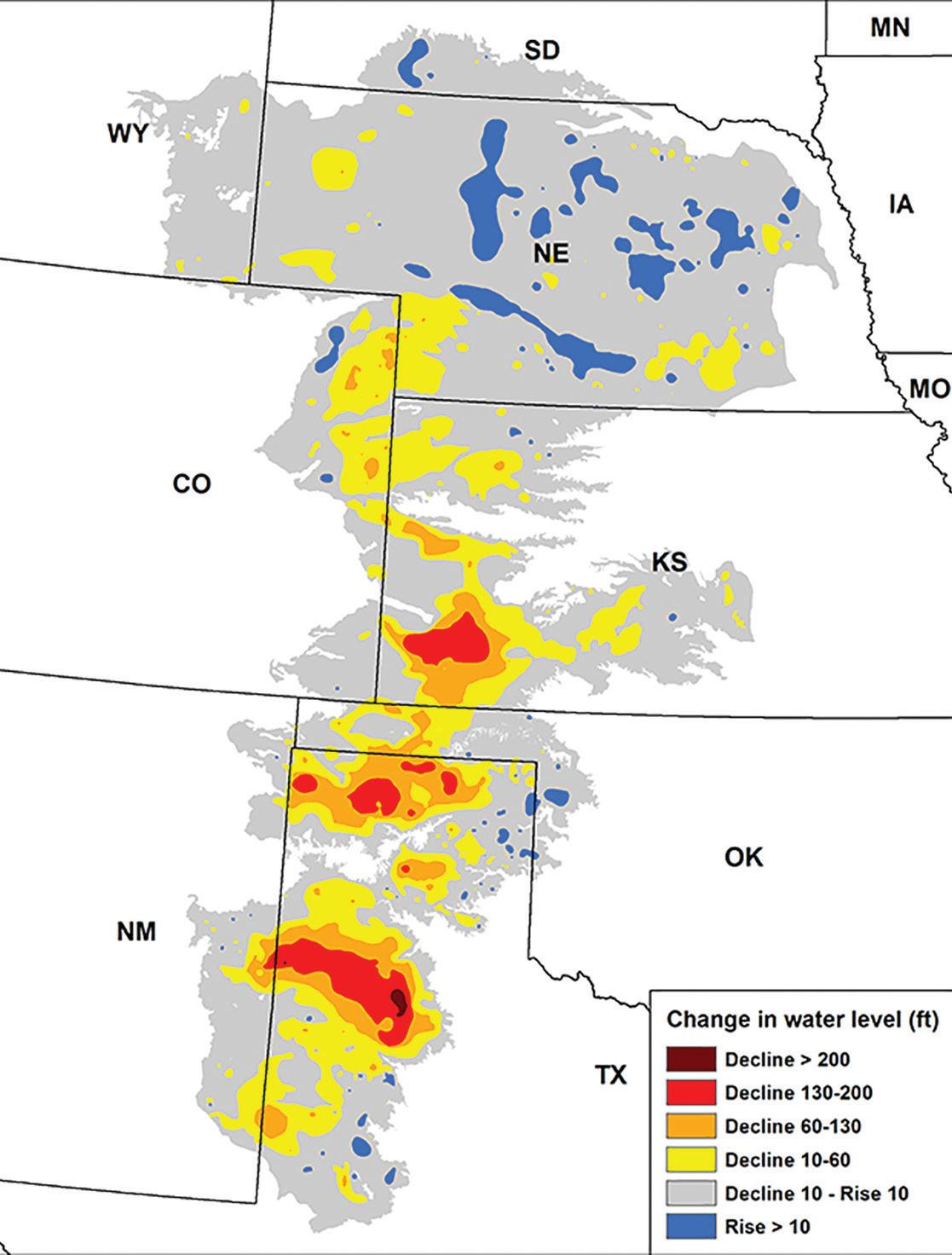

She adds that the diversity of water resources is abundant in Kansas. The eastern side of the state typically receives more than 40 inches of precipitation in an average year, while the western part of the state is very dry and relies on the OgallalaHigh Plains Aquifer for its water supplies. The Ogallala Aquifer underlies eight states, including Kansas. It is the largest underground reservoir in the United States and plays a crucial role in sustaining regional agriculture, economies and communities.

“The problem is that the Ogallala, despite being mind-bogglingly vast, is a finite resource. We’re using it faster than it can replenish. That’s why K-State’s work in irrigation technology and other water-related research is so important,” Metzger said.

Cotton Is An Option

The research team at the Southwest Research-Extension Center in Garden City has been working on projects, such as implementing deficit irrigation management, improving water efficiency using various irrigation technologies, creating advanced irrigation scheduling systems and studying alternative crops — like cotton — for a water-limited environment.

“One of the reasons we are looking at cotton is because it is drought resistant, or at least doesn’t need a lot of water compared to other crops grown in southwest Kansas,” said Jonathan Aguilar, a water resources engineer at the Southwest ResearchExtension Center.

He said current research indicates that a non-traditional crop like cotton can be grown in Kansas, and it can be profitable.

Metzger said this “out-of-the-box” approach to big issues can lead to successful research solutions.

Multidisciplinary Approach

“One of the most compelling things about the work our scientists are doing is that they are not limiting their work to the lab or even the experimental field,” she said. “K-State researchers are demonstrating the capacity of these technologies on working farms with Kansas farmers. They are also forming

partnerships with sociologists to examine the perceptions behind water use in our region, so that we can understand not just the scientific state of the aquifer, but the cultural significance of the Ogallala as well.”

A recent K-State study determined that Kansas producers have a very different view of water use and the Ogallala Aquifer than they did 35 years ago. The study indicated that, today, many producers believe in the importance of conserving groundwater. This is a big step, Metzger said.

“The communities and economy of western Kansas represent the heart of what stands to be gained — or lost — based on how resilient our agricultural industries, infrastructure and supply chains can be to climate and water-related risks,” she said.

“Conserving and extending the future of our water resources will require multidisciplinary research and outreach and educating the next generation of water and natural resource professionals. K-State is here to meet that need.”

More information is available online from the Kansas Center for Agricultural Resources and the Environment.

6 COTTON FARMING OCTOBER 2023 COTTONFARMING.COM

Western Kansas mainly relies on the Ogallala-High Plains Aquifer for its water supplies.

OKLAHOMA STATE UNIVERSITY EXTENSION

In The Path Of The Storm

Hurricane Idalia — What Happened To Cotton In the Southeast?

BY CARROLL SMITH EDITOR

BY CARROLL SMITH EDITOR

At the end of August, Hurricane Idalia entered the Gulf of Mexico and slammed into Florida’s Big Bend region as a Category 3 storm. Cotton farmers in the Southeast kept a close eye on the forecast to try to determine where it would go from there. It was soon obvious that the path included coastal Georgia before heading into South Carolina and eventually North Carolina.

Georgia cotton specialist Camp Hand said the most affected areas in his state were Lowndes and Brooks counties. From there, it tracked northeast through Cook, Berrien, Clinch and Lanier counties, over to Appling County and then into Bulloch County and the Statesboro area.

“Idalia hit a good bit of Georgia but, fortunately, by the time it got out of Brooks, Lowndes, Lanier and Clinch counties, it was mostly rain,” he said. “We had a good bit of wind in spots that blew the cotton around, and there were some fields where the cotton plants were on the ground. Statesboro got about 10 inches of rain, and other areas reported 4 to 6 inches.”

Hand said the cotton was in various stages at the time. Some fields were close to defoliating, and others had not even started opening.

How The Carolinas Fared

Idalia’s next stop was South Carolina where cotton consultant and farmer, Drake Perrow, is located in Calhoun County. He said they had a good bit of 45-mph-wind, which was enough to tangle up the cotton and make it impossible to see the rows. But the rain was probably the most notable aspect of the storm.

“In a 20-mile radius from where I am, the rainfall was anywhere from 3 inches to 13 inches,” Perrow said. “I had 6 inches here at my house. The cotton was just starting to open in the bottom, and we had started dropping some leaves so the air was circulating. The sun was out the next morning, and I noticed very little boll rot afterwards. The worst thing I saw was the tangled cotton, which means you can’t go through the crop with ground equipment anymore. However, we were at the last stink bug and Pix applications, so if we had to have a storm, this was probably the best timing for it.”

North Carolina cotton specialist Guy Collins said, “Normally, we cringe when we hear the word hurricane, but when Idalia came through, our cotton was closed, and we were real dry. This storm that brought rain was more of a blessing than anything.”

Collins said the crop ended up being kind of early because of

8 COTTON FARMING OCTOBER 2023 COTTONFARMING.COM COVER STORY

If the crop has already been defoliated, cotton typically litters the eld in the a ermath of a storm.

GUY COLLINS/NCSU

the drought stress, but as of mid-September, it was not ready to harvest yet.

“My wife will tell you that after Labor Day my blood pressure goes through the roof,” he said. “Too many times I’ve seen a real good crop go completely south because of a hurricane. And sometimes it’s not just a hurricane. September can be cloudy and wet, so the crop doesn’t dry out. Then we are set up to have hard lock issues and maybe some boll rot — another way of losing the crop. I’m just uneasy at that time.”

Tracking A Storm

When there are reports of a hurricane or tropical storm potentially threatening the Southeast, Hand said his first reaction is to tighten up while thinking, “Oh, no, there’s another one heading this way.” Then he starts watching the forecast. Two of his favorite resources to follow are James Spann — a meteorologist with ABC 33/40 in Birmingham, Alabama — and climatologist Pam Knox with University of Georgia Extension who runs the UGA weather monitoring network.

“If a storm is getting close, James provides updates three times a day,” Hand says. “I keep my eye on that. Pam also provides extremely well-timed updates on storms, tracking and potential impacts. She stays in contact with Extension specialists and county Extension agents. I pay attention to what local people are saying and follow the National Weather Service. I put a lot of time into tracking a storm — where it’s headed, how strong it’s going to be and the amount of wind and rain to expect. I start having conversations pretty early with Taylor Sills, the executive director of the Georgia Cotton Commission, in terms of what we need to be getting ready for.”

Hand says as soon as the storm passes through, he hits the road to check fields to see how bad the damage is. Over the next few days, he reaches out to county Extension agents to tell them what he has seen and ask what they have seen, so they all can work together on a path forward.

Collins said when he sees a storm developing, he watches it like a hawk. If one looks like it can potentially hit, he advises growers not to defoliate if they have closed bolls. If the storm

is about a week away, and some of the cotton has already been defoliated, he recommends harvesting it the best you can and get it out of the field or at least in a module.

“The problem is we don’t always have a lot of notice as to whether a storm is coming here,” Collins said. “We may know if it’s going to get close, but getting close is essentially no impact, but a direct hit is a major impact. If we could have more precise notice, we’d be better off in terms of making decisions.”

Defoliation Decisions

“When I see a storm coming, I am not going to defoliate,” Perrow said. “I want all the leaves on there to protect the cotton a little bit. I remember when Hurricane Hugo hit, we had just defoliated a lot of the crop. Afterwards, cotton was everywhere. The ground looked like snow.

“A good many people take out hurricane insurance now. That helps. There are a couple different qualifications to collect, such as sustained winds at a sustained speed for a certain amount of time. The amount of rainfall is also considered. One good point about this insurance is that if one county meets these qualifications, then an adjoining county can benefit from it, too.”

To gather data that will back up North Carolina’s recommendations to farmers about waiting until the storm passes before defoliating, Collins is working on a simulated study about what can happen with various degrees of wind.

“Most growers are concerned they are going to get behind schedule if they don’t go ahead and defoliate,” he said. “But there is not much point in being on time if there is nothing to harvest. We want to protect the crop as much as we can, so we are creating hurricane force winds and trying to quantify what the losses would be for both a stormproof variety and one that’s looser in the burr.

“The study is being conducted with leaf blowers and a pressure washer. I underestimated how much work it would be and that we would be out there getting wet! Sometimes we try to get creative in our research, and this is one of them. 2023 is an experimental year to see if we can make it work and how well we can make it work. It’s quite an undertaking.”

TWITTER: @COTTONFARMING OCTOBER 2023 COTTON FARMING 9

DRAKE PERROW

is drone photo shows a eld of tangled cotton in Calhoun County, South Carolina, a er Hurricane Idalia rolled through.

Tire Pressure And Soil Compaction

Exploring Theory To Increase Yields In Cotton, Peanut Rotation

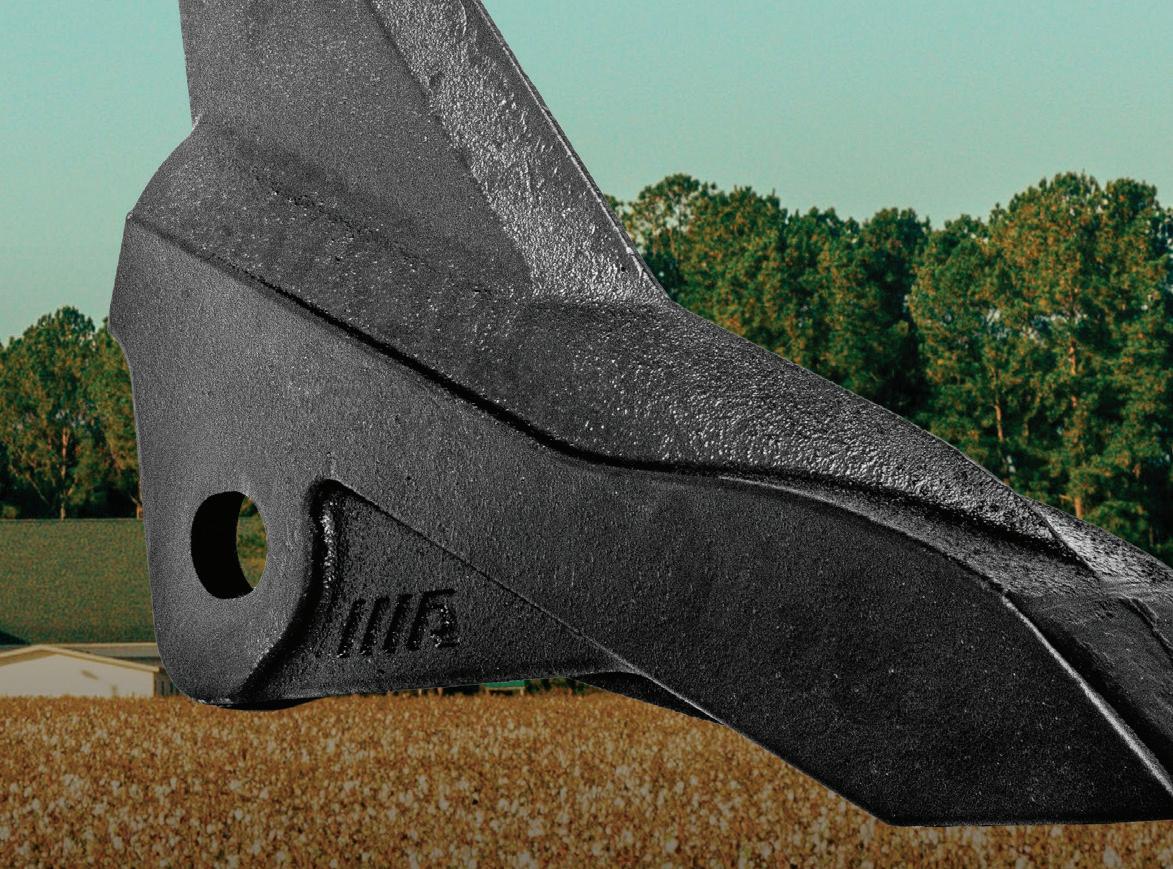

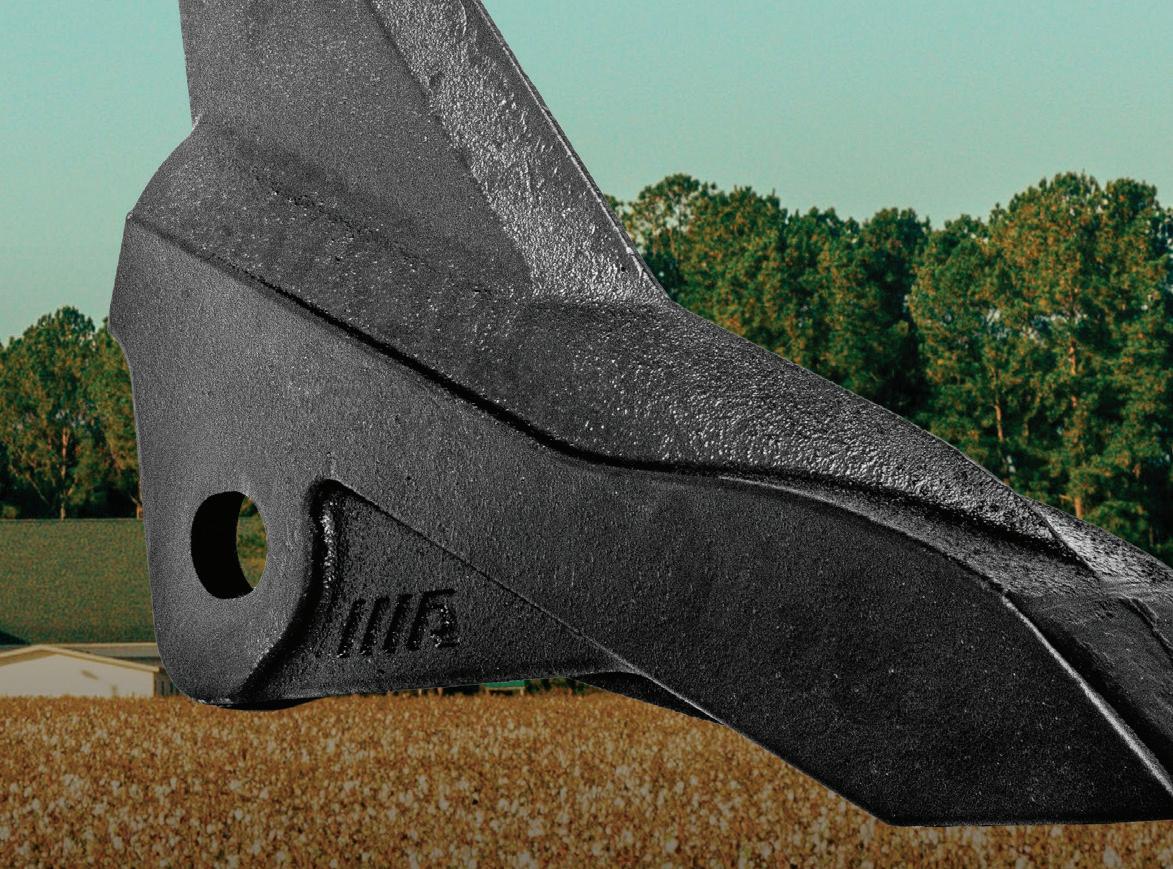

Soil compaction is a major problem that affects plant growth and development, resulting in yield losses of up to 50% on some localized, high-traffic areas of South Carolina farms, such as end-rows.

Clemson University and Michelin North America, Inc. researchers believe low-pressure tires can reduce soil compaction to help increase crop yields for South Carolina farmers.

Cotton, Peanut Rotations

Kendall Kirk, Clemson Cooperative Extension Service precision agriculture engineer and director of the Clemson University Center for Agricultural Technology (CU-CAT) and Dan Anco, Clemson Extension peanut specialist, are working with Martin Crouch, Michelin Agriculture account executive and Steve Rosen, Michelin Agriculture field engineer, to determine if low-pressure tires can help increase yields in cotton and

peanut rotations.

“Cotton and peanuts are two of the major crops grown in South Carolina,” Kirk said. “The overall goal of this study is to learn whether there is an economic benefit to implementing low-pressure tire technologies in a cotton-peanut production system.”

Soil compaction is caused by continuous wheel or foot traffic that squeezes air from between soil particles causing the soil to become hard, resulting in a decrease of water reaching plants’ roots. Information from the National Institute for Food and Agriculture shows most sandy soils in South Carolina have a compacted zone known as a “hardpan” that roots can’t penetrate.

A hardpan is usually found at a depth of 10 to 16 inches and can be 2 to 8 inches thick. This prohibits roots from reaching water and nutrients found in deeper soil. A Clemson study shows a hardpan can reduce crop yields by as much as

50% and make plants more susceptible to drought stress.

Increasing Tire Footprint

Typically, compaction and the effects of compaction are more prevalent on end-rows or turn-rows, where machines turn around at the end of a pass. But some degree of compaction occurs everywhere there is ground traffic in a field.

A reduction in tire pressure reduces soil compaction because the tire footprint or flat plate area — the portion of the tire that touches the surface — increases as the tire is deflated. Because the weight supported by the tire is unchanged and the area over which it distributes this weight is increased, pressure exerted on the soil is reduced.

For this study, researchers are looking at the effects of planting tractors and harvest machinery equipped with Michelin’s Ultraflex VF (Very High

10 COTTON FARMING | OCTOBER 2023 COTTONFARMING.COM

Pictured (from left) are: Steve Rosen and Martin Crouch from Michelin North America Inc., and Kendall Kirk and Ben Fogle from Clemson University.

U.S. Cotton Trust Protocol Launches 3-Year Enrollment

Trust Protocol participating producers will find the new streamlined enrollment for the 2022-2024 crops easy and quick. Production data, which remains confidential, now can be more efficiently uploaded into the Protocol platform, thus paving the way for a potential redistribution of program revenue.

As before, crop consultants can be authorized to enter information and the John Deere Operations Center can pre-populate up to 40% of the data needed to complete the Fieldprint analysis for those utilizing the Protocol platform.

Conservation Districts trap loan program or receive direct control through APHIS.

The Texas Feral Swine Eradication and Control Pilot Program activities are funded through a U.S. Department of Agriculture-Natural Resources Conservation Services grant and administered by the Texas State Soil and Water Conservation Board.

TFB Distributes Nearly $178,000 To Wildfire Victims

CCOY

Cotton Consultant of the Year Footprints In The Field

established 1981

To learn more or begin enrollment, visit www.TrustUSCotton.org or reach out to the Grower Helpdesk at growers@ trustuscotton.org.

Flexion) tire technology on yield and related variables in different soil types.

At 40 tons loaded, modern cotton pickers are among the heaviest field machines used in major row-crop production. The Ultraflex technology is designed to operate at low pressures and adapt to changes in pressure without affecting tire structure.

South Carolina cotton and peanut crops, revenue benefits could be as much as $30 to $45 per acre,” Kirk said.

Thanks to nearly 150 generous contributions, Texas Farm Bureau (TFB) and its West Texas Wildfire Relief Fund recently distributed $177,930 to farmers and ranchers impacted by spring wildfires in the state.

Feral Hog Control Workshop: Nueces County, Texas, Oct. 13

A group of Texas agencies is working together to help landowners address the issues that feral swine pose to agriculture, ecosystems and the health of humans and animals.

“Clemson is conducting these tests in South Carolina, which will provide region-specific information for farmers,” Crouch said.

Michelin Ultraflex radial tires are designed to operate at lower air pressures as compared to standard radial tires. This technology also can be coupled with a Central Tire Inflation System, or CTIS, which equipment operators use to control tire pressure from the cab, such as when changing between field and road travel.

“While the wildfires were still burning, Farm Bureau members, organizations and others from across the state called in asking how they could help,” TFB President Russell Boening said. “While this aid cannot replace everything that was lost, we hope it truly helps those still recovering from the disaster.”

CCO Y

“We safe, a chance U.S.

Several workshops were held in September, and one will be offered in Nueces County Oct. 13 from 10:30 a.m. to 1:30 p.m. at the Johnny Caledron Building, 710 E. Main St. Suite 1, Robstown. Contact Jaime Lopez, AgriLife Extension agent for Nueces County at jaime.lopez@ag.tamu.edu.

“We know Clemson researchers will determine what information is best for the region’s farmers. Their proven track record and history in the agricultural world make Clemson one of the academic leaders in this type of real-world research. If you want to learn from the leader in cellphone technology, you go to Apple. If you want to learn from the leader in agriculture, you go to Clemson.”

Wildfires burned more than 150,000 acres across the state in March, causing millions of dollars in damage. Fires devoured pastureland and farmland, livestock, homes, barns and equipment.

“Operators can decrease tire pressure when they enter a field,” Rosen said. “Using lower tire pressure in fields increases the tire’s footprint to reduce ground pressures in the field, helping improve soil aeration, water infiltration and allowing for better root distribution.”

The CTIS is compatible with most agricultural machinery.

Farmers and ranchers with unreimbursed agricultural losses were encouraged to apply for assistance. The TFB West Texas Wildfire Relief Fund was established through the organization’s nonprofit Agriculture Research and Education Foundation.

A Team Effort

The Cotton Consultant of the Year award, sponsored by Syngenta and Cotton Farming magazine, has honored the “boots on the ground” segment of the industry for more than four decades. The prestigious award recognizes a cotton consultant who demonstrates outstanding customer relations, leadership and innovation. Each year, the nominees are voted on by the past CCOY recipients. This award is even more special as the winner is chosen by his or her peers.

Central Tire Inflation

Feral swine are a threat to waterways and ecosystems as their numbers rapidly increase daily across the state. Texas is a private-land state, with 83% of its land mass in family owned farms, ranches and forests, making education and awareness of wild pig damage a priority for maintaining healthy ecosystems.

Providing learning opportunities to landowners about effective management strategies remains crucial to the success of abating damages associated with these feral swine.

A similar study was conducted on wheat by researchers at Harper Adams University in the United Kingdom. Researchers found a 4% increase in yields when machinery equipped with Michelin Ultraflex (IF/VF) radial tires was used, as compared to machinery using standard radial tires. A 2015 study by researchers at the University of Illinois at Urbana-Champaign on corn and soybeans found a 4.3% yield gain using Michelin Ultraflex radial tires versus standard radial tires.

This first year of a three-year study is a “team effort,” Kirk said. In addition to Kirk and Anco, CU-CAT specialists, and the Michelin representatives, others helping with this research include trades specialists who work at the Edisto REC Tim Still and Kim Still. Others involved with the project are the South Carolina Peanut and Cotton boards and cooperating farmers.

“We cannot say thank you enough for the generous contributions sent in to help our fellow Texans,” Boening said. “Farm Bureau members have always stepped up to help their neighbors in need, and this wildfire relief fund collected tax-deductible donations to meet the needs in affected areas.”

Syngenta and Cotton Farming are pleased to sponsor an award that recognizes the vital role cotton consultants play in production agriculture.

“If similar yield benefits are found in

“This project is unique in that it has buy-in and support from people in various sectors of agriculture,” Kirk said. “It is a model for the type of collaborations we seek to establish through Clemson’s Center for Agricultural Technology.”

A group of volunteer leaders selected by the TFB board of directors determined the allotment of aid. TFB and non-TFB members received funding for unreimbursed expenses related to the wildfires.

The services consultants provide their farmer clients are invaluable for achieving e iciency and profitability.

Cotton Consultant of the Year sponsored by

For more information about the center or collaboration opportunities, contact Mallory Douglass, CU-CAT business manager, at mmdougl@clemson.edu or 708-837-6256.

The Feral Swine Control Pilot Program consists of a “smart trap” loan program, educational and outreach activities, and direct-control activities by Animal and Plant Health Inspection Service. Landowners in participating counties may be eligible to use a feral swine smart trap on their property through the Soil and Water

“Farming and ranching is an expensive business,” Boening said. “We hope with this support, those impacted can continue to rebuild and recover from the wildfires that devastated areas of our state.”

Cotton Farming

One sionate farmers Trust Gary president ment Protocol retailers in sustainable also tainability over-year data anonymously producers.” White Protocol “We retailers are growing right says. increase ter price, Cotton nies Everyone vide “There and Go to and you mon You a few

TWITTER: @COTTONFARMING OCTOBER 2023 | COTTON FARMING 11 Industry News

10 COTTON FARMING | OCTOBER 2021

Clemson and Michelin researchers are collaborating to determine if low-pressure tires can help increase yields in cotton and peanut rotations.

A Job Well Done

Mississippi Farmer Honored For Row Crops, Enthusiasm For Agriculture

BY ROBERT NATHAN GREGORY MISSISSIPPI STATE UNIVERSITY EXTENSION

Gaddis & McLaurin sounds more like the name of a law firm than a general store, but since the 1870s, the name is synonymous with all manner of dry goods in the Hinds County community of Bolton.

Its expansive range of inventory is one reason for its longevity. Items normally found at local co-ops — animal feed, grass seed, lumber, tools and hardware — have been the store’s calling card for much of its existence. Over time, store owner and longtime row-crop producer Kendall Garraway has brought in a multitude of home and garden items.

“We have great management in place, and it has really grown in the past 10 years,” Garraway said. “Not only does it supply and act as a hub for the community, but it helps keep the value of the land assets up.”

data received in making variety selections and management decisions,” Lewis said. “He has made great strides in timberland and wildlife management with timber harvest and prescribed fire management. He allows us to use his store for programs and demonstrations and is always ready to help in any capacity.”

A Family Affair

The store is hardly the only business operation flourishing under Garraway’s watch. His primary focus has always been on growing row crops, raising cattle and managing timber at his family farm, Gaddis Farms.

Garraway also operates a cotton gin, leases portions of his land for hunting and invests in commercial and retail real estate. He has several acres of solar panels installed as a financial investment that could potentially become a solar farm.

Despite the leadership responsibilities he juggles, Garraway says his work rarely seems like a real job. He is quick to point out the heavy involvement his uncle and cousin, Ted Kendall III and Ted Kendall IV, share with him on the numerous business ventures.

“I did not attend a school with an agriculture program, so I majored in banking and finance,” he explains. “After graduating, I almost went to work for a bank but was offered a job on a farm by my uncle, and I’ve never looked back.”

Protecting The Soil

Garraway uses soil health and stabilization practices in his row-crop operation by adopting minimal tillage. On about half of his acres, he uses no-till planting along with cover crops.

Recent Award Winner

Garraway’s success earned him a major accolade as he was recently named the Mississippi winner of the 2023 Sunbelt Ag Expo Southeastern Farmer of the Year award. He joins growers from nine other states who received the same distinction. All 10 growers will be considered for the overall regional award at the Sunbelt Ag Expo in October.

Kyle Lewis, an agent with the Mississippi State University Extension Service in Hinds County, nominated Garraway for the award.

“Mr. Kendall has been a friend of MSU Extension by hosting on-farm demo tests in soybean and cotton where he uses the

“We have used several programs to take highly erodible land out of row crops and put it into timber to better utilize and protect the soil,” Garraway says. “We have been practicing no-till and minimum till on our row crops. This method uses less fuel and helps prevent erosion. Hunting and wildlife are important to me for recreation and to provide income to the farm, so habitat management has always been important.”

MSU Regional Extension coordinator Theresa Hand said Garraway’s support of MSU Extension, 4-H, Master Gardeners, Farm Bureau and other community organizations is the center of Garraway’s success.

“Kendall is an influential community leader who has served on numerous boards and in advisory roles with MSU Extension at the local, regional and state level,” Hand says. “His enthusiasm for agriculture and his open honesty is what makes his input so valuable.”

12 COTTON FARMING | OCTOBER 2023 COTTONFARMING.COM

Kendall Garraway of Holmes County, Mississippi — along with his uncle and cousin — has an extensive agricultural portfolio that includes an historic general store, on-farm demo tests in cotton and soybeans, cattle, timber, a cotton gin, hunting leases and real estate investments.

Highlights From The UGA Cotton Research Field Day

BY AMANDA HUBER SOUTHEAST EDITOR

Research is all about adding to the knowledge base of a given topic or problem until specific recommendations can be made. Even during that process, before there’s a real take-home message for producers, there are suggestions and advice researchers and Extension can offer. One opportunity to learn more about what researchers are working on is at the annual University of Georgia cotton and peanut research field day in Tifton in early September.

At the field day and standing in front of cotton plants bent over slightly from Hurricane Idalia, UGA Extension cotton specialist Camp Hand talked about the Georgia crop and what farmers should be doing in the field.

“This is a great time to evaluate what worked and what didn’t on your farm to plan for next year,” said Hand. “Look at what’s gone on in the field in terms of what that means for next year.”

Hand said now is a good time to pull nematode samples if that might be the answer to a problem in cotton fields.

Field Day Highlights:

“Fertility is also something to think about. This time of year, you can see where you might have an issue with potash and adjust for next year. Those are the things I would be thinking about.”

• Defoliate efficiently, stay on target and get the crop out of the field to maximize yields.

• Position cotton trait technology to get the greatest value.

Finally, Hand said Georgia leads the way in losing more of the crop at harvest than any other state — not something you want to be No. 1 at.

lished this year is that ThryvOn is not perfect. It’s a tool. There still may be a need to treat ThryvOn cotton for plant bugs.”

That said, according to Roberts, the number of times farmers needed to treat tarnished plant bug was reduced by 50% in the ThryvOn cotton, which is good.

In closing, Roberts said, “We know when we plant early, we have a higher risk of thrips. Interestingly, the same risk factor — planting date — also holds for tarnished plant bugs. I think most farmers would agree, the worst plant bugs are on Aprilplanted cotton or that planted the first two weeks of May. As a grower, position the technology to get the greatest value.”

• Work continues on how varietal differences play a role in CLRDV response.

“On average, the U.S. Department of Agriculture says we lose 150 pounds per acre more than any other state, and I think it’s because we’re leaving the crop out there a little too long,” Hand said. “Whenever the price is 85, 86, 88 cents per pound, every pound counts and 150 pounds is a lot. We need to defoliate efficiently, stay on target and get the crop out of the field to maximize yields.”

More About ThryvOn Trait

UGA Extension entomologist Phillip Roberts said a high priority coming into 2023 was a better understanding of how the ThryvOn cotton trait would help with tarnished plant bug. After seven years of research, they know how good it is for thrips control.

“ThryvOn provides excellent protection from thrips feeding and injury. In all the years we have looked at this trait, we’ve never had an occasion where we would even consider making a foliar spray for thrips,” he said.

Tarnished plant bug has traditionally been a pest farmers deal with only occasionally, Roberts said. “However, 2023 will go down as likely the worst tarnished plant bug year we have experienced in Georgia. Certain parts of the state had to spray multiple times, and one of the things I think we’ve clearly estab-

Cotton Leafroll Dwarf Virus

UGA crop virologist Sudeep Bag said work is continuing on cotton leafroll dwarf virus, although the virus has not been as prominent in the field of late.

“We have worked on CLRDV for the past four years and have gained a lot of knowledge in the field. However, for the past two years, we have not seen as much incidence of the virus,” he said.

They are still monitoring CLRDV at the research farm and responding to any calls from farmers or Extension to go take a look. As for research, they have moved into a more controlled environment to learn more.

“We are now in the greenhouse trying to understand why this particular virus is having an impact on some varieties versus not showing any incidence at all on other varieties,” Bag said. “We have a clone of the virus that we use to inoculate plants. Then we can see what symptoms CLRDV is producing. We are learning more about how the host is responding to the presence of the virus, if it is transmitting the virus and how different varieties, mainly just three cultivars at this point, respond to the virus.”

Although it may seem to take years to learn about how to manage some insects or viruses in cotton, the work researchers do each year is astounding and only adds to the mountain of what we already know about this unique crop.

TWITTER: @COTTONFARMING OCTOBER 2023 | COTTON FARMING 13

is cotton plant exhibits symptoms of cotton leafroll virus.

TRAIT STEWARDSHIP RESPONSIBILITIES NOTICE TO FARMERS

Bayer is a member of Excellence Through Stewardship® (ETS). Bayer products are commercialized in accordance with ETS Product Launch Stewardship Guidance, and in compliance with Bayer’s Policy for Commercialization of Biotechnology-Derived Plant Products in Commodity Crops. Commercialized products have been approved for import into key export markets with functioning regulatory systems. Any crop or material produced from this product can only be exported to, or used, processed or sold in countries where all necessary regulatory approvals have been granted. It is a violation of national and international law to move material containing biotech traits across boundaries into nations where import is not permitted. Growers should talk to their grain handler or product purchaser to confirm their buying position for this product.

ALWAYS READ AND FOLLOW PESTICIDE LABEL DIRECTIONS. It is a violation of federal and state law to use any pesticide product other than in accordance with its labeling. NOT ALL formulations of dicamba, glyphosate or glufosinate are approved for in-crop use with XtendFlex® Cotton. ONLY USE FORMULATIONS THAT ARE SPECIFICALLY LABELED FOR SUCH USES AND APPROVED FOR SUCH USE IN THE STATE OF APPLICATION. Contact the U.S. EPA and your state pesticide regulatory agency with any questions about the approval status of dicamba herbicide products for in-crop use with XtendFlex® Cotton. B.t. products may not yet be registered in all states. Check with your representative for the registration status in your state. Products with XtendFlex® Technology contains genes that confer tolerance to glyphosate, glufosinate and dicamba. Glyphosate will kill crops that are not tolerant to glyphosate. Glufosinate will kill crops that are not tolerant to glufosinate. Dicamba will kill crops that are not tolerant to dicamba. Contact your seed brand dealer or refer to the Bayer Technology Use Guide for recommended weed control programs. Insect control technology provided by Vip3A is utilized under license from Syngenta Crop Protection AG. Bollgard®, Respect the Refuge and Cotton Design®, Roundup Ready Flex® and XtendFlex® are registered trademarks of Bayer Group. LibertyLink® and the Water Droplet Design® are registered trademarks of BASF. Agrisure Viptera® is a registered trademark of Syngenta Group Company. Excellence Through Stewardship® is a registered trademark of Excellence Through Stewardship. All other products, company names and trademarks are the property of their respective owners.

Farmers Discuss Cotton At United Nations Headquarters

Farmers across the globe are working to meet the demand for sustainably grown cotton. True sustainable sourcing of natural fibers can be complex and challenging, which is why BASF Agricultural Solutions brought together a global delegation of farmers from Europe and the United States to ensure their voices are heard and supported.

The event — United for the Biggest Job on Earth — was held at the United Nations headquarters and featured farmers from Greece and the United States, as well as leadership from BASF.

“We really appreciated the opportunity to attend this event and have our voices heard,” said Texas cotton growers Randy and Pat Smith. “Consumers aren’t aware of the effort growers like us are putting into regenerative agriculture practices, and we want to continue to share our story and gain their support.”

Before opening a bag of seed, be sure to read, understand and accept the stewardship requirements, including applicable refuge requirements for insect resistance management, for the biotechnology traits expressed in the seed as set forth in the Technology Stewardship Agreement that you sign. By opening and using a bag of seed, you are reaffirming your obligation to comply with the most recent stewardship requirements.

BASF supports cotton production in the United States with the e3 Sustainable Cotton program and in Europe with the Certified Sustainable FiberMax program. Both provide field-level traceability for cotton, as well as a way for farmers to track and measure the environmental and social impacts of their cotton production.

The Trust Protocol Welcomes Macy’s, Inc. As A Member

The U.S. Cotton Trust Protocol recently announced the membership of leading American retailer Macy’s, Inc.

The company represents more than 700 store locations nationwide across three iconic nameplates including Macy’s, Bloomingdale’s and Bluemercury.

Membership in the program will bolster Macy’s efforts in sourcing cotton sustainability, driving positive social and environmental change within the cotton industry and enhancing transparency throughout its supply chain.

As a reminder, for growers who are enrolled in the Trust Protocol, please upload your 2023 bales by March 1, 2024. For growers who are not yet enrolled in the Trust Protocol be sure to visit TrustUSCotton.org to learn more ahead of the next enrollment period that opens in January.

Since the Trust Protocol’s launch in 2020, the program has already welcomed more than 1,800 brand, retailer, mill and manufacturer members, including brands and retailers such as, Levi Strauss & Co., Old Navy, Gap, American Eagle Outfitter, Inc. and J.Crew.

Aerial Applicators Seeding Cover Crops Early This Fall

While the farm season is winding down, aerial applicators are still working by seeding cover crops via aircraft. You may continue to hear the hum of an aircraft’s engine until early fall.

One of the conservation practices aerial applicators can assist farmers with is aerially applying cover crop seeds, which are grasses, legumes, small grains and other low-maintenance crops planted specifically to improve soil health and biodiversity.

14 COTTON FARMING | OCTOBER 2023 COTTONFARMING.COM Industry News

Cotton growers from the United States and Greece gather outside the United Nations Headquarters in NYC to discuss the future of sustainable agriculture with BASF.

Cover crops are important to farmlands because they control erosion; nourish, retain and recycle soil nutrients; build organic matter and add hydration to improve soil health; improve water quality; and break disease and insect cycles. The roots of the cover crop improve soil structure by creating passages that allow for increased moisture and aeration. Soil compaction is essentially eliminated when seeding is done with aerial application.

Growing cover crops also increases soil carbon sequestration, which involves removing and storing carbon dioxide from the atmosphere.

Aerial application offers the ability to spread the cover crop seed over the existing cash crop without any disruption to the standing crop. This means the cover crop can already be established when the cash crop is harvested. Using a drill to plant cover crops requires a terrestrial vehicle and for the grower to wait until their cash crop is out of the field. This can be especially true in northern parts of the U.S. where the first frost can interfere with cover crop growth if they are

seeded too late. Aerial application can also be used when the soil is wet.

LSU AgCenter Creates DIRT For Irrigation Scheduling

Described as a labor of love by one of its developers, the LSU AgCenter’s new web-based Drought Irrigation Response Tool, or DIRT, will greatly benefit farmers. The DIRT webpage describes the tool as “an integrative platform that assists farmers in making irrigation scheduling decisions during the crop season,” not only during drought years, but every year.

Upon signing into the DIRT portal, users set up a field or single irrigation set using a map and basic inputs like crop type and planting date. From there, the tool estimates soil moisture in the field and alerts the user when irrigation is needed.

One of the principal investigators during the project’s development, AgCenter state Extension irrigation specialist Stacia L. Davis Conger, said the tool was developed while educating

farmers on how to install, use and interpret soil moisture sensors for making their scheduling decisions.

Conger took sensor data collected from three AgCenter research station plot studies conducted in 2015 and 2016 as well as multiple on-farm trials collected over the same years and used it to calibrate and validate an irrigation scheduling spreadsheet.

“The idea was that we may not be able to help farmers pay for, install or manage a sensor every year, but we can support the training needed to teach farmers how to use the spreadsheet,” she said. “And it would be free to use as an Extension tool.

“We applied for funding through the U.S. Department of Agriculture Rapid Response to Extreme Weather Events Program to convert the spreadsheet into a web tool,” Conger said.

“This funding allowed us to connect the web tool with a reliable weather data source while we work on a better longterm solution.”

The DIRT webpage can be found at https://www.lsuagcenter.com/topics/ crops/irrigation/dirt.

TWITTER: @COTTONFARMING OCTOBER 2023 | COTTON FARMING 15

Industry News

2024 NAICC Annual Meeting & AG PRO EXPO January 15-19, 2024 • San Antonio, Texas www.NAICC.org STATEMENT OF OWNERSHIP MANAGEMENT AND CIRCULATION 1. Publication Title: Cotton Farming 2. Publication Number: 0746-8385 3. Filing Date: October 2023 4. Issue Frequency: Jan - Dec 5. Number of Issues: 12x/year 6. Annual Subscription Price: Free to qualified subscribers 7&8. Mailing Address of Known Office/Headquarters: 875 W. Poplar Ave., Ste. 23, Box 305, Collierville, TN 38017 Contact Person: David Boyd (901-626-1730) 9. Publisher: Lia Guthrie, 7100 Black Bart Trail, Redwood Valley, CA 95470 Editor: Carroll Smith, 875 W. Poplar Ave., Ste. 23, Box 305, Collierville, TN 38017 10. Owners: Cornelia Guthrie, 7100 Black Bart Trail, Redwood Valley, CA 95470; Dr. David Scott Guthrie, Sr., 7100 Black Bart Trail, Redwood Valley, CA 95470; Morris Ike Lamensdorf, 17 S. Third St., Rolling Fork, MS 39159; Mary Jane Lamensdorf, 17 S. Third St., Rolling Fork, MS 39159 11. Known Bondholders, Mortgagees and Other Security Holders Owning/Holding1% or More of Total Amount of Bonds, Mortgages or Other Securities: None 12. Tax Status: Has Not Changed During Preceding 12 Months 14. Issue Date for Circulation Data Below: September 2023 15.a. Total Number of Copies (net press run): (Average No. Copies each Issue During Preceding 12 Months – 21,445) (No. Copies of Single Issue Published Nearest to Filing Date – 15,549) 15.b.(1) Outside County Paid/Requested Mail Subscriptions: (Average No. Copies Each Issue During Preceding 12 Months – 16,223) (No. Copies of Single Issue Nearest to Filing Date – 7,609) 15.c. Total Paid and/or Requested Circulation: (Average No. Copies Each Issue During Preceding 12 Months – 16,223) (No. Copies of Single Issue Nearest to Filing Date – 7,609) 15.d.(1) Outside County Nonrequested Copies (Average No. Copies Each Issue DuringPreceding 12 Months – 4,882) (No. Copies of Single Issue Published Nearest toFiling Date – 7,594) 15.d.(4) Nonrequested Copies Distributed Outside the Mail: (Average No. Copies Each Issue During Preceding 12 Months – 31) (No. Copies of Single Issue Published Nearest to Filing Date -0-) 15.e. Total Nonrequested Distribution: (Average No. Copies Each Issue During Preceding 12 Months – 4,913) (No Copies of Single Issue Published Nearest to Filing Date – 7,594) 15.f. Total Distribution: (Average No. Copies Each Issue During Preceding 12 Months -21,136) (No Copies of Single Issue Published Nearest to Filing Date – 15,203) 15.g. Copies Not Distributed: (Average No. Copies Each Issue During Preceding12 Months – 269) (No. Copies of Single Issue Published Nearest to Filing Date - 346) 15.h. Total: (Average No. copies Each Issue During Preceding 12 Months –21,405)(No. Copies of Single Issue Published Nearest to Filing Date – 15,549) 15.i. Percent Paid and/or Requested Circulation: (Average No. Copies Each IssueDuring Preceding 12 Months – 76.8%) (No. Copies of Single Issue Published Nearest to Filing Date – 50.04%) 18. I certify that all information furnished above is true and complete. Lia Guthrie, Publisher

Cotton Incorporated’s Efforts In Asia

The cotton market is truly global in scope. The United States exports around 80% of its produced cotton fiber each year and imports about 18 million bales of cotton in apparel, home goods and other finished textile goods annually. Because of the market’s global nature, Cotton Incorporated promotes cotton to spinning mills and manufacturers around the world on behalf of U.S. cotton producers and importers. They have offices in North America, Latin America, China, Japan and Hong Kong.

As the organization that oversees Cotton Incorporated’s activities, The Cotton Board conducts an executive evaluation of Cotton Incorporated’s international offices and activities every few years. Earlier this year, a delegation of Cotton Board and Cotton Incorporated leadership visited cotton spinners, textile manufacturers, cut/sew manufacturers and retailers in Hong Kong, Singapore, Malaysia, Bangladesh and Thailand to review Cotton Incorporated’s activities promoting cotton use in Asia. The delegation included Cotton Board CEO Bill Gillon, Cotton Board VP of Importer Relations Elizabeth King and Cotton Board Members Sonja Chapman (importer), Mark Nichols (producer, Oklahoma) and Laurie Rando (importer). Cotton Incorporated’s Chief Operating Officer William Kimbrell, Senior VP of Global Supply Chain Marketing Mark Messura

BY STACEY GORMAN WARREN, ARKANSAS

and Chairman James Johnson (producer, New Mexico) also attended.

Transparency, Traceability

Over the span of 11 days, the delegation visited one international retailer, two local retail companies, six apparel manufacturers and two fabric mills. The group toured fabric weaving, dyeing and finishing mills and several cut/sew operations. Most companies visited were generally committed to cotton with a bias toward U.S. cotton.

Cotton Incorporated’s presence and influence in the region was apparent on the visit. Mark Nichols said, “It was clear that Cotton Incorporated staff had been working with many of these companies over a long period of time and had developed strong, professional relationships.” Cotton Incorporated’s Global Supply Chain Marketing division works with companies to help them successful-

ly incorporate cotton fabric innovations into their product lines. “Each company we visited had been utilizing one or more Cotton Incorporated technologies in their products,” said Nichols.

During the evaluation trip, a topic that continued to rise to the forefront of conversation was supply chain transparency and traceability. The supply chain for cotton products imported into the United States is changing for traceability and sustainability reasons. In 2022, implementation of the United State’s Uyghur Forced Labor Prevention Act (Public Law No. 117-78 also known as the UFLPA), enforced the prohibition on the importation of goods into the United States that were manufactured wholly or in part with forced labor in the People’s Republic of China, especially from the Xinjiang Uyghur Autonomous Region, or Xinjiang.

Sonja Chapman said, “The textile and apparel manufacturing companies we met with were all focused on developing different, more transparent supply chains to comply with the U.S. UFLPA and other similar legislation they expect to be enacted in other major markets.”

Positive Results

The passage of UFLPA by the United States has required an immediate shift in resources and a shift in actual, physical locations of cotton product manufacturing operations. Bill Gillon noted that the evaluation trip provided clear evidence that sourcing patterns and documentation requirements are changing quickly. “As an organization, we are well positioned to help the industry face these challenges,” Gillon said.

The evaluation revealed a strong, intelligent, committed Cotton Incorporated staff in Asia that seems cohesive, happy and energetic. The trip provided the delegation with overwhelming evidence that Cotton Incorporated is working with cotton users at every stage of the processing and retail process to enhance the use of cotton and to enhance cotton’s market performance in international markets.

16 COTTON FARMING | OCTOBER 2023 COTTONFARMING.COM

RESEARCH & PROMOTION

Stacey Gorman is The Cotton Board’s director of communications. Contact her at sgorman@cottonboard.org.

The Executive Delegation in Singapore visits Ghim Li Global, which owns manufacturing facilities in Malaysia, Cambodia and Indonesia. Ghim Li Global is a major supplier to Macy’s.

2023 Harvest Update

ALABAMA Steve M. Brown

Long ago, I was part of a group that received, for research purposes, a one-row, self-propelled, low drum, red picker — probably a late 1950s version. We sent the machine to the repair shop for new spindles and moisture pads and added a platform and diversion shoot for plot harvest. The shop said it had a great picking mechanism, but we soon saw it was not designed for high-volume flow and high yields.

I learned a few other things. The man who first drove it probably thought he was king of the world, riding on a machine that cleanly gathered the crop and eliminated hand picking. While he may have felt great atop the slow-moving picker, when I drove it, I felt like I was riding on a concrete block. Comfortable — it was NOT. When spindles collided with the column of moisture pads, I also learned to estimate necessary repair costs to be about $100 per pound. With inflation, that number has probably tripled.

I’ve also ridden in JD roll pickers. Incredible machines! Every bit as revolutionary as Bt and herbicide-tolerant technologies. They gobble up cotton six rows at a time and at amazing speeds. In a year when I questioned the link between spindle versus ground speeds and bark issues (Extraneous Matter deductions), one farmer friend said to me, “You know why we drive/pick as fast as we do?” then quickly answered, “’Cause we can’t go any faster!”

Regardless of whether the machine is brand new or aged, a cotton picker requires meticulous daily maintenance and occasional repair. So many moving parts, often in places so hard to access! It is also a place for bruises, cuts and, unfortunately, amputations. Not only is downtime frustrating, but missing a few good days or a week of picking can be terribly costly. Injuries can be even more costly.

Admittedly, there are times when I’ve driven across the Southeast and wished I had a giant vacuum cleaner capable of gathering all the white cotton waiting for harvest.

Whether your cotton dumps in a basket and then in a module or wraps in a round roll, enjoy the ride. Be safe. cottonbrown@auburn.edu

ARIZONA Randy Norton

As we head into harvest this fall, I do believe we are going to see a mixed bag of results from across the state. High levels of heat stress experienced in the low desert during the month of July will likely have a negative impact on the crop in 2023.

The majority of the crop in Arizona has had irrigation terminated and now, decisions turn to harvest preparation and defoliation. These can be difficult decisions to make as effective harvest preparation is dependent on so many factors with a high degree of variability. These factors may include, but are not limited to, crop moisture and nutrient level, fruit load, crop vigor, etc. We have several guidelines to help in making a decision regarding timing of an effective defoliant application that have proven successful in the past. These include estimates of open boll percentages and timing from the final irrigation event.

A certain level of moisture stress in the crop will aid in defoliation, and as a general rule of thumb, approximately two times the late-season irrigation interval serves as a general guidepost for timing the defoliation application. For example, if your late-season irrigation interval was 12 days, then at approximately 24 days post final irrigation, you should begin looking seriously at harvest prep activity. This guideline will vary with soil texture and weather conditions. Sandy or coarse-textured soils and hotter temperatures may decrease this interval and the time needed to achieve the appropriate amount of crop stress.

Another rule of thumb that can serve as a guide in making defoliation decisions is percentage open boll. Research has shown that at approximately 60% open boll, the crop is at a stage where it will most effectively respond to a defoliant application. Open boll can be estimated by counting the total number of nodes above the upper most, first position cracked boll, to the upper most harvestable boll. When this number reaches four, the crop is at approximately 60% open boll.

We have published some guidelines regarding defoliation materials and recommended use rates based on crop and environment conditions that can be found at our Cooperative Extension publications website at extension.arizona.edu/crops-soils. rnorton@cals.arizona.edu

GEORGIA Camp Hand

As I write this Sept. 7, we are nearing the end of the line on this cotton crop. Fortunately, the weather has been phenomenal across the state and overall — we are looking at a good crop. This year has been the first since I started where we have not seen significant losses due to boll rot. My advice is to defoliate and harvest this crop in a timely manner. Let’s get this crop out, get paid and start getting ready for next year.

Looking at historical data, by the time this article will be published, Georgia should be roughly 15% harvested. In my conversations with people lately, it seems like growers are gearing up and itching to get started. I anticipate that we will be at 15% around the same time per usual, unless something wildly abnormal happens.

As we are harvesting the crop, take note of weak spots in the field, along with what worked and what didn’t. There is no time like harvest to start getting ready for next season. Nematode samples should be taken now, while I would start planning for other things like soil sampling and fertility. Look at the crop and evaluate how successful pest management

TWITTER: @COTTONFARMING OCTOBER 2023 | COTTON FARMING 17

Specialists Speaking

Specialists Speaking

strategies were. If they weren’t successful, and you don’t have a consultant, that might be the nudge you need to consider hiring one.

As always, your local UGA county Extension agent and specialists are here to help! Reach out if you have any questions. camphand@uga.edu

MISSISSIPPI Brian Pieralisi

As I write this Sept. 5, dry weather is still the story for most of the state. However, some areas did experience abundant rainfall over the weekend. Nevertheless, cotton bolls are opening quickly and harvest is about one to two weeks away. Some cotton was harvested last week, but it was not our best cotton as it was drought stressed. e U.S. Department of Agriculture has the Mississippi cotton yield estimated at around 1,100 pounds per acre. is is possibly a little optimistic, but we will see how it all shakes out. Hopefully, dry weather will continue and everyone has a successful harvest season. bkp4@msstate.edu

MISSOURI Bradley Wilson

It is beginning to feel and look like cotton harvest will be shortly upon us in Missouri. Lately, cotton pickers have been pulled out and producers are servicing them in preparation for cotton harvest. We are still two to three weeks away from our rst harvest aid application. Cotton got some much-needed heat and sunlight in the past few weeks; however, the future forecast is predicting cooler daytime and nighttime temperatures, which may impact product selection with respect to harvest aids.

Helpful information on harvest aid selection under various climate conditions can be found in the 2023 Mid-South Cotton Defoliation Guide. As always, you can reach out to me for any additional information you may need. I believe the Missouri cotton crop looks good overall for the 2023 season; we just need to have the weather conditions to get it out quickly to preserve ber quality. brwilson@missouri.edu

NORTH CAROLINA Keith Edmisten

As I write this in early September, we are reaching the point where the probability of a white bloom resulting in a harvesting boll is diminishing fast. In other words, the bolls you have on the plant at this point are likely all you are going to have a reasonable chance to harvest. e spotty rain we had in August has resulted in basically two di erent crops. e areas that had little to no rain in August will likely be below average and ready to defoliate at some point in September. ose elds will likely have high residual nitrogen due to reduced boll load and need to be defoliated under warmer conditions. Warmer conditions are good for defoliant activity, but with the residual nitrogen available, also have the potential to have regrowth if we get rains in September. Including idiazuron at higher-labeled rates will be needed if you intend to prevent regrowth. is is especially important

18 COTTON FARMING | OCTOBER 2023

where you will be waiting more than 10 to 14 days to harvest or already have existing regrowth.

The cotton that received rains in August will be ready to defoliate later than the drought-stressed cotton and be less likely to have regrowth. For both types of crops, we should start cutting the least-immature harvestable bolls to determine maturity when the crop reaches four nodes above cracked bolls. keith_edmisten@ncsu.edu

TENNESSEE Tyson Raper

As I write this on the sixth of September, our crop is moving quickly toward the finish line. Bloom numbers are beginning to decline rapidly, and many fields have already begun to turn — yellow, red and purple hues are appearing on thin ground. We have seen some boll rot in cotton that was a little tall or was grown on soils with relatively high water holding capacity, but overall, our crop appears to be an excellent one.

Plant bug numbers (particularly clouded plant bug) have generally been light after a heavy start to the season, and retention has generally been very good. I suspect, by the time most of my growers will read this, our first shot of defoliant will be out on the majority of our crop and the second shot may very well be in the sprayer. For dryland acres, keep in mind that we have a relatively high potential for regrowth, given our dry finish to the growing season. If harvest is delayed for any reason after the first or second harvest aid application and rainfall provides adequate moisture, this crop will be off to the races.

Specialists Speaking

Watching the forecast and properly timing harvest after the last harvest aid application will be very important this year. For those who have not applied a harvest aid, the first week in October is historically our last good chance at getting enough heat units to efficiently develop an abscission zone or boll suture. Waiting any longer for immature bolls to mature is extremely risky; unfortunately, our area experienced a freeze mid-October of last year and subsequently lost part of our latest-maturing crop. traper@utk.edu

TEXAS Ben McKnight

As I write this Sept. 5, cotton harvesting is nearly complete in the Lower Rio Grande Valley with only a small portion of the planted acreage remaining following the Sept. 1 stalk destruction deadline.

Further north in the Coastal Bend, harvesting is nearing completion as well. Yields in the Coastal Bend are a mixed bag this year, and the earlier planted acres that received timely precipitation are producing the highest yields. Initial yield reports from this region range from approximately 350 pounds per acre on later-planted fields to approximately 650 pounds per acre on earlier-planted fields.

In the Upper Gulf Coast region, harvesting is under way and should be close to finished, if not complete, by the time you are reading this in October. The dryland yields in this region are also highly variable and dependent on whether the crop received any substantial, timely rainfall. Some fields that missed the rain will be in the 250 pounds per acre to 350 pounds per-acre range, and others that received some precipitation have been yielding 700 pounds per acre to 900 pounds per acre. Irrigated acres in the region look much better with many fields expected to yield 1,200 pounds per acre to 1,600 pounds per acre, and a few even higher.

Like many parts of the state, the Blackland Prairie experienced one of the longest consecutive stretches of 100+ degree daytime high temperatures, and coupled with very little rainfall, dryland yields are suffering. Across this growing region, yields are anticipated to be below average and range from 200 pounds per acre to 350 pounds per acre. The irrigated acres typically found in the river bottoms within this region are expecting good yields this year of 1,000 pounds per acre to 1,500 pounds per acre if irrigation capabilities were abundant and timely throughout the growing season.

Further north in the Rolling Plains, very warm temperatures have progressed the dryland crop and many fields have been at, or beyond, physiological cutout for a couple of weeks. bmcknight@tamu.edu

TWITTER: @COTTONFARMING OCTOBER 2023 | COTTON FARMING 19

Ginners Marketplace

MTS And Kimbell Gin Machinery Join Forces

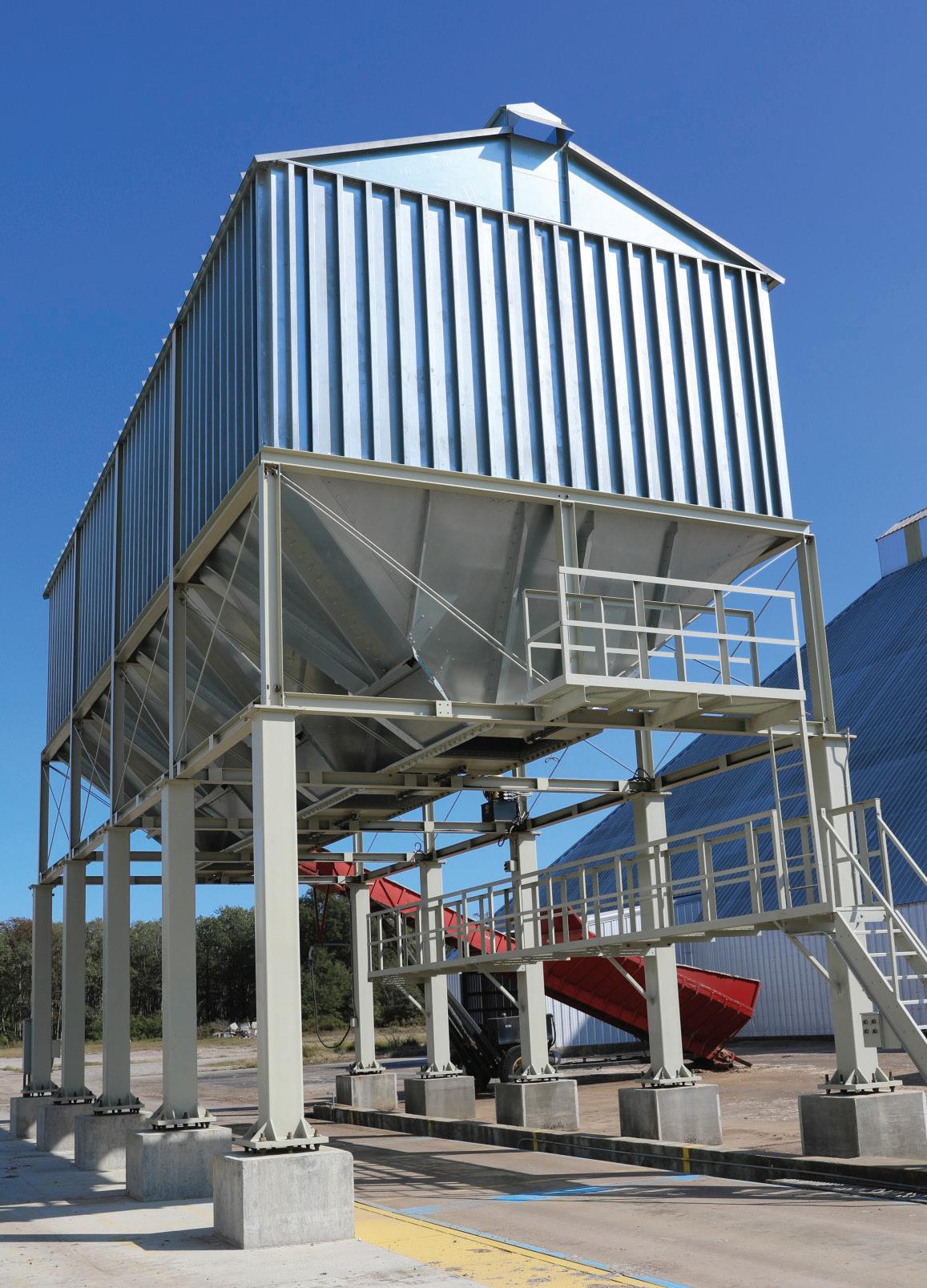

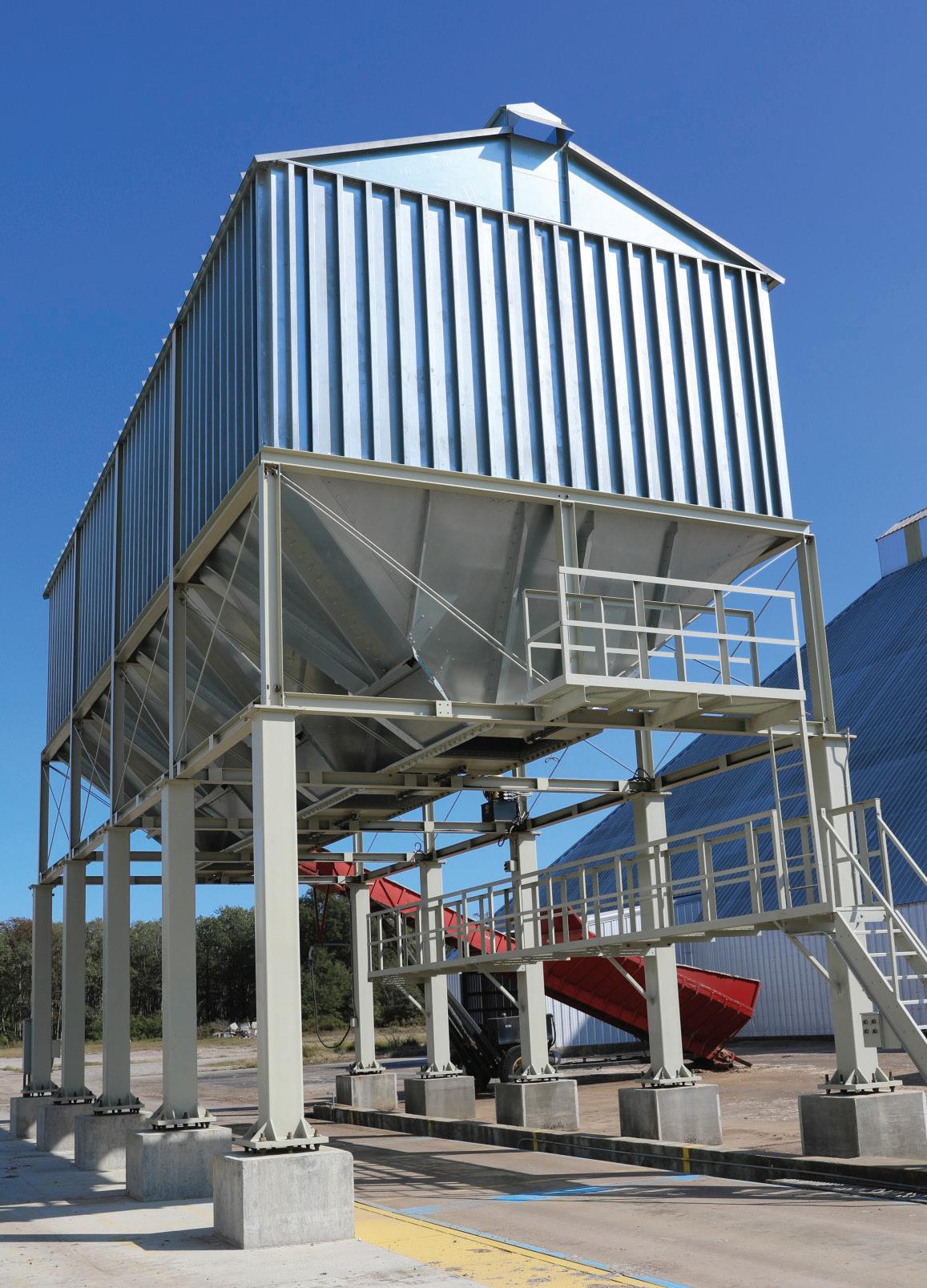

Module Truck Systems, Inc. (MTS) has purchased the assets of Kimbell Gin Machinery Company (KGM), including Diamond K Manufacturing. The two Lubbock-based manufacturers have been supplying essential equipment, parts and service to cotton gins across the Cotton Belt for many years and the leaders of both companies are excited to have the opportunity to combine their experienced and talented teams and their product lines.

Richard (Dick) Kimbell founded KGM in Earth, Texas, in 1954, and moved it to its current location in Lubbock in 1964. His son, Wylie Kimbell, has led the company since 1979. KGM is known for building e icient, highly durable centrifugal fans, cleaners, module feeders, dryers and other components for today’s high-capacity cotton gins. The company’s current president, Donnie Wren, has been with KGM since 1989. He and his wife, Dondra Kimbell Wren, will continue to manage the KGM operations at their current location, 226 NE Loop 289 in Lubbock.

Wren said, “I believe combining the engineering, fabrication and service talent of these companies will provide cotton gins and other industries a unique, reliable source for traditional and innovative new products. Our employees are excited to

join the MTS team and provide our customers with great products and service.”

The history of MTS goes back to the introduction of the cotton module truck in 1974. The company has been led since 1996 by its chairman, Curtis Gri ith. MTS has been the leader for

Cotton Ginners Marketplace 20 COTTON FARMING OCTOBER 2023 COTTONFARMING.COM

COTTON

COTTON FARMING IS THE OFFICIAL PUBLICATION OF THE GINNING INDUSTRY.

“We chose this seed house because of its reputation for performance.”

Steeper Hoppers with 10-Gauge Steel 50% Larger Square Hydraulic Doors Conversion Kits for Most Seed Houses Call Jim - (972) 381-8899 / cliffgranberrycorp.com ELEVATED SEED HOUSE MINIMIZE SEED BRIDGING • SAFER • FASTER • STRONGER

Quito Gin Co., Itta Bena, MS

Adrian Salazar, MTS director of manufacturing, welds some pipe for a gin.

many years in the number and quality of module trucks moving cotton from the field to the gin from Virginia to California. Since 2002, it has been located at 2010 East 50th Street in Lubbock.

Ginners Marketplace

Dolle Barker purchased control of the company in 2020 and today is its president and CEO. Under her leadership, MTS acquired Mettran, Inc. including the Gene Winn designs for the hot shelf dryer, the Big Mach cleaner and the Winn module feeder, among others that have become increasingly popular in the cotton gin industry. MTS also designs, builds and refurbishes equipment for TxDOT and other area businesses.

Take A Hard Look At Insurance Costs And Safety Culture At The Gin

Barker said, “We are working to diversify MTS while still being the preferred source for cotton module trucks. Bringing together the awesome teams of these two historic companies will give us the engineering and fabrication talent and tools to be the vendor of choice for not only the products they have built for many years but for many new products as well. We will continue to operate both companies in their current locations for now but are looking forward to bringing them together in a brand-new facility in the near future.”

Distractions have become “routine” in our daily lives. Our phones go o , we get text messages and we’re bombarded by the never-ending news cycle. Everything seems to be trying to get our attention, and it’s easy to lose sight of what’s important. Things can sneak up on you, and those are the ones that will jump up and bite you.

tions have been aware of this and have brought it to the attention of our memberships. But I think many of us got distracted by the other things going on and have now been hit with the reality that it’s not getting better.

In the last year or so, we’ve seen huge increases in our costs. As I write this, we’re getting news of the highest inflation in more than a generation… maybe two.

Module Truck Systems, Inc. provided this information.

While I’m personally seeing some of the things that increased so much ease down a bit, it’s not common for costs that have gone up this much, this fast, to come down or come down very much. We will likely have to learn to live with some of them.

The Cost Of Insurance

One of the costs that snuck up on many gins in the past year or so is the cost of insurance. Normally, this is a once-a-year expense we get hit with.

662-809-9730 for an example report

The past renewal cycle or two have been more than a bit of sticker shock for many in the ginning industry. Your associa-

This is a simplified explanation, but insurance companies are going to do what they need to in order to stay in business. They must make money like we do. The companies take our premium and invest it. They pay claims with it, and they expect to have some left over. If losses are low and return on investment is good, you have happy insurance companies. We get stable premiums and competition.