6 minute read

Feature

from OPI APP NOVEMBER/DECEMBER 2021 B

by OPI

Packaging up a SOLUTION

Tackling the mounting packaging problem is no easy feat, but there is a profusion of companies devoted to finding answers. OPI’s Michelle Sturman takes a look at some of the developments

It doesn’t take a genius to work out that the mammoth rise in packages being shipped around the world isn’t great for the environment. To put the $900 billion global packaging industry into perspective, the most recent Pitney Bowes Parcel Shipping Index reveals global parcel volumes reached 131.2 billion in 2020. Or, to put it another way, 4,160 parcels are shipped per second.

According to the Index, parcel volumes could be as high as 303 billion by 2026, although the most likely outcome is that they will double to reach about 266 billion with an 11% CAGR from 2021-2026. Whatever the final figure, it’s a staggering number of packages and accompanying packaging material which are finding their way into our homes and workplaces.

Some progress is being made in addressing the issue, with the banning of single-use plastic gaining momentum, for example. But different plastics are still found in packaging materials.

And while the focus has been on increasing recycled content within packaging and improving overall recyclability – although global recycling rates remain below par – the emphasis is now in fact shifting to reaching net-zero.

One way to help reduce carbon emissions is to embrace a circular economy which calls for significant advancements in solving the complex issue of making packaging more sustainable and non-linear (see also Spotlight, page 28).

OPI looks at a few of the interesting innovations that are already available or are in the testing/ prototype phase.

THE BOUNTY OF THE SEA

The humble seaweed, found in abundance in seas the world over and with the added ability to be farmed sustainably, is becoming a genuine contender for replacing plastics in packaging. The European seaweed industry alone is predicted to be worth almost €9 billion ($10.4 billion) by 2030. Companies that include traditional packaging giants as well as start-ups are currently investigating its potential.

UK-based paper and packaging firm DS Smith, for instance, is exploring how seaweed fibres can be used as a raw material in products as an alternative to wood. The company is also examining the potential of using seaweed as a replacement for petroleum-based barrier coatings.

In addition, as part of its £100 million ($134 million) circular economy R&D programme, DS Smith is researching other natural materials. These include straw, hemp, miscanthus and cotton as well as agricultural waste such as cocoa shells and bagasse.

A collaboration between two Finnish companies is analysing the possibilities of seaweed and algae. Origin by Ocean harvests algae and seaweed from the Baltic Sea and transforms it into sustainable ingredients. In partnership with bio-sourced materials business Brightplus, the focus is on examining the different decorative and barrier properties of the biomass.

THE WHOLE PICTURE

Creating circular products isn’t solely about the packaging material itself. It equally involves right-sizing containers and ensuring eco-friendly void fill options are included.

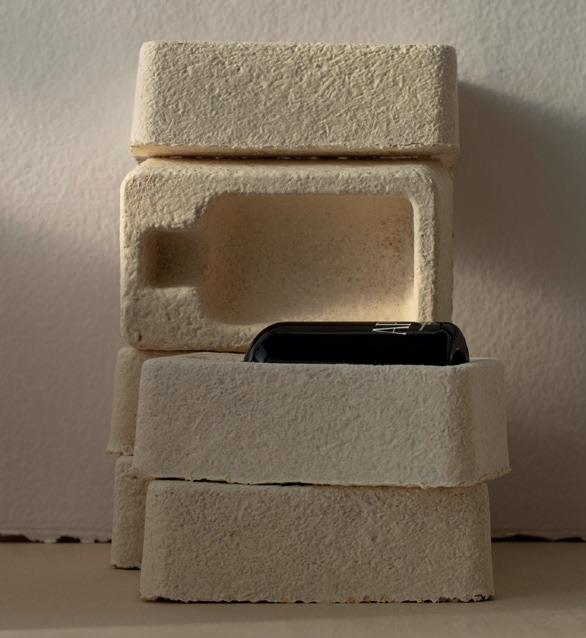

US-based Cruz Foam has been operational for a few years, but its product is now gaining real traction as businesses look for viable eco-friendly and circular economy alternatives. The company uses chitin from shrimp shells

sourced from sustainable farming and paper recycling waste to manufacture a compostable foam. It’s comparable to polystyrene in terms of its mechanical properties and thermal insulation.

FOR THE LANDLUBBERS

Back on dry land, mycelium – the mass of branched, tubular filaments of fungi, or mushroom roots – is proving its worth as a packaging material. One of the forerunners of this technology is US-based Ecovative, a biotech firm that uses mycelium to combat problems such as plastic pollution. Mushroom Packaging, a division of Ecovative, focuses on custom-moulded protective packaging.

This solution is made with two ingredients: hemp hurd and mycelium. It is grown to shape in seven days, is flame and water-resistant, biodegradable and fully home compostable. Mushroom Packaging is, furthermore, Cradle to Cradle Gold Certified.

A Life Cycle Assessment found the packaging consumes a tenth of the energy and emits an eighth of the greenhouse gases as an equivalent volume of foam. Currently, there are four licensees of Mushroom Packaging based in New Zealand, the US, the Netherlands and the UK.

Using Ecovative’s mycelium composite technology, UK licensee Magical Mushroom Company takes post-processing waste from agricultural products, including hemp, hops, corn and timber, and combines it with mycelium. The firm says its product performs as well as polystyrene and also avoids the new plastic packaging tax.

PAPERCHASE

While not being liable for the tax may serve as a minor motivation, for the biggest plastic polluters like The Coca-Cola Company, Nestlé and PepsiCo, consumer backlash will likely provide the biggest incentive to up their environmental game. To be fair, many global businesses – on the surface at least – seem to be searching for sustainable and circular alternatives already.

One such substitute being explored is the paper bottle. Formed in 2019, Paboco is a joint venture between Swedish paper packaging material developer BillerudKorsnäs and Austrian bottle manufacturing specialist Alpla. Paboco’s mandate is to create the world’s first 100% bio-based and recyclable paper bottle at scale.

Drinks manufacturer The Absolut Company was the first to launch a test batch of around 2,000 bottles containing 57% paper and 43% plastic. The plastic barrier was made from 100% recycled PET which could be recycled after use.

This was followed by a Coca-Cola prototype trialled in Hungary. These launch trials will help provide valuable learnings throughout the value chain, including logistics, consumer experience, recycling, etc.

Paboco recently launched its next-generation bottle, where the plastic barrier film has been replaced with a new, fully integrated version, and different bio-based coatings are being tested.

The company, together with digital services firm recycl3R and traceability platform Kezzler, has developed a recycling app concept. Consumers can scan a QR code on a bottle for information on recycling depending on their location. It will further contain details about the packaging, sustainability footprint and product journey.

Pulpex – a collaboration between drinks manufacturer Diageo, venture management firm Pilot Lite and Stora Enso – is another entity racing to develop paper bottles for global brands such as Unilever and PepsiCo.

RETURNING FULL CIRCLE

Finding a single solution that addresses every aspect of sustainability is difficult. US-based start-up Returnity aims to overcome part of the problem by providing reusable shipping and delivery packaging systems.

The custom-designed mailer bags, envelopes and shipping boxes are made from recycled plastic bottles, eliminate over 40 single-use packages, and are fully recyclable at their end of life. Returnity provides client-specific circularity systems to ensure the right economic, operational and environmental choice to help the shift to a non-linear economy.

With COVID-19 still top of mind, the company has teamed up with chemicals firm Polygiene to use its ViralOff antimicrobial treatment which is effective for 30 washes.

All the aforementioned innovations represent just a tiny selection of what’s achievable, but they aptly demonstrate that the packaging issue is being confronted head-on. This bodes well for our industry in terms of increasing the availability of sustainable options.

From top left clockwise: Absolut paper bottle; Cruz Foam chitin-based foam; Returnity reusable shipping package; Mushroom Packaging mycelium protective packaging