27 minute read

Mobile Juice Factory

Okanagan orchardists can have Mobile Juice Factory turn their excess fruit into juice, increase their income and help the environment.

By Tom Walker

Advertisement

It’s not surprising that an award-winning organic orchardist, viticulturist and wine maker would be concerned about the impact that the fruit industry has on the environment. “Every year there are thousands of pounds of waste fruit going into the landfills,” says Karnail Sidhu, who recently won the BC Grapegrowers Association Viticulturalist of the Year award. But it doesn’t have to be that way. Okanagan orchardists have a convenient option if they want to turn their excess fruit into juice, increase their income and help the environment. In addition to growing and making award winning organic wines, Karnail owns the Mobile Juice Factory and will travel to your orchard and press your fruit. “We provide orchardists an alternative to dumping, as well as creating a value-added product,” Karnail explains. “We serve the smaller fruit grower, someone who might have their own roadside stand. If they have extra fruit at the end of the season or culls that they want to use, we can turn them into juice and pack it up in a bag in the box.” The Mobile Juice Factory will travel to an orchard if a grower has as little as 10 bins of fruit. “That is the minimum order that we can process at an orchard site,” Karnail explains. But if you have less, he will

We are dedicated to helping you achieve your business goals and creating a flexible and customized banking solution that is right for your farming operation.

Jeremy Siddall District Vice President – Pacific Agriculture Services British Columbia 250-681-4656 jeremy.siddall@td.com

Michelle Curcio Account Manager Vancouver Island 250-246-0859 michelle.curcio@td.com

Ted Hallman Account Manager BC Interior 250-470-7557 ted.hallman@td.com

Alyssa Barr Account Manager BC Interior 250-575-5047 alyssa.barr@td.com Ken Uppal MMBBAA P. APg.Ag District Manager Abbotsford & Fraser Valley 604-621-3350 kanwar.uppal@td.com

Connor Watson B.Comm Account Manager Abbotsford & Fraser Valley 778-201-5753 connor.watson@td.com

Dave Gill Account Manager Abbotsford & Fraser Valley 604-807-4761 baldev.gill@td.com

Rahan Ahmad Account Manager Abbotsford & Fraser Valley 778-847-1566 rahan.ahmad@td.com

® The TD logo and other trade-marks are the property of The Toronto-Dominion Bank. M05338 (0120)

Turn Excess Fruit into New Revenue!

EXTENDED SHELF LIFE:

Unopened: Up to 1 Year Opened: Up to 3 Months Refrigeration NOT Required We Come to You! • Super Fast and Efficient Flash Pasteurized • Packaging Included

YOUR FRUIT! YOUR JUICE!

THE ORIGINAL MOBILE JUICING EXPERTS (In the BC Interior)

MOST FRUIT! Apples, Pears, Peaches, Apricots, Nectarines, Plums, Cherries, Berries We Do Custom Juicing for Cideries

work to see if he can coordinate with another farm. “If I have a call for six bins in Oliver for instance, I will try and connect with another grower in the area and see if we can make up the 10-bin minimum for the trip.” And backyard growers won’t be left out. “We also offer a juicing service to home growers, through our community juicing events,” Karnail explains. “Someone who may only have one or two trees in their yard, but they want to put up some juice for their family. “We set up the juice factory here at the winery in West Kelowna and we also travel to other communities such as Salmon Arm, Armstrong and Abbotsford and hold day-long juicing events,” Karnail explains. With a minimum of 150 pounds of fruit, the backyard grower will go home with nine or ten, 5-liter bag-inthe-box containers of juice. If you are a small winery or cidery, the juice factory can adapt their line to produce unpasteurized juice, suitable for fermentation. If you want custom labels or a different size box, they can do that too.

Apples are the most common juicing option, but Karnail says they can handle pears, cherries and other stone fruits, berries, grapes and even some vegetables. Indeed, Kalala sells organic ABC juice (Apple, Beet and Carrot) at the winery tasting room. The fruit just needs to be clean and Karnail warns they should not be windfalls that could carry a fungus. The fruit is loaded into the juice machine by hand. “We are able to give one last sort to the fruit as we load it,” Karnail says. The fruit is washed twice on the way to be shredded and then pressed. After being flash pasteurized, the pure juice (no additives) comes off the line and is vacuum packed into plastic pouches. The leftover fruit mash is collected in a bin. The boxed juice is shelf stable for a year and can stay fresh for up to three months after opening, without refrigeration. Keep it out of the landfill, join a juicing event and get an amazing product with your very own fruit. “This is the healthiest juice that you can get,” says Karnail. “The list of ingredients is just two words, ‘pure juice’."

DEFinately easier to own.

Ultra-narrow and powerful, T4F/T4V vineyard and orchard tractors are one of the only specialty tractors on the market that are DEF-free for lower ownership costs. Add in a best-in-class 600-hour service interval on their turbocharged four-cylinder engines, and you’ve got tractors that go where others can’t and save you money doing it.

Get your hands on one of these easy-to-own, DEF-free T4F/T4V narrow tractors before the new 2021 models arrive. Stop in today or visit newholland.com to learn more.

Toll Free 1-800-242-9737 www.rollinsmachinery.com

KELOWNA:

202-150 Campion Street, Kelowna, BC 250-765-8266

CHEMAINUS:

3306 Smiley Road, Chemainus, BC 250-246-1203

AG CENTRE: Chilliwack

44725 Yale Road West, Chilliwack, BC 604-792-1301

HEAD OFFICE: Langley

21869-56th Avenue, Langley, BC 1-800-665-9060

©2018 CNH Industrial America LLC. All rights reserved. “New Holland” is a trademark registered in the United States and many other countries, owned by or licensed to CNH Industrial N.V., its subsidiaries or affiliates. “Equipped For A New World” is a trademark in the United States and many other countries, owned by or licensed to CNH Industrial N.V., its subsidaries and affiliates.

AGRICULTURAL NETTING & FABRICS

• Strong HDPE knit, open-mesh nets • 10 year UV warranty • Easy to apply and remove • Hail, shade, rain & other fabrics • Nets for grapes, cherries & berry crops • Custom nets and structures UNBEATABLE BIRD PROTECTION

• Strong HDPE knitted fabric • 10 year UV warranty • Easy to apply and remove • Adjustable reflectivity • Good porosity to prevent water buildup • Custom widths available HIGH QUALITY REFLECTIVE COVERS

Premium Grapevines and Rootstock

Taking Orders for Custom Budding Gisela 6 and Mazzard Cherries

CALISSI FARMS Inc. 250 317 2164

james_calissi@telus.net • www.calissifarms.com 3810 East Kelowna Road, Kelowna, BC, V1W 4H2

Small but Mighty: BC’s 2020 Vintage

Some are calling 2020 the vintage of the decade, and for good reason. A small but mighty vintage, 2020 produced low yields of high-quality fruit, which created wines with excellent flavour concentration, ripe tannins and great acidity and structure which will have wine lovers clamouring to get their hands on a bottle or two before this incredible vintage is gone. On December 2, 2020, Wine Growers British Columbia (WGBC) held its annual Winemakers & Viticulturalists' Forum for the first time virtually to adhere to provincial COVID-19 restrictions on gatherings and events. The virtual event, led by Master of Wine Rhys Pender, saw 61 winemakers and viticulturalists from around the province gather online to discuss the 2019/2020 growing season from winter through harvest. Due to the virtual nature of this year’s event, a panel of six winemakers and viticulturalists were invited to help facilitate an engaging discussion with attendees. Prior to the forum, WGBC collected responses from an industrywide survey and collated together with the virtual discussion to form the 2020 Vintage Report. In the Okanagan Valley, the sentiments from winemakers and viticulturalists were very similar. Ideal summer weather which continued into the fall provided a long growing season with lots of sun and low rainfall, contributing to exceptional quality of fruit with high concentration, ripe tannins and great natural acidity, along with the balance, complexity and freshness that will provide great ageability. The Similkameen Valley saw very similar conditions to the Okanagan Valley, with one notable difference – none of the cooler and damper weather around flowering that the Okanagan Valley experienced which contributed to lower yields. Many Similkameen winemakers reported a full and healthy crop. The rest of the BC interior had similar weather with a cooler and damper start to the season before the warm, sunny summer kicked in to provide ideal ripening conditions, which produced wines with crisp, fresh acidity and excellent flavour. The Coastal regions, which typically experience a very different vintage due to the moderating influence of the Pacific Ocean and the Strait of Georgia, saw a cooler and rainy June before the sun returned for July and August producing fruit that created wines with the typical fresh island style, natural acidity, balance and slightly lower alcohol levels.

The 2020 Icewine vintage was just as unique as the overall 2020 vintage, producing the smallest Icewine crop in the last 20 years, with only seven of the 14 wineries registered picking 74.75 tonnes of the 300 registered tonnes. As with every vintage, 2020 had its own exceptional personality and story, producing lower quantities of extremely high-quality fruit that have produced wines with incredible flavour and ripe tannins which make for elegant, fresh and balanced wines that beautifully express BC's distinctive terroir and climate. The 2020 vintage is perfect for savouring today or cellaring for a special occasion. View the full 2020 Vintage Report on WineBC.com. Carie Jones, Communications Manager, Wine Growers British Columbia

To advertise in the next issue call: 778-754-7078

info@orchardandvine.net

THE POWER OF CAN

Get $100 towards your first order with Vessel, exclusive to Orchard & Vine readers.

Claim your discount and find out more about how we can help you take your business to the next level at:

How to Take Your Own Brand Photos: 10 Tips & Tricks

Need fresh, new photos for your brand’s social media or website but don’t have access to a professional photographer? Thanks to smartphones and photo editing apps, you can now take high-quality photos yourself! Check out our 10 tips below to improve your phone photography game:

1 - Use Gridlines

Balancing your shot with gridlines is a quick and easy way to significantly improve your photos! Turn on this camera function and follow the “rule of thirds” by placing along the lines. Your photo will appear more level and natural.

2 - Resolution is Key

In a nutshell, resolution is the quality of the image. The higher the resolution, the clearer, sharper, more defined and detailed the image. When capturing photos, aim for as high of a resolution your device will allow. Remember: you can always make images smaller, but not the other way around! We recommend always keeping a backup of your original photo when editing, just in case.

3 - Use Natural Light

Flash often makes photos look overexposed, negatively altering colors and making human subjects look washed out. Take advantage of the sources of natural light you can find around the house, whether it’s by a window, on the balcony or in the backyard. When posting or staging objects, follow model Isabella Carr’s advice of always turning toward the light - especially if it’s natural sunlight - because “this brightens your face and makes you glow, which kind of results in your blemishes being blurred away!”

4 - Focus on One Subject

For novice photographers, start small and focus shots on a single subject. That way, you can spend extra time cleaning up the surrounding environment and playing around with angles. Be sure you tap the screen of your smartphone to focus the camera and ensure that it's properly focused.

5 - Avoid Zooming In

Tempted to zoom in when you’re trying to capture something from a distance? To prevent pixelating the photo and compromising quality, try to move closer to your subject – maintaining a safe social distance, of course - or take the photo from a distance and crop it when editing.

6 - Embrace Negative Space

Referring to the areas around and between the subjects in an image, including empty space, will help your subject stand out. Negative space can take the form of open sky, empty fields, large wall, or body of water.

7 - Ask for Assistance

For a more professional look, either ask a family member, partner or roommate to press the shutter, or turn on your camera’s self-timer. Pro tip: ensure the shot comes out as you pictured by taking the same photo of someone else first, so that they can reference it when they’re behind the camera. As model Shannon Thaler once said, “When taking a full-body pic, I like to have the camera [person] hold the camera just below eye-level. A pic aimed everso-slightly upward makes for long lines—Hello, legs!”

8 - But First, Let Me Take a Selfie

Here are three best practices to keep in mind when taking the perfect selfie: • Know Your Angles: Hold your phone at arm’s-length to capture subjects from the waist-up. • Relax: According to influencer Kate Rooney, the best way to look calm, cool and collected in your photos is to actually be calm, cool and collected. Shake off the nerves by taking deep breaths, putting on music you can groove to, and using fun props! • #OOTD (outfit of the day): Experiment with outfit colours and styles to see what translates best on camera. Black and white are safe options, but don’t be afraid to amp it up with patterns and brand-aligned palettes.

SERVICES • Land Contouring For Orchards & Vineyards • Surface Modelling and GPS Machine Controlled Excavation • Retaining Wall Construction • Excavators, Rock Trucks and Dozers • Services by the Hour or Contract

Cruiser Contracting Ltd. Call 778-753-6499

info@cruisercontracting.com cruisercontracting.com

VINEYARD NETTING

Redden Net & Rope is continually working with the latest technologies & materials

Economical Side Netting

Machine Applicators

MESH SIZE: 5/8” X 3/4” 2.9 lbs/msf BLACK POLYPROPYLENE 3’5” WIDE X 5000 FT. LONG roll weight = 63 lbs. 4’6” WIDE X 5000 FT. LONG roll weight = 84 lbs. 5’8” WIDE X 5000 FT. LONG - most popular roll weight = 105 lbs. 7 ft. WIDE X 5000 FT. LONG roll weight = 125 lbs. 14 ft. WIDE X 5000 FT. LONG roll weight = 250 lbs. 17 ft. WIDE X 5000 FT. LONG roll weight = 320 lbs.

DISTRIBUTOR PRICING & VOLUME DISCOUNTS AVAILABLE

Redden Net & Rope LTD.

#27 12491 No. 2 Road, Richmond, BC, V7E 2G3 Telephone: 604-274-1422 Fax: 604-274-9068 E-mail: mark@redden-net.com https://www.redden-rope.com/vineyard-netting

Order Toll-Free 1-866-233-1422

9 - Capture Candids

With social media platforms increasingly emphasizing authentic content and organic growth, spontaneous and behindthe-scenes shots can be far more intriguing for your online audience. Candid photos capture the emotion and essence of a moment more effectively. One of the best ways to capture candids is take as many as possible! That way, you'll have more to choose from when editing.

10 - Find Inspiration

Galleries such as Pinterest are a great resource for finding photo inspiration for a wide range of topics, including wine & drink, sports, corporate, and many more. Check out the 30 best photography Instagram accounts to follow in 2021 Ready to give these phone photography tips a try? Grab your smartphone and snap away! Leeann Froese owns Town Hall Brands – a marketing and graphic design agency that specializes in branding and promoting in the areas of agriculture, beverage alcohol, food, and hospitality. See more at townhallbrands.com or on social @townhallbrands

Orchard & Vine SUBSCRIBE

Delivery to Canada or the United States 6 times per year. Get your copy delivered to your mailbox! www.orchardandvine.net/Subscribe 778-754-7078

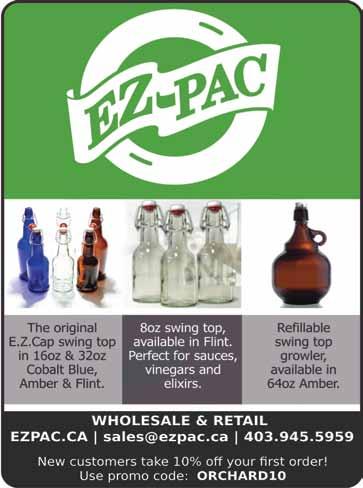

Providing Packaging, Bottling, Corks, Screwcaps, Capsules & Closures for Wineries and U-Vins

• Wine Bottles

• Rigid Packaging • Amorim Neutrocork Corks

• Aluminum Screwcaps

• PolyLam Capsules

• Closures Proudly Locally Owned & Operated

1989 Harvey Avenue Kelowna, BC, V1Y 6G5 info@interiorbeverages.com Toll Free: 1 (888) 703-6505 Local: 1 (250) 491-9266 www.interiorbeverages.com

The Impact of Changes to Agristability for Growers

Canada’s federal, provincial, and territorial (FPT) ministers of agriculture recently agreed to remove the reference margin limit (RML) for AgriStability, one of the business risk management (BRM) programs under the Canadian Agricultural Partnership. The removal of the RML will be made retroactive to the 2020 program year. The objectives in making this change are to help simplify the program and help farmers in need by increasing the level of support for agricultural operations that are highly mechanized or use family labour causing lower allowable expenses. BC Ministry of Agriculture led the way for this change. The British Columbia AgriStability Enhancement program that was introduced in 2019 also included the elimination of the RML.

How do these changes benefit you and your farm?

Producers and sectors which had low AgriStability eligible costs and corresponding limited reference margins, will now benefit from higher reference margins and better coverage. The most important thing to understand is that RML increased the margin drop required to trigger benefits substantially when we relate it back to the original reference margin. Specifically, farms for which RML applied required a 30 to 51% drop, depending on degree of limiting, relative to their original reference margin to trigger AgriStability benefits. That is what made the program so much less responsive when RML applied. Under RML, many farms had required a 30-51% margin drop to trigger benefits. With its removal, ALL farms now require only a 30% margin drop to trigger benefits.

AgriStability program changes FAQ

Q: Doesn’t AgriStability require a 30% revenue drop for any farm to trigger benefits? A: No, the 30% drop advertised by the AgriStability Program is a drop relative to your reference margin. The revenue drop required varies depending on the type of

60%

Percentage Drop in Revenue 50%

40%

30%

20%

10% REVENUE DROP REQUIRED TO TRIGGER AGRISTABILITY

0%

0.00 0.10 0.20 0.30 0.40 0.50 0.60 0.70 0.80 0.90 1.0 Eligible Expenses/ Eligible Revenue Ratio

INDUSTRY SECTORS:

Group 1 • Beef - Feedlot • Greenhouse • Hog - Farrow to Finish • Nursery • Tree Fruits Group 2 • Beef- Cow/Calf • Dairy • Grain/Oilseed • Hog - Farrow to Finish • Hutterite Colony • Poultry Group 3 • Apiary • Bee Pollinator • Cranberry • Maple Syrup • Organic Crop

Low Cost Structures GROUP 3 GROUP 2 GROUP 1 High Cost Structures

The graph above examines the cost structure for various farming sectors and shows how cost structure relates to the responsiveness of the AgriStability program. We highlight the revenue trigger points required to trigger AgriStability for various types of farms. Revenue trigger points represent the drop in revenue (through production loss, price loss or a combination of both) required to trigger AgriStability. We have found that revenue trigger points are easier for producers to relate to than margin trigger points, because most farm disasters have a significant revenue loss component. It also helps producers who may have dropped out of the AgriStability program in the past, whether due to perceived impacts of RML or otherwise, visualize that they should probably get back going forward.

farm and cost structure. Revenue drop percentages are labelled along the line graph with very low revenue drops in the bottom right hand corner and higher revenue drops on the left-hand side of the graph. Q: Where would different types of farms fit on this graph and what kind of revenue drops would they require to trigger AgriStability benefits? A: Farms with a high cost structure (Industry Sectors Group 1) fit on the bottom right hand side and require a revenue drop of 1.5% - 12% to trigger AgriStability benefits. Moving left on the graph, farms with a moderate cost structure (Industry Sectors Group 2) require an estimated 12% - 19.5% revenue drop, and those with a low-cost structure (Industry Sectors Group 3) require an estimated 19.5% - 25.5% revenue drop. Q: What difference does knowing the revenue drop required to trigger AgriStability benefits make for me? A: It is critical that you know and understand what level of revenue drop is required, as well as what risks might contribute to a revenue drop for your operation to make a proper decision on AgriStability participation. Q: What difference did removal of the RML have on the revenue drops required to trigger AgriStability benefits? A: The orange line (labelled RML) on the graph, when compared to the white line (labelled No RML), shows the potential impact that RML had on revenue drop trigger points for certain farms in Group 2 and Group 3. Certain farms in these sectors will benefits from substantially lower revenue drop trigger points now that RML has been removed.

Q: How would I go about figuring out the eligible expense to eligible revenue ratio to determine where my farming operation would fit on this graph? A: Eligible revenue and eligible expense are both defined by AgriStability program rules. Ideally, you would have to know the average eligible revenue and eligible expense from the three years used to calculate your Olympic Average reference margin for AgriStability. These amounts can be estimated using the most recent AgriStability Calculation of Program Benefits (COB) notices and / or accrued financial statements. Estimation of AgriStability reference margins, particularly if you have not participated in AgriStability recently or if you do not have up to date COBs can be difficult for a number of reasons. We would recommend the estimates not be undertaken without the assistance of an advisor that is proficient in AgriStability policy and procedures.

Next steps

AJ Gill is the Regional Leader for Agriculture Risk Management Resources with MNP. Contact AJ to enroll if you have either previously opted out of or never participated in the AgriStability Program. The 2021 AgriStability Enrolment Deadline has been extended from April 30 to June 30, 2021, and enrollment has been simplified for returning participants, who now you have a choice to base coverage on the past three years or a five-year average. AJ can help you to determine the option that gives you the highest coverage. Contact AJ at 250-469-6488 or aj.gill@ mnp.ca or visit MNP.ca/ARMR to watch a short video further explaining the AgriStability changes.

Farm • Orchard • Vineyard • Berry Trellising

KILN DRIED PRESSURE TREATED ROUND WOOD POSTS AND RAILS Preferred supplier for British Columbia Ministries & Parks Canada.

Bill Everitt 250.295.7911 ext #102 beveritt@xplornet.ca • Toll free 1.877.797.7678 ext #102

Princeton Wood Preservers Ltd. 1821 Hwy 3 Princeton, B.C. V0X 1W0

Designed for pruning professionals

Grape Vines | Tree Fruits | Blueberries | Landscaping

• 120 Wh Lithium Battery • Weight 1.7 lbs

PRUNING KITS IN STOCK NOW!

How to Use the Tree Fruit Production Guide

The Tree Fruit Production Guide is an important part of tree fruit farming, as it not only contains the all-important spray schedules, but also the ‘how-to’ of growing tree fruit crops in the Interior of BC.

The Guide covers both organic and conventional tree fruit production practices. While some think of the TFPG as simply the spray schedules, the Guide contains much more information, and the BCFGA has also created an electronic, on-line version that can provide the spray products information (e.g. pest, REI, PHI, and rates) via internet to connected programs such as DAS and Crop Tracker. It is an exciting future, but we need more growers to participate in these programs. The TFPG is available at no charge on-line and includes the following chapters: • Safety • Integrated Fruit Production (IFP) and Organics • Horticulture (Crop Management, Fruit Tree Nutrition, Varieties and Pollination, Irrigation and Air Quality, Spray Thinning, Growth Regulators and Sunburn Protection) • Pests (Insects and Mites, Diseases, Wildlife Damage Prevention, Weed Control) • Pesticides • Resources (including Grower Records) The content of the guide is reviewed and authorized by the BC Ministry of Agriculture and published by the BCFGA. The spray schedules are the most used and therefore important part of the TFPG. For quick, in-field reference, the spray schedules are viewable on cell phones, with products displayed in the ‘card’ format. Most growers like to have a printed version of the spray schedules. Spray schedules can be printed on-line (look in the upper right hand corner of the spray schedule for a printer icon, then print the schedule with your PDF viewer), or ordered from the BCFGA at www.bcfga.com// orderform.php?pageID=318. Through the magic of technology, if a change to the spray schedule is made this morning (e.g. a new product or application rate), the change is entered into the TFPG database and when the grower logs in, the information provided is the most recent, updated version. Because of this ability to change within the year, we have implemented two important ‘control’ items: • First, a printed spray schedule will have the most recent change date recorded at the top of the page, so that growers may check if their printed copy is up-to-date.

339 Sumas Way, Abbotsford, BC 604-850-3601| 888-302-3612

• Aluminum • Stainless steel • Fruit and wine industry • Marine fabrication • General fabrication • Shop and Site work

Unit 2 - 876 Leathead, Kelowna BC

250.470.2658

mike@ironvalleyfabrication.com www.ironvalleyfabrication.com

• Second, a “Change Log” in the upper right-hand corner of the TFPG homepage will show all changes and the dates of the changes. Growers can check the change log to see if there is anything new in the spray schedules.

But the TFPG can do much more and provide more value to growers. Since the spray schedule information is in a database that is “in the cloud”, there is an ability to link the spray schedule to other programs. For example, SIR’s Decision Aid System (DAS) links into the spray schedule database. What does this mean for growers? • First, there is no need to cross-reference information. It is ‘drawn in’ from the cloud database to the DAS system. • Second, instead of ‘hard coding’ the spray information into DAS, the system draws out the information from the cloud database and the information is up-to-date to that moment in time. With hard coding, any changes needed to be re-entered manually (which could result in delays and transcription errors). • Third, the DAS system automatically finds and displays the spray information on the pest, instead of having to find it in the spray schedule. Work to link the spray schedule to Crop Tracker (a spray record-keeping program) has been delayed by COVID-19, but we are meeting with Crop Tracker in May 2021 to get the project back on track. This will be a great time saver for growers recording their sprays, and there is a huge benefit (time saving and added value) of being able to easily share the records. As one small example, you can share a map which highlights reentry dates, so your workers and family, SIR staff, and horticultural advisors (and others you have shared the map with) will be able to check the map on their phones to see which areas of the orchard are safe to enter.

A concern is the capability of growers to take on electronic spray records. A recent study completed by Lee Cartier and Svan Lembke at Okanagan College indicated that:

• 98% of growers keep spray records but only 16.7% in digital format with opportunities for analysis.

• The industry has free use of a Decision Aid Systems (DAS) with spray information for apple and cherry growers. Only 30% of growers use the DAS. Many growers receive generic information from the DAS via emails sent by horticultural advisors. The email information is not orchard specific. The researchers proposed that the tree fruit industry should set goals of increasing the number of growers who electronically record their crop practices, and developing a critical mass with growers that can and want to adopt new tree fruit farming solutions such as DAS and other “precision agriculture” technologies. To achieve these goals, the following steps are proposed by the researchers: 1. Develop a technology adoption strategic plan, setting out goals and milestones for the identification, testing and adoption of new technologies. 2. Develop a multi-year training plan that outlines how to communicate with growers and enable them to understand and adopt new solutions for their established farming practices. 3. Research projects to enable economic impact analysis of innovations such as smart irrigation, smart spraying, etc. 4. Development of information technology systems that enable easy capture of grower data (eg. via a smartphone app [such as Crop Tracker]) to be used for specific orchard and industry-wide decision making about pest management. The second point on the list - providing grower education sessions to help growers achieve the capabilities and the comfort to adopt new technology - will be critical to the success of any industrywide adoption of new technology. With training, growers will be able to take full advantage of the tools made possible by an electronic TFPG. The BCFGA will seek to support this ambitious plan for its members.

The linkage to the cloud database for TFPG spray schedules was put in place five years ago. Now it is time for growers and programs to catch up and make use of this excellent resource through automated spray recording programs and DAS. Glen Lucas BCFGA

GO TO GUSMER

FOR ALL YOUR WINEMAKING SOLUTIONS

At Gusmer, we want to be your go to provider

for all your winemaking solutions! We understand that producing wine is both an art and a science, that each winemaker can be unique and make their own mark within the industry. That’s why for over 95 years, Gusmer has o ered a full range of innovative enological tools that enable your creative expression. Equipment, analytical instruments and processing aids brought to you from leading suppliers in the wine industry, all backed by strong Gusmer technical support. The options for expression have never been greater and the tools have never been better – so go ahead, express yourself and create your own story.

Fermentation Nutrients Filter Sheets, Lenticular Cartridges, Cellulose Pre-Coat Fibers Oak-Mor®/Oak Avantage® Chipsand Granular Oak

Malolactic Bacteria, Non-Saccharomyces Yeasts

Liquid Enzymes

Inline Process Sensors H2S Preventing Saccharomyces Yeasts

Granular Enzymes Enological Tannins

Divergan F – PVPP

Keg Washing and Filling Equipment

French Oak Membrane Cartridge Filters, Laboratory Consumables

Portable Ozone Systems Cross Flow Filters, RO Systems

Lysozyme

www.GusmerWine.com sales@gusmerenterprises.com West Coast: 559.485.2692 East Coast: 908.301.1811

BC’s Winery Insurance Experts

Contact a CapriCMW Risk Advisor for a coverage review for your winery today.

1 800 670 1877 capricmw.ca/winery