5 minute read

Eagle Manufacturing

Meeting Expectations

~story and photos by Bob Gustin

Left to right: Autumn Bryant, Josh Woodard, Cheyenne Dinsmore (Advisor), John Stowers, Dean Keefauver (Advisor).

As Brown County High School students head back to classes this fall, some of them are going into a program which aims to give them real-world work experience, advanced training more typical of college-level courses, and problem-solving skills they can use for the rest of their lives.

About a fifth of the high school students are part of the Eagle Manufacturing program or are preparing to enroll in it. And when they graduate, the goal is for them to be immediately employable if that’s the path they choose.

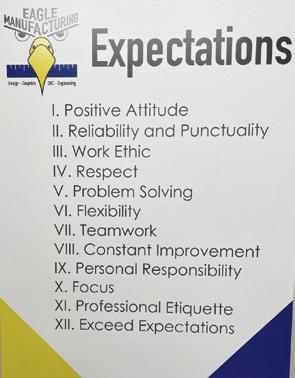

Students get training on specific job-related tasks, including engineering, programming, design, administration and operation of complex machinery. But more importantly, they learn how to thrive in a work environment.

Though one goal of the program is to get it to be selfsupporting, advisor Chris Townsend says the most important aspiration is to produce students who are workforce ready, self-sufficient, and able to solve problems given the resources they have at hand.

“If they can do that, they can do anything,” he said.

Students are encouraged to overcome problems on their own, and only seek advice from advisors if they are unable to do so, Townsend said. Other advisors in the program are Dean Keefauver and Cheyenne Dinsmore. A former Eagle Manufacturing student, Dinsmore teaches at the high school as she continues her education.

Eagle Manufacturing began in 2018 in the high school building, then moved to remodeled space in the former Nashville elementary school building when schools were consolidated. A private donation funded the remodeling and equipping of the facility. Though the startup costs for a program are high, Townsend expects growth and efficiency will eventually increase revenue, making it less expensive to operate than more traditional high school sequences.

“Our goal is to teach, not make money,” he said.

The high school program is not as efficient as a private enterprise, he said, because they are working in non-ideal conditions, including 100 percent turnover every year, and 47-minute work shifts, the length of class sessions. But he said the culture of the program is important, providing a family environment where students support one another.

Students in the program function as a business, providing goods and services to private companies and individuals at contracted rates. Students communicate with customers, learn business practices, and are responsible for end results. Any profits from the student-led business are reinvested for educational needs.

Last year Eagle Manufacturing received about 275 orders of various sizes from the private sector, each with an average price of about $225, Townsend said. While some of those orders come from large multinational corporations such as Cummins, Inc., based in Columbus, others are from small local businesses. The program has a group of 50 to 75 core clients every year, spread across Indiana and about eight other states.

Students earn educational credits through Eagle Manufacturing, and those working through summer session also get hourly wages, working six hours a day for five days a week.

“We get paid to learn,” during summer sessions, said Joshua

Woodard, student manager for manufacturing. “Our motto is student-led and quality-driven.” In addition to technical training, the program provides inspiration, he said.

Other students said the program has allowed them to learn skills and get experience while in high school, rather than waiting for college. Among the best parts of the program involve learning to problem-solve, they said.

Both Woodward and Stringer plan to continue their educations after high school.

About 50 high school students are enrolled in the program, but those studying in introductory classes brings the total to about 115. All students in the program must also complete traditional Core 40 classes to graduate.

Eagle Manufacturing is one of approximately 25 student-based enterprise programs in Indiana.

“We help teach students employment skills and put them in an environment to develop those skills,” Townsend said. “That’s unique to most of the educational process.”

“All the jobs are real jobs,” Townsend said. “That’s the best way to learn employment skills.”

The program has an advisory board composed of community, business and industry leaders, which provides feedback, direction and support. Townsend said the board has been less active since the pandemic, and he hopes it can be reinvigorated.

“I am immensely proud of Eagle Manufacturing and the unique opportunities it provides our students,” said Superintendent of Schools Emily Tracy. “This exceptional student-run enterprise is not only one of the best in Indiana, but it also embodies the spirit of innovation and hands-on learning that we strive to cultivate in our district. Through their work in manufacturing, embroidery, screen printing, laser engraving, and more, our 10th to 12th grade students are gaining real-world experience and essential employability skills that will serve them well beyond graduation.

“Eagle Manufacturing isn’t just a program,” she said. “It’s a launchpad that helps our students discover their passions and equips them with the tools they need to confidently step into their futures. The experiences they gain here will guide them as they decide what they want to do the Monday morning after graduation, whether that’s continuing their education, entering the workforce, or pursuing entrepreneurship. Eagle Manufacturing is a testament to the limitless potential of our students, and its success is a source of pride for our entire community.”

“Eagle Manufacturing is very important for Brown County to arm these kids to go out into the working world and have a skill set they can use to make a career,” he said. Among those skills are business management, basic communication skills, work ethic, and a knowledge of risk and reward, he said.

To start a project, become a partner, or get more information, contact Eagle Manufacturing at info@bceaglemfg.com or call 812-988-6606, extension 1251. The facility is located at Brown County High School campus in Nashville.