of

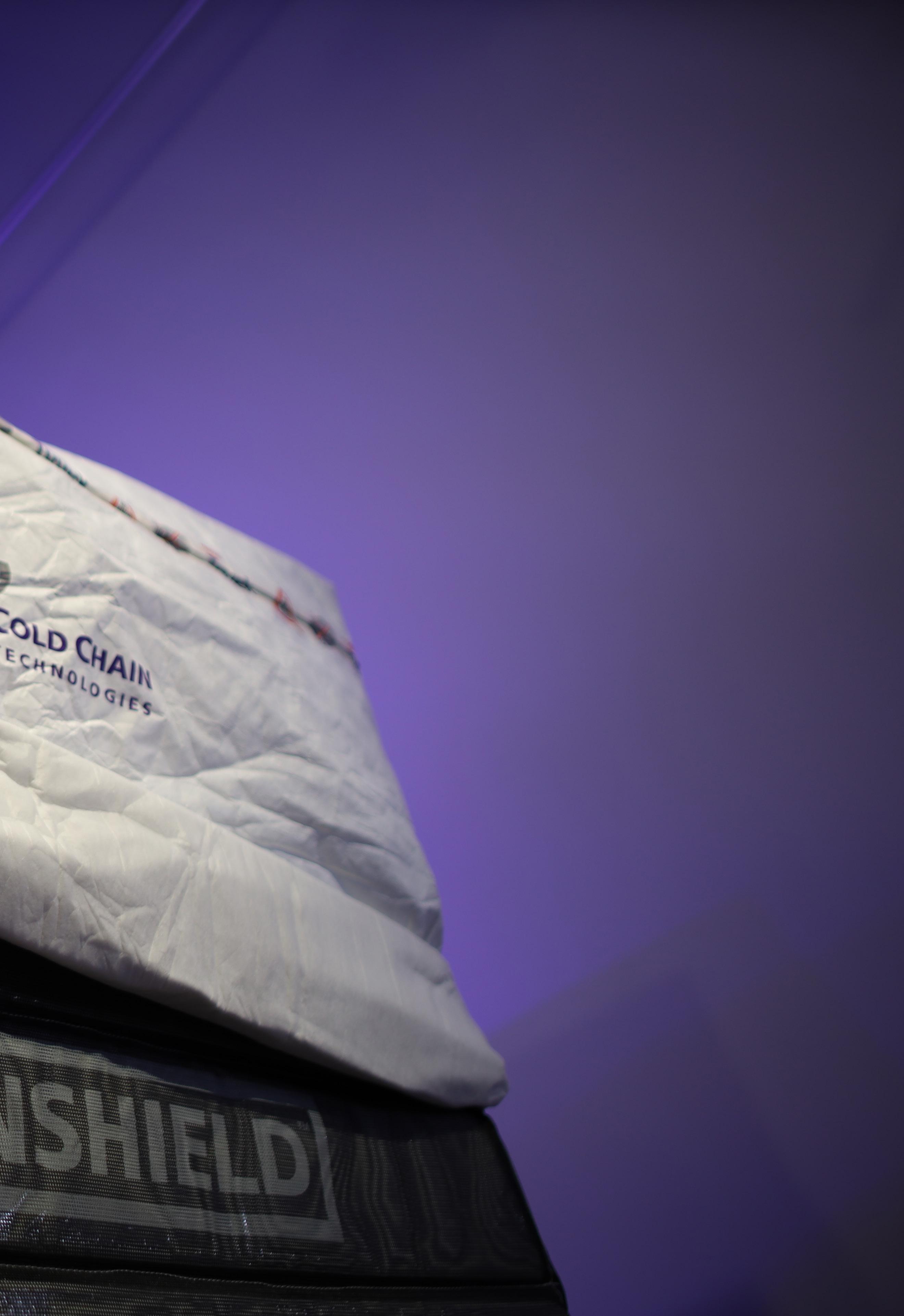

emphasizes how the company not only produces cuttingedge packaging for transporting biopharmaceuticals and vaccines but also plays a pivotal role in saving lives by ensuring the safe and effective delivery of vital drugs

Writer: Rachel Carr | Project Manager: Michael Sommerfield

The US boasts the world’s largest pharmaceuticals market, with more leading companies than any other country.

The drug industry is supported by a robust pharma services sector, which includes packaging manufacturers.

The BioTech, pharmaceutical, and medical technology industries are experiencing significant growth in the healthcare sector. Therefore, specialized transportation methods, advanced thermal packaging, and digital monitoring solutions are vital to maintaining the efficacy and safety of pharmaceuticals and vaccines globally.

Crucial to a delivery network of lifesaving care from the doors of specialty pharmacies, life sciences distributors, and manufacturers to patients is Cold Chain Technologies (CCT).

Pharmaceuticals must be transported under controlled conditions and temperatures, which is where CCT’s products, services, and digital solutions come in.

“We played a significant role in developing thermal packaging for the global transportation of the mRNA COVID-19 vaccine. In addition, we now provide this service for a broader range of biopharmaceuticals,” opens Ranjeet Banerjee, CEO.

Headquartered in Franklin near Boston, Massachusetts, and operating for over five decades, CCT has focused on driving innovative life sciences solutions and products for the last 25 years.

“We have multiple ISO-certified locations, including manufacturing facilities, distribution centres, and offices in the US, Europe, Latin America, and Asia,” Banerjee adds.

The team at CCT partners with customers to understand problems and potential challenges and they collaboratively select the appropriate packaging solution tailored to their needs.

“We provide two options: a comprehensive portfolio of existing products, or, as we have the capabilities to do so, we can

On a journey to become the trusted knowledge partner for life sciences customers, CCT offers expertise in products and services, understands its clients’ needs, and delivers comprehensive solutions to address those needs.

“It is challenging to maintain every individual product at a specific temperature, as there are millions of shipments happening around the world and each one has to be delivered while meeting the right conditions.

“If that fails, not only are millions of dollars at stake but more importantly, someone’s life could be at risk. A key motto at CCT is “Our Work Matters”, Banerjee points out.

CCT prides in being a trusted and knowledgeable partner through advanced products, services, and global presence. It strives to be the top choice for customers by leveraging its expertise in collaboration with companies that excel in drug development.

“We specialize in ensuring that drugs are maintained under the right conditions to the very end. As someone said during the COVID-19 pandemic, having a vaccine available is not the same as being vaccinated, because the entire endto-end process, from factory to patient or recipient, needs to have a high level of assurance,” he notes.

design something tailored to the needs of our strategic partners. Any product undergoes testing, and our customers will be provided the validation documents for quality and compliance purposes,” he elaborates.

Banerjee is excited about the global and complex aspects of supply chain trends and the new therapeutics in drug development are experiencing significant innovation.

“Biopharmaceuticals, such as vaccines, antibody drugs, and cell and gene therapy, are large-molecule formulations that require special temperature monitoring and control during transportation.

“Companies can excel in drug development and manufacturing, but if the transportation isn’t handled properly, the drugs could lose their efficacy and safety, which impacts patient outcomes – this is where we come in,” Banerjee voices.

With many years of experience working with multiple large global pharmaceuticals, medical technology, and diagnostic companies and distributors worldwide, CCT offers its expertise through a comprehensive product portfolio and service as well as providing consulting expertise.

Through advanced product design and digital capabilities, CCT delivers high-quality solutions to track, trace, and predict, which can often prevent any temperature excursions before they occur.

“Ultimately, we aim to assure customers that the lifesaving vaccines and other pharmaceutical products transported in our advanced solutions are maintained under the precise conditions required throughout their journey from lab or plant to patient.”

Acutely aware of compromising patient safety, CCT ensures efficient deliveries through digital solutions for remote tracking, tracing, and monitoring with state-of-the-art

Empower your business with DaVinci’s cutting-edge sustainable packaging solutions tailored for the medical industry. Elevate your brand by partnering with us for expert design, precision automated manufacturing, and efficient delivery of sustainable packaging, parts, and components.

At DaVinci, we go beyond traditional engineering. Our team of experts brings a wealth of knowledge in raw materials, design, prototyping, testing, and validation to ensure your products not only meet but exceed industry standards. We pride ourselves on being your strategic ally in the pursuit of innovative and eco-friendly solutions.

Together, let’s revolutionize your products, reduce environmental impact, and boost your sales with the power of sustainable innovation.

Materials

• FDA compliant

• Sustainable

• Reusable/Recyclable

• Cost Effective Packaging Expertise

• 40 Years of Plastics Engineering Experience

• Automation

• Thermoforming

• Blow Molding

• Injection Molding

Customer Solutions

• Diagnostic Reservoirs

• Sterile Barrier Packaging

• Heat Seal Systems

• Contract Packaging

• Cold Chain Packaging

• Validation Services

Internet of Things (IoT) devices.

“Our data and digital tracking platforms go one step further by predicting issues such as interruptions in the supply chain and assist in decision making. For instance, if there is a delay in air freight, we can remotely detect it, which will lead to an alert, and that in turn could lead to an intervention if necessary,” explains Banerjee.

While technology can lead to substantial cost savings, Banerjee acknowledges that what is more important is the benefits of improving patient safety and driving better patient outcomes.

“According to an independent study,

$35 billion worth of pharmaceutical products are wasted yearly due to temperature fluctuations. Ensuring the safe administration of drugs and vaccines is a significant and challenging task as it involves transporting them from A to B and then to the recipient,” he shares.

With diverse core competencies and a broad portfolio of solutions, customers can confidently approach CCT with unique challenges.

“During the COVID-19 pandemic, a vaccine manufacturer approached us with a product that required

DID CCT’S ROLE IN THE COVID-19 PANDEMIC INCREASE ITS VISIBILITY WITHIN THE LIFE SCIENCES INDUSTRY?

Ranjeet Banerjee, CEO: “We have spent the past 25 years establishing trust in the healthcare sector; it is ingrained in our company culture to prioritize the well-being of our customers and the wider industry.

“We never cut corners, especially considering we transport life-saving drugs and vaccines. This trust has only continued to strengthen over the past four years as we supported the COVID-19 vaccine distribution, demonstrating the reliability and quality of our work during a crisis.

“We were featured in the national news and showcased on primetime television when the first shipments of the COVID-19 vaccine began. As a purpose-driven organization, our role served as a reminder that there is a patient at the end of everything we do.”

transportation at ultra-low temperatures. We collaborated with the company, leveraging our thermal design and engineering capabilities to solve the issue,” Banerjee reflects.

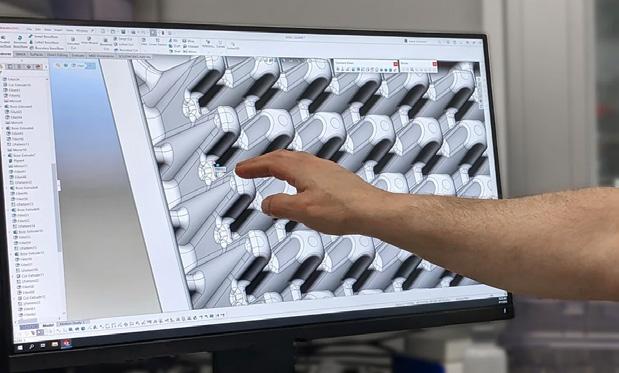

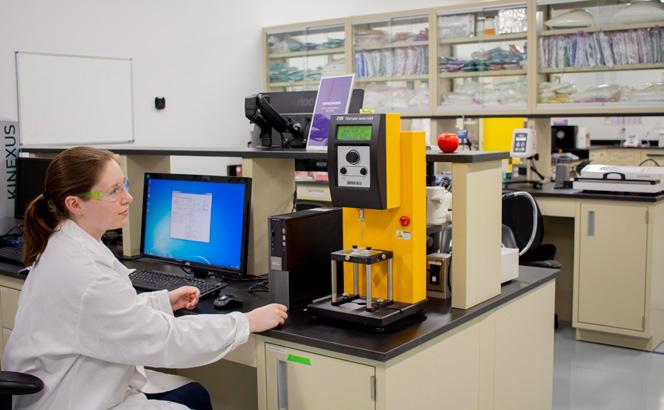

Another facet of CCT is its material science capabilities, including its proprietary phase-change materials (PCMs), a thermal energy storage and release technique.

The company utilizes cuttingedge insulations, and the interplay of thermal design and engineering ensures that the temperature is maintained for extended periods.

Subject to rigorous testing, CCT also adheres to industry standards to validate products.

“In our R&D centre near Boston, we operate one of the largest ISTA-certified testing laboratories for thermal packaging solutions worldwide. The reports from these tests are often included in regulatory submissions,” he notes.

Moreover, customers are continually supported during onboarding to ensure they use the products correctly. Additionally, digital tracking and optimization provide customers with package location updates.

“Even though carriers can provide package tracking information, what sets us apart is our ability to monitor temperatures accurately. We can also predict temperature excursions, offering a comprehensive range of capabilities from design and selection to manufacturing and tracking,” Banerjee emphasizes.

Addressing important challenges in manufacturing, CCT offers sustainable packaging solutions that also meet customer performance and cost requirements.

“Our extensive line of reusable products features EcoFlex™, a parcel shipping solution that includes a fully capable monitoring platform, allowing us to track and trace the location

of items and monitor the temperatures they are exposed to,” Banerjee enlightens.

The company took its first significant step towards sustainability four years ago when EcoFlex™ was extensively used for transporting the COVID-19 vaccine.

“We were a large part of the Operation Warp Speed program for the US federal government. The product is performing exceptionally well, and as a result, we have expanded our product line to include an ultra-low temperature range of -80°F,” he divulges.

“ULTIMATELY, WE AIM TO ASSURE CUSTOMERS THAT THE LIFESAVING VACCINES AND OTHER

PHARMACEUTICAL PRODUCTS TRANSPORTED IN OUR ADVANCED SOLUTIONS ARE MAINTAINED UNDER THE PRECISE CONDITIONS REQUIRED THROUGHOUT THEIR JOURNEY FROM LAB OR PLANT TO PATIENT”

– RANJEET BANERJEE, CEO, COLD CHAIN TECHNOLOGIES

Furthermore, CCT has the industry’s largest fleet for EcoFlex™, reducing fossil fuel-based raw material use through container reuse. The other element of sustainability is high-quality, high-performing, yet affordable

single-use sustainable products. Two years ago, CCT acquired Packaging Technology Group (PTG) and subsequently gained capabilities in using cellulose, a naturally occurring material, in thermal packaging.

Creating high-quality, highperforming insulation from cellulose, which can be transformed into singleuse packaging using automated programs, results in cost-effective products.

“We have successfully launched our cellulose-based eco-friendly packaging in Europe and the US,” states Banerjee.

The EcoFlex™ and cellulose packaging options both aim to provide customers with sustainable solutions. CCT also equips customers with data to support environmental benefit claims from using their products.

Continuing the development of sustainable products and reducing reliance on fossil fuel-based materials are two important goals for CCT.

“Initially, we wanted to avoid 50 million pounds (Ibs) of landfill by 2025, and we beat that ahead of time because our reusable products started taking off. We extended our goal to 75 million lbs, and now we are on track to eliminate 100 million lbs through sustainable products and solutions. We have the largest fleet, and as we keep growing, so do the sustainability benefits,” Banerjee explains.

Furthermore, CCT is excited about assuring customers with sophisticated digital solutions. Predicting an excursion and intervening before it happens is a powerful tool that the company can achieve through automated monitoring.

For more than five decades, DonahueCorry has been a trusted name in the packaging industry.

Our partnership with Cold Chain Technologies exemplifies our dedication to the pharmaceutical sector. Together, we provide cutting-edge flexible packaging solutions that guarantee the safe transport of critical pharmaceuticals, reflecting our unwavering commitment to quality and reliability.

495 Business Center

44 Central Street Berlin, MA 01503

+1 978-838-0255

Donahue-Corry.com

“WE NEVER CUT CORNERS, ESPECIALLY CONSIDERING WE TRANSPORT LIFE-SAVING DRUGS AND VACCINES”

– RANJEET BANERJEE, CEO, COLD CHAIN TECHNOLOGIES

“We are also incorporating decision support capabilities that can reduce waste in last-mile delivery, create value, and improve patient safety,” he points out.

This convergence of IoT and artificial intelligence (AI) in data sciences means CCT now collects and utilizes data from its packaging.

“Our packages transmit data – the ‘intelligent connective tissue’ across the last mile from manufacturer to patient. The information we receive from this can be used to support decision making,” outlines Banerjee.

CCT, therefore, uses data to minimize waste in the system,

enhance patient safety, and is planning to roll out intelligent applications on an ongoing basis.

The company continues to expand globally and is currently building another plant to complement its multiple locations in Europe, as well as the recent acquisition of a company in Europe.

“We recently established a new manufacturing facility in Breda, Netherlands, which is now up and running. Additionally, we are expanding our operations in São Paulo, Brazil – there is a lot of expansion occurring

within the pharmaceutical value chain worldwide,” concludes Banerjee.

Demonstrating a commitment to patients, CCT takes pride in addressing the unique challenges faced by the life sciences sector. Through innovative packaging technology, it ensures that products receive the correct care throughout the cold chain journey, thereby entrusting the future of healthcare to the vanguard of the manufacturing industry.

+1 (800) 370-8566