LEADERS IN DUST COLLECTION EQUIPMENT

We speak to executive members of renowned dust management solutions provider and equipment manufacturer, Grydale, about the company’s innovative equipment, sustainable operations, and continuous improvement

Writer: Rachel Carr | Project Manager: Eddie Clinton

Mines are busy environments that use heavy industrial equipment, often creating dust clouds.

As health and safety experts focus on protecting workers, the demand for dust control solutions is subsequently increasing. Many industries face harmful dust

caused by dangerous minerals such as asbestos and crystalline silica, which can be inhaled during activities like grinding, drilling, cutting, or sanding –this is where Grydale excels.

Established in 2011, the company specialises in engineering, manufacturing, and servicing a range of fixed, mobile, and onboard

industrial dust collection equipment.

Grydale’s patented technologies effectively control dust and airborne contaminants in a range of industrial applications, including tunnelling, mining, quarrying, and air quality management in factories.

“Thanks to our proprietary technology, Grydale’s dust collectors

have gained a reputation worldwide. They are transforming how dust extraction processes and ventilation design are approached across various industries and projects,” opens Alex de Andrade, CEO of Grydale.

The company distinguishes itself in the market with protected intellectual property that meets the

most stringent air quality standards mandated within major projects and has built a strong portfolio for fixed, mobile, and onboard dust solutions.

“This provides a significant and sustainable competitive advantage within the global dust control market,” adds General Manager of Sales, Adam Wallace.

The company is further looking to invest in independent air quality monitoring technology, providing certified evidence of air quality and filtration efficiencies as it maintains an unwavering commitment to continuous improvement and innovation to keep ahead of global air quality regulations.

“Our patented technology has allowed us to deliver solutions to dust challenges that were previously not possible. This, combined with our passionate team, supplier parts selection, and manufacturing and quality processes, are the attributes that truly set us apart in the market.

“We select and test the best available parts for our machines to have maximum uptime and this attests to the support we get from our longstanding suppliers on a 24-hour basis,” de Andrade prides.

The risk of dust-related diseases increases with exposure levels, therefore, workplace health and safety legislation now requires strict dust management and diesel particulate matter (DPM) control through permissible exposure limits (PEL) and workplace exposure limits (WEL).

Regulations are periodically reviewed and updated to reflect current scientific evidence linking exposure to disease.

“Our dedicated engineers and artisans are committed to continuous improvement, with a strong focus on eliminating waste and minimising safety risks,” urges de Andrade.

Silicosis is the most common occupational lung disease worldwide and is often referred to as the modern-day asbestos.

“By adopting Grydale’s advanced dust control methods, companies can protect their workers, comply with regulations, and enhance overall operational efficiency,” de Andrade suggests.

Grydale is rapidly building a robust reputation for driving up industry standards with its safe and efficient dust extractors as accountability and compliance regulations relating to health and safety within the

construction industry are continually tightened.

The extremely high safety standards set by the company extend to its own team, who are willing to enact the exact level of caution for co-workers, family, and friends, as well as the next generation.

“With our dedication to ISO 14001 compliance, we handle the washing of our machines and returned rental units with the utmost care. The same way we protect the operators servicing our machines from any exposure, we do likewise for the environment and neighbours,” de Andrade assures.

Grydale believes there is always a safer and cleaner way of doing any task, accordingly, it retains all washed water and slurry in contained bunded areas and recycling tanks, disposing of the contents through certified waste handling companies.

“OUR INTELLECTUAL PROPERTY IS PATENTPROTECTED AND MANUFACTURED WITH THE HIGHEST QUALITY CONTROL STANDARDS AND THE BEST COMPONENTRY FOR EACH APPLICATION”

– ALEX DE ANDRADE, CEO, GRYDALE

“There is no compromise for protecting the most amazing part of the country around us in the Moreton Bay region,” de Andrade affirms.

Employees are drawn to Grydale’s strong culture and ethical principles, which prioritise safety by eliminating risks and providing a safe working environment.

The company currently has staff across Australia, the US, and Canada, with service contractors and spare parts also in the UK, New Zealand, and Saudi Arabia. It also has plans

to expand its consignment and field support within the UAE, Hong Kong, and Europe.

“Our dedicated field service technicians work closely with clients to provide routine and preventative maintenance schedules, ensuring maximum machine uptime and optimising our solutions’ operational efficiency,” shares Jamie Baskett, General Manager of Field Service.

“We understand that dust control solutions are often critical parts of operations, so our service team works closely with our warehouse and procurement teams to ensure stock of

essential spare parts and service items is available to our customer base when required as part of our worldclass customer and service support.”

To enable efficient and timely operations, Grydale’s team utilises advanced, state-of-the-art equipment.

“Our in-house team of engineers and designers use advanced 5D building information modelling (BIM) and computer-aided design (CAD) with material property metadata, integrated into our enterprise resource planning (ERP) procurement system, to create bills of materials and drawings for production,” de Andrade expands.

As Grydale transitions from a 15-year-old family-owned business to a shareholder-owned entity with an investment for steady longterm growth, some manufacturing workflow changes have been necessary to meet customer demands and lift the service deliverables in full and on time.

A.T. Hydraulics Pty Ltd is an Australian owned company established in 1990 to service the Australian fluid power market. With branches located in Sydney, Perth and South of Brisbane the company is well situated to offer servicing and support for the entire Australian market on its range of exclusive products.

All our factories are well equipped with full machining and service facilities backed by our highly qualifed sales, workshop and engineering staff. Whether you need components, repairs, service or an entire hydraulic system, we can deliver. We are dedicated in providing complete customer satisfaction. With our exclusive product ranges and distribution of some of the world’s leading brands we can offer our customers a single source of hydraulics.

At A.T. Hydraulics, we specialise in delivering complete hydraulic solutions tailored to your project’s unique needs. From initial design through to fabrication, installation, and commissioning, we ensure your hydraulic systems are powered, optimized, and ready for peak performance. With years of expertise across a broad range of industries, we are proud to provide high-quality hydraulic power packs designed to meet the demands of the most diverse sectors.

Our Expertise in Hydraulic Power Packs

Whether you need a simple,

compact unit for a small-scale application or a complex, heavy-duty system for industrial use, A.T. Hydraulics offers comprehensive hydraulic power packs for a wide range of sectors. Our custom-designed systems ensure efficiency, reliability, and flexibility, no matter the scope of your project.

Industries We Serve: Manufacturing & Industrial Automation

Hydraulic power packs are essential for industries relying on automation and heavy machinery. We design systems that integrate seamlessly with manufacturing processes to

improve productivity, precision, and consistency. Whether it’s for assembly lines, presses, or conveyors, our solutions deliver the power you need for highdemand operations.

The mining industry requires robust, high-performance hydraulic systems for demanding environments. Our power packs are built to withstand extreme conditions, offering reliable operation in mobile equipment, drilling rigs, excavators, and more. A.T. Hydraulics ensures your mining equipment operates smoothly under even the most challenging circumstances.

Hydraulic systems are crucial in the construction industry, driving cranes, excavators, and pile drivers. A.T. Hydraulics designs durable, efficient power packs tailored for the construction sector, ensuring that your equipment is reliable and ready for use at any project site, from small builds to largescale infrastructure projects.

In the oil and gas sector, hydraulic power packs are pivotal for offshore platforms, drilling operations, and refining equipment. We design high-performance,

corrosion-resistant systems that meet the industry’s strict standards for safety, reliability, and efficiency, ensuring that critical operations can continue uninterrupted.

Hydraulic power packs play a vital role in modern farming, powering machinery such as harvesters, planters, and irrigation systems. Our designs are focused on providing reliable, cost-effective systems to support efficient farming practices and maximize productivity.

From vessel deck machinery to offshore rigs, hydraulic systems are indispensable in the marine industry. A.T. Hydraulics engineers power packs designed for extreme marine environments, offering exceptional durability and performance for ship lifts, winches, and other essential systems.

Automotive & Transport

Hydraulic systems are widely used in the automotive industry for tasks such as testing equipment, jacking systems, and vehicle lifts. We provide power packs that ensure smooth, efficient operation for both production lines and repair facilities, optimizing workflows across automotive operations.

Our hydraulic power packs are also designed for use in power plants, utility services, and renewable energy projects. Whether it’s for turbine maintenance, energy storage systems, or hydraulic dampers, we supply high-efficiency solutions that support the stable operation of critical infrastructure.

Why Choose A.T. Hydraulics?

Tailored Design: We work closely with you to understand your specific requirements, ensuring each hydraulic power pack is custom-designed to meet your unique needs.

Precision Engineering: Our systems are designed for optimal performance, energy efficiency, and long-term durability.

End-to-End Service: From consultation to design, fabrication, and final commissioning, A.T. Hydraulics provides a comprehensive service to ensure smooth project execution.

Expert Installation & Commissioning: Our experienced technicians handle every aspect of installation and commissioning, ensuring that your hydraulic power pack functions at its best from day one.

Quality Assurance: We only use premium materials and components, and all our systems undergo rigorous testing to guarantee reliability and performance.

Whether you’re working on a large-scale industrial project or need a compact solution for specialized equipment, A.T. Hydraulics is here to provide the hydraulic power packs you need. Contact us today to discuss your requirements and how we can help streamline your hydraulic operations.

Sydney 1300 760 531

Brisbane 1300 760 531

Perth 1300 760 531

Under challenging product specifications, the founding team and owner moved the company forward to a formidable original equipment manufacturer (OEM) brand that has proven itself in the market.

“Our shift to a multi-national structure aims to build a foundation for scalable growth whilst retaining agility. As a result, the focus moves from completing individual projects on schedule to a global model prioritising quality, consistency, and delivery on time,” acknowledges de Andrade.

Each machine must fundamentally be a replica of the one before it so that simultaneous, consistent technical support is possible on all machines worldwide.

“When customers request spare parts or performance support, we must ensure the as-built status and accuracy of the parts book, manuals, maintenance procedures, and troubleshooting guides cater for

MINING OUTLOOK: HOW DOES GRYDALE INCORPORATE SUSTAINABILITY INTO ITS OPERATIONS?

Andy Greenslade, COO: “In an era prioritising environmental responsibility, Grydale has earned ISO 14001 environmental standard accreditation, showcasing its commitment to sustainability. ISO 14001 is a globally recognised environmental management system that enables organisations to enhance their environmental performance through efficient resource use and waste reduction.

“Our dust extraction equipment tackles significant dust emissions in construction, mining, and manufacturing industries. Dust is managed at the source, improving air quality and ensuring safety compliance.

“We focus on energy efficiency and recyclable materials, helping clients meet sustainability goals whilst reducing their carbon footprint. Partnering with us enables clients to navigate environmental regulations and enhance their reputation and business opportunities.

“The company recognises aligning operations with global environmental standards is vital for fostering a sustainable future. Grydale’s focus on continuous improvement, staff training, and stakeholder engagement ensures that ecological considerations are integral to its business strategy. As organisations seek to meet carbon reduction commitments, our ISO 14001 certification reflects our dedication to environmental stewardship and contributes to a cleaner, safer planet for future generations.”

global supply equivalent parts but sourced locally.

“Our business model ensures that field service teams or local contractors are available in-country, maintaining strong face-to-face interactions and relationships, with routine monthly inspections of our rental fleet,” de Andrade notes.

Grydale is committed to developing people skills and succession as it grows, creating more opportunities for its employees.

In addition to apprenticeship and graduate programmes, Grydale offers advanced leadership training and sponsored tertiary education support for key roles like technical degrees and Master of Business Administration (MBA) programmes to improve service quality through training and retention.

“We are testing productivity and efficiency for four-day roster work

weeks in certain divisions, empowering a culture of completing the job correctly the first time and enabling us to try new rosters and lifestyle approaches,” de Andrade delights.

Grydale’s team ensures complete control over the design and manufacturing of dust control solutions, exceeding performance, safety, and environmental standards to create leading products in the market.

“Our approach involves customers in the process, which is beneficial. Engaging a multi-disciplined team in the design has often led to new ideas and allowed us to push the boundaries of what is possible,” Wallace insights.

The team aims to understand the holistic dust control challenge by

communicating with customers, visiting sites, exchanging documents, and evaluating key factors such as dust type, particle size, air volume, and industrial processes.

“Input from stakeholders, including project, plant, and operations managers, health and safety officers, and procurement teams, is essential. Their insights help us define project goals and find effective solutions, making every team member a vital part of the process,” Wallace emphasises.

Production begins when designs are finalised, with the company using a triple ISO certification platform, namely ISO 9001 Quality, 14001 Environment and 45001 Safety accredited quality control process.

Utilising LEAN principles and semiautomation, the company produces both standard and customised equipment, achieving a 94 percent on-time delivery rate.

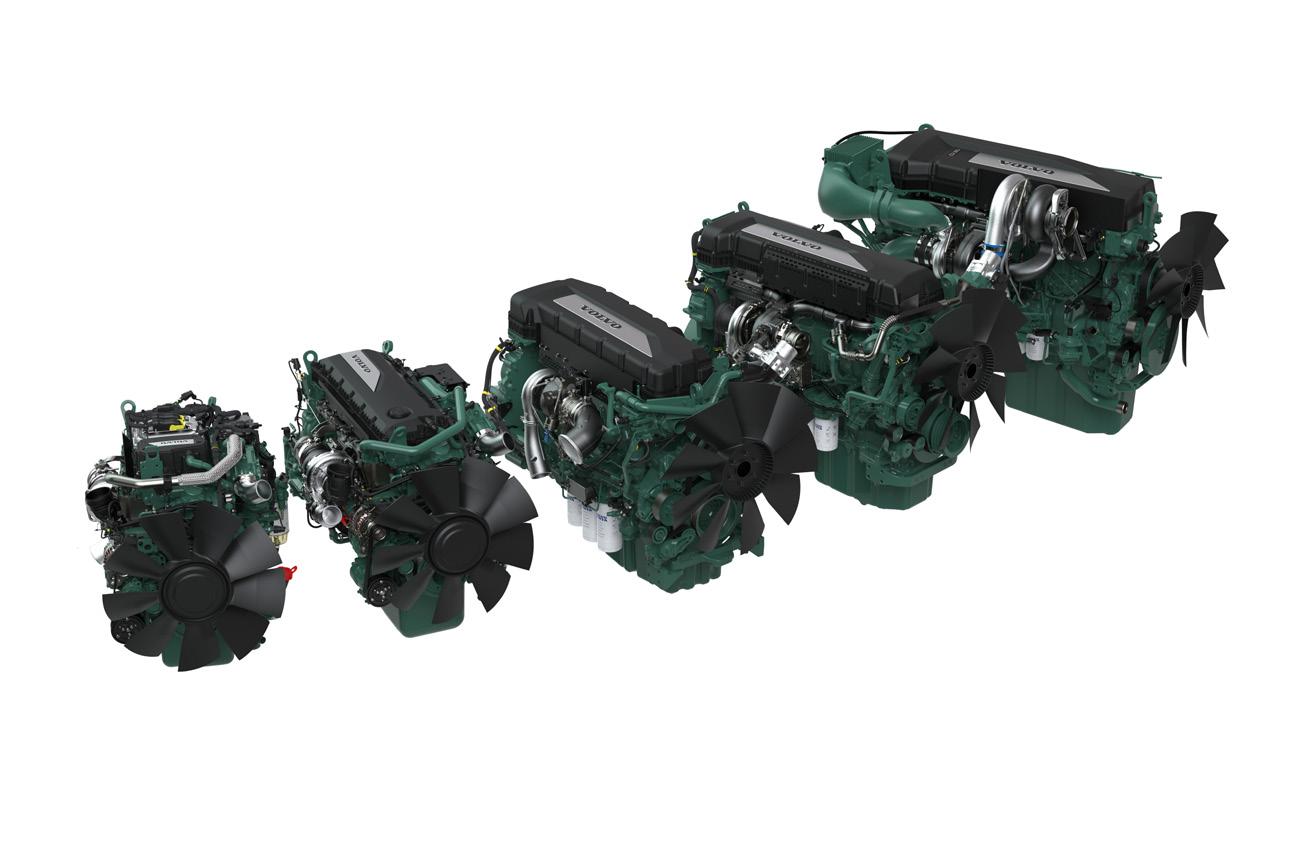

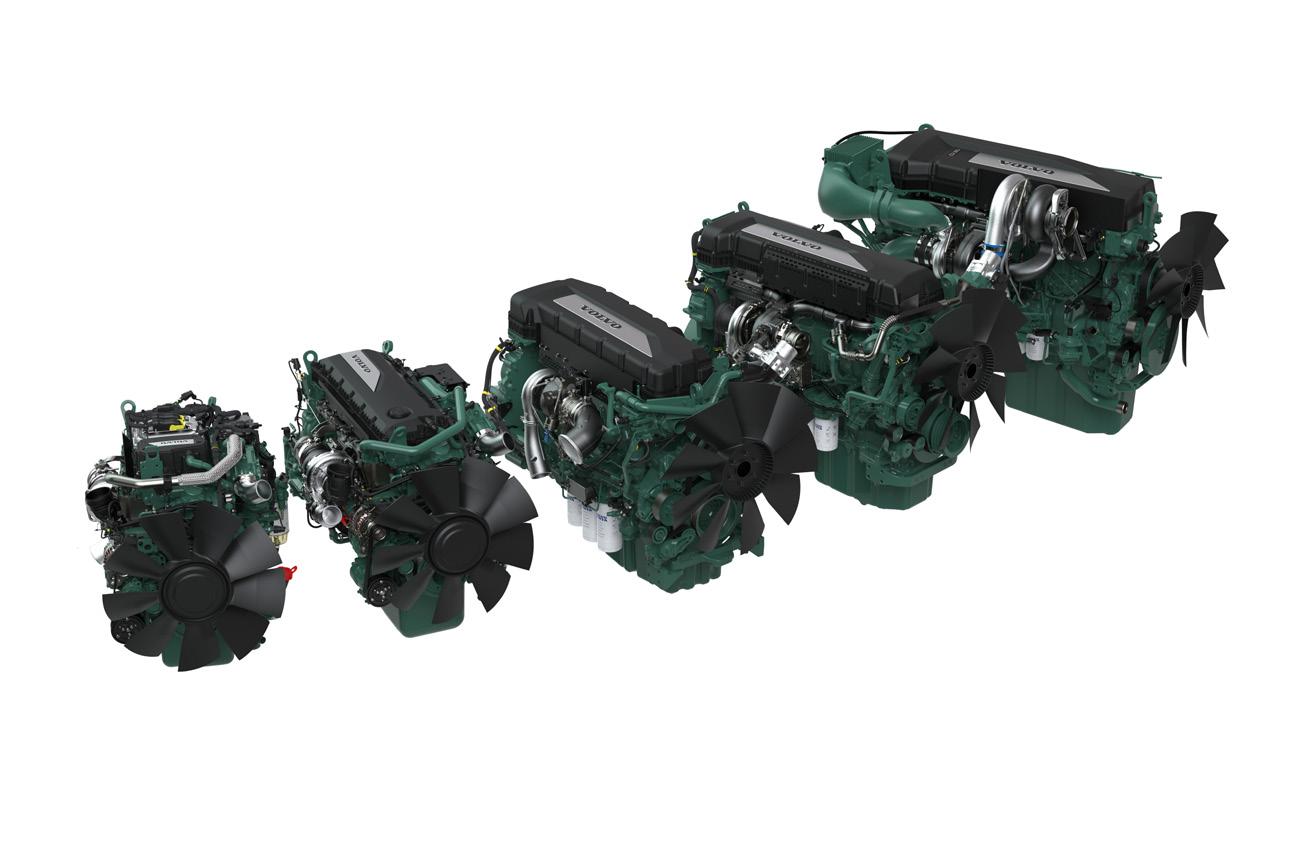

At Volvo Penta, powerful industrial solutions and strong partnerships drive success. From optimizing your application to providing global dealer support, we are committed to assisting you. With cutting-edge technology shared across the entire Volvo Group, our innovations are shaping the future of industrial power systems.

Volvo Penta’s engines deliver high

performance, are powerful and reliable, and are fuel efficient. Designed for versatility, they feature a low-weight, compact design for easy installation, and with optional equipment packages making them ideal for a wide range of machine and equipment applications and industries. Our engines power applications in construction, agriculture, underground mining, dewatering, port handling, drilling, crushing, and power generation, ensuring dependable performance in demanding environments.

Volvo Penta’s off-road diesel engines can be configured as either stand-alone units or mounted on robust base frames in a power pack configuration, featuring our renowned heavy-duty cooling packs and high-dust intake systems, complimented with an extensive offering of accessories including power take-offs, air-conditioning, and air compressors. Our impressive compliment of engine models ranging from 105 to 585 kW / 140 to 785 hp - this makes our engines the perfect fit for your industrial power application.

Volvo Penta is dedicated to meeting and exceeding global emissions standards, ensuring you a power solution which is compliant with global emissions regulations. Our engines share a common base platform and are certified for hydrotreated vegetable oil (HVO) fuel. Volvo Penta also offers dualfuel engines capable of running on a mix of 80% Hydrogen / 20% Diesel and we continue to explore renewable fuel options, including natural gas and 100% Hydrogen.

Beyond traditional combustion engines, Volvo Penta is pioneering with innovative electric driveline technology for the diverse and evolving needs of industries. Leveraging Volvo Groups proven expertise, we have successfully integrated electric solutions into a variety of industrial applications.

Our Battery Energy Storage System (BESS) leads the market - enhancing energy reliability and sustainability by storing surplus electricity, often from renewable sources of wind and solar, providing a solution for backup power or cost optimization.

Volvo Penta diesel engines are designed to maximise uptime and productivity, safeguarding operations the world over. Our reliability and performance ensuring your operation can deliver. Paired with our extensive aftermarket support, we keep your business running day in, day out.

In Australia, our global parts distribution network and over 65 dedicated Service

Dealers ensure around-the-clock service. Operators benefit from extended service intervals of up to 1,000 hours and are backed by Volvo Penta’s comprehensive engine and parts warranties.

Volvo Penta’s Australian distributors are trusted sales, service, and support partners.

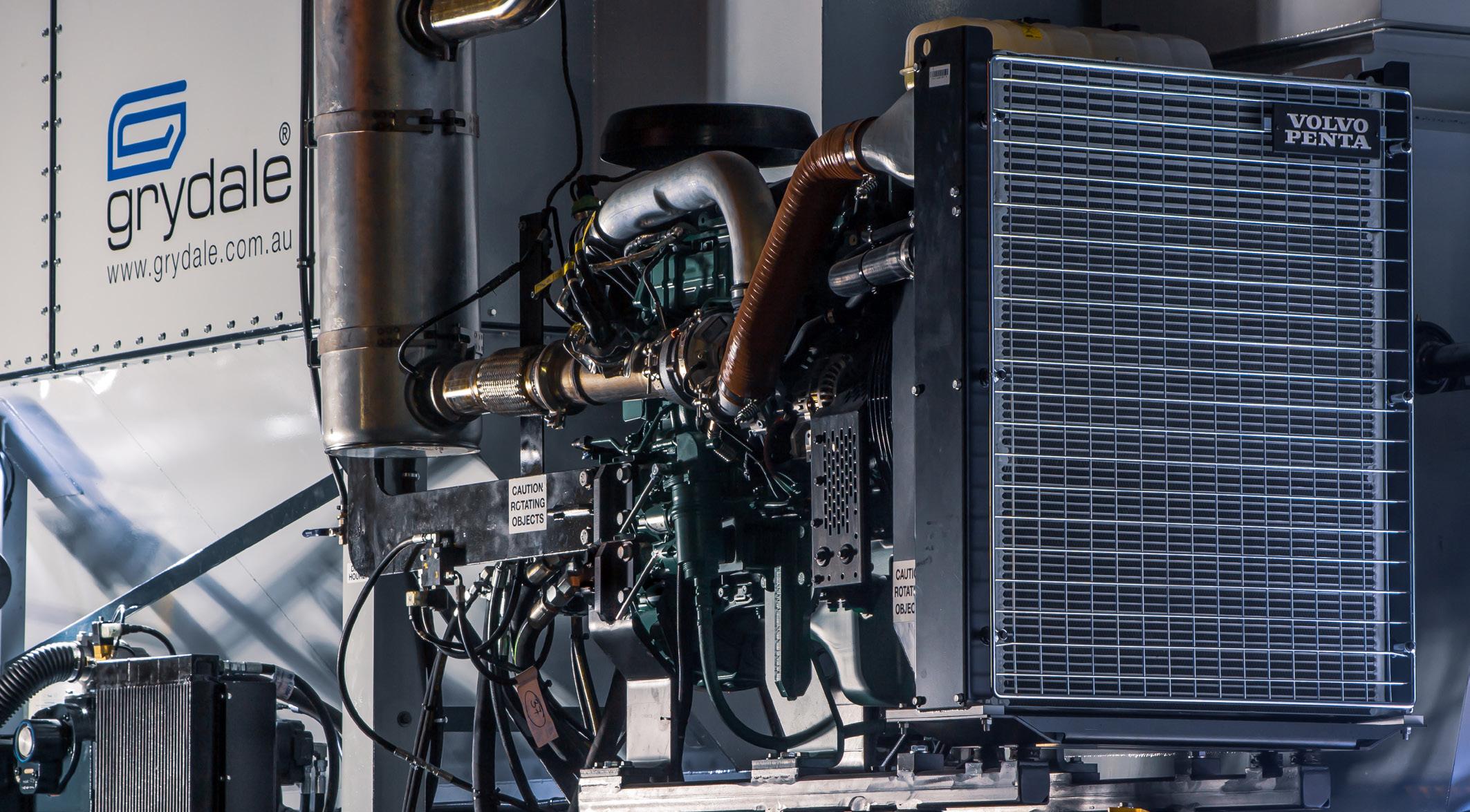

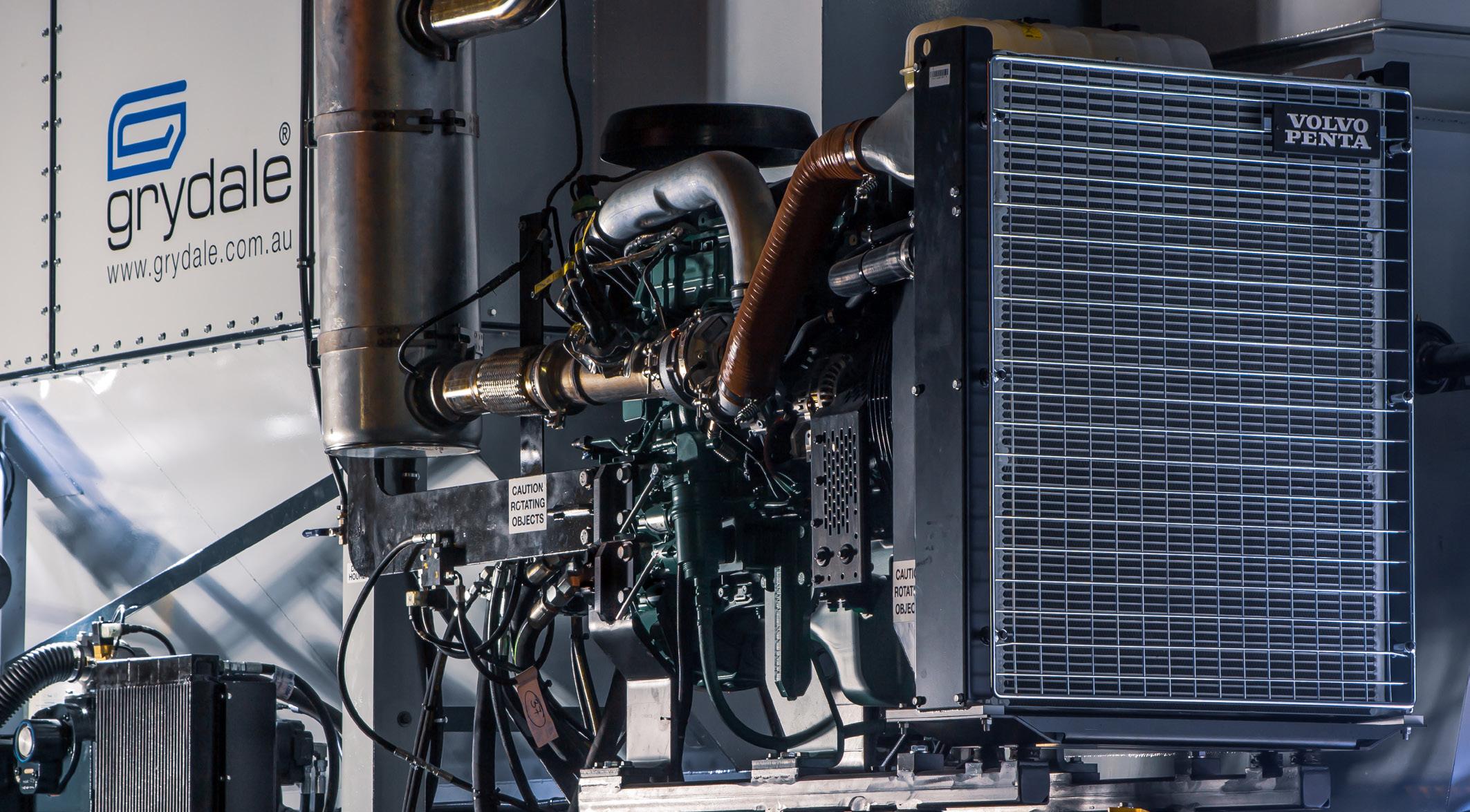

In Queensland, the Distributor Seamech has partnered with Grydale, Australia’s leading manufacturer of dust collectors and ventilation systems. Grydale required a heavy-duty engine that met stringent Tier 4 Final emissions standards. Through the collaboration with Seamech, Grydale became the first Australian machinery manufacturer to integrate Volvo Penta’s Tier 4 emission-reducing engines in local machinery production.

This successful partnership between Grydale and Seamech has resulted in nearly 100 locally produced machines equipped with Volvo Penta engines. Seamech continues to support Grydale’s operations with access to diagnostic tooling, extensive parts inventory, and 24/7 support.

In neighbouring New South Wales, the Distributor Fenquin has partnered with Jacon Equipment, a leading manufacturer of underground mining and construction equipment. Jacon now offers Volvo Penta’s 8-litre 235kw Tier 4 final engines in its MaxiJet, WaterJet, and JSV3 vehicles.

As a leading global supplier of

underground mining engines, Volvo Penta’s strong presence and experience with global OEMs in these harsh environments provided Grydale and Jacon with confidence in their chosen engine solution. This was particularly important considering the extreme conditions, with high dust, heat, and difficult access often endured by their machinery.

Volvo Penta’s heavy-duty engines proved the perfect match.

Volvo Penta’s Australian distributors are committed to partnering to power your business. From project inception to operation, our in-house application support, technical expertise and industry experience ensure the right engine for your needs, backed by unparalleled, dependable local

support for you, your business, and your customer.

For more information or to find your nearest dealer, visit volvopenta.com.

Queensland: Seamech (07) 3890 7615 www.seamech.com.au

New South Wales: Fenquin (02) 9605 5522 www.fenquin.com.au

Victoria: Industrial Power Systems (03) 8353 0400 www.industrialpowersystems.com.au

South Australia: Don Morton (08) 8347 0011 www.donmorton.com.au

Western Australia: Ches Power Group (08) 6144 3111

www.chespower.com.au

“Our fabrication facility has its own world-class laser cutting, bending, and pressing machines, which allow us to be in control of quality and reduce manufacturing lead times,” de Andrade elaborates.

In-process inspections and tests are performed at each stage of the manufacturing cycle, ensuring adherence to specifications and reliable final designs.

“After installation, performance is monitored when equipment is operating and feedback is sought from site personnel to optimise the solution further and inform future improvements, fostering a cycle of continuous innovation,” outlines Andy Greenslade, COO.

Grydale also has a fleet of rental equipment, which has opened up new market opportunities where there are short-term or temporary dust control requirements. Rental equipment has also supported major infrastructure projects with out-of-sequence and subcontracted temporary works.

“There should be no reason why an employer isn’t trying out our gear for a one-to-three-month rental trial and obtaining feedback from their work crew as to how much safer they felt the air quality was when they

were alongside a Grydale machine,” acclaims de Andrade.

Grydale developed a patented, trackmounted mobile dust collector initially for underground use, enhancing efficiency in tunnel construction and transforming ventilation and excavation methods.

Dust collector supply contracts in Australia quickly followed, with major contracts for Melbourne Metro, WestConnex Stage 3A and 3B.

In 2021, over 100 units operated underground for ventilation and dust control during tunnel excavation. Recently, they have also been used in major projects such as City Rail Link (CRL) in Auckland, Sydney Metro Central Station, HS2 in the UK, Neom in Saudi Arabia, the Western Sydney Airport Tunnel, M6 in Sydney, and Northeast Link in Melbourne.

Grydale has additionally worked on significant projects within the mining, quarrying, abrasive blasting, and ship loading industries.

The Melbourne Metro Tunnel project posed significant challenges for the ventilation design, such as space and noise constraints. However, Grydale overcame these by using

Ventsim Design 5.0 to simulate ventilation, airflows, pressures, heat, gases, radon, fire, and other critical factors.

The company’s approach was to implement an alternative ventilation design, using a full extract ventilation model, with dust collectors operating on the surface during the excavation of underground stations. This led to the design and manufacture of the largest airflow mobile dust collector available on the market – 60m3/s, 125,000 cubic feet per minute (CFM).

Elsewhere, Australia’s largest public transport project Sydney Metro, in the country’s most populous city, is expanding its network and increasing the frequency of trains. The upgrade of Central Station incorporated Grydale’s JMS-50-MES dust collector for ventilation and dust control during excavation works.

CRL, meanwhile, is New Zealand’s first underground rail line and largest transport infrastructure project.

FIXED UNIT DUST COLLECTORS – JMS F-SERIES: This cost-effective solution controls dust, efficiently handling high-volume dust loads. Its modular design allows for flexible sizing based on airflow requirements. The engineering team uses site drawings to determine airflow needs and design the ducting for an effective dust control solution.

CUSTOM ONBOARD UNITS – Using the company’s expertise in dust control, Grydale has developed and patented a range of onboard dust control solutions for excavation equipment, including surface miners, large track trenchers, skid steers, and posi-track loaders.

The onboard dust control solutions are effective for dealing with residual dust and debris and offer a fuel, emissions, and labour-efficient solution when space constraints prevent using a trail-behind dust system.

Skid-mounted dust collection units are ideal for static dust generation scenarios. In contrast, internationally patented track-mounted units offer mobility, allowing them to move with dust generation processes or be used temporarily.

These track-mounted dust collectors are easy to transport and operate with minimal setup, eliminating the need for costly ducting. Powered by a diesel motor, they don’t require an external power supply, making it easy to relocate them during operation alongside dust-generating equipment. In addition, hybrid-powered track units support environmental and sustainability agendas.

Grydale designed a ventilation system for Karangahape Road, one of the main streets in the central business district (CBD) of Auckland, that uses negative pressure to draw air through the tunnel and expel it via ducting to the JMS-60-MES dust collector.

“We are also supplying units for the North-East Link tunnelling project in Victoria, including the JMS-60-MES with 1,000-volt harmonics and the JMS-30-MHT dust collectors. These solutions offer significant advantages for our customers and enhance our market position,” Wallace adds.

Grydale dust collectors have also provided effective dust control during major mine shutdown works, including demolition and relining of calciners and furnaces.

The use of dust collectors has helped to provide a clean and safe working environment for contractors and generate operational efficiencies. This approach is now being cited as industry best practice.

Grydale’s JMS M-Series of mobile dust collectors range in airflow from 12,000 CFM to 125,000 CFM and are available as diesel, electric, or hybrid solutions.

1. Air is pulled through the dirty air intake by the centrifugal fan.

2. Larger dust particles are separated from the air stream.

3. Dust is trapped on the filters, forming a cake on the surface as air passes through the filter house.

4. Reverse pulse filter cleaning system cleans the filters.

5. Dust particles are discharged from the machine via the augers and rotary valves.

6. The velocity probe monitors air speed and turns the centrifugal fan up or down to maintain air volume.

7. Clean air exhausts from the machine with a filtration efficiency compliant with international regulations.

Currently, Grydale has 16 units working in the Neom Tunnels in Saudi Arabia and is finalising a distributor agreement to provide additional local support for existing units operating and future sales into the UAE.

“This partnership will provide us with local sales, service, and support staff in a key growth region, where dust control regulations are rising in response to growing health, safety, and environmental concerns,” de Andrade assures.

The global tunnel construction market will continue to be a major focus for Grydale, complemented by its work in the mining sector in Australia and North America.

“To support our expanding customer base in Western Australia, we are selecting a location for a field service centre in the region. Facilities will hold consignment stock and inventory to provide spare parts and

rental equipment to better service the region,” de Andrade continues.

In 2023, Grydale focused on diversifying its equipment for deeper mining applications by upgrading its CAD system and design database.

This allows machinery, such as laser cutting and bending equipment, to operate directly from CAD files, improving change management efficiency.

Grydale has also introduced a Remote Monitoring Service that provides access to key data on machines worldwide. This service helps customers and our team to ensure equipment is operating efficiently and optimised to maximise dust collection efficiency and machine up-time.

“At the same time, customers can use these parameters and reports for predictive maintenance, finding

“PARTNERING WITH GRYDALE OFFERS CLIENTS ADVANTAGES IN NAVIGATING STRINGENT ENVIRONMENTAL REGULATIONS AND ENHANCES THEIR REPUTATION AND BUSINESS OPPORTUNITIES

– ANDY GREENSLADE, COO, GRYDALE

faults, and keeping machines at optimal performance. In mid-2025, we will offer hands-on onboarding for operators using our equipment for the first time,” de Andrade reveals.

The second area of innovation is onboard dust control systems, where a kit is designed, manufactured, and tested by Grydale in collaboration with the customer or the OEM.

“The on-board systems reduce the need for an additional dust control unit to operate onsite,” de Andrade sets out.

The company is working with four partners on repeat business for skid

steers, and surface miners and large track trenchers.

“The onboard dust control solution for skid steers to manage dust when sweeping areas with silica sands is a game-changer,” declares de Andrade.

Alongside a two-year strategy to build a solid foundation for future growth, Grydale’s long-term plan is to expand and support loyal customers in North America and Western Australia.

“We have successfully increased production throughput capacity at world-class quality standards and have been acknowledged with our

triple ISO accreditation for those efforts.

“Our goal is to raise awareness of health and safety concerning dust and harmful respirable levels. By working with key industry sectors, we aim to create safer work environments, to allow people to return home safely and enjoy their jobs.

www.grydale.com.au