72 minute read

Exmar Offshore Company

MAKE IT IMPACTFUL. MAKE IT BETTER. MAKE IT INSPIRING. MAKE IT LAST. MAKE IT POWERFUL.

& WE MAKE IT WORK RIGHT THE FIRST TIME. WWW.GATE.ENERGY

on the shipping side of the wider company, Exmar Offshore specialises in the assembly, leasing, operation, and maintenance of company designed semisubmersible drilling and production platforms.

OPTI® – AN INDUSTRY STANDARD-SETTER

The company has a long history of working in offshore. It was generally focused on industry floating solutions but specifically dealt with drilling and production, and in 2006 the firm took a bold move and built the OPTI-EX™ production submersible – the first Exmar OPTI® design to enter the industry.

“Exmar Offshore Company has a reputation for efficiency and in these times its practical and lower cost solutions receive the greatest attention,” Cotaya says. “The OPTI® production semisubmersible was

OPTI® KEY FEATURES

MOTIONS: The design includes a proprietary multi-sided column which reduces drag forces, leading to lower mooring forces and negligible VIM. The proprietary ring pontoon shape, featuring surfaces outboard of the columns, reducing heave motions. Combined, these features result in motions suitable for both SCRs and flexibles and minimised mooring equipment requirements.

CONSTRUCTABILITY: The form of the hull is designed to reduce motions; the hull structure is designed to simplify construction. Minimal structural shapes, thicknesses, and steel material grades are selected to reduce fabrication costs and improve shipyard efficiency. A truss structure with a flat upper deck allows for modular equipment skids to be integrated near-ground level in a flexible sequence, while the spacious lower deck accommodates further equipment as needed.

SCALABILITY: The hull form and deck truss fit a broad selection of global fabricator capabilities. The structurally repeatable columns, pontoons, and nodes allow for both easy repetition across projects and are easy scalability. The large, flat deck facilitates the removal or modification of modules with minimal impact.

Bexco

A leading producer of ultra-deepwater mooring rope in the Gulf of Mexico

BEXCO has decades of expertise and knowhow in designing and manufacturing its reliable, made-tomeasure synthetic ultra-deepwater mooring solution for full production systems in the Gulf of Mexico.

DeepRope® has been installed and operational on the DELTAHOUSE OPTI® Floating Production System since 2014 and is proudly awaiting its delivered DeepRope® reels to be installed on the King’s Quay Floating Production System (FPS).

Both of these utilizes EXMAR Offshore´s unique OPTI® semisubmersible design, making it the scalable GOM standard for specialised independent energy companies dedicated to oil and natural gas development and exploration.

From the pre-FEED to project management, installation and support, BEXCO´s expert engineers are on hand to partner with all stakeholders to deliver its proven DeepRope® solution in the field.

The Exmar OPTI-EX® production semisubmersible en route to LLOG’s Who Dat development

www.bexco.be

conceived nearly 20 years ago as a standard, scalable and low-cost solution for deep-water production.”

The firm’s activities are historically grounded in naval architecture and structural engineering. On top of this, it houses decades of experience and knowledge in related fields such as production and marine systems. Seen as a reliable, dependable partner, it is this reputation which has kept the company buoyant in challenging times.

Indeed, Exmar’s OPTI® is a standout in the oil and gas industry. Conceived two decades ago, it is a proven and accepted deep water development solution – the semisubmersible hull design platform is revolutionary within a conservative industry that is relatively averse to change.

The OPTI® is formed of a hull and deck truss form that aids in the execution of offshore projects and leads to lower lifecycle costs. The OPTI® proprietary hull form and single deck truss features combine superior hydrodynamic performance with payload weight efficiency, ease of construction, simple integration, and rapid, flexible project execution.

This design achieves optimised motions by utilising a deeper draft and ringed pontoon design and has become something of a company hallmark.

“The OPTI® has become nearly synonymous with Exmar Offshore Company, and although its business includes significant non-OPTI® related engineering services, the OPTI® makes us particularly proud,” Lim says.

This design has given Exmar an edge over its competition in the industry. Through owning the design, the firm has the independence to work with any EPC contractor, shipyard, or operator under a license agreement. But the company is also forward thinking in its business approach.

“Its commitment to continual innovation and practical solutions has

Bardex

Since the 1960’s Bardex has been providing solutions to lift, move, position or restrain heavy loads in Oil & Gas and Shipyard applications.

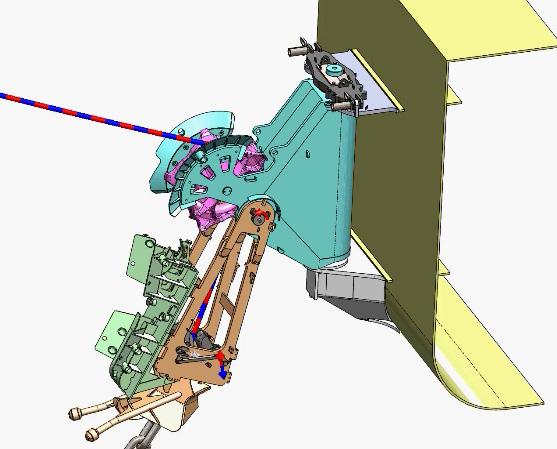

The mooring systems we have used on Exmar FPU hulls in the past have been Moveable/Removable Topside Tensioning Systems and most recently the newly designed (OVT) Off Vessel Tensioning Systems.

These 2 types of mooring systems offer considerable advantages, with the latter saving considerably more weight, space and costs.

www.bardex.com

OPTI® MODELS

OPTI-MICRO™: Introduced in 2016 as a solution for limited recoverable reserves or as an early production system, the OPTI-micro™ offers a flexible development solution with upside production potential. With a 40,000 barrels per day production capability, the OPTImicro™ offers a strategic alternative to a complicated, expensive tie-back at a lower cost than a larger conventional hub.

greater production rates and enhanced oil and gas OPTI-EX®: Exmar’s confidence in the OPTI® concept and design was so great that it took the ultimate risk, and OPTI-EX® became the industry’s first speculative build semisubmersible floating production system. A decade later, OPTI-EX®, with up to a 60,000 barrels per day capacity, continues safely producing for LLOG with unrivalled uptime availability.

OPTI-11000™: Sized specifically to take advantage of the largest platform integration crane available on the US Gulf Coast, the OPTI-11000™ offers increased industry leading and award-winning Delta House facility operated by Murphy Oil Corporation. OPTI-16000™: To meet future hub applications, where

capacity up to 100,000 barrels per day. The result is the recovery requirements demand a larger deck and load capability, Exmar has developed the OPTI-16000™. The design will provide production rates in excess of 120,000 barrels per day and provide space and load capacity for water flood, gas injection, and subsea boosting equipment. It retains all the technical features and construction strategies of previous designs for a cost-effective facility.

The OPTI-11000™ hull for the Delta House offshore installation makes ready to sail from South Korea to Ingleside, Texas

Bardex Mooring System Solutions –

To Save Space, Weight & Costs

Movable & Removable Topside Tensioning (to save equipment weight & costs)

Off Vessel Tensioning (to capture all topsides space, eliminate topsides weight & minimize CAPEX & OPEX costs) www.bardex.com

Features & Benefits of Bardex Mooring Systems

DIFFERENTIATORS

• CAPEX & OPEX savings systems designs • Innovative Chain Management Solutions to save weight, costs and installation time. • Field proven designs • Reliable, unique load measurement systems • Designed to reduce chain stress and wear • Patented BarLatch UFCS to reduce or eliminate OPB/IPB • Low friction bearing on Conventional & UFCS fairlead designs. • Minimized FPU Hull Interface Structures & Associated Costs • Reduced Mooring Equipment Lifecycle Costs

EXPERIENCE

• Inventors of the Chain Jack; patented and in use for over 50+ years. • Top level technical team with the longest track record in the industry, specializing in client’s technical requirements. • Designs Reviewed and Certified by ABS, BV and DNV-GL • Mooring & Design analysis with flexible design configurations • Numerous mooring high profile Global & Gulf of Mexico references with key oil & gas Majors & Supermajors • Engineering Services from concept design to Construction & Installation to Decommissioning. • Lifecycle Support Services ensuring equipment availability, operating at peak performance

The OPTI-11000™ hull for Murphy Oil Corporation’s King’s Quay deep water development in the Gulf of Mexico

driven Exmar Offshore Company to develop and improve products with clear intent,” Cotaya adds.

While the OPTI® and its deployment is an in-house feature of Exmar, Lim and Cotaya acknowledge that the company would not be able to provision its whole service offering without the presence of a number of strategic partnerships with external companies. The professional relationships that the firm cultivates and maintains are both mutual and beneficial for both parties and the end customer.

“The company works closely with subsurface and subsea companies. It also works with topsides companies, typically selected by the operator,” Cotaya says. “For the execution of projects, we work closely with shipyards relying on the network and reputation of the Exmar Group which has extensive construction experience.

“For instance, we have had relationships with riser and mooring companies that have been instrumental in developing an optimised performance solution.”

LOOKING TO THE FUTURE

Just as partnerships are held in the highest regard, the individual efforts of the Exmar workforce drive the design, production, and services the company provides its varied customer base.

The firm prides itself on its workforce of employees from diverse backgrounds that collectively make up the drive behind high-performance service.

“Exmar is full of examples of technically innovative successes, whether it is FSRUs, FLNG, LPG fuelled LPG carriers or OPTIs®, and exciting projects attract creative people,” Cotaya says. “Keeping creative people motivated means giving them challenges and real responsibilities.

“It is not a large company among its peers, but it achieves great things, and each person is able to point to where they contributed to that success.”

TIMES” – DAVID LIM

The King’s Quay process facility and deck truss under construction at Hyundai Heavy Industries, South Korea

THE CHAIRMAN’S VIEW

OUTLOOK PUBLISHING (OP): Tell us a bit about yourself and your background in the industry. How did you get involved with Exmar?

NICOLAS SAVERYS (NS): My family has been involved in the maritime industry for more than 190 years, mainly through shipbuilding. Since the 60s and 70s, as a family we have been diversifying more into shipping activities. I founded Exmar in 1981, starting as a new player active in the LPG shipping industry.

As a family, we bought CMB in 1991, at that time Belgium’s largest ship-owner. After demerger we recreated three companies as from 2003, CMB (Bocimar), Euronav, and Exmar.

OP: How important is LNG regasification to Exmar? Can you tell us about the company’s legacy in this field, and what your outlook is for the future?

NS: Nearly 20 years ago Exmar started floating LNG regasification as a true pioneer, bringing the first FSRUs to the market. Exmar’s practical approach to problem solving has led the way the industry thinks about floating regasification from the design itself, the floating transfer of LNG cargo and most recently barge-based regasification.

With an ever-growing need in the market for flexible solutions, floating LNG technology will continue to progress. The well-known advantages of being fast track, re-deployable and cost efficient have led to the unlocking of many new LNG markets over the past decade thanks to FSRUs.

As for the future, there are still non-traditional markets where gas as an energy source are needed. These markets can be small and in developing countries. The barriers to opening these new markets are economics and permitting. Exmar has the proven, technical solutions and operational experience to quickly bring clean gas to these markets.

OP: What innovations are you introducing to the LPG shipping sector?

NS: LPG is more mature market and Exmar has had a significant presence in it since the early 1980s as a shipowner. Like it has done in all its businesses, Exmar embraces innovation that leads to better solutions meaning higher efficiency with a cost benefit, but always safe. We have in the meantime developed our seventh generation of midsize LPG carriers (segment between 20,000 – 40,000 cubic metres), and we have since Exmar’s inception continuously been pushing the limits of new ship designs. Also, operationally we have been ground-breaking in the shift over between different types of cargos.

Today Exmar is building the world’s first Very Large Gas Carriers (VLGCs) that can use LPG as a fuel instead of traditional fuel oil. These vessels, being built in China and to be chartered to Equinor, were the first of their kind and now others have followed suit.

OP: What trends are currently shaping the gas industry?

NS: Oil and gas will be there for the longer term, the next decades. Natural gas is the cleanest fossil fuel, and it will continue to grow. Renewables are not a reliable source of energy.

When looking at trends, we see that the market requires the flexibility that floating LNG infrastructure provides. Drivers for this flexibility are:

Shorter term contracts.

More uncertainty on the longer term from competing fuels.

Political uncertainty.

Not only flexibility but also cost competitiveness remains key for the business portfolio. Exmar has a role to play on bringing costs down for its customers in the gas value chain.

OP: Looking ahead, what are your views on the transition to a low carbon energy mix? How do you see it developing?

NS: Energy demand is going only in one direction. Low carbon sources of fuel (specifically gas) have increased substantially and will take a greater share in the near future. Hydrogen and ammonia are also coming, but not immediately. Renewables are seeing a large investment that will drive their share of supply. There will not be a complete replacement of fossil fuels, but the mix or ratio is changing as more sources of energy are needed. Exmar is involved in all these areas of the transition.

Nicolas Saverys, Chairman

AREAS OF THE TRANSITION” – NICOLAS SAVERYS

The COVID-19 pandemic has thrown many obstacles in the way all industries approach the workplace, and Exmar is one firm that has risen to the challenge. The company promoted remote working for its employees and aided the transition to such an environment.

“Flexibility combined with a strong work ethic that was consistent whether at home or in the office helped us to succeed in these difficult times, and we believe that while the landscape is very different now,” Lim continues. “We believe we are better and stronger.”

Indeed, it was this kind of individual employee focus that has defined Lim’s own tenure at the company.

His career had veered towards law before he was presented with the opportunity to join Exmar. He had originally joined the firm to gain experience in shipping to later explore the avenues of becoming an admiralty lawyer. Starting in Exmar’s Hong Kong office in 1997, he began with the trading of pressurised LPG vehicles. The 2000s saw Lim’s career leap forward through the firm.

He was given the opportunity to move to Exmar’s headquarters in Antwerp in 2001, then to Houston to develop the company’s nascent LNG regasification business, and a few years after he was presented with yet another opportunity.

“In 2004 I was given the responsibility of taking Exmar Offshore Company from a technically strong design development company to a commercially profitable services and project development company,” Lim says.

Now, as Exmar continues to serve its customers, energy is starting to pick back up, and optimism remains the primary emotion for Lim.

“While deep-water exploration and development was paused in the early days of the pandemic, we are starting to see activity returning after months of re-evaluation,” he says. “Projects have been delayed but have not been cancelled.”

The firm plans to deliver the installation of the King’s Quay FPS for Murphy Oil and its partners, as well as the sanctioning of another project in 2021. On top of this, OPTI® studies are ongoing, the aim being to move these forward for approval in the next 12-24 months.

One of the most exciting prospects, however, is Exmar’s plans to explore the offshore renewables space, an area where the firm can take and apply its knowledge to a more sustainable sphere of the energy spectrum.

“I am very optimistic for the coming year and beyond,” Cotaya says, bringing the conversation to a close.

“I don’t believe the doomsday scenarios will be as bad as predicted. Difficult times lay ahead but the industry has always regrouped and redoubled its efforts. The offshore industry has weathered extreme highs and lows and continues to improve. We are in the age of energy transition and Exmar is part of it.”

EXMAR OFFSHORE COMPANY

Tel: +1-281-679-3900 info@exmaroffshore.com www.exmaroffshore.com

Mark Haubert, Vice President at Ranger Energy Services, discusses the organisation’s innovative approach and how it is underpinned by a positive energy culture

We drive new thinking.” It’s a mantra that works well for Mark Haubert and Ranger Energy Services.

An oil and gas completion and production solutions organisation focused on well servicing, it was founded in 2014 and has grown to become a leading provider of high specification well servicing rigs and ancillary equipment, known for its ability to pioneer new ideas.

Haubert is the company’s Vice President. From an early age, he foresaw a career in engineering and credits his family as important influences on his career direction.

“Growing up, I was good in math and science so I knew that I wanted to study an engineering field. When I was choosing my career and field of study, the petroleum industry was booming in the U.S.,” he explains. “I also had exposure to the industry through my father and uncle who both worked in natural gas production and storage. It was an easy choice and it sounded like it would be an adventurous career.”

However, by the time Haubert had completed his degree, the industry was experiencing a severe downturn.

“I decided to pursue a backup career as a Navy pilot, but fortunately landed a position in oilfield services,” he says. Having demonstrated success transforming firms into becoming profitable, market-driven organisations within the energy sector, Haubert recognises the importance of company culture and orchestrating successful change management.

Challenging the Norm

Throughout his career, he has experienced a number of growth and contraction cycles. “In the U.S. unconventional market, these cycles have become more frequent and more extreme each time,” says Haubert. “This last contraction occurred due to an oversupply of oil and demand erosion due to COVID-19 causing active drilling rig count and frac crew completion count to contract by two-thirds in a few months. The US land market reached a record low of about 290 drilling rigs in July, which is the lowest rig count ever recorded by Baker Hughes and perhaps dating back to the 1890s.”

Ranger consists of three brands: Ranger Energy Services, Mallard Completions, and Torrent Energy Services that provide services throughout the U.S. unconventional basins. The company employs around 1,000 people across its field locations, with its corporate headquarters based in Houston, Texas.

Haubert values innovation, and driving innovation is at the forefront of decision-making at Ranger.

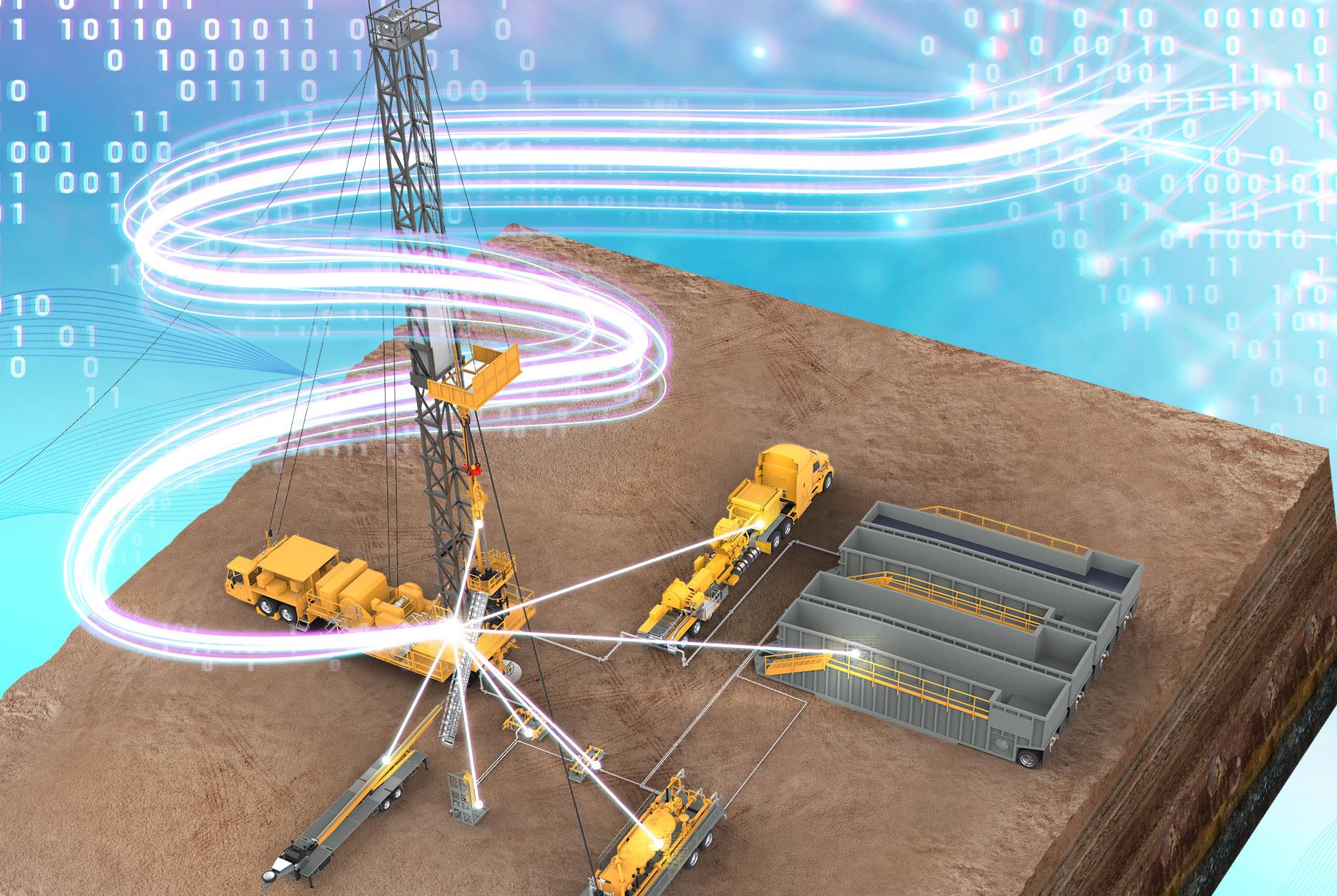

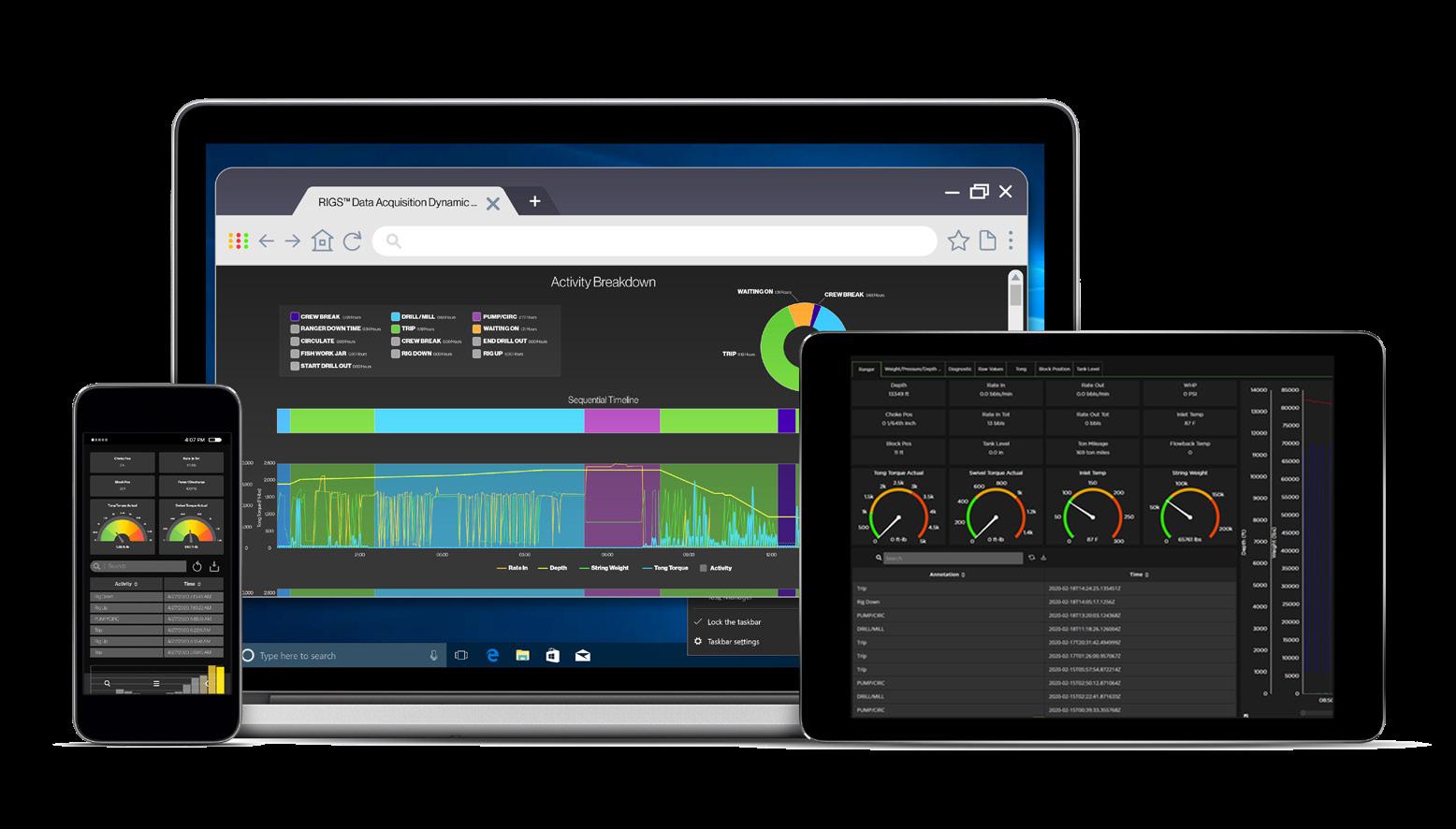

As a result, the firm strives to transform the well service industry by introducing data capture and analytics throughout its brands and services, and one of these innovations is Ranger Live™.

The Ranger Live™ mobile platform delivers a customised suite of applications to the firm’s field crews at the job site via tablet. This platform allows the crew to access data on the job site and to input data that is stored on Ranger’s servers. The Ranger Live™ Customer Portal offers access via any device from any location to real-time job data and post job metric reports. Providing real-time data and analytics to decision makers leads to safer and more efficient operations.

It is an example of the pioneering spirit housed within the company, a spirit which over the years has been recognised through numerous nominations and awards.

ONE GROUP, THREE BRANDS

1Ranger Energy Services is one of the largest providers of high specification well service rigs and associated services in the United States. Ranger offers Elite completion solutions, production maintenance, workover solutions, and well abandonment solutions using our high spec service rigs, rig-assist snubbing, equipment rentals, and well flowback services.

2Mallard Completions offers horizontal wireline perforating and pump down solutions. Mallard uses wireline trucks and 2,500 HP pump trucks to pump frac plugs and perforating guns into extended reach horizontal wells for pump down perforating completion operations. Mallard offers industryleading safe and efficient operations due to its use of fit-for-purpose wireline perforating solutions and plug and play gun technology.

3Torrent Energy Services offers modular equipment and services to process natural gas at the wellhead in the field when drilling and completion activity has outpaced the development of permanent processing infrastructure. Its premium and proprietary solutions include mechanical refrigeration units and pressure reduction units coupled with turnkey services to mobilise, install, commission and start up the units. Its natural gas processing solutions assist customers with meeting pipeline specifications, extracting higher value NGLs, providing fuel gas and reducing emissions.

DynaEnergetics™

DynaEnergetics™, the only provider of fully Factory-Assembled, Performance-Assured™ perforating systems for unconventional well completions, is a proud supporter of Ranger Energy Services and its Mallard Completions division.

Ranger and Mallard have built a reputation for unsurpassed safety, quality and efficiency in serving the unconventional oil and gas industry. Since its inception, Mallard exclusively has used DynaEnergetics’ DS perforating systems in its well completions.

Customised DS systems are delivered just-in-time to the wellsite, and reduce investments in assembly and storage infrastructure. DynaEnergetics is proud of the role these systems play in supporting Mallard’s ultra-efficient business model.

dyna.sales@dynaenergetics.com

IN FOCUS: RANGER LIVE

Ranger Live includes the following applications:

EQHSE™ - Enables and supports its quality and safety management systems. It provides each crew with easy access to all policies, forms, safety alerts, its Learning Management System, standard operating procedures, observation entry, corrective action implementation and notification.

ETICKET™ - Its electronic ticketing system used to capture work activities and the associated timeline during a job and to provide benchmarking and post-job metric reporting.

ERIGS™ (Ranger Information Gathering System) - Its data acquisition system that gathers data such as pump rates, pressures, volumes, weight, depth, and torque via sensors on the rig and ancillary equipment. This data can be monitored real-time through the Ranger Live™ Customer Portal and it can be used for benchmarking and post-job metric reporting.

EDRIVE™ - Its driving application that enables driver behaviour monitoring and improvement facilitated by monthly driver scorecards. It also enables Federal Motor Carrier Safety Administration compliance for our DOT-regulated vehicles.

EPMM™ - Ranger’s preventative maintenance management system used to document periodic equipment inspections and scheduled maintenance.

The organisation was recently selected as a finalist in the Houston Business Journal Middle Market 50 Award for 2020. This honour is given to the 50 fastest-growing locallybased middle market companies with annual revenues of $28 million to $1 billion. Ranger Energy Services was ranked as the 21st fastest growing company with 118 percent growth over the two years from 2017 to 2019.

The firm was also selected as a finalist in the Houston Chronicle’s Top 100 Leading Companies for 2020. Ranger was ranked 34th overall, 11th for earnings per share growth, and 29th for revenue growth over the two years from 2017 to 2019. But for Haubert, while being recognised in such ways is a testament to the company’s success, there are more fundamentally important priorities that need addressing on a day to day basis.

For instance, Ranger is focused on providing the highest quality of service while protecting its employees and the environment in which it works. Haubert explains that in order to make this a reality, his organisation has introduced an award-winning, behavior-based QHSE management system that is formed by six core elements and consists of 36 total elements.

“Together, they form a complex interrelated structure with maximum synergies where one element supports many other elements,” he says. “The six core elements include: Policies and Procedures, Executive Leadership, Employee Engagement, Continuous Improvement and Failure Adaptation, all supported by the Ranger Live™ Mobile Platform.

“Further, we’re pursuing the ISO 45001 certification which is the internationally recognised standard relating to health and safety in a business environment. We anticipate becoming one of the first service companies in the U.S. to receive this certification in early 2021.”

A result of implementing this QHSE management system and developing a safety focused culture is that Ranger has been presented with the Large Well Servicing Rig Division safety award by the Association of Energy Service Companies (AESC) for the previous two years.

eRIGS cloud portal

HOW IMPORTANT ARE PARTNER AND SUPPLIER RELATIONS TO THE SUCCESS OF YOUR BUSINESS?

MARK HAUBERT: “Partner and supplier relationships are critical to our success. Since we are primarily a service company, we partner with other companies to design and manufacture the equipment and products that we use to perform our services as well as to provide us with professional services. “Ranger Energy requires mobile rigs, reversing unit pumps, power swivels, pipe handlers, chemical mixing plants, chemicals, tanks, trucks and trailers. Mallard Completions requires wireline trucks, cable spools, pump down pumps, perforating gun systems, pressure control kits, and hydraulic latch assemblies. While Torrent designs their own natural gas processing equipment, they require other companies to manufacture them.”

“We also have critical partnerships that provide professional and consulting services to us such as finance, accounting, insurance, legal, and safety services. These partners are key to our success and our continued growth.”

Indeed, Haubert places a considerable amount of value on harbouring a high-performance culture that is based on its purpose and values.

“Our purpose, “We exist to generate positive energy” permeates everything we do.” “We continuously strive for our customers, stakeholders and communities to have a positive experience when interacting with Ranger. To accomplish our purpose, we must drive new thinking and encourage everyone’s input to share ideas. We aren’t afraid to engage in healthy debate. The innovation that results is what sets us apart from our competition.”

Haubert strives for high standards and believes that teamwork is essential in order to achieve longterm success. “We take responsibility for supporting one another and our clients in moving forward,” he adds. “We challenge each other to improve and to leave things better than we found them. This means encouraging the best and celebrating so that we all rise up together.”

With the future in mind, the Vice President is excited about the next couple of years and adds that Ranger will be introducing a new solution at the beginning of 2021.

“We will launch our Ranger Elite™ Completion Solutions in early 2021,” he explains. “Ranger Elite™ is a comprehensive frac plug drillout and completion solution including elite personnel, elite equipment, and elite systems and solutions. Our elite personnel are highly trained and qualified with specialised technical and leadership certifications. In addition, they are armed with stateof-the-art equipment and our Ranger Live mobile platform.”

Over the course of 2021 and beyond, Haubert is determined to continue building a positive energy culture across Ranger while strengthening the overall brand awareness.

“It’s important that we continue to develop and implement differentiating technologies while strengthening existing partnerships and developing new partnerships with major independent and multi-national operators,” he says, bringing the conversation to a close.

“We’re in a position to evaluate numerous expansion opportunities and we anticipate expanding our portfolio of companies and services. We rise to challenges. When a roadblock is thrown in our path, we pull together to eliminate barriers and overcome the challenge. We come to work every day filled with positive energy, a smile on our face and willing to stick through to the end to accomplish what needs to be done that day. We enjoy working together and celebrate each other’s success.”

RANGER ENERGY SERVICES

Tel: (713) 935-8900 contact@rangerenergy.com www.rangerenergy.com

COVID-19:

Rising to the Challenge

Against the backdrop of the COVID-19 pandemic, we preview Hellmann Worldwide Logistics’ COVID-19 handbook and gain insight from David Bang, Global VP of Strategic Development at the organisation

The COVID-19 pandemic has created a multitude of obstacles during the course of 2020. This has propelled businesses across the world to rethink operations and adopt agile approaches to business in order to deal with the ever-changing global situation.

However, despite such disruption from both a human and a business perspective, a vaccine for the deadly disease has been announced and is being rolled out throughout December and into 2021. With the vaccine now declared safe for us, the logistics

HELLMANN WORLDWIDE LOGISTICS

COVID-19 HANDBOOK

industry is now tasked with distributing the vaccine to the most vulnerable as efficiently as possible. Anticipated to be a mammoth task, the Pfizer vaccine for instance, is unable to travel above -70°C more than four times which means logistics companies such as Hellmann are vital. Some other vaccines are suitable to be transported at more modest temperature ranges like +2 to +8°C or -20°C, but transporting safely billions of doses globally in addition to all other vaccines and healthcare products as well as all other commodities based on

stronger economic return in 2021 and 2022, it will surely be one of the most challenging and critical temperature controlled logistics tasks we’ve ever seen.

Logistics has been one of the industries that has undergone the most disruption. As an influential part of value chains, both within and across international borders, logistics firms facilitate trade and commerce while helping businesses get their products to customers.

Initially, the impact of COVID-19 was felt in Asia as a result of the role the region plays in global manufacturing. With over 200 of Fortune Global 500 firms having a presence there, this meant that disruptions to manufacturing in the country then caused issues across global supply chains. For example, cargo was backlogged at China’s major container ports as travel restrictions led to a shortage of truck drivers picking up containers and ocean carriers cancelled sailings. Subsequently, the pandemic spread to the rest of the world and led to lockdowns and border closures which restricted the movement of goods worldwide. For example, air cargo capacity significantly reduced globally and decreased by around 60 percent overall.

Now capacity is slowly recovering although in many cases still volatile, and we have a monumental task in front of us to distribute COVID-19 vaccines from production to point of care for at least 70-80 percent of global population for herd immunity in every corner of the world, regardless of economic or geo-political bases.

As a result, Hellmann Worldwide Logistics has compiled a COVID19 handbook which provides commentary from industry experts at Emballiso, Hanhaa, Air France-KLM Cargo, Maestro Cargo and Validaide about the measures taken to distribute the vaccine and the major challenges to overcome.

Founded in 1871, Hellmann Worldwide Logistics has become one of the largest privately-owned international logistics providers.

HELLMANN HISTORY

1925 - In Germany, Hellmann was one of the first companies to replace their horse-drawn fleet with coal-powered trucks

1968 - With 20 years of post-war expansion across Europe, the company’s shares were transferred to the fourth generation, Klaus and Jost Hellmann

SQA

SQA works with its client partners and their supply chains in over 70 countries annually, with over 1,000 quality professionals. SQA understands the complexity and challenges of a global supply chain and our clients count on us to extend their reach, uphold their name, and ultimately protect the patient.

Annually, SQA performs over 3,000 audits, provides component inspection of over 1m parts at the source, and 50,000 hours of engineering supplier development. This occurs in the form of managed programs at supplier sites that include, but may not be limited to: audit, assessments, supplier development, part approvals, inspection, remediation, desktop evaluation and full time surveillance. We’re excited to share the SQA’s outsourced risk management “partnership”. We have boots on the ground worldwide allowing SQA to accommodate even the most complex supply chains.

www.sqaservices.com

2006 - Hellmann receives the coveted ‘Award of Excellence’ from the Global Institute of Logistics

SQA has a global footprint that supports critical supply chains. We are a leader in assessing, monitoring and improving supplier quality for our client partners. The partnerships SQA has created over the past 25 years have provided benefits for our clients integrated strategies where SQA supports on a flexible, long-term basis. For industries where quality survives!

For industries where quality survives

2017 - With the foundation of the legally independent business units Air & Sea, Road & Rail and Contract Logistics as well as the Holding company, Hellmann reacts to the changing market conditions and its own Group size - initially on a national level, from 2018 also internationally

Through its partner network, the organisation is represented across the globe, with around 20,500 employees across 489 offices in 173 countries. Its range of services includes classic forwarding services by truck, rail, air and sea freight, as well as a comprehensive offer for CEP services, contract logistics, industry and IT solutions.

David Bang is the Global VP of Strategic Development at Hellmann Worldwide Logistics. He recognises that 2020 has been a challenging year in the supply chain and stresses that lessons have been learnt. “From a supply chain and logistics point of view, the year 2020 clearly showed that, even with many advanced technology advancements, there are

– DAVID BANG

still many vulnerabilities in our global supply chain,” he explains. “There was the toilet paper fiasco as well as other consumables you couldn’t find on the local grocery shelves, PPE shortage, etc. However, let’s not forget that there have been nearly one and a half million lives lost globally (as of early December 2020) and millions of other people’s lives have been turned completely upside and down. Although it is not just about the supply chain issue alone, we must learn and improve.”

Most governments have responded to the crisis by designating ports, shipping and trucking services as essential and exempting them from

The Pfizer vaccine is unable to travel at temperatures above -70°C, which means logistics companies, with capabilties such as Hellmann, are vital

lockdown rules. For example, the Indian government exempted the movement of cargo through ports, supply chains and the transport of essential commodities from lockdown rules. While lots of airports worldwide remain closed to passenger flights, most still remain open to cargo flights.

Even prior to COVID-19, almost 30 percent of global vaccines annually had supply chain and logistics issues, according to GAVI. “And that was only for a two billion dose operation,” says Bang. “Now, with an almost 15 billion dose operation for COVID-19, we need to work and collaborate much better. Hellmann plays an important role in this and wanted to lay out a practical path forward that can benefit many others (even if some of them may be our competitors).

“We are fortunate to have our partners and friends who are like-minded and came along with us for this project and we couldn’t have done this without them. This handbook lays out some practical areas we all can review and reflect on our own organisation to improve and contribute positively to the big picture.” Even prior to COVID-19, almost 30 percent of global vaccines annually had supply chain and logistics issues. “Now, with an almost 15 billion dose operation for COVID-19, we need to work and collaborate much better”

Bang points out that the handbook isn’t a consulting or academic paper but rather practical contents that are helpful to transport the COVID-19 vaccines safely, securely and costeffectively from production sites to point of cares, while also adding that Hellmann’s handbook caters to a wide demographic. Also, it covers multiple transport mode situations such as air, sea, and road as well as warehousing and last mile deliveries “You may be with a local government, a logistics company, a distributor, ministry of health, a vaccine producer, or a supplier to a vaccine producer,” he explains. “It’s important that they are equipped with practical and costefficient guidance on how to prepare, execute and measure the cold chain logistics of COVID-19 vaccines for the top objective, product integrity and patient safety.”

HELLMANN WORLDWIDE LOGISTICS

Tel: +1 305 406 4500 US-Marketing@hellmann.com www.hellmann.com

GOING THE EXTRA MILE

The Women In Trucking Association is an all-inclusive, trailblazing organisation working to improve gender diversity in the trucking industry

Written by: Dani Redd

I was one of the lucky people whose mom told me I could do anything I wanted, and there were no “girl” careers,” explains Ellen Voie, Founder & CEO of the Women In Trucking Association.

In 1972, Title IX of the Federal Civil Rights Act was adopted in America – it stated that no student in a federal education programme could be prohibited from learning an activity based on their sex. Until it was in place, girls studied home economics and boys took shop class. But in 1975, encouraged by her mother, Voie joined shop class, learning woodworking, welding, drafting and auto mechanics.

“Shop class was so much fun, and my instructor insisted I was the best welder he’d ever had! I loved the auto mechanics lessons, and when I wanted to use the family car, I disconnected the distributor cap so my older brother couldn’t get it started! These were more valuable to me than cooking, baking or cleaning!” Voie explains.

In 1978, she was hired at a steel fabricating plant in central Wisconsin and worked in the drafting department, designing material handling equipment, such as steel pallets, bins, and racking. A year later, her employers invited her to transfer into the Traffic Department. Upon earning a diploma in Traffic and Transportation Management in 1980 from LaSalle Extension University, Voie was then promoted to the role of Traffic Manager.

She was responsible for managing three plants creating parts such as material handling and jacks, for shipping out finished products and managing the company’s fleet of three trucks and their drivers.

“I ended up marrying a professional driver, and we started our own trucking company,” Voie says. “I also did freelance work as a transportation consultant while I ran our small carrier, raised two children and attended college to earn my bachelor’s and then master’s degree in communication. I was offered numerous writing opportunities in various magazines. My monthly columns were about family life in the trucking industry.

“I completed my Master’s Thesis on

‘The Complex Identities of Women Married to Professional Drivers.’ I later published a book filled with some of my most popular articles called, ‘Marriage In the Long Run’.”

Two decades later, her marriage ended and she was hired as the Executive Director of Trucker Buddy International, a unique not-for-profit in which long distance truckers become pen-pals to a class of school children, sending them postcards and letters from the places they visit across the country.

After six years in the position, she was recruited by Schneider National to lead their retention efforts, with a remit to initiate corporate level programmes designed to attract and retain non-traditional groups, such as women.

“At the time, I was completing my pilot’s license, and I belonged to an organisation for female pilots. It struck me that there wasn’t a similar group for women in the trucking industry; so I started one,” she says.

And so, in 2007, she founded the Women In Trucking Association (WIT).

SUPPORT AND INCLUSION

In its current incarnation, WIT is a non-profit organisation with over 5,000 individual and corporate members located in 10 countries. Its mission: to encourage the employment

of women in the trucking industry, promote their accomplishments, and minimise obstacles faced by women working within the trucking industry. It is the only association focused on gender diversity for both drivers and management in the trucking industry, so has little competition.

“Our membership consists of anyone who believes in our mission. To that point, nearly anyone can join the association. However, we want to attract people who believe in the benefits of gender diversity,” the CEO explains.

This includes men, who make up 17 percent of the membership.

“Women In Trucking is not an association FOR women, it’s ABOUT women and their success and support in this industry,” Voie says. “If you think about it, you don’t need to be a dog to support the humane society, do you? The Arbor Day Foundation doesn’t require that you’re a tree to fund their efforts.”

Voie is often asked to explain what issues women in the trucking industry face that are different to men.

“The answer is ‘none’. Every one of the concerns that our members have affects both men and women,” she says. “But there are issues that affect women more than they affect men. These are some of the concerns we are focusing our efforts on and working to alleviate.”

The first of these pertains to the image of the trucking industry as a ‘man’s world’, which puts women off from joining it.

“There may be a greater percentage of men than women responsible for moving the nation’s freight, but that doesn’t mean that women aren’t welcome. In fact, some of the most

CASE STUDY

COMMUNICATION AUDIT SURVEY

WIT’s goal is to be a resource for the industry, providing trucking companies, drivers, the government and its members with the best information to help facilitate more gender diverse workforces.

Last year, it reached out to members and non-members with a communication audit survey, to get feedback on the way it communicates. 216 respondents completed the survey.

The results of the survey showed that its weekly e-newsletter was the most popular method of communication (57 percent), followed by social media (47 percent) and its print publication, Redefining the Road.

The organisation learned that only eight percent of respondents have used the Engage platform, a members-only communication tool. However, around a third visit the website at least once a week – the most popular feature is the “Member of the Month” article.

Most interestingly, “gender issues” only ranked 11/20 on a list of topics of interest. “Leadership issues” was second highest, while “safety” was third highest.

WIT reviewed the results of the survey, and concluded that it needed to revamp its website and better focus its social media campaigns. Now it knows the key topics of interest and issues faced by its audience, it will be better equipped to create value-added communications. encouraging and supportive people in trucking are men!” the CEO says.

To counteract this image, WIT aims to ensure women know all about the fantastic opportunities in the industry, from driving to maintaining and managing equipment.

“Often, when I tell women about the organisation they are curious, but when I start describing the potential opportunities available to them, they tell me they aren’t “built” to drive a truck, or that they aren’t mechanically minded enough to service an engine,” Voie says.

“I tell them that they’re wrong. I tell them they can learn and they are capable and most importantly, they are needed.”

A second issue is one of safety. Voie cites a study from the US Department of Justice which found that women are three times more likely to be raped than men, three times more likely to be stalked, and twice as likely to be injured during an assault.

“This industry can’t afford to lose women because they do not feel safe in their work environment. Everyone deserves to have the security to do their job, and whether their workplace is an office, a truck or a maintenance facility, our goal is to help women overcome some of the challenges they might face in ensuring that they are safe while they are on the job,” she states.

A third issue is cleanliness of truck stops and toilet facilities, which puts women off from taking driving jobs. A final, more serious issue is that of harassment.

“Many of our female members have told us that they are often verbally accosted by an anonymous male voice when they key the mic on their CB radio,” Voie explains. “Diane, an owner operator from Canada, said that she had been called some pretty nasty things when she talked on the CB. She turns it off except for the few occasions she needs it to communicate with a fellow driver.”

MAKING AN IMPACT

So what has WIT done to help women overcome these obstacles and encourage them to join the industry?

Since its first membership drive in 2007 (which attracted 500 members) it has launched a number of positive, innovative events and initiatives to encourage women into the industry. In 2009, for example, it organised the first ‘Salute to the Women Behind the Wheel,’ a group photo shoot for professional female drivers, which takes place at a larger trucking event. Six years later it launched its own trucking event and expo, Accelerate!, devoted entirely to redressing the gender imbalance in the trucking industry.

In 2010, it created the Women In Trucking Scholarship Foundation. In the same year it established the first annual Influential Women In Trucking Award, set up to recognise women in the trucking industry who make or influence key decisions, have a proven record of responsibility, and mentor and serve as a role model for other women. This year’s award was jointly shared with Kristy Knichel, CEO of Knichel Logistics (also featured in this Ellen Voie and the WIT team

edition of North America Outlook) and Jodie Teuton, Vice President, Kenworth of Louisiana/Hino of Baton Rouge and Monroe.

In 2011, the Women In Trucking industry launched Redefining the Road, a thrice-yearly publication available to its members, while 2014 saw the introduction of the weekly ‘WIT e-News’. A mentoring board was also added to the website, enabling new starters in the industry to connect to those with more professional experience.

Over the years, Voie has attended an increasing number of engagements around the world to publicise the organisation. She has even visited the White House, who in 2012 recognised WIT as “Transportation Innovator

Champion of Change”. Voie herself has received many accolades, such as being named in Insights Success Magazine’s “2020’s Most Influential Women to Watch” and is known as a trailblazer in the industry.

LOOKING AHEAD

Of course, the transport and logistics industry has been affected by the COVID-19 pandemic, alongside many others. Voie admits her own career has dramatically changed and has had to learn a new way of working.

“My job was formerly about traveling all over the world to talk about how to bring more women into supply chain careers,” Voie says. “I haven’t been on a commercial flight in months, but I’ve learned to give presentations virtually, and we’re all getting more comfortable sitting in front of our computers instead of in front of a crowd.”

Despite the pandemic, the organisation has continued to work towards its goal of improving gender diversity within the trucking industry. It is in the process of rolling out a D&I Index, a novel diversity and inclusion programme that will promote and share what different carriers are doing to support and expand the needs of the evolving trucking workforce. In doing so, it will help identify and promote best practice, as well as encouraging creativity and innovation.

It also launched its Driver Ambassador Program in February, to help promote career opportunities within the trucking industry and increase membership for the organisation.

Since the launch the official WIT Driver Ambassador Kellylynn McLaughlin has been involved in media interviews and speaking engagements. But since COVID-19 halted the latter, she began to engage with members through a daily video series on social media, and via writing blogs for the WIT association.

WIT is now embarking on the next phase of its programme, which will involve McLaughin travelling the country in a WIT-branded trailer. Its interior functions as an educational unit, introducing viewers to the career of professional truck driving and featuring success stories of women drivers.

“It’s going to be a powerful and very visible symbol of what women have to offer the freight industry. I will be so proud to haul it,” McLaughlin says.

Despite the difficulties of this year, WIT is going from strength to strength as it increases its reach and engagement. Alongside its digital communications it is also working on creating chapters for its increasing number of members to connect on a local or regional level.

“I started in 2007 with a great team who shared my passion, and we put together a fantastic staff, board and support group. Here we are, 13 years later, with a success story I could never have imagined,” Voie concludes.

COMPANY NAME

Tel: 888-464-9482 ellen@womenintrucking.org www.womenintrucking.org

Identifying Innovation

With a new year around the corner, we take a look at ID Logistics and the company’s sustainable, innovative, and service-centric developments amid its expansion into the US

ID Logistics stands as a key player in the North American logistics industry. From its inception in France in 2001, the company was designed with an international focus in mind.

Following the launch of French services for large format retailors, ID kicked off its global expansion with the opening of its first subsidiary in Taiwan during early 2002. Following this, the firm continued with a steady growth of logistics activities through the opening of several sites across France, as well as subsidiaries in Brazil, the Indian Ocean region, Spain, China, and Indonesia.

From there, ID gained a foothold in multiple continents and took to strengthening its position in the e-commerce space. Now it consolidates itself as a market leader in order picking in Europe (after the acquisition of CEPL), maintaining a strong presence in luxury goods, and moved on to breach the US market in 2019.

Following the purchase of Jagged Peak (a US company specialising in e-commerce logistics), ID stamped its footprint on luxury goods in America, opening itself up to additional opportunities for development, innovation, and acquisition-led growth prospects.

The extension of e-commerce services remains an extremely important aspect of business for ID Logistics. With a wide variety of products to sell, with a multitude of different requirements with regards to the speed and excellence of service, it is within ID’s requirements to anticipate unpredictability and overcome everyday challenges.

Similarly, the company’s retail department require specific knowledge and attention to identify potential peaks in activity that require management, coupled with the logistical flows when regarding storage or simply the just-in-time deliveries that are expected. ID additionally specialises in providing fast moving consumer goods (FMCG) that require the high-quality standards of factory-to-client fluidity management.

Advantix Logistics is committed to providing superior labor solutions for your warehousing and distribution facilities. Advantix Logistics provides motivated and dependable labor for freight handling, warehouse services, warehouse management, and on-site management. Advantix Logistics has been supplying warehouse and distribution clients with skilled associates for nearly three decades. Whether it’s admintrative or a manager overseeing operations, we recruit and hire top-of-the-line staffing. We have continued to grow over the years as we have helped our clients grow their businesses with focused, competent associates who comply with proper security and safety practices. Our intensive screening and training procedures, combined with our intelligent matching system, increase your bottom line. Advantix Logistics will build out a diverse team with extensive experience based upon your company’s request. We know each client values honest and consistent communication and Advantix Logistics strives to meet all commitments within the timeframe requested. Distribution centers need to lower costs while getting the right products delivered damage-free and on time. We provide trained staff who are well versed in our client’s SOPs. We review both client and staff expectations on an ongoing basis to ensure that both sides of the equation are meeting expectations.

OUR VALUES –

We build strong relationships with our clients by providing highly screened and trained associates at a competitive cost.

Advantix has partnered to successfully serve a variety of distribution and manufacturing operations. Here are some industries we proudly serve. • All Modes of Packaging • Automotive • Discount Retail • Electronics & Appliances • Food Service • General Merchandise • Grocery • Health & Beauty • Furnishings • Medical • Sporting Goods & Hobby • Short Term Projects • Third Party Logistics

SUSTAINABILITY AT THE FORE

These activities do not only take the service of company to consumer into mind. Another side to ID’s business practices are the company-wide environmental standards that it sets for itself.

ID stands as a company that supports and encourages the active development of sustainability practices organisation wide, and externally. Its sustainability developments focus around three key areas that cover a broad ecological plan.

IDEO AT A GLANCE

IDEO offers a unique transport management as a collaborative and assetsfree European fourth-party logistics provider (4PL). IDEO utilises of two important aspects of business:

COLLABORATION:

The world would be a better place if it was one unique supply chain. As a multi-client control tower, IDEO shares resources, experiences, and backhauling synergies to maximise potential.

ASSETS FREE:

• Without owning vehicles to make benefit with, our hauliers’ selection and allocation is totally independent. Our decisions are only done in alignment with our customers’ benefits. • We provide to our customers a management of their operations from creation of an order to its fulfilment. We act on three levels: 1. Management and coordination of road and rail transport 2. Costs and service optimisation 3. Innovation and process engineering

OUR HISTORY

We started as a European-based entity in Saint Priest, close to Lyon in France, the control tower IDEO had been created in 2014 and is specialised in road and rail transport management across Europe. Four years later, IDEO regroups more than 100 experts in the supply chain and transport sectors. We serve customers such as Danone, Auchan, Orangina Suntory Factory, Bericap, BMI, and PepsiCo. Operational excellence and added value created by our advance supply chain management have built our reputation to what it is today. As a result, IDEO was awarded “King of Supply Chain 2017” by Supply Chain Magazine.

“KING OF SUPPLY CHAIN” 2017

This award was granted to IDEO for the setting up of a dedicated rail hub. The project evacuates Evian’s products as soon as they arrive via a rail shuttles connection between the factory and the rail hub. IDEO serves to maintain our seamless and professional logistics service throughout Europe.

The social and civic aspect of these developments sees ID maintain responsibility as an employer and contributor to the economy within local communities that are intertwined with the company’s presence and business. ID is focused on increasing the involvement and security of its employees through means of training and awareness programmes – encouraging responsible initiatives by which the employees can grow and develop.

The company’s investment in economic efficiency and the support of customers and clients is another. Through the implementation of optimised and innovative solutions, ID manages to address the issues of company economic and environmental performance needs.

And of course, the third key area that completes the triangle of sustainability development is environmental protection. Taking action on pollution and pollutive elements, unsustainable energy consumption and wastage, the firm actively improves the environmental quality of resources utilised in its practices, including vehicles and sites, with the goal of being a continually greener business.

“Born and raised in New Jersey, I remember my father giving me the opportunity to work each summer break with him in his trucking business since I was ten years old vs. offering me summer camp to hang with my friends. I have been blessed to work in the logistics industry all of my life.

My family started on the trucking side of the logistical business. Our daily challenge was making timely deliveries to supermarket and warehouses because of constant delays in unloading. When I complained to any customer about the congestion on their docks, received the same response from each of them - if you can do better, than do it! Took the challenge personally and came up with my own solution. Advantix Logistics was created, and my team started performing unloading services at distribution centers. Found that with our discipline and dedication we did a better job than the customer. From this humble beginning Advantix Logistics morphed into supplying all functions in distribution centers and warehouses.

Advantix Logistics is not your average temp agency, we are a labor solutions provider. Our full-time associates are dedicated to the performance and success of our clients. With Pride an Advantix Logistics Associate is well trained and driven for the success of our clients.

Proud of our formula for success, Advantix Logistics is built on the fundamentals of customer service, dedication, and driven hard working associates. Advantix Logistics can provide labor solutions to all needs in warehouses or distribution centers. Can unload containers, pull orders, move the freight, load out, administrative and management support. Our services are like a menu, pick what you want!

The Advantix Logistics leadership team prides ourselves on our labor solution model. Every customer we service will see an improvement in their distribution in quality and time with cost savings.

As the Frank Sinatra song says: “If you can make it here, you can make it anywhere. Well, we made it in NJ/NY Metro Market, the toughest market in America and we all are proud of it!”

Michael J Mortorano

T (866) 402-5011 | E info@advantixlogistics.com | www.advantixlogistics.com

COMPANY VALUES

ID Logistics follows a set of four founding values that guide the group’s expansion in the industry. These are the building blocks of the company’s success and continued growth and development.

The four founding values:

1ENTREPRENEURSHIP

Daring, imagining, and developing with a rigorous approach in the implementation and measurement of risk.

2OPERATING EXCELLENCE

Complying with specifications and service standards, while prioritising new technologies.

3HIGH STANDARDS

Responsibility and professionalism in human relations within the company as well as with clients and partners.

4SOLIDARITY

Promoting solidarity within the group and committing to sustainable development together with our employees, clients, and partners.

To further consolidate its sustainability practices, ID has provided a “sustainable development toolbox” made up of a list of 110 actions with implementation guidelines – one that has been available since 2008. These guidelines cover the entire spectrum of sustainable development and provide the followers of such actions with the easy deployment of chosen projects.

The commitment levels of participants are checked during site certification audits to ensure that they are maintaining the goal of at least three projects in a year following the sustainability guidelines - one of these must be in collaboration with a client to further promote ecological activity.

ID Logistics makes use of active involvement when it comes to customers’ sustainability programmes. Annually, the company gets involved with evaluations made by Ecovadis (the world’s largest and most trusted provider of business sustainability ratings) or Sedex (one of the world’s leading ethical trade membership organisations). These groups help establish a long-standing environmental stance both in-house and with external businesses.

Stemming from this, ID also play an active role within the Demeter club. This organisation brings together key players in the supply chain (distribution, manufacturers, logistics service providers, and public authorities) to promote collective ecological actions in a collaborative way.

INNOVATION IN THE INDUSTRY

In recent years, ID Logistics has ramped up its deliverance of innovative development. 2014 saw the company set up a true innovation unit – four engineers were tasked with setting this up, and they utilised collaborative methodology to centralise the group’s innovative projects.

In order to manage the unit, the firm created an innovation committee made up of managers from multiple departments including operations, IT systems, and development departments, to monitor the team’s focus on future topics.

A part of this increase of innovative development is the improvement of customer service across the company.

State of the Art Fulfillment Services Pick & Pack | Custom Packaging | International Shipping Serving Domestic and International Business Strong Incentive Rates with Carriers Knowledge in Hazardous Shipping and International Custom Requirements

First on the West coast to have the SCREEN TruePress Jet520 HD SC Ink

31 Years in Business 916-442-3613 | 800-201-6777 admailwest.com | sales@admailwest.com

521 N 10th Street, Sacramento, CA 95811 FULFILLMENT 800 N 10th Street, Suite F, Sacramento, CA 95811 DIGITAL PRINT 840 Embarcadero Drive, Suite 80, West Sacramento, CA 95605

US 1 Express

Courier Services Same Day - 24/7/365

2515 East State Street Trenton 08619 800-494-4644 609-890-7770 609-890-3183

us1express@aol.com www.us1express.com

ID’s aim is to allow customers to benefit from the new solutions they produce, and improving the service provided, by making it much more efficient and flexible. Within this, ID will be offering a variety of different kinds of products that stand out to the consumer.

However, the company’s focus is not only restricted to operation excellence. ID works towards anticipating the future needs of its customers and the industry through the application of incremental technological developments.

The partner and supplier relationships that ID maintains are held with absolute importance. Working with multiple external businesses means that the fluidity of service and communication between them is paramount to success.

It is due to this element of logistics that ID unites its partners around an ecosystem of innovation. Each external body is approached on a regular basis to share with ID the product development and service plans they each plan for the future. Existing suppliers then look into each development plan to analyse its potential, as well as issues, that could arise.

The organisational structure allows for a simple but effective process of identifying prospective subjects, analysing their relevance, setting up a representative trial, and ensuring the ease of its development (scaling up the trial to fit the realistic needs of the subject).

The communication and sharing of knowledge and planning between the integrated businesses allows ID, as well as each company involved, to gain the latest in development, innovation, and progression to help each collaboratively move forward in the industry.

With 2021 around the corner, ID Logistics continues with its expansion into various countries around the globe and aims to grow its influence in the North American market. It is fair to say that ID is one logistics company that is worth keeping an eye out for in the coming new year.

ID LOGISTICS

Tel. +1 (813) 514 2580 us_contact@id-logistics.com www.id-logistics.com

The Building Blocks of Business

Outlook interviewed Robert Cumming, Director of Environment, and David Redfern, CEO, of Lafarge Eastern Canada for a closer look at how the company is making sustainability a core component of its operations

Writer: Marcus Kääpä | Project Manager: Ryan Gray

Construction has always been at the centre of civilisation and urban planning—that is, for as long as humans have had buildings to build.

From the first wooden forts and lookout towers, to motte-and-bailey castles, and the Great Pyramids of Giza, construction has served as the building blocks of civilisations. And with the unique and innovative designs of the Roman Empire, with grand structures such as the Colosseum and aqueducts, the world saw its first use of an early form of cement en masse.

Today, cement, concrete and other materials dominate the construction industry as primary materials for buildings, bridges, walkways, roads, paths, and a multitude of other structures all over the globe. There is more concrete sold per year than all other building materials combined.

And in Canada, the construction industry has undergone a dramatic change. Due to a mixture of rapidly evolving innovations, a global focus on sustainability, and recent challenges posed by the current COVID-19 pandemic, Canadian construction has renewed itself to align with an ever-advancing sector.

“We’ll look back on this time period in 10 years and recognise that the industry was going through a huge shift – the biggest changes in the building materials sector in over 100 years,” begins David Redfern, CEO of Lafarge Eastern Canada.

“The change won’t happen if we act alone. We must change the ‘tragedy of the commons’ into ‘the power of the commons,’. To do so, we need to activate a framework of partners with governments, developers, NGOs and businesses to act interdependently and to collectively drive a sustainability-focused mindset in our shared-resource system.”

AN INSIGHT INTO OPERATIONS

With 6,000 employees and 400 sites across Canada, the company’s mission is to provide construction solutions that build better cities and communities. From cement and aggregates, to ready-mix and precast concrete as well as asphalt, paving and construction, Lafarge Canada brings value to every project.

“In Eastern Canada, we have three main product lines—Cement, Ready-Mix and Aggregates—in addition to our Geocycle business that focuses on waste management solutions. Together, all four are vertically integrated; where Geocycle supplies fuel and raw materials, derived from by-products, to our cement manufacturing plants, and our cement and aggregates are then used to produce our ready-mix concrete products,” explains Cumming.

“Cement and cement alternatives are produced at seven locations in Ontario, Quebec, and Nova Scotia, and shipped to terminals and to ready mix concrete plants by ship, rail, and truck.

“We produce multiple types of cement and concrete blends with differing performance capabilities. Many of our concrete products include by-products from the power and steel sectors and are used in proprietary blends to produce cements with enhanced properties,” he adds.

The company also operates around 120 aggregate quarries and sand pits. Here too, circularity has a role such as a specialty program through which excess soils from construction sites are conserved and used to rehabilitate land in and around the company’s quarries using industry leading quality protocols. Lafarge also recycles over one million tonnes of demolition concrete per year into a specialised product called Aggneo.

Lafarge Canada has around 80 ready-mix plants that combine aggregates and cement mixes – and water is added – to produce ready-mix concrete which is delivered swiftly to various construction sites. In doing so, the firm is also a large transportation company and operates a fleet of nearly 800 ready-mix delivery trucks.

Geocycle is a subsidiary of Lafarge and specialises in finding industrial by-products that can be recycled into the company’s cement plants, and processing and diverting waste materials from landfills to cement plants to replace coal and petcoke in the manufacturing of cement.

Robert Cumming, Director of Environment for Lafarge Canada

Lafarge Canada is the largest Canadian provider of diversified construction materials, as well as being a member of the global group and brand, LafargeHolcim.

The company’s Canadian entity is split into the two divisions: Eastern and Western Canada, and functions as a materials supplier while engaging in construction streams such as buildings and housing, infrastructure, energy, and mining. The company prides itself on providing time, cost, performance, innovation, and sustainability benefits to its customers’ projects.

Having worked for Lafarge for over twenty years, Redfern has witnessed first-hand recent industry developments and has had the honour of helping the company further its aims and reach new goals. Robert Cumming, Director of Environment for Lafarge Canada, agrees.

“Sustainable construction is the way forward, and Lafarge is definitely headed in the right direction,” he tells us.

After completing his chemical engineering degree in 1989, Cumming worked in an engineering firm, and during a part time master’s in environmental engineering he developed a passion for the promotion and preservation of sustainability and the environment.

Cumming then joined an environmental services company where he learned the importance of the relationships with stakeholders, partnerships, environmental management systems, and how to increase profits through sustainable thinking.

“Long before sustainability was a widely established goal, I knew that I wanted to focus on making a lighter environmental footprint from within the industrial sector – and to do so efficiently, effectively, and profitably,” Cumming says.

“In 2004 I joined Lafarge Canada just as the company was embarking

PRODUCTS AND SERVICES

Lafarge’s solutions for buildings, roads and homes draw on all its product lines. The cities where Canadians live, work, and raise their families along with the community’s infrastructure benefit from the solutions provided by Lafarge.

“Whether the goal is to build durably, aesthetically, quickly (or all three), we bring innovations like Agilia® self-consolidating concrete, DuraCycle™ asphalt engineered with recycled materials, NewCem Plus™ low carbon cement and now ECOPact Green Concrete to the table,” Redfern tells us.

List of services:

• Aggregates • Asphalt • Cement

• Concrete products • Concrete ready-mix • Construction

• Services

• Remote site solutions

• Ductal

David Redfern, CEO on a circular economy program to repurpose waste materials into fuels. Construction and demolition are mirror images and lend themselves well to circularity.”

SUSTAINABLE CEMENT SOLUTIONS

Indeed, CEO Redfern and Lafarge Canada attribute the firm’s longstanding success and reputation to three key factors: innovation, peoplecentricity and, critically, sustainability.

With the aim of taking serious actions towards increased sustainability, Lafarge signed a Net Zero Pledge with science-based targets as of September 2020. Having joined the Science Based Targets initiative (SBTi), LafargeHolcim is the first international building materials company to sign the “Business Ambition for 1.5°C” in line with the net zero pathway aim.

A part of this is its 2030 goals that include lowering its target for CO2 in cement production to 475 kilogrammes per tonne and, as of signing the pledge, partnering with SBTi to develop an active plan for aligning climate targets to a 1.5°C future in the sector – paving the way for a greener industry.

“It has been an important priority for our company, especially in recent years. The appointment of our Chief Sustainability Officer, Magali Anderson at the LafargeHolcim level, clearly signalled that sustainability is now a central theme to our company’s growth strategy,” Redfern elaborates.

“With 60 percent of the world’s 2050 infrastructure needs not being built yet, and the simultaneous global imperative to reach net-zero carbon emissions in all walks of life, we see this as an immense opportunity for growth – rewarding our shareholders, our employees, our neighbours, and of course our customers.”

Earlier this year Lafarge mapped out the firm’s decarbonisation strategy and moved an extra step forward to ensure its 2030 goal and plans were certified by science-based targets. This was to signal to company stakeholders that environmental aims such as decarbonisation are true business aims, not simply aspirational goals without a business case attached to them.

To support this, Lafarge ensures that over 55 percent of its research, conducted by its Lyon, France Labs – the world’s largest building materials laboratory – is focused on issues surrounding climate solutions within the industry.

“We are replacing our fossil fuels with low carbon fuels thus avoiding their landfilling (or incineration) and the associated greenhouse gases,” Cumming adds. “On top of this, the company is innovating with advanced cement blends further integrating steel and electricity production by-products, investing in energy efficiency, and demonstrating novel carbon capture and utilisation technologies with partners.

“We are also working with our customers and governments to move towards lower carbon procurement and supporting the metrics and performance standards needed to facilitate this. For example, in early 2021, the Canadian Standards Association (CSA) in conjunction with the American Society for Testing & Materials (ASTM) will publish the CarbonStar standard which will allow a consistent means of measuring carbon content in a cubic meter or cubic yard of concrete,” concludes Redfern. Lafarge Canada has also launched the ECOPact product line consisting of low-carbon concrete product offers. This will enable customers to choose lower carbon, greener options that are more financially viable, and suit their specific needs.

Lafarge Eastern Canada already recycles two million metric tonnes of industrial and commercial by-products annually, and the national company is eager to carry out its five international carbon capture pilot projects, including CO2Ment – a project focused around capturing industry greenhouse gases and recycling them into lowcarbon fuels for the Western Canada business unit.

Aside from Lafarge’s progressive sustainability story, the firm is equally determined on being a peoplecentric organisation that ensures its employees are proud of and enjoy their work, assuring quality results for its customers, and engaging with the wider community.

“We have a wide array of sponsorships and partnerships with local community leaders. From product donations for the University of Dalhousie’s Engineering Building, sponsorship of NGO conferences, donations to various community organisations, and even small hyperlocal donations like the Angel Tree Gifts for Kids, in the village of Bath, Ontario,” Cumming tells us.

Engaging with local communities is not only a positive company aim, but also a necessity. With a product like concrete which only takes a few hours of transport time before it sets, the firm’s concrete plants must be strategically located close to markets. Given transportation costs the aggregate quarries must also be close to the concrete plant - transportation networks are critical to success.

“David Redfern, CEO Lafarge Eastern Canada, has signed a UN declaration with an extensive array of programs to attract and retain women in our organisation and industry. We have also been awarded a place in Canada’s Best Diversity Employers awards.”