Revolutionizing rail travel, Stadler US is making its mark with its state-of-the-art facility, which manufactures cutting-edge trains that are not only tailored to meet the unique needs of customers but also set new standards in the industry

Writer: Rachel Carr | Project Manager: Kieron Harvey

Since the 1820s, railroads have played a pivotal role in US transportation.

Initially, horses and steam engines pulled rudimentary wooden freight cars, but as the industry evolved, the US soon began developing its own rail manufacturing capability as early as the 1830s.

During the Industrial Revolution, railroads advanced significantly, becoming a critical mode of transportation for raw materials over long distances. Since then, trains have undergone major improvements, a testament to the innovation and growth of the rail travel industry.

Not only did this progress shape the nation’s infrastructure and economy, but it also laid the foundations for companies like Stadler US to thrive.

In 2023, Utah State University (USU), the ASPIRE Engineering Research Center (ASPIRE), and Stadler US collaborated to develop and test a battery-powered passenger train.

Based on the Fast Light Intercity and Regional Train (FLIRT) Akku concept, it has been successfully implemented in the US as the first multiple-unit train with a battery drive.

However, adapting the project to US infrastructure and national regulations requires extensive R&D.

Despite starting as a transport pioneer, the US railway system has been deteriorating for decades with almost no upgrades. As a result, only one percent of rail lines are electrified in the country. However, years of neglect have created the ideal conditions for Stadler US’ battery-powered passenger train, which provides a zero-emission alternative to dieselpowered vehicles.

ASPIRE is developing the trackside charging infrastructure for the train, which will enable emission-free rail transport on nonelectrified routes in the US.

An ideal transportation solution for areas without overhead electric infrastructure, it also allows for longer routes, as the FLIRT Akku train has demonstrated a range of 185 kilometers.

Stadler US is the stateside division of Swiss manufacturer, Stadler Rail, whose rich history dates back to 1942 when Ernst Stadler founded an engineering office in Zurich.

Three years later, Stadler Rail began producing battery and dieselpowered locomotives, with its first passenger vehicles rolling off the production line in 1984. This history of innovation and expertise has been a cornerstone of the company’s success and earned it a reputation for reliability and trust in the rail travel industry.

In 1989, Stadler Rail made a groundbreaking contribution with the introduction of the first modular vehicle. This innovation paved the way for successful business development and solidified the company’s position as the world’s leading manufacturer in the rack and pinion sector.

These lightweight vehicles, equipped with various rack and pinion systems as well as track gauges, are designed to handle extreme landscapes and gradients, showcasing Stadler Rail’s longstanding leadership in the industry.

Today, Stadler US has a varied product range of rail cars and rolling stock for the North American market, spanning from trams to high-speed trains.

Although the company has been operating in the country since 2002, it wasn’t until 2019 that Stadler US opened its first production site in Salt Lake City, Utah.

The facility imports car shells and bodies from Europe, but Stadler US plans to change this to reduce its carbon footprint.

In the rapidly evolving landscape of Smart City Transportation, the r2p Group stands out as a beacon of innovation and excellence. Founded with the mission to design and develop intelligent technology systems that set the highest standards in quality and safety, r2p has become synonymous with cutting-edge solutions for the mobile transport sector. Our collaboration with Stadler US is a testament to our shared values of innovation and excellence, marking a significant milestone in our journey to redefine transportation.

Since its inception, r2p has embarked on an extraordinary journey of growth and innovation. Our comprehensive portfolio includes CCTV, Passenger Information Systems, Network Audio Solutions and Automatic Passenger Counting, all equipped with real-time data transfer capabilities for rail and road vehicles, as well as fixed infrastructure.

Headquartered in Flensburg, Germany, the rapidly growing r2p Group operates internationally in 45 countries with competence centers in Australia, Canada, Malaysia, Denmark and the United Kingdom. With additional subsidiaries and offices in the US, Spain, Italy, Switzerland and Brazil, r2p takes pride in being a truly global company.

The r2p NetSpire solution redefines flexibility and scalability in Passenger Information System applications. As a clienthosted, networked IP-based system, it offers unparalleled modularity, allowing for easy configuration and integration with existing infrastructure. From integrated public address systems to passenger information displays and passenger emergency intercoms, r2p NetSpire delivers a comprehensive integrated solution that enhances passenger experience and safety, supported by a robust web interface for effortless transit operator management.

Our flagship CCTV software solution, r2p HORIZON,

Passenger Information System

epitomizes innovation by unifying our entire CCTV product portfolio under one intuitive, modular platform. Designed for efficiency and ease of use, r2p HORIZON allows for seamless remote management and maintenance of r2p CCTV services, ensuring our customers can enjoy reduced operational costs and enhanced fleet availability. r2p Horizon is available as a highlysecured Software-as-aService or on-premise hosting solution, with our experts’ user support and software maintenance. All options comply with our high GDPR and security standards.

Our newest subsidiary, r2p USA Inc., harnesses the r2p Group’s unparalleled global depth of knowledge in OEM

hardware manufacturing, software development, and systems integration. As a wholly owned subsidiary of T.G. Baker Americas Inc. (part of the r2p Group, headquartered in Toronto, Canada), who has been delivering major transit projects for many years, r2p USA Inc. is equipped with the tools to successfully support the full turnkey project delivery of our integrated Passenger Information Systems, mobile CCTV and Automatic Passenger Counting solutions across the US. Our state-of-the-art manufacturing facility in Buffalo represents our commitment to delivering Buy American Act (BAA)compliant products that exceed industry standards. Our involvement in several major existing US CCTV and Passenger Information System projects including

the MARTA Metro Train Replacement Project (Atlanta, GA), the KCATA Streetcar Project (Kansas City, MO), the HART LRT Rail Project (Honolulu, HI) and the MBTA Green Line Project (Boston, MA) underscores our dedication to excellence and innovation as well as signaling our intent to expand our presence in the US market. With the implementation of our strategic sales presence in Chicago, IL, and our BAAcompliant manufacturing facility in Buffalo, NY, r2p is poised for further growth, ready to forge new partnerships and explore new opportunities in the North American market.

At r2p, we are driven by a vision to revolutionize the landscape of intelligent transportation solutions.

Our commitment to quality, innovation, and customer service is unwavering, as we continue to push the boundaries of what is possible. We invite you to join us on this exciting journey to explore the possibilities and shape the future of Smart Mobility in

Rob Little Senior Account Manager - Integrated Systems

T: +1 312 771 028 6 | M: robert.little@r2p.com

Sean Coster Managing Director

T: +1 843 907 2085 | M: sean.coster@r2p.com

the US. Let’s embark on this road to innovation together, with r2p leading the way. To learn more about our capabilities, discuss partnership opportunities, or schedule a visit to our manufacturing facility, please contact our dedicated team.

r2p USA Inc.

50 Fountain Plaza Suite 1400

Buffalo 14202

USA

T: +1 905 669 8422 M: usa-info@r2p.com

Modular vehicle concepts

HIGH-SPEED – SMILE

INTERCITY – FLIRT200, KISS200

REGIONAL TRAINS – GTW, WINK, KISS, FLIRT160

CITY TRANSPORT – TINA, TANGO, TRAMLINK, VARIOBAHN, METELITSA, CITYLINK, underground trains

LOCOMOTIVES – EURO9000,

EURODUAL, EURO6000, EURO4001, EUROLIGHT, SALI, Central Cab, customized locomotives

TAILOR-MADE – Multiple unit rail vehicles, rack railways, carriages

Alternative drive solutions

BATTERY ELECTRIC DRIVE – FLIRT Akku

HYDROGEN DRIVE – FLIRT H2

In 2022, the company also signed a Memorandum of Understanding (MoU) with the California State Transportation Agency (CalSTA) and the California Department of Transportation (Caltrans) for the design and delivery of four zeroemission trains, with the option to purchase up to 25 units.

FLIRT has been successfully operating in extreme climates worldwide, from Africa to the Arctic

Circle. As part of the company’s range of alternative solutions, the FLIRT H2 model utilizes hydrogen fuel cells as its energy source. The train operates entirely on electricity and stores kinetic energy in batteries under braking. The electricity generated is then used to power the train, charge the lithiumion traction batteries, and feed the onboard heating, ventilation, and air conditioning (HVAC)

system. The propulsion system, meanwhile, allows FLIRT H2 to operate throughout the day without refueling.

Stadler US delivered the first hydrogen-powered train for passenger rail transport in 2019, selling its first FLIRT H2 vehicle in the country. The lightweight aluminum single-decker model can be arranged in two to four-car compositions.

This year, Stadler US proudly announced that the FLIRT H2 was entered into the Guinness World Records database for the longest distance achieved by a pilot hydrogen fuel cell electric multiple-unit passenger train without refueling or recharging – 1,741.7 miles.

The company’s innovative strength and technological prowess in sustainable rail transport have been highlighted by this impressive achievement.

Knowledge Architects Inc. and Stadler Rail are set to revolutionize workforce development training and its delivery through the implementation of advanced training aids to support transit agencies across the US. Sheila Jordan, Knowledge Architects Inc.’s CEO, reflects on how this strategic partnership represents a significant leap forward in the realm of transportation training.

Step into the future of transportation training with Knowledge Architects Inc. (KA) and Stadler Rail as they embark on a groundbreaking partnership to redefine workforce development in transit agencies across the United States. Sheila Jordan, the visionary CEO of KA, shares insights into this exciting collaboration and its transformative potential.

At the heart of KA’s mission is a dedication to leveraging cuttingedge technology and

innovative instructional design to empower the workforce. Renowned for their expertise in crafting immersive training solutions, KA is teaming up with Stadler Rail, a global leader in railway

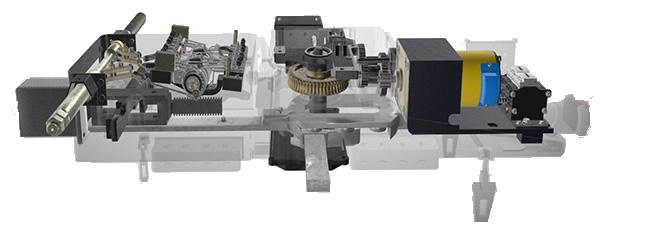

The partnership kicks off in Atlanta, GA, where KA and Stadler will deliver over 3,000 hours of training content specifically designed for the new rail cars being delivered to MARTA (Metropolitan Atlanta Rapid Transit Authority). Sheila Jordan emphasizes the importance of imparting technical knowledge

vehicle manufacturing, to elevate training standards to unprecedented heights

and instilling practical skills for real-world scenarios. With over two

decades of experience in organizational development and learning technology, Sheila is passionate about nurturing the talents of the next generation of workers. KA and Stadler’s collaboration extend to Boston, MA, where they’ve developed interactive 3D models and 4K simulation video content for the Massachusetts Bay Transportation Authority (MBTA), focusing on the innovative Green Line Train Protection System (GLTPS) designed exclusively for MBTA. This system incorporates cuttingedge Assisted Braking and Collision Avoidance functionality. Through engaging video content, KA demystifies the intricacies of GLTPS, emphasizing safety and operational excellence, thus reassuring the transit agency leaders, and making them feel confident in the training initiatives.

But their vision doesn’t stop there. With the opening of a new office in

Chicago, IL, KA is poised to make a nationwide impact. As Chicago’s Metra invests in Stadler’s Battery Electric Multiple Units (BEMUs), KA stands ready to provide tailored training solutions, ensuring that Metra has access to the latest advancements in technology and instructional design. This nationwide expansion should make the employees in the transportation industry feel proud and part of a larger mission.

These exciting transit projects cement KA’s solid

partnership with Stadler to revolutionize transportation training and set new standards of excellence and innovation. With each partnership, they’re not just shaping the future of workforce development –they’re driving it forward with passion and purpose.

“We are delighted to partner and collaborate with Stadler on projects in Atlanta, Boston, and Chicago

Sheila Jordan CEO, Knowledge Architects Inc.

“WE ARE CONSTANTLY IMPROVING THE PERFORMANCE AND EFFICIENCY OF OUR TRAINS USING STATE-OF-THE-ART TECHNOLOGIES”

– STADLER US

Stadler US is happy to create custom vehicles to suit each customer.

After starting with the production of single vehicles and small-batch series, the company now offers many years of experience and engineering expertise to meet specific needs, guaranteeing flexibility and quality.

Rail operators benefit from Stadler US’ personalized approach, allowing for tailor-made locomotives

to meet special requirements in construction, shunting, and journeys with combined gear wheels and adhesion.

Alongside trains, Stadler US offers customized signaling and digital solutions and services to ensure efficient and sustainable rail operations. It also provides continuous customer care beyond train delivery, ensuring reliable and safe rail operations.

HaslerRail is the market-leader and innovative supplier of performance and safety-relevant on-board electronics, sensor, software and data management products and solutions for the railway industry.

Our on-board product range includes event recorders, speed and odometry sensors, energy measurement systems and HMIs. For operators of passenger and freight services connectivity and information are key.

By combining our on-board technology and software solutions we unleash the full power of Big Data analytics to uncover trends, patterns, and correlations in large amounts of raw data. This provides operations and maintenance teams valuable insights and empowers them to make data-informed decisions.

Our products and solutions are available for new build or retrofit projects.

We can specify, manufacture and deliver field-proven solutions that enable the safe, efficient and sustainable operation of intercity, regional and light rail vehicle fleets.

And our worldwide network of manufacturing and customer service facilities means that we can provide support swiftly and locally.

Elliot Flores, Sales & Business Development Manager - elliot.flores@haslerrail.com

Monica Morgan, Project & Site Manager - monica.morgan@haslerrail.com

Robin Foreshew, RailData Sales & Business Development Manager - robin.foreshew@haslerrail.com

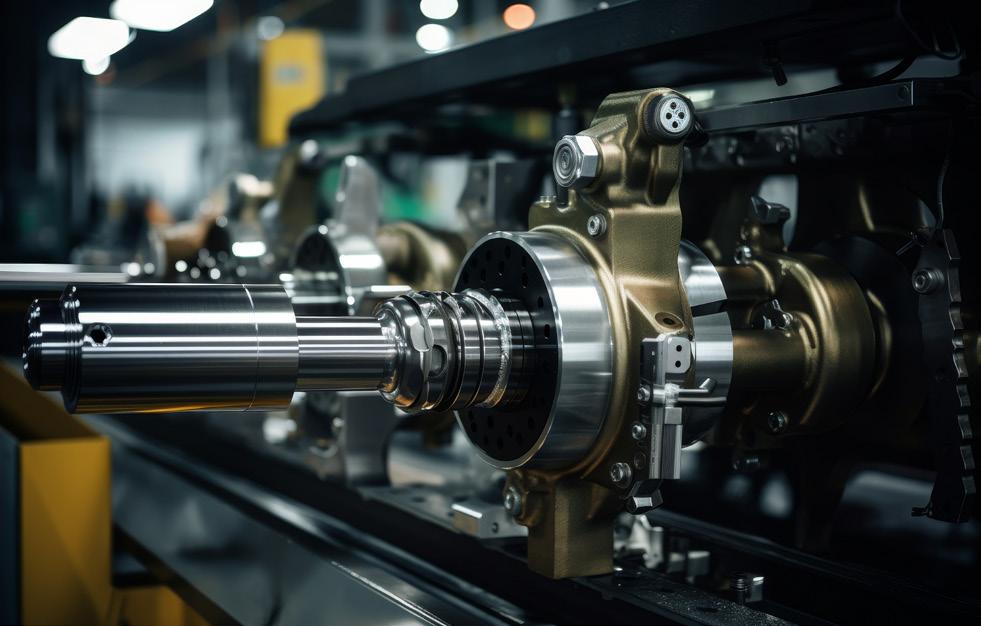

As a specialist in the design and manufacture of highly complex assemblies for rail vehicles, we offer customized solutions of the highest quality. Our lean organizational structures enable efficient production and short communication channels, resulting in rapid implementation of your projects.

We understand our customers’ requirements and offer assemblies that can be supplied with fire protection certificates, insulation and other specific requirements on request.

With our many years of experience, state-of-the-art technology and infrastructure, we are your reliable partner for complex assemblies in rail vehicle construction. Place your trust in the expertise of Letrona AG for highquality, customized solutions that meet your exact requirements.

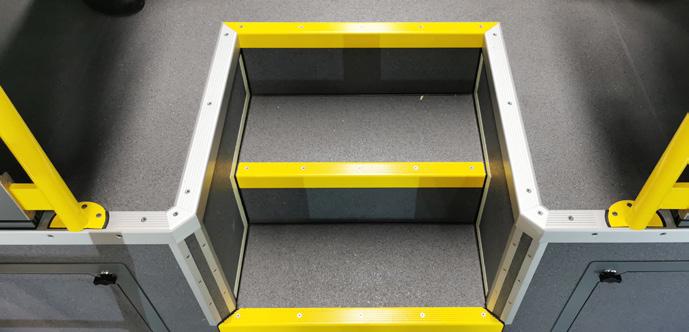

Stadler US trains are produced in small series and optimized for individualization and quality, in contrast to the model series of tailormade multiple units. The company offers custom-made carriages for driving trailers, passenger cars, panoramic carriages, and sleepers with a wide range of interior design, HVAC, and technology options. Furthermore, its trains are

cost-effective and cutting-edge, providing passengers with maximum comfort.

In 2019, Stadler US was also contracted by the Dallas Area Rapid Transport (DART) to build eight FLIRT trains and design the equipment maintenance facility (EMF) for the Cotton Belt Regional Rail Project.

In the same year, the Metropolitan Atlanta Rapid Transit Authority (MARTA) awarded Stadler US a contract worth over $600 million to build 127 metro trains for the Atlanta area.

The contract specified that the new trains must be based on the previous models and required the integration of modern technology into the old specifications.

Stadler US has implemented a Youth Apprenticeship Program inspired by the Swiss model to handle the high volume of contracts it receives.

This program is designed to ensure that the company has the necessary talent to complete the orders. In the first year, students can choose between the Automatic Technician (electrical) and Production Technician (mechanical) tracks.

In the second year of their apprenticeship, trainees attend courses at Salt Lake Community College, receive supplementary training from Stadler US, and are integrated into regular production.

In the final year, advanced lectures are conducted at the college, whilst more skilled, practical training continues at the company. To graduate from the program, apprentices must successfully complete final testing and a final project.

The purpose of the intensive training is to ensure Stadler US maintains the high standards of the long and illustrious history of Stadler Rail.

Transforming Transit with New CQ400 Trains

Thanks to Stadler, MARTA will provide a safe, modern ride, moving millions of people through our region and propelling transit into the future.

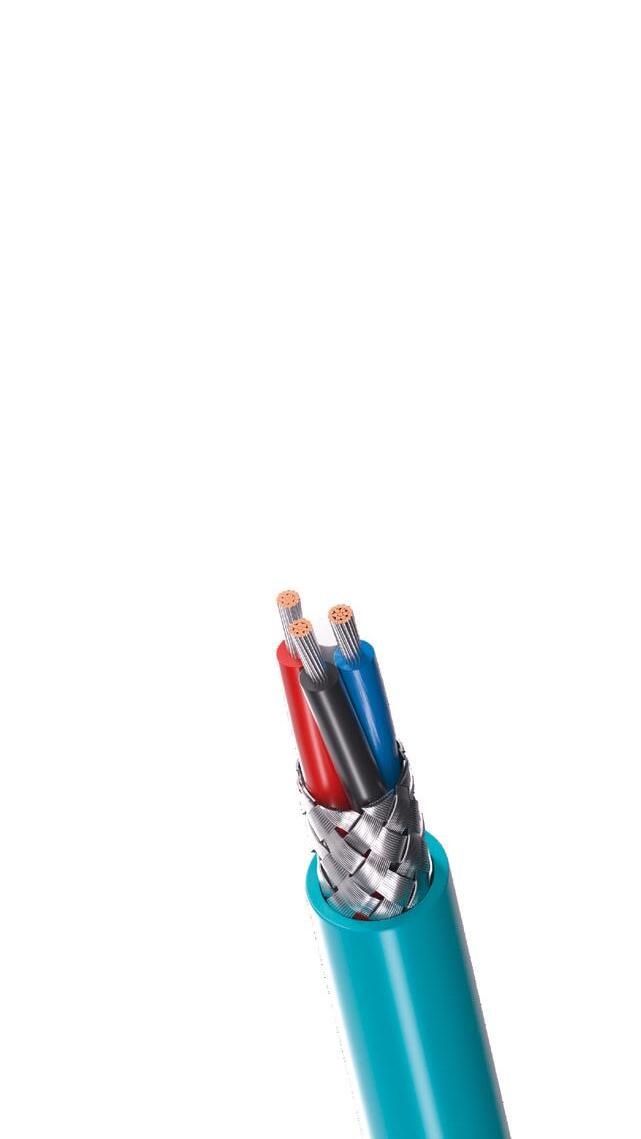

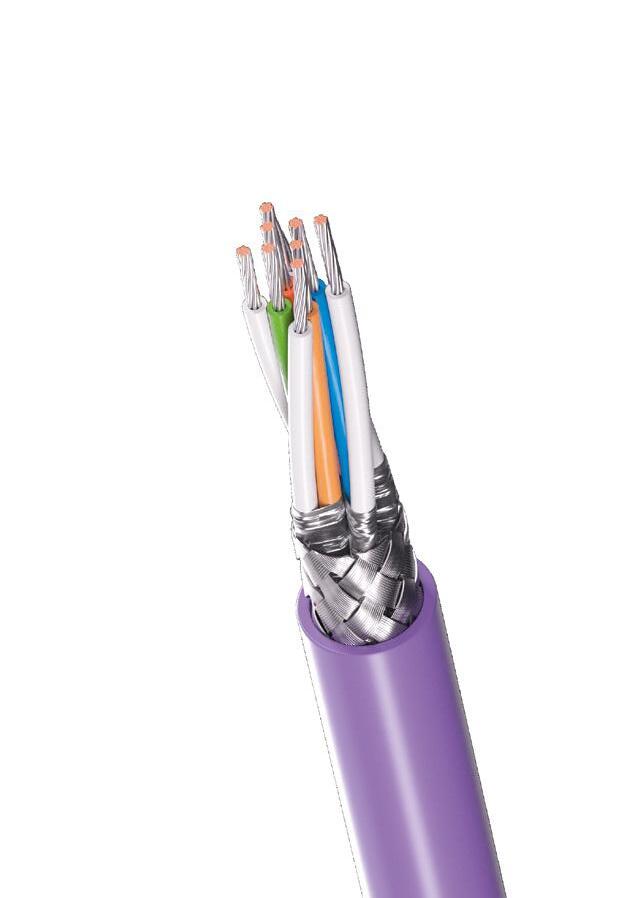

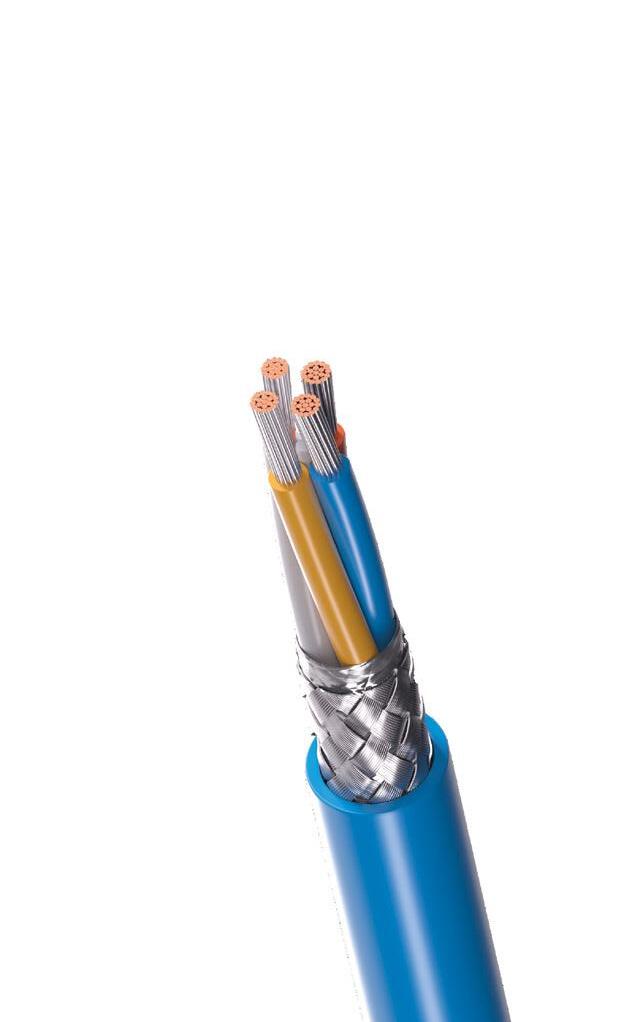

Swiss Quality Rolling Stock Cables for sustainable mobility

www.studercables.com

Worldwide, BETAtrans® GKW-ENX cables are selected for their low LCC. They offer outstanding performance with their lightweight design, low fire-load and high L.O.I., providing additional advantages.