MADE IN GERMANY. SINCE 1889.

WE ARE AN INTERNATIONAL RENOWNED HIGH - QUALITY GLASSWARE

MANUFACTURER, SPECIALIZED IN THE PULLING PROCESS.

OUR CRYSTALLINE GLASSES LOOK LIKE MOUTH - BLOWN, ARE VERY LIGHT AND VERY ROBUST.

MADE IN GERMANY. SINCE 1889.

WE ARE AN INTERNATIONAL RENOWNED HIGH - QUALITY GLASSWARE

MANUFACTURER, SPECIALIZED IN THE PULLING PROCESS.

OUR CRYSTALLINE GLASSES LOOK LIKE MOUTH - BLOWN, ARE VERY LIGHT AND VERY ROBUST.

1889 - 1945

1908

First production of mouth - blown stems

1935 - 1942

Distinctive design by Bauhaus pioneer Prof. Wilhelm Wagenfeld

1991 - 1995

1991

Biggest glassworks in former GDR

1992

Privatization of the "Lausitzer Glaswerke"

2000 - 2018

2005

Name change to "Stölzle Lausitz GmbH"

2010

Commissioning of the 4th production line

1889

Founding of the company "Oberlausitzer Glaswerke

J. Schweig & Co" in Weißwasser (Germany)

1946 - 1990

1946

Becoming a state company

1960

First mechanical production of tumblers

1968 - 1969

First mechanical production of stem glasses

1996

1996

Take - over by "CAG Holding GmbH", name change to "Stölzle Oberglas Lausitz GmbH"

Construction of the new production hall, 3 production lines and 2 furnaces

2019

130th anniversary

Merger of the "Oberglas GmbH" into the "Stölzle Lausitz GmbH"

Stölzle Lausitz GmbH belongs to the CAG Holding, a family - owned group of companies owned by Dr. Cornelius Alexander Grupp.

The activities of the group are diversified, including some of the most renowned brands involved in processing glass and aluminium.

The CAG Group operates through 60+ factories worldwide and employs globally more than 9.000 employees, generating annual sales of 2B € .

Manufacturer of lead - free, high - quality

crystalline glasses since 1889

Made in Germany, production in Weißwasser (2 hours away from Berlin)

425 employees

45M glasses produced annually

75M € turnover

Delivery to over 120 countries

Private Label, B2B, B2C and DTC

End - to - end solutions (inhouse design, glass and decor production, packaging, warehouse and logistic)

From the extraction of raw materials to production and delivery, we make sure that our environment is affected as little as possible.

• Production in Weißwasser , made in Germany

• Investment in hybrid furnace (gas/electronic) reducing absolute energy consumption by up to 20% and reducing carbon emissions

• High - quality raw materials supplied locally based on longterm partnerships to ensure quality and to reduce carbon footprint

• 100% lead - free production and no use of any other harmful substances, which means our glasses are also easily recyclable

• Since 2005 active participant in the EU Emission Trading Scheme, to reduce energy consumption and greenhouse gases

• Certified energy management system to increase energy efficiency (DIN EN ISO 50001)

• 100% recycling of own glass shards

• Water cooling system for the production is fed by rainwater

• Packaging, filling material and pallets are made of recyclable material

Thin rim

Glasses seam mouth - blown

Glasses are very light

No rolled edge

Polished rim (hot/cold cut)

Pulled Stem

Glasses have a high breakage resistance

No seamlines

High elegance

Lie gently in the hand

Strong base

Safe base of the glass

Without seamlines

100% lead - free

Professional, timeless and functional design

High brilliance & clearness

Gentle sound

High breakage resistance, especially glasses with pulled or fire - polished stem

Dishwasher - safe

Made in Germany

From Wine, Champagne, Cocktails, Spirits, Beers, Water, Smoothies, Juices, Coffee to Tea...

STEM GLASSES TUMBLERS OTHERS

(DECANTERS,CARAFES, COOLERS, JUGS, STRAWS...)

Plenty forms are possible, with stem and/or as tumbler. Here a few examples.

ROUND ANGULAR CURVED

Plenty optics are possible. Here a few examples.

Plenty cuttings are possible. Here a few examples.

Different stemps are possible from shining to various shapes. Here a few examples.

Ceramic & organic printing (up to 8 colors)

UV printing (up to 8 colors)

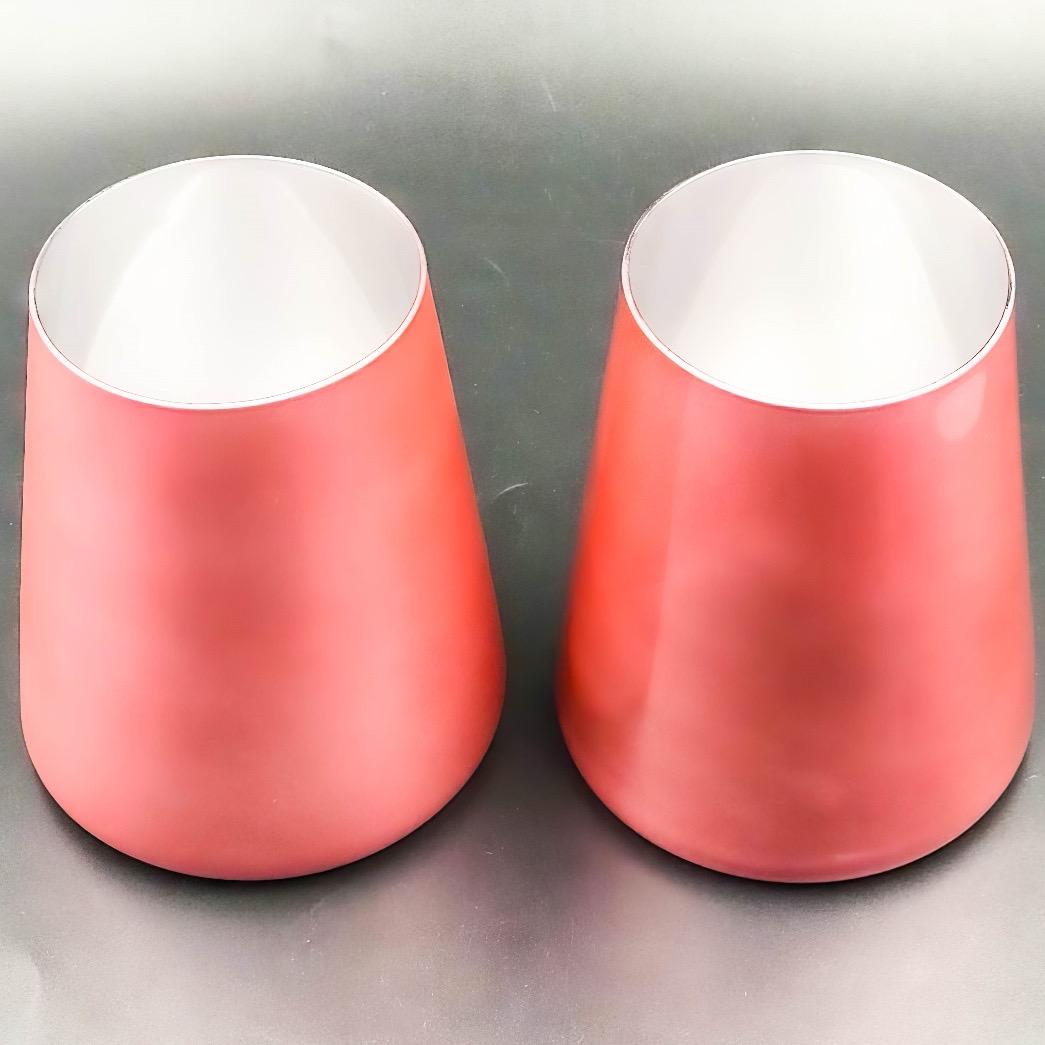

Organic coating (partially or fully, multicolor)

Machine - cutting / engraving

Digital printing (up to 1000 colors per glass)

Filling lines by screen printing and laser

Handmade - decal

Handmade artistry

Multicolour logo print additionally possible

Metallic silver inside and metallic multicolour outside

Multicolour logo print additionally possible

Multicolour logo print additionally possible

New color options and combinations.

Additional colors and glass shapes available upon request.

New color options and combinations.

Additional colors and glass shapes available upon request.