8 minute read

The Magic Of Coal Preparation Plants

hydrophobic (floatable) material is separated and reported as FCP. This is combined, at the mixing point, with the DMC product to make the TPP.

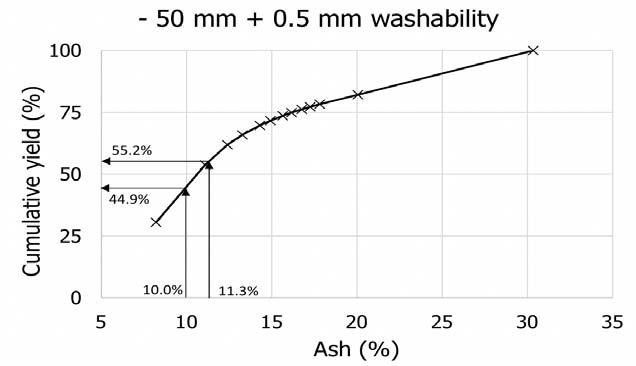

Incremental ash is a concept that relates to the ash value distribution of particles that comprise a TPP. Due to this distribution, although the product may have a given overall ash value (e.g. 10%), it actually comprises a mixture of particles with a wide range of ash values. It may contain individual particles that have a 5%, 6%, or 7% ash value mixed with particles that have higher ash values. In fact, it is conceivable that there is an individual particle with a 25% ash value in a shipment that is sold as having a 10% average ash value. Figure 2. Coarse coal yield/ash washability curve.

In an analogous way, the ash value of particles in the CCP and FCP streams also have distributions. If the Table 4. TPP yield from combing coarse and fi ne circuit separating condition of the DMC is changed by a small products amount to increase the overall product ash value, then a small (incremental) increase in yield would result in an Processing associated ash value (incremental ash). A similar eff ect Circuit Split (%) Yield (%) Ash (%) occurs in relation to the operating condition of the FCP Coarse 75 44.9 10 stream. In this context, the incremental ash equalisation Fines 25 55 10 concept is that TPP yield will be maximised only when the Total plant product 47.4 10 incremental ash of the CCP and FCF streams are the same at the mixing point.

To summarise, maximum yield in the CPP is comprising the final products are equalised. The corollary achieved when the incremental ash values of all streams is that yield is lost in the CPP when they are not.

“Everything has the potential for improvement –

Elsa helps you tap into the cost-effective solutions.”

Contact t Andrew w today. . Independent and unbiased: supporting coal handling and preparation plants, mineral processing plants and allied processing industries through a cost effective, world class, Australia-based consultancy business model.

Elsa Consulting Group Pty Ltd

Info@ElsaConsultingGroup.com SKYPE: ElsaConsultingGroup +61 408 076 088

With more than 36 years processing experience, Dr Andrew Vince C. Eng., F.I.Chem.E. (Elsa Consulting Group) offers amazing realistically achievable, technological, and operational improvement solutions for new or existing processing operations.

Impact of mixing point

If the desired TPP has a specification of, for example, 10% ash, then this can be met from 10% ash CCP material and 10% ash FCP material, as the combined TTP would have 10% ash aft er the mixing point in Figure 1.

For a 10% ash CCP, the data shown by Figure 2 indicates the yield would be 44.9%. For a 10% ash FCP with 55% yield, Table 4 shows that the TPP yield would be 47.4 % for a 10% TPP ash.

Approximately 25 years ago, tall column FCF machines were commercialised that were in some instances capable of achieving the same flotation yield, but with a 2 – 4% lower concentrate ash value. Transposing that eff ect to the example in Figure 2 would result in a flotation yield of 55% and ash of 6%, for which the TPP yield remains the same (47.4%) but the ash becomes 8.8% (Table 5).

A detailed examination of the original CCP and FCP streams indicated that they had very diff erent incremental ash values, and the eff ect of the new FCF technology was to enable the incremental ash values of the two streams to draw closer together.

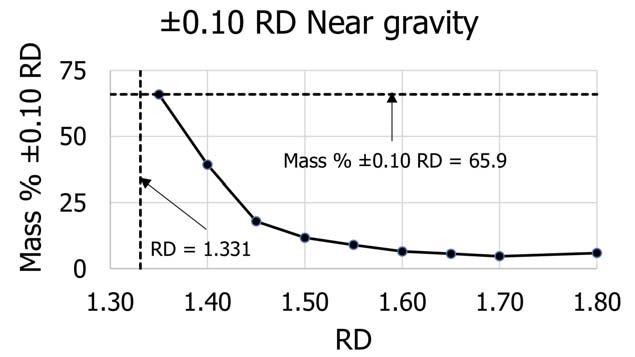

To reattain the 10% TPP ash, it is necessary to increase the DMC separating relative density (RD). Figures 3 and 4 demonstrate that this will have the eff ect of increasing the yield significantly. In fact, to achieve a TPP ash of 10%, it becomes necessary to increase the separating RD from 1.33 to 1.36 to give a CCP ash of 11.3%. The net eff ect on the overall process is summarised by Table 6, which indicates a TPP net yield increase of 7.8% points is achieved.

In summary, a reduction in operating parallel circuit incremental ash diff erence results in superior overall separations. The corollary is inferior CPP separations occur whenever incremental ash diff erences are increased.

Table 5. TPP yield from combing coarse and fi ne circuit products with closer incremental ash values Processing Circuit Split (%) Yield (%) Ash (%) Coarse 75 44.9 10 Fines 25 55 6 Total plant product 47.4 8.8

Figure 3. Expanded cumulative ash/RD curve showing revised DMC RD and ash values to maintain 10% TPP ash.

Figure 4. Cumulative yield/cumulative ash curve showing revised DMC RD and ash values necessary to maintain 10% TPP ash.

Table 6. Increased DMC product ash and yield required to maintain TPP ash

Processing Circuit Split (%) Yield (%) Ash (%) Coarse 75 55.2 11.3 Fines 25 55 6 Total plant product 55.2 10

Near gravity capture concept

The near gravity capture concept relates to the amount of material present in the DMC feed that is within close vicinity to the separating RD. Here, this concept is used to address how the TPP yield is increased whilst still producing a 10% ash product, using the advantages of the low FCP ash provided by the tall FCF column. In order to do this, it is helpful to consider some example washability data.

For this example, Figure 4 depicts how the cumulative mass percentage yield increases with increasing product cumulative ash for the material fed to the DMC unit. This has been derived by examining the results of routine raw coal laboratory RD fractionations with ash analyses.

By looking at this data further, the mass percentage of near gravity material, within ±0.10 RD units of each fraction, can be discerned, and a plot is shown by Figure 5. It is clear that the near gravity level at 1.33 RD would be >65.9%. That is, at 1.33 RD there is a significant amount of material between the values 1.23 RD and 1.43 RD. This is important because it relates to the amount of material that is subject to misplacement to rejects by any ineff iciencies in the DMC circuit when processing this raw coal.

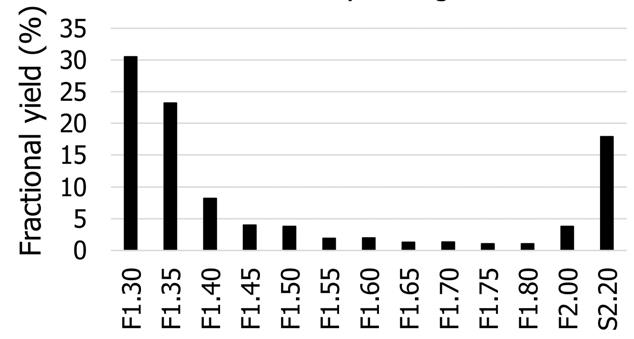

Figure 6 is a washability histogram, which shows graphically the mass percentages in each RD fraction.

Taking a simplified approach of only considering washability data (i.e. assuming perfect separations),

the data shown by Figure 6 indicates that the revised separations occur at much lower near gravity levels.

To summarise, disproportionate but favourably large additional yield in the CPP is achieved by a small increase in DMC separating RD due to equalising incremental ash of parallel streams.

It is important to note that if the DMC separating point were at 1.75 RD, for example, a yield increase would also occur but its magnitude would be much diminished, due to the diminished amount of relevant near gravity material.

In summary, much larger yield increases in the CPP are achieved by a small increase in DMC separating RD, due to equalising incremental ash of parallel streams when there are large proportions of near gravity material present.

Conclusion

Coal preparation plants incur small relative costs and yet enable high prices to be attained for saleable coal. They enable highly leveraged incremental accounting to be utilised, as well as aff ording significant yield increases via straightforward operational setting optimisation, which can include significant near gravity material capture. It truly is magical when incremental accounting, incremental ash equalisation, and near gravity capture are used to obtain money for ‘nothing’.

A major threat to this magic will be discussed in a subsequent article in World Coal.

Figure 5. Mass percent of material between ±0.10 RD units of RD of consideration.

Figure 6. Yield washability histogram.

World Coal Online

The home for the latest coal industry news, analysis, comment and events

Thomas Sloan, Quaker Houghton, USA, explores the importance of dust suppressants in the mining industry.

The need for dust suppressants in the mining industry continues to increase due to health, safety, and regulatory reasons. Whether in a surface or underground mine, dust and other particulates are a constant safety concern for those working in the mining industry. These hazards can also cause a wide range of issues including respiratory illnesses, exposure to noxious gases, and operational risks. For underground mining operations, dust reduction activities tend to focus on the mining process where the majority of the dust is generated.

However, there are also issues with the generation of dust during the transportation of the run of mine product to the surface. As the mined ore moves along the conveyer system, it is dried by the incoming air that is used to ventilate the working section. The conveying system transports material in the opposite direction to the incoming air, increasing the drying process and allowing the