SMACNA & SMART—Building a Future Together

July / August 2023

and SMART are going the distance to win residential market share

INProgress Partners

SMACNA

CONTENTS

July / August 2023 - Volume 17, Number 3

3 PARTNERS IN PROGRESS 2024: THE FUTURE IS NOW

Registration for the 2024 Partners in Progress Conference opens September 6.

4

Key labor-management partnerships are helping local areas reclaim residential market share. 6

Local

INProgress Partners

MICHAEL COLEMAN

ANTHONY KOCUREK

Co-Publishers

KAARIN ENGELMANN editor@pinpmagazine.org

Editor-in-Chief

JESSICA KIRBY jkirby@pointonemedia.com

Editor

POINT ONE MEDIA INC. artdept@pointonemedia.com

Creative Services

Partners in Progress is a publication of the Sheet Metal Industry LaborManagement Cooperation Fund.

All contents ©2023 by the Sheet Metal Industry Labor-Management Cooperation Fund, P.O. Box 221211, Chantilly, VA 20153-1211.

Find Partners in Progress online at pinp.org or at issuu.com/ partnersinprogress. An archive of all issues is available. Issues may be downloaded and printed for no fee.

For comments or questions, email editor@pinpmagazine.org.

It’s

From

2 » Partners in Progress » www.pinp.org

RECLAIMING RESIDENTIAL MARKET

SHARE

FORGING UNITY AND SUCCESS

difference

and

GETTING HELP WHEN IT’S NEEDED MOST SMACNA and SMART have partnered to further mental health support initiatives, earning a Mental Health Visionaries award for their efforts.

BREAKING DOWN BARRIERS

85 and Georgia-SMACNA strive at collaboration and explain the

between a grievance

a gripe. 9

12

nursing mothers

work

Western Washington and Local 66 members

down

DIGGING DEEP FOR MARKET SHARE

Lactation pods for

returning to

help SMACNA-

break

barriers. 14

the toughest non-union market in America, but Florida SMACNA and Local 15 are working hard and staying the course.

16 MY JOURNEY: RENEE WILLIAMSON

SMACNA & SMART—Building a Future Together

Cornell to curious, Renee Williamson took a non-traditional route to her career in sheet metal.

SH EE T ME TA L AI R R AIL TR AN SPO RT AT ION 14

The Future Is Now

Prepare to get back to the future at the Partners in Progress Conference from February 27-28, 2024, in Orlando, Florida.

It is hard to believe it has been nearly a year and a half since the last Partners in Progress (PINP) Conference and that the next conference is fast approaching.

An incredible amount of time and commitment go into planning the sheet metal industry’s premier and largest attended labormanagement meeting. Behind the scenes preparation requires identification of and site visits to hotels that have the meeting facilities and capacity to provide an effective and comfortable learning environment for attendees. Then it is necessary to negotiate affordable room rates, charges for meeting facilities, and food and beverage costs for the conference. Once the hotel arrangements are nailed down, it is time for the SMACNA and SMART Best Practices’ Market Expansion Task Force (BPMETF) members and staff and leadership of the two associations to review feedback and experience from previous conferences to determine content and logistics and line-up speakers. Those are just a few of the reasons the SMACNA and SMART began preparing for the 2024 conference within days of the March 2 closing of the 2022 conference.

New Venue, New Leadership, New Ideas and Best Practices New Venue – Orlando, Florida

Based on feedback from previous conferences, the PINP planning committee and staff selected Orlando, Florida, as the venue for the 2024 Conference to lessen the travel time for those on the east coast. This is not the first time a meeting of this nature has been scheduled in Orlando. The 2018 conference was there, as well as the predecessor—the very first SMART-SMACNA LaborManagement Partnership Conference—in 2000.

The 2024 Conference will be held at the Walt Disney World Swan and Dolphin Hotel in Lake Buena Vista, Florida. Rooms must be booked no later than January 19, 2024, although the safest approach is to book rooms early when registering for the conference.

New Leadership

The 2024 PINP Conference will give attendees an opportunity to hear from the new leaders of both SMART and SMACNA. Carol Duncan, the CEO and owner of General Sheet Metal in Clackamas, Oregon, will become President of SMACNA in October 2023. Michael Coleman, formerly SMART Assistant to the General President and Business Manager of Local 33, ascended to SMART’s General Presidency on June 1, 2023. Carol and Mike, having served as the Labor and Management Co-Chairs of the BPMETF, are uniquely qualified to inspire conference participants with their views on the importance of labor-management collaboration to shape the industry’s future.

New Ideas & Best Practices

The 2024 Partners in Progress Conference will provide an exceptional opportunity for all local union leaders, SMACNA member contractors, chapter executives, training coordinators, and future leaders to come together to strengthen existing relationships and discover innovative strategies to shape a more prosperous future.

As a keynote speaker, Victoria Labalme will share her recommendations to elevate attendees’ ability to communicate, connect, and come alive to win over the individuals they serve.

Kevin Brown, a branding and culture expert, will explain why success in business and life requires anything but conventional thinking and he will share his philosophy about “The Hero Effect”.

Educational tracks for the conference will provide valuable information on Industry Best Practices; Diversity, Equity, and Inclusion; Innovative Recruiting and Retention Strategies; and Leadership Skills. Sessions will feature ways to foster and mentor emerging leaders, address future workforce needs, and employ technology to succeed in future markets.

Conference Schedule

Attendees are encouraged to arrive on Monday, February 26, in time for an early evening Networking Meet and Greet Reception. The conference officially opens Tuesday, February 27, and concludes on Wednesday, February 28.

Labor and Management JATC Trustees are encouraged to stay an additional day, February 29, for an educational program sponsored by the International Training Institute devoted to issues and updates of importance to training fund trustees.

Plan to Register Wednesday, September 6

Reduced Early Bird Registration fees that will save SMACNA and SMART members $200 will end on December 15, 2023. Hotel reservations are best made as early as possible before the cut-off date on Friday, January 19.

Find information on the 2024 PINP Conference at pinp.org. The knowledge that participants will acquire at the 2024 Partners in Progress Conference will be of immediate benefit in their local markets. Make it a priority for labor and management leaders and emerging leaders from your area to attend and be part of the conversation. The Future is Now ▪

Partners in Progress » July / August 2023 » 3

Reclaiming Residential Market Share

By / Sheralyn Belyeu

By / Sheralyn Belyeu

Many contractors across the United States have moved away from the residential HVAC market. “Today, more of our contractors are concentrating on the large commercial or industrial side,” says Mark Saba, executive director of SMACNA Detroit. “A lot of the smaller work has gone nonunion because trying to stay competitive in that market is tough.”

“Before the 2008 crash, 40% of Local 265’s hours were residential new construction,” says Tony Adolfs, executive vice president of SMACNA Greater Chicago. “They lost a lot of work when the crash hit, and most of that work came back non-union.”

John Daniel, president and business manager of Local 265 in Illinois, is hard at work to reclaim those lost residential hours. “When I first started, every construction project had at least six to 10 people on it,” he says. “Now that we need fewer people to do the same work, there’s less opportunity to make work hours in construction. But it takes the same amount of time and energy to change out a home furnace or air conditioner today as it did 32 years ago.”

4 » Partners in Progress » www.pinp.org

All three agree that SMART and SMACNA have great opportunities to grow by aggressively going after the residential service sector together. “Right now, the unionized sector might represent 5% of the residential marketplace, so unions have up to 90-95% growth potential,” Daniel says. “If we don’t go there collectively, we’re going to be sorry.”

Metro Air’s experience in Bloomfield, Michigan, proves how profitable the sector can be. “I started in residential, and I’ve never let it go,” says Metro Air President Jay Levin. “We have expanded that market because it’s been very lucrative for us. The cash flow helps me through slow times, and it’s a much higher profit margin than the commercial and industrial markets. When there’s a downturn in construction, we’re still putting in furnaces and air conditioners almost every day.”

Millions of federal dollars are encouraging United States citizens to convert their homes from natural gas to carbonfree products. These policies give SMACNA and SMART new openings to win residential hours. “The legislation doesn’t necessarily say union,” Daniel says, “but the pieces that give preference say you should be part of an apprenticeship program and part of creating pathways to a career.”

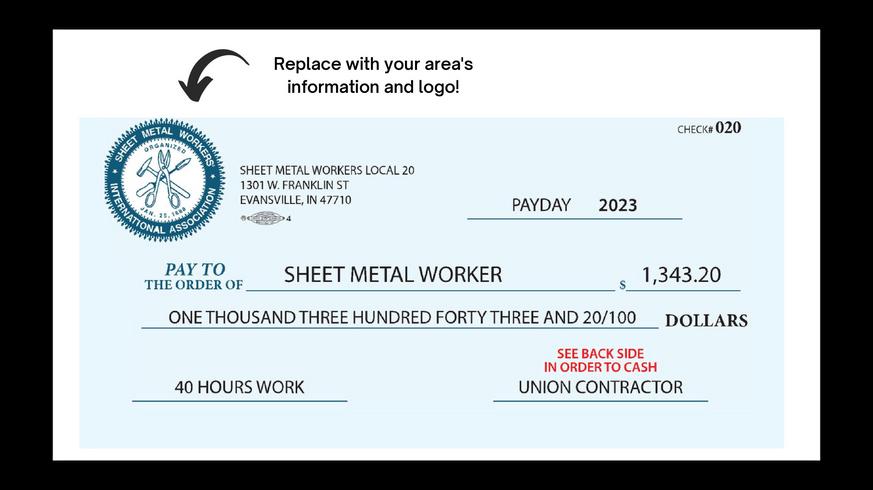

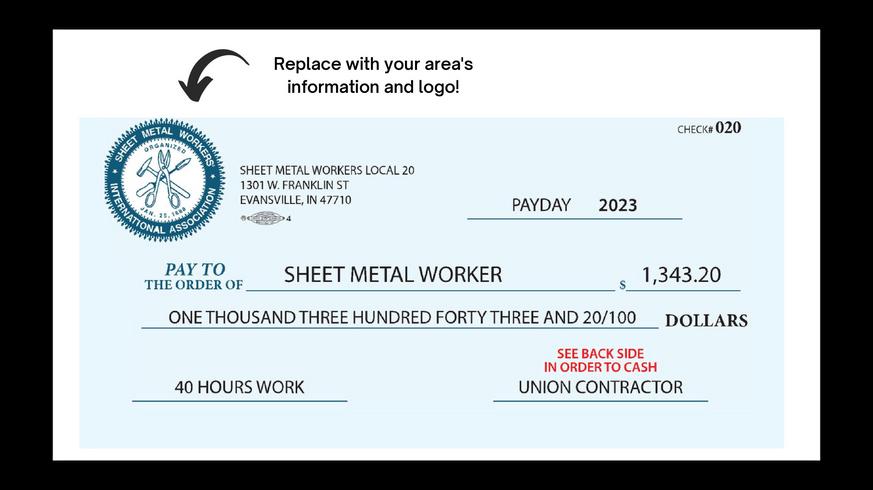

Local 265 is a founding member of the IWantSMART.com network, an online marketing tool that teaches customers about SMART’s expertise. This creates a funnel encouraging homeowners to call SMACNA contractors, with rebate offers to help close the deal. The program sends a $200 rebate check directly to the customer if they hire a partner SMACNA contractor to swap out an air conditioning unit, furnace, or heat pump. Several Locals around the country participate in the program—Local 265 alone gives out approximately $1.3 million in rebates per year, or between $100,000 and $130,000 in rebate checks per month.

To provide a fast and efficient experience for the end user, IWantSMART has streamlined its rebate processing and leverages a digital format as often as possible. The smooth process keeps customers happy because they receive their rebates in about a week, and the Locals appreciate compiling detailed data on every job performed. Daniel can display residential activity on a map to see which communities already trust SMART and which communities would benefit from more targeted marketing. “It helps us develop a growth strategy and more potential for our contractors and members alike,” he says.

Illinois’s biggest energy provider, ComEd, also offers incentives for equipment upgrades. “Most of our customers can get $1,400 in rebates from ComEd,” says Tess Salek, residential sales manager for Air-Rite Heating and Cooling in Naperville, Illinois. “That’s instant to the customer, so they get it at the point of sale. Some municipalities offer rebates from $300 up, and customers may qualify for a $2,000 federal tax credit.”

Salek helps customers identify the Local and provider programs they qualify for and encourages them to consult a tax

advisor for details on federal programs.

In Detroit, Local 80 helps SMACNA contractors like Metro Air with targeting funds when they are bidding against a nonunion provider. “They fund rebates that that my competitors can’t give,” Levin says.

Metro Air finds new referrals through their large customer base. “We go into hundreds of customer homes for replacement, repair, and maintenance,” Levin says. “By late April, we were booked to do non-stop maintenance into June.” His team leaves a $30 coupon in each home, which customers can redeem any time they refer a new customer to Metro Air.

All residential market recovery efforts are built on the bedrock of SMART’s highly skilled workforce. “We have a service lab, which directly pertains to the residential side of the field,” says Tim Mulligan, business manager for Local 80 in Detroit. “We’ve got furnaces and AC units and offer courses on home equipment at our training center.”

Metro Air invests in advanced education through supply houses. “Manufacturers want you to know how to properly install and service their equipment,” Levin says. “It’s very technical. You would never want a guy working on a furnace who did not go through the program and have some formal training on that piece of equipment.”

When systems are not installed and maintained correctly, energy savings go out the window. “You can pay for a 90% efficient system, but if it’s not put in right, you’re not going to get that efficiency,” Daniel says. “If the people who are doing the work are not qualified, you’re just burning money, and you’ll never even know it.”

As important as cost and technical skills are, they are only part of the calculation homeowners make when they decide who to allow inside their homes. “Communication is the key to understanding and repairing any issues that may occur,” Daniel says. “Understanding the customer’s problems and resolving them together is the key to building relationships and trust.”

Customers also need to know that service technicians will respect their property. Because the residential sector is less regulated, homeowners are wary of being cheated. “Too often it’s in and out, fly-by-night type stuff,” Daniel says. “We are not that way. We’ve been here for a long time, and we’re going to be here in the future. Let’s ask how we get people to trust us and call us, because they’re not only going to get a competitive price, but they will also get a better end product and a team they can trust.” ▪

A Colorado native, Sheralyn Belyeu lives and writes deep in the woods of Alabama. When she’s not writing, she grows organic blueberries and collects misspellings of her name.

Partners in Progress » July / August 2023 » 5

Forging Unity and Success:

Transforming the Sheet Metal Industry through Collaboration and Leadership

By / Natalie Bruckner

By / Natalie Bruckner

In the dynamic realm of the sheet metal industry, achieving remarkable success and fostering industry growth relies on labor and management cooperation. Recognizing this fundamental truth, Local 85 and Georgia-SMACNA embarked on an inspiring journey to revolutionize their collaborative culture and communication practices. Through strategic initiatives encompassing regular meetings, enhanced transparency, ongoing education, recruitment endeavors, and the construction of a cutting-edge facility, these organizations have cultivated a profound sense of community and solidarity.

This journey began more than 10 years ago when the relationship between Local 85 and Georgia-SMACNA resembled a cordial yet disjointed dance, lacking the synchronized steps of strategic collaboration. “Not many strategic things were happening back then,” recalls Matt Terek, board member at SMACNA-Georgia and McKenney’s COO.

Recognizing the need for change, Georgia-SMACNA started

to bridge the divide. The contractor’s association understood that the first crucial step was aligning the contractors’ goals and agendas. “Instead of entering labor-management meetings with each contractor pursuing different objectives, we aimed to bring everyone together on the same page,” Terek says. “We needed a comprehensive strategic plan.”

Simultaneously, on the labor side, Local 85’s business manager, Steve Langley, was determined to establish open communication channels. “We prioritized opening up the lines of communication and began scheduling meetings with the JCC, our negotiating committee,” he says. “This enabled us to extend contracts, freeing them to focus on securing projects while we prepared for challenging negotiations. Our negotiation meetings decreased from 21 in 2012 to just five or six in 2021.”

By creating strong lines of communication, both labor and management were suddenly able to address concerns promptly and establish a great deal of trust through this proactive

6 » Partners in Progress » www.pinp.org

approach to problem-solving. Terek emphasizes the importance of proactive communication. “You need to be able to put things on the table and talk through the real issues, rather than waiting for problems to arise,” he says. “It’s about being proactive and reaching out to the labor side whenever we’ve got an issue. Labor forecasts, for example, help our labor partners understand the challenges and opportunities ahead for contractors so the Local can proactively work on these needs ahead of time.”

While labor and management may not always share the same perspectives, establishing open lines of communication played a crucial role in addressing conflicts effectively. However, there was another secret ingredient: having those tough conversations. “It’s about putting all your cards on the table, no matter how difficult those conversations may be, and then holding all parties accountable,” Terek says. “By working together, it’s amazing how you can navigate any issue, and this ultimately builds a deep sense of trust.”

Langley agrees, “I try to be 100% transparent, whether that’s what we spend our membership fees on or what challenges we are facing. There is no question I won’t answer.”

And it isn’t just “on the field” where this relationship has developed. Langley and Terek understood the importance of engaging in social activities as the catalyst for genuine relatability and trust. Langley humorously recalls recent events, saying, “Just recently, we had a cornhole tournament, which was a great success. We’ve even had axe throwing weekends, and no one has had an axe thrown at them—that tells you something. For us, we like to have a good time and get issues dealt with in a friendly environment, rather than adopting the attitude of ‘it’s my way or the highway.’”

Thanks to their relationship, Local 85 and GeorgiaSMACNA have also achieved notable milestones in the sheet metal industry. They have successfully captured market share, expanded the number of union members and contractors in their area, and effectively addressed the industry’s recruitment challenges. Terek emphasizes the joint responsibility of labor and management in recruiting for the trades. “For too long, many contractors delegated the recruiting of new apprentices to their union partners,” he says. “However, the most effective firms are those who participate in joint recruiting efforts.”

To attract talent, Local 85 and Georgia-SMACNA proactively discuss labor needs for upcoming projects at regular meetings. They engage in various initiatives, such as organizing job fairs, the Heavy Metal Summer Experience, and offering tours of the Joint Apprenticeship Training Center (JATC). Additionally, they have discovered that advertising in unconventional channels yields remarkable success, such as during Georgia high schools’ football games, which has resulted in a significant increase in inquiries. “We will average anywhere from 125 to 400 inquiries the week following the commercials,” Langley says.

Moreover, the organizations have focused on attracting nonunion contractors, achieving notable success in this endeavor. Langley shares the impressive success story of signing Water

GRIPE VERSUS GRIEVANCE

Understanding the distinction between gripes and grievances is crucial, particularly for labor organizations like Local 85. Steve Langley, business manager, emphasizes that a gripe refers to a simple dissatisfaction or complaint, while a grievance involves a violation of the collective bargaining agreement (CBA) or official documents.

In Local 85’s experience, the occurrence of SMACNA-initiated grievances from is relatively low. However, the aim is to prevent gripes from escalating into grievances—a proactive approach the union takes seriously.

On the production side, Langley says the situation is different, with a higher number of grievances. When members raise concerns that fall within the contract, Langley or his agents address them by engaging with the foreperson. If the issue persists, escalation within the hierarchy is necessary. However, when a member is merely griping without any contractual violation, Langley encourages them to focus on their work, recognizing the importance of maintaining a balance between addressing valid concerns and avoiding excessive demands.

Langley’s experience has taught him that people will complain about various matters, but if the matter does not contravene the CBA, it does not qualify as a grievance. Notably, filing a grievance rests solely with the union, with members unable to initiate the process individually. Local 85 assumes responsibility for resolving grievances, ensuring a fair settlement.

Langley’s extensive experience managing major projects in Atlanta has taught him that prioritizing member welfare while adhering to the contract fosters high morale, which he says is crucial for success. By distinguishing between gripes and grievances and taking appropriate action, Local 85 endeavors to create a harmonious and productive working environment. ▪

Partners in Progress » July / August 2023 » 7

© Can Stock Photo / Glopphy

5 TOP TIPS FOR ATTRACTING POTENTIAL UNION CONTRACTORS

Matt Terek, Georgia-SMACNA, shares tips for creating an inviting environment for potential union contractors.

Foster Collaboration: I cannot overemphasise the importance of labor and management working together to create an atmosphere of collaboration. This also helps highlight to potential union contractors that union membership is not an “us versus them” situation.

Build Relationships: Encourage contractors that may be interested in partnering with your firm on a particular project to explore the potential of becoming a union contractor. This is especially important for small minority contractors where you can provide mentoring to help them grow and foster stronger relationships and trust.

Educate on Benefits: Educate potential union contractors on the advantages of being a union contractor. Show them the potential business opportunities that can arise from partnering with larger union contractors who already have established networks and resources. Highlight how being a union contractor can lead to increased credibility, access to specialized training, and potential growth.

Show the Value: Help potential new contractors understand the value to contractor relationships and the benefits of SMACNA. This network can provide significant value through education, technical standards, and industry resources.

Practice Patience: Adding union contractors is a gradual process that requires patience. Understand that it takes time and effort to build trust, overcome misconceptions, and convince contractors of the benefits. Recognize that it’s more of a marathon than a sprint, and be persistent in your efforts, while maintaining a long-term perspective. ▪

Mechanical. “They were a non-union mechanical, and we signed them up to be a union sheet metal contractor,” he says. “We have done such a good job at getting the workforce for them that they have signed up with both UA Locals in Savannah and Atlanta, as well.”

Local 85 and Georgia-SMACNA remain committed to staying ahead and continuously improving. They have recently enhanced their online presence to appeal to younger talent. Recognizing the shift in communication preferences, Local 85 revamped its website to include interactive elements and tailored experiences for different user segments. “Younger people don’t really read, but they will watch a video,” Langley says. “It’s about finding the right ways to educate people.”

For Local 85 and Georgia-SMACNA, building a community is at the core of their mission, exemplified by their newly constructed union facility, scheduled to open in September. The new facility, built with the help of seven SMACNA contractors, will double the size of the existing building and features stateof-the-art amenities, including the first certified TAB lab in the southeast, 40 weld machines, a computer room, a state-of-theart JATC, and a spacious banquet hall. Langley emphasizes the significance of the facility in showcasing the union’s sense of brother and sisterhood. “We may not always see eye to eye, but we are a big family,” Langley says. ▪

Natalie is an award-winning writer who has worked in the United Kingdom, Germany, Spain, the United States, and Canada. She has more than 23 years experience as a journalist, editor, and brand builder, specializing in construction and transportation. When she’s not writing, you will likely find her snowboarding, mountain biking, or climbing mountains with her rescue dog.

8 » Partners in Progress » www.pinp.org

Forging Unity and Success

© Can Stock Photo / Deskcube

Getting help when it’s needed most

Eliminating the stigmas and stereotypes around mental health and drug addiction

By / Michael McConnell

By / Michael McConnell

If you ask many contractors how they prevent construction accidents, they’ll probably talk about their extensive training, safety culture, and experienced workforce.

But if you ask those same contractors what they’re doing to prevent employee suicides, they might not have an answer, even though suicide claims almost five times more construction workers annually than job site accidents.

Chris Carlough and Justin Crandol are two people working to change those figures. They have a shared goal of ensuring no signatory sheet metal workers suffer from mental health or drug abuse problems. Carlough is the SMART Member Assistance Program (SMART Map) coordinator. He oversees the union’s efforts to help workers who are or may be struggling with addiction or mental health issues. Crandol is SMACNA’s safety director.

With the support of the jointly funded Sheet Metal Health Institute Trust (SMOHIT) and administrator Aldo Zambetti, Carlough and Crandol have been working for over a decade to increase awareness of the problem. Carlough will lead updated SMART Map workshops across North America this year to educate contractors and their employees about the signs of trouble and how they can help.

It’s a subject that Carlough, a 60-year-old, third-generation sheet metal worker, knows well. For almost 40 years, he’s been in recovery from drug and alcohol addiction. It hasn’t been a smooth journey—Carlough relapsed after 16 years of sobriety—but it’s one that he wants to share with people who may be facing the same struggle.

“I’m in a place right now where I can reach a lot of people,” Carlough says. “It’s a major problem in the construction industry and, really, lots of industries. We have one of the highest rates of substance use disorder, and we have one of the highest rates of suicide. It was just time to start talking about it.”

Crandol agrees. He says SMACNA was one of the founding members of the Construction Industry Alliance for Suicide Prevention, a five-year-old group whose mission is to make the industry suicide-free and remove barriers to getting treatment. Working with other associations, such as the National Electrical Contractors Association (NECA), the Association of Union Constructors (TAUC), and the Mechanical Contractors

Partners in Progress » July / August 2023 » 9

is the mission of an award-winning labor-management initiative.

Chris Carlough

Justin Crandol

© Can Stock Photo / Deskcube

— Chris Carlough, SMART Member Assistance Program (MAP) coordinator.

Association of America (MCAA), SMACNA recently started giving out poker chips and hard hat stickers depicting the new “988” suicide prevention hotline.

“We pushed tens of thousands of those hard hats and stickers all across our chapters throughout the United States,” Crandol says. “They were well-received.”

At SMACNA.org, the association has a page dedicated to mental health and drug abuse resources, including links to the Centers for Disease Control and Prevention (CDC), the Occupational Safety and Health Administration (OSHA), the National Safety Council (NCS), and the SMOHIT Helpline, which offers 24/7 professional assistance to people in crisis.

“When you call this number, you will connect with some amazing therapists like Jeremy Holburn,” Zambetti says. “He offers a caring voice to help sheet metal workers and their families daily.”

SMACNA also reminds members of the health services available through SMOHIT using newsletters and social media channels, such as LinkedIn and Facebook.

“We want to make resources readily available to build out a mental health culture for a company,” Crandol says. “It’s hard to find someone who hasn’t been touched in some way by mental health or suicide. Anecdotally, if you ask a room full of people if they have been involved with a workplace incident, a couple might raise their hands. Ask who has been in an auto accident and you might get half the room. Ask who has been affected by suicide or mental health, and everyone in the room raises their hand, every time.”

The reasons for the prevalence are readily apparent to anyone familiar with the industry: Long hours, physically demanding work, projects that can take workers away from their families for long spells, and the push to return quickly to work after injury. After three years of a global pandemic that caused many project delays and some layoffs, Carlough says it’s not surprising that more people seem to be struggling.

“I definitely think that the pandemic amped up all of the anxiety, all of the depression, all of the substance abuse,” he says. “‘COVID drinking’ was a thing, and so I do believe that had something to do with it. Now that everybody’s kind of back out and about, we’re still getting a lot of calls.”

Carlough says construction has earned its reputation as an industry where you learn to avoid showing any signs of weakness. “That’s the fabric of our people,” he says. “‘Stop whining. Tough it out. Rub some dirt on it.’ We’re trying to get people to recognize that and to change some of the stigmas around mental health and asking for help.”

SMART and SMOHIT efforts were recognized last spring at the 2022 Construction Working Minds Summit in Denver. The union and trust were given the Mental Health Visionary Award for their longstanding commitment to wellness in the industry with peer-to-peer substance abuse training, employee assistance programs, and suicide prevention initiatives. A three-day mental health training they sponsor teaches how to recognize the signs of substance abuse and mental illness in employees and co-workers, how to help them find treatment, and the best ways to support their recovery.

It’s an essential program, Carlough says, even if some would rather pretend the problem didn’t exist.

“There are those in our industry who would like to say, ‘Well, maybe it’s not that big of a deal,’” Carlough says. “But the more we talk to our members, the more we hear stories of resilience.”

As an example, Carlough says he was approached by someone who attended the suicide prevention training and was able to respond firsthand to a family crisis involving a suicide attempt.

“They let me know that the training we provide—and the absolute belief that we were there with them—provided the comfort and strength they needed to handle that situation,” he says. “I want all of our members to know that they don’t have to be alone when they’re struggling with any life issue.”

10 » Partners in Progress » www.pinp.org

“There are those in our industry who would like to say, ‘Well, maybe it’s not that big of a deal.’”

Getting Help When It’s Needed Most

Coupled with the two-day local peer training, SMART Map is developing mentors from trusted rank-and-file members who are learning advanced communication techniques and guiding members to local resources.

“It’s inspiring,” Carlough says. “There is nothing more incredible than watching our members stand before their peers and declare their desire to seek out therapy, meditate, or just commit to get more sleep. This is how we kill stigma.”

SMART and SMOHIT are now starting work on other initiatives related to mental health. One central issue is the evaluation of employee assistance programs and treatment centers to ensure they’re meeting members’ needs.

“We want to make sure that they have solid, competent support in mental health,” Carlough says. “It can make a big difference.”

Another is a sleep incentive app study, since sleep quality can have a major impact on mental and physical health. SMOHIT is developing a Sleep Challenge program that will provide motivation to get better sleep and improve overall health. The app will generate a sleep score and allow participants to compete against their friends and colleagues.

“I couldn’t be any prouder of our entire team at SMOHIT,” Zambetti says. “We are making a huge difference in the lives of union sheet metal workers and their families, and there’s so much more to come.” ▪

2022-2023 CONSTRUCTION INDUSTRY STATISTICS:

• Almost 5,000 construction workers die each year from suicide.

• Workers involved in construction are almost four times as likely to commit suicide as the overall population.

• Construction workers have one of the highest drug overdose death rates.

• More than 80% say they have experienced a mental health issue

• According to the Substance Abuse and Mental Health Services Administration, 14.3% of industry workers have a substance abuse disorder.

• Those in construction have consistently high rates of heavy and binge drinking.

Partners in Progress » July / August 2023 » 11

Breaking Down Barriers

By Deb Draper

Across the United States and Canada, construction industries are grappling with a shortage of skilled trades workers, and the sheet metal industry is no exception. Today, less than 10% of sheet metal workers are women, making them a virtually untapped resource for the future’s workforce.

Attracting more women means first understanding the challenges and gender-specific barriers women face. Industry women’s groups, training centers, and labor-management partnerships are helping to share opportunities and address workplace culture issues, but one important obstacle remains: many women must choose between being a full participant in the construction industry workforce and having a family.

SMACNA-Western Washington and Local 66 have announced a joint initiative that will begin to mitigate this barrier. The organizations have partnered to make lactation pods available to new mothers working in the sheet metal industry—a step they say begins to bridge the work-family gap for women entering the industry.

SMACNA-Western Washington Executive Vice President Julie Muller grew up in a construction family. She has always understood that women can go far in the industry if their needs are met.

“I transferred from Southern California to Western Washington with one-year-old twins,” she says. “During an industry event, I met a young journeywoman with young children of her own. We exchanged stories about motherhood, and she said the only way she could continue to breastfeed her baby was to go down to her car parked on the jobsite, cover the windows with sheets, and use the cigarette lighter to pump. I instantly realized the inequality and that it was much easier for me to return to work with an office job than it was for her, working on a construction site.”

Several years later, while walking through an airport, Muller noticed lactation pods–unobtrusive, attractive tiny “rooms” set up with secure access for the privacy and comfort of breastfeeding moms. “Right away, I thought about how these could be used for women in construction,” she says. “Upon further research, I learned the only models available were not suitable for outdoor use, so I went on to find someone who could manufacture pods that could perform outside.”

Once she found a manufacturer, Muller brought the Women’s Committees at SMACNA–Western Washington and Local 66 to see if they were interested in joining forces on bringing the pods to construction sites.

12 » Partners in Progress » www.pinp.org

SMACNA-Western Washington and Local 66 collaborate to break barriers for women entering the sheet metal industry

© Can Stock Photo / iftikharalam

“Julie is very supportive of all women in the trades,” says Local 66 Women’s Committee Chairperson Tammy Meyer. “We can be candid with her because she is so caring toward us. When she came to us to talk about lactation pods for construction and whether we’d support it if she brought it to our union leadership, we said ‘Yes! Absolutely we would.’ As it stands right now, sisters have to use restrooms or their cars, and that’s not sanitary or comfortable.”

Both management and labor got behind the concept, pooling their resources and support. “SMACNA and the Joint Labor Management Committee are going to pay for the pods,” Meyer says. “Local 66 will help store and maintain them and make sure they get to where they’re needed.”

The first two outdoor lactation pods were manufactured in Southern California and delivered to the two Local 66 training facilities in Everett and in Dupont in June.

“They look similar to a porta-potty with that familiar shape but a bit larger, completely weatherproof, and accessed by remote entry and eventually an app,” Meyer says. “They will have solar plug-ins for equipment, a refrigerator to store the milk, air conditioning, and Wi-Fi.”

The pods also contain a seating area, a sink with water, and cleaning supplies. They can be easily loaded onto a trailer and placed on any jobsite in the Puget Sound area or in a big shop, wherever they’re needed.

“We’ll have online access to put in a request for one,” Muller says. “We’re also developing some type of collateral for the contractor or union to be able to approach the general contractor and request permission to place a pod on the jobsite.”

Meyer noted that having this product available and discreetly in place takes away the awkward conversation on the jobsite about ‘What do we do with her?’ “It’s all set up and ready to go,” she says. “And our sisters will know that they’re cared for and valuable members of the team.” ▪

From her desk in Calgary, Alberta, Deb Smith writes for trade and business publications across North America, specializing in profiles and stories within the hospitality, food service, mining, recreation, and construction industries. When not writing, she’s likely traveling, gardening, or taking long walks with her big white dog.

Tammy Meyer, Local 66 Women’s Committee Chairperson.

“I instantly realized the inequality and that it was much easier for me to return to work with an office job than it was for her, working on a construction site.”

Partners in Progress » July / August 2023 » 13

—Julie Muller, executive vice president, SMACNA-Western Washington

Digging Deep for Market Share

Florida SMACNA and Local 15 are working together to keep moving forward in America’s toughest non-union market

By / Jessica Kirby

Local 15 and Florida SMACNA have a treasure, and they are guarding it fiercely. Despite a steady decline of union sheet metal market share in their Local area, their working relationship is excellent and stronger than ever.

“In state of Florida, the union market share is 4% to 5% and in our local area, it is closer to 2%,” says Local 15 Business Manager, Patrick O’Leary. “We have been a little higher and it seems like every year it is getting more difficult because contractors move here from up north looking to do their own thing. People want to live in the sunshine and good weather.”

Dan Lapin is owner of Lapin Sheet Metal in Orlando and president of SMACNA Florida. He says there are several reasons Florida is America’s toughest non-union market, including the fact that the large, out-of-state, non-union mechanical contractors tend to do their own sheet metal.

“They take a big portion of the market share,” he says. “They operate in more than one state and have the resources to underquote and get better prices from various suppliers. That gives them an obvious advantage.”

O’Leary points to the most glaring reason for the tough market share—Florida being a right-to-work state (the first, actually, along with Arkansas) and the implications of this on training.

“This has affected how we approach our apprenticeship program and make sure the curriculum is meeting contractors’ needs as they are trying to bid projects and make sure our skilled laborers are going out,” O’Leary says. “But with the whole country being short on labor, all the trades I know of are having trouble getting enough people.”

With this kind of pressure, it is imperative that labor and management tackle the market together, combining forces in key areas, like targeting work, recruitment, and training.

As a contractor, Lapin has been working with the union for 10 years. He is a second-generation sheet metal worker raised on trade union membership. That’s why he knows how important labor-management relationships are to success in any market.

“Our relationship with Local 15 is strong, and we both strive to reach goals that benefit both union members and contractors,” he says. “I feel like we have a good understanding of each other’s wants and needs, and if something is on my mind, I don’t hesitate

14 » Partners in Progress » www.pinp.org

to call Pat and express my concerns, needs, or wants. He’s pretty open to it. We are both straight shooters.”

“What I don’t do is look at the Local members as the enemy,” he adds. “We are all here for the same reason, and I look at it like a partnership, and in some instances, I consider us friends. We have to work together to help reach our goals. Open communication gets us where we need to be.”

O’Leary has been in trade for 35 years. Florida is his home Local where he served his apprenticeship, worked on the tools, and took on the business manager position. During 15 years in office, O’Leary has experienced the benefits of positive labormanagement relations, including positive, open communication. “We work together and try to reach an agreement on issues as they come up,” he says. “Then we come up with a solution together.”

For starters, Lapin says large mechanicals’ method of swallowing up huge swaths of work is back-firing for non-union companies who then must rush in with poor workpersonship and an impossible schedule to complete all the work they’ve won

underbidding. That’s where quality and integrity win the day.

“The market is booming, so a lot of non-union get full plates,” Lapin says. “That opens a door for us. They get their workloads and quotas full, and that gives us an upper hand on being selective with taking on projects that are larger and practical for our operations.”

The labor shortage has created a monumental push in recruitment and retention initiatives, because being short of labor and on work to keep existing labor busy makes it hard to secure long-term union members.

Local 15 participates in a number of recruitment initiatives, including job fairs and school visits, and keeps a healthy wordof-mouth network flowing so everyone knows what the other needs. Florida SMACNA participates when possible, but also supports the efforts with open communication, joint planning, and event promotion on social media.

“If they have the bodies and want to bring people, they will,” O’Leary says. “They will help in any way they can, and we know we can approach SMACNA if we need to.”

Together, they also target jobs and team up to find the best way to win the work. As partners, they will estimate the shop and field labor, and assess the competition. About 90% of the time, they can reach an agreement.

“General contractors on big projects will also recommend good contractors to the mechanical contractors, and because we can get the job done, they keep giving us recommendations,” Lapin says.

O’Leary says those reputations are rooted in training the best workforce available so that they stand out in a highly competitive market.

“You need a skilled workforce,” he says. “With our reputation and training, we get the job done on time and under budget. We do the best we can, and we work to stay competitive. We look good and do everything we can to show general contractors that hiring union is clearly the best choice.”

“Contractors and unions operating in tough markets have to remember that they have more knowledge and are better at their craft than that competition, and that is where they will always shine above,” Lapin adds.

For labor-management partners currently struggling to communication and work together, O’Leary has some sage advice.

“Today, contact your reps and chapter and get the lines of communication going,” he says. “Pay attention to their reactions, set up meetings, and listen to each other. Build the relationship that way. Communication is the key. You have to be able to listen and act on what you need to do.” ▪

Jessica Kirby is editor-publisher for Point One Media, a small but sturdy family-owned trade magazine creator representing some of North America’s best construction associations. She can usually be found among piles of paper in her home office or exploring British Columbia’s incredible wilderness.

Partners in Progress » July / August 2023 » 15

My Journey: Renee Williamson

2nd Year Balancer apprentice, J.F. Coffey & Associates

My journey into sheet metal was a little unconventional. I had always been interested in the trades and working with my hands, but I did not know anyone who did that. There was no clear path for me to learn a trade at the time. Since I was good at school, I pursued academics instead.

I ended up at Cornell University where I decided to study psychology and Italian. I was interested in psychology because I wanted a job where I could help people and make a positive impact in society. I also wanted a job where I could be constantly learning and improving. Of all the things to study, psychology seemed to be the best way to do that. At this point, I had no idea that a sheet metal career even existed.

After college, I became an educator at a workforce development program that helps students ages 16–24 earn their high school equivalency and find a solid career in construction. It was supposed to be my role between college and grad school. However, I ended up working closely with the construction training instructors to bridge my curriculum with theirs to better benefit the students and the program. Through this collaboration, I actually met people in the trades. Hearing about both their work and their paychecks intrigued me. My organization, turns out, was paying women less than men, and the idea of an equal pay scale with spelled-out raises and expectations sounded heavenly. As the pandemic went on and remote teaching became more and more draining, I began to consider a career in the trades as another way to have a positive impact on society. I spoke about it with one of my coworkers, and he told me about a buddy he has who is a balancer. He offered to see if they were hiring. I had never heard of balancing, so after a few YouTube videos and some Googling, I sent over my resume. I am now in my second year of apprenticeship.

I find the work quite fulfilling. Every day there is something new to learn or a new solution to discover. It is amazing to

be a part of the process of making laboratories and hospitals function correctly, safely, and efficiently.

I did face something that most other women face on the job site—harassment. When I first started, I had very little connection to the union aside from our company’s owner. As casual hazing escalated into serious harassment, I felt alone and completely vulnerable. I was terrified to be a burden on the company and did not know where to turn for help. Fortunately, the owner of my company and the union handled it, and because of that experience, I found ways to become involved in the community of women in the trades in Boston. I have become an enthusiastic member of our union’s women’s committee and I hope that if and when others experience situations like mine, they know they are not alone. And one day, I hope it’s not a “when”. I am so grateful for the women, mentors, and understanding union leaders for the support they have given me.

If I could advise a young person considering a career in sheet metal, particularly if they are entirely new to the field, I would urge them to meet people and find their community in sheet metal as soon as they can. Mentorship is vital to learning our trade. There is also no need for regret when finding our path in life. Life lessons and approaches I learned through my studies at Cornell still apply in sheet metal. Nothing is for naught. ▪

16 » Partners in Progress » www.pinp.org

JOB FAIR PACKAGE

If your local area is looking to attract talent, attending a job fair is a great way to do it. But preparing for a job fair can be timeconsuming and overwhelming. That's where this job fair package comes in.

This comprehensive package includes everything needed to make a big impact at any job fair. With these resources, your local can save time and energy, while still making a great impression at any job fair you attend

Customizable slide deck with talking points

Printable index cards with conversation starters, talking points, and questions

Handouts to engage applicants

A guide on how to use these resources And more!

BEST PRACTICES MARKET EXPANSION TASK FORCE

E v e r y t h i n g i s l o c a t e d i n a n e a s i l y a c c e s s i b l e G o o g l e D r i v e F o l d e r w h i c h w i l l b e u p d a t e d r e g u l a r l y w i t h n e w r e s o u r c e s . S c a n t h i s Q R c o d e t o a c c e s s t h e r e s o u r c e s !

The Package Includes:

Videos

N e e d h e l p c u s t o m i z i n g t h e c o n t e n t ? E m a i l i n f o @ i n d u s t r i a l a t h l e t e o f f i c a l o r g

By / Sheralyn Belyeu

By / Sheralyn Belyeu

By / Natalie Bruckner

By / Natalie Bruckner

By / Michael McConnell

By / Michael McConnell