By / Don Procter Photos courtesy of Partners in Progress

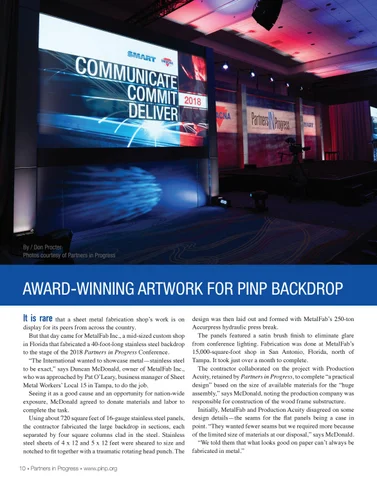

AWARD-WINNING ARTWORK FOR PINP BACKDROP It is rare that a sheet metal fabrication shop’s work is on

display for its peers from across the country. But that day came for MetalFab Inc., a mid-sized custom shop in Florida that fabricated a 40-foot-long stainless steel backdrop to the stage of the 2018 Partners in Progress Conference. “The International wanted to showcase metal—stainless steel to be exact,” says Duncan McDonald, owner of MetalFab Inc., who was approached by Pat O’Leary, business manager of Sheet Metal Workers’ Local 15 in Tampa, to do the job. Seeing it as a good cause and an opportunity for nation-wide exposure, McDonald agreed to donate materials and labor to complete the task. Using about 720 square feet of 16-gauge stainless steel panels, the contractor fabricated the large backdrop in sections, each separated by four square columns clad in the steel. Stainless steel sheets of 4 x 12 and 5 x 12 feet were sheared to size and notched to fit together with a traumatic rotating head punch. The

10 » Partners in Progress » www.pinp.org

design was then laid out and formed with MetalFab’s 250-ton Accurpress hydraulic press break. The panels featured a satin brush finish to eliminate glare from conference lighting. Fabrication was done at MetalFab’s 15,000-square-foot shop in San Antonio, Florida, north of Tampa. It took just over a month to complete. The contractor collaborated on the project with Production Acuity, retained by Partners in Progress, to complete “a practical design” based on the size of available materials for the “huge assembly,” says McDonald, noting the production company was responsible for construction of the wood frame substructure. Initially, MetalFab and Production Acuity disagreed on some design details—the seams for the flat panels being a case in point. “They wanted fewer seams but we required more because of the limited size of materials at our disposal,” says McDonald. “We told them that what looks good on paper can’t always be fabricated in metal.”