6 minute read

TECHNOLOGY REVOLUTION SMACNA and SMART work together to adapt to a changing future.

By / Natalie Bruckner • Photos courtesy of the ITI, Local 88, and Local 4

In today’s world technology is the number one driver of change, no matter what industry you are in.

This can seem a rather daunting concept, especially considering the speed at which technology is evolving and the impact it is having on the workforce. And yet, are the current changes we are experiencing really any different from previous iterative technological improvements? Remember the hand crank drill, which performed a job now done by a machine? Could technology help open up more opportunities to those in the industry and attract a more diverse workforce?

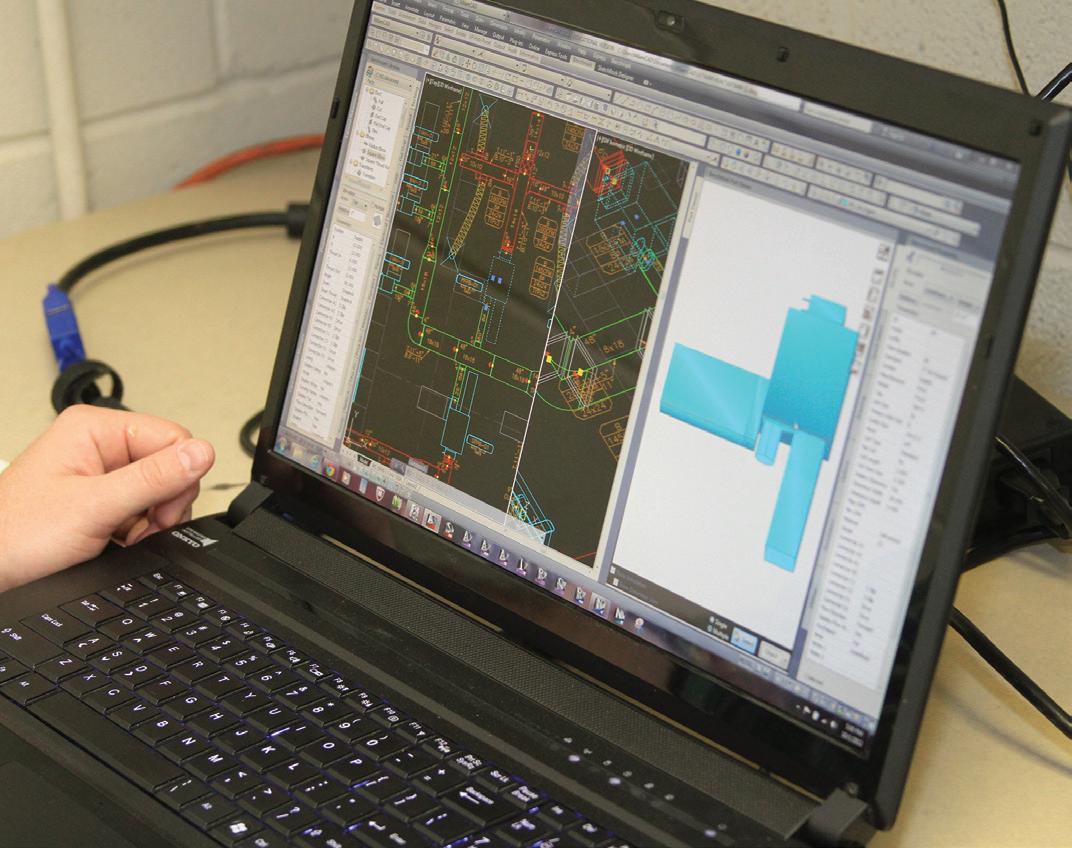

Ron McGuire, BIM specialist at the International Training Institute (ITI), believes so. He is witnessing the benefits of technological advancements first-hand. “Technology provides us with an opportunity to gain more market share as our numbers become more competitive due to improved technological efficiencies,” he says. “It also gives our apprentices the chance to experience real-life scenarios and can extend the work life of those who may, for whatever reason, have had to leave the industry.”

One example of this is John Sciara, project manager for SMACNA member CS3, Inc. in Tennessee. In 2016, Sciara suffered a stroke while out hunting with his son. For many, this could have meant the end of a successful 24-year career as a sheet metal worker. However, Sciara had the foresight a few years earlier to take an AutoCAD course, paid for by SMART Local 4 in Memphis and the ITI, as part of his union membership. It was fortuitous as this meant Sciara could continue working in the industry. To support him as he transitioned across, his employer invested in software that not only enabled Sciara to do his job better, but also the company.

“John’s success story is a perfect example of the benefits of welcoming technology into our industry and the importance of adding it to our toolbox,” McGuire says. “It was not only an opportunity for him, but also for his contractor, as they were able to land more complex jobs that required state-of-the-art technology.”

John Williams, business manager/financial secretary at Local 4, agrees. “We don’t want to stay in the Middle Ages,” he says. “It’s healthy for the industry to keep moving forward. With age, sheet metal workers notoriously get crooked spines and arthritis in their hands. Technology reduces the physical demands and increases longevity in the job. The reality is that technology will take on some of the more back-breaking, monotonous jobs, and it opens up new opportunities.”

CS3, along with Sciara, are proof of this. The company has become well known for combining cutting-edge control technologies with traditional contracting services in the mechanical/HVAC industry. Most recently, the company installed the Orion—a compact hybrid-style laser cutting machine that will allow CS3 to leverage this new material handling and cutting technology with time saving operations to meet the demands of its customers. CS3 personnel have been trained with the latest in 2D and 3D software that allows them to meet the demands of BIM technology, while using the direct throughput this new equipment offers.

To further provide its members with opportunities in this field, Local 4 has embraced technology with both hands and sees it as an important part of training during every stage of its members’ careers.

“Everything these days is plasma, laser, or waterjet,” Williams says. “That degree of technology is amazing, and it’s very much a part of training today. When you grow and learn you make yourself more valuable.

“It’s amazing how well we’ve already adapted as an industry,” he adds. “Most of our members have iPads on the job sites, and our guys out in the field use their phones to make calculations for things like offsets. It’s nothing to be afraid of and not really new, when you think about it.”

Williams adds that when he entered the industry in 1985 as an apprentice, he was writing DOS operating system code for his company’s punch press. That was before Windows came out. “I remember the program software changing to AutoCAD, which made things so much easier,” he says. “Now I click a button to write the code for the lasers and punch presses. Today, you can even 3D scan buildings and import that straight into AutoCAD, and BIM technology takes it from there. It amazes and excites me,” he says.

There is, of course, a tendency for many to feel a little intimidated by technology. In fact, according to the 2019 Edelman Trust Barometer, 55% of all employees fear automation and other innovations will take their jobs away. However, the truth is that technology is transforming the nature of work as we know it and eliminating the need for workers who perform repetitive and often dangerous tasks. Rather than fewer jobs, it means different jobs requiring different skills.

“For labor-management the best way to get people onboard is to show them the value behind it,” McGuire says. “Whether that’s via a presentation at a conference, like at Partners In Progress, or through a workshop at their local JATC, it’s about making people aware of the technology.”

To meet demand, the ITI conducts what it calls strikeforce training to provide union members with the latest information on specific materials, equipment, or systems and to give JATC instructors the required knowledge to take that training forward. This can be anything from architectural specialization and Bluebeam Revu training (a solution used for converting Microsoft documents and CAD drawings into PDF format) to robotic stations.

“In the last year or so, I’ve seen countless people change their minds after seeing robotic stations, and ultimately end up wanting a robot of their own,” McGuire says. “It’s an opportunity for both the member and the contractor when a robot can do something four or five times faster. Obviously, I am coming from the training and member side, but from the contractor side, it is a win-win to invest in something that will pay itself off in a few years and provide you a market advantage.”

CS3’s project portfolio and Sciara’s story are strong indicators of the possibilities technology can help the industry realize. “I love what I do,” Sciara says. “I have a passion for it, but my body was telling me to slow down. I’m coming into my own with all the software. When I started, I was a stump on a log in Ron’s class. Being in poor health never entered my mind. I just wanted to learn something new and be better at what I do. I just saw it as an advantage.” ▪

Natalie is an award-winning writer who has worked in the United Kingdom, Germany, Spain, the United States, and Canada. She has more than 23 years experience as a journalist, editor, and brand builder, specializing in construction and transportation.

“John’s success story is a perfect example of the benefits of welcoming technology into our industry and the importance of adding it to your toolbox,” says Ron

McGuire, BIM specialist at the ITI.