Partners

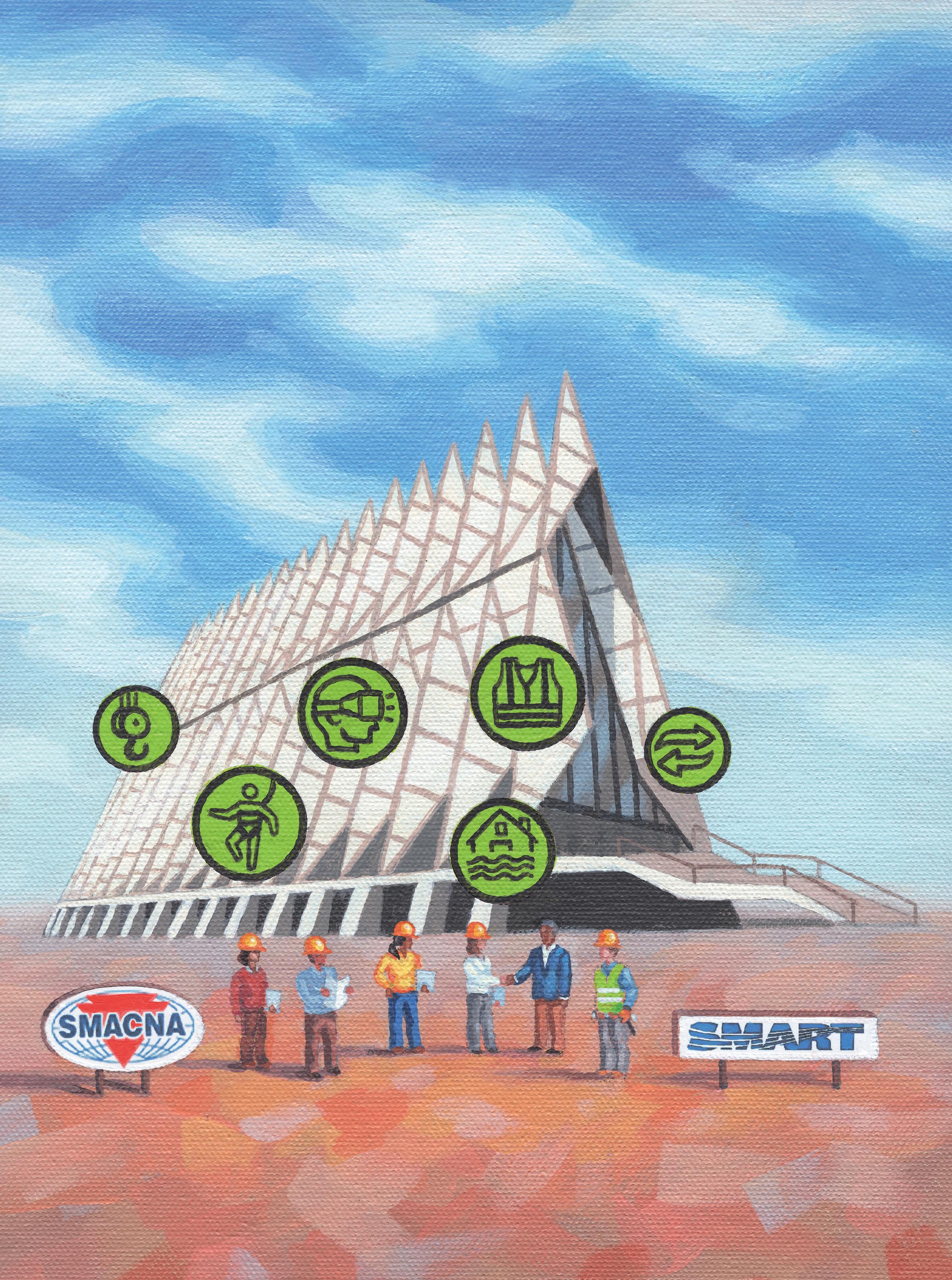

training, fine-tuned logistics, and a can-do attitude brought SMACNA and SMART together on a historic US Air Force Academy project...

SMACNA & SMART—Building a Future Together INProgress

October/November 2022 Expert

CONTENTS

October / November 2022 - Volume 16, Number 6

3 CREATE AND PROMOTE A LASTING PARTNERSHIP

If you want to promote partnership, you have to show it off.

4 MAKING HISTORY

An A. Zahner Co. and Local 9 partnership brings expertise and a can-do attitude to a historic US Air Force Academy project.

7 SOLDERING TRAINING FOR LOCAL 80 WORKFORCE

CASS Sheet Metal and Local 80 members secure market share with soldering certification provided by the ITI.

10 CONTRACTOR OF THE YEAR: JACK KNOX

SMACNA’s Contractor of the Year says labor-management cooperation is the secret to longevity in the sheet metal industry.

12 LEADING BY EXAMPLE – TAKE PRIDE IN YOUR PARTNERSHIP

SMACNA National and SMART International involve each other’s members in industry events to demonstrate partnership. You should, too.

INProgress Partners

JOSEPH SELLERS, JR. ANTHONY KOCUREK

Co-Publishers

KAARIN ENGELMANN editor@pinpmagazine.org Editor-in-Chief

JESSICA KIRBY jkirby@pointonemedia.com Editor

POINT ONE MEDIA INC. artdept@pointonemedia.com Creative Services

Partners in Progress is a publication of the Sheet Metal Industry LaborManagement Cooperation Fund.

All contents ©2022 by the Sheet Metal Industry Labor-Management Cooperation Fund, P.O. Box 221211, Chantilly, VA 20153-1211.

Find Partners in Progress online at pinp.org or at issuu.com/ partnersinprogress. An archive of all issues is available. Issues may be downloaded and printed for no fee.

For comments or questions, email editor@pinpmagazine.org.

14

SOCIAL MEDIA GIVES AIR CONDITIONING A SPIKE

Did you know the Windmill window AC unit was a hit among young people? Neither did we, until it came to TikTok.

15 IS MEMBER LOYALTY A THING OF THE PAST?

Take these three steps to help build lasting loyalty among your membership.

17 MY JOURNEY: ALDO ZAMBETTI

From apprentice to SMOHIT administrator, Zambetti’s journey has had many legs and even more successes.

2 » Partners in Progress » www.pinp.org

&

a Future Together

SMACNA

SMART—Building

SH EE T ME TA L AI R R AIL TR AN SPO RT AT ION

7

Create and Promote a Lasting Partnership

When differing perspectives on an important issue divide labor and management, it is human nature (and far too easy) to let those differences negatively impact the partnership. It takes a lot of practice and patience to prevent that from happening or to get the partnership back on track if division does occur. Those in the sheet metal industry who have the strongest labor-management partnerships and can endure setbacks have something in common. They make sure that their partnership is constantly visible to their respective members.

At the national level, SMACNA and SMART do just that. Partners in Progress is sent to all members of both organizations to reinforce the message that labor and management will have the most impact improving the industry if they work together. Additionally, SMACNA and SMART do not limit the message to highlighting the good work of union and contractor representatives. They bring attention to the critical role of jointly funded organizations—including ITI, NEMI, and SMOHIT—in strengthening the union sheet metal industry.

Our lead article (page 4) focuses on a collaboration between the A. Zahner Company, Local 9, SMACNA Colorado, and ITI. It examines their work on a unique architectural project that required training in rigging and other skills to ensure that sheet metal workers can work safely in diverse environments. This is a great example of ITI leaping into action to provide the specific training required to restore an iconic chapel and secure market share for our industry.

Similarly, “Soldering Training for Local 80” (page 7) describes the essential role the ITI played in certifying 23 sheet metal workers. Soldering skills are critical for high profile architectural projects that will be visible in Detroit for decades. This story reminds SMACNA and SMART members that the ITI has resources and talented staff to provide specific or niche training, as required. This helps contractors bid work that they previously could not, and it augments the workforce’s skill set, making signatory sheet metal workers more proficient and marketable.

Need another reason that unions and contractors benefit from a good labor-management partnership? How about business longevity? SMACNA’s 2022 Contractor of the Year, Jack Knox, attributes collaboration with labor as a key to his family business’s success for over 100 years. Local 85 Business Manager Steve Langley agrees, noting that the Local’s success is tied to its partnerships with contractors like Jack. See page 10 for more insight.

SMART and SMACNA continue to demonstrate how they keep strong labor-management partnerships in front of their members. We encourage Locals, SMACNA chapters, and

contractors to follow their lead and prioritize the creation and promotion of strong local partnerships that will endure and improve the industry and all in it. See page 12 for ideas.

Social media is a great way for contractors to increase sales and work opportunities. The challenge is knowing what to post and which social media sites will be most effective. “Social Media Gives Air Conditioning a Spike” (page 14) provides advice and a real-life example of how a simple post about a window air conditioning unit went viral.

Some may question—in the wake of the “The Great Resignation” and among general labor shortages—whether loyalty is a thing of the past. We sure hope that is not the case. But if you are in an area investing substantial resources to recruit and retain a stable workforce, turn to page 15 for advice from a construction industry leadership coach on generating loyalty in your members.

This edition’s “My Journey” (page 17) follows Aldo Zambetti’s career path from sheet metal worker to training coordinator to his current position as administrator at SMOHIT. Aldo describes how safety in the sheet metal industry is no longer limited to personal safety on the jobsite. It has evolved to encompass mental health, and Aldo emphasizes that in addition to SMOHIT, it takes the work of fellow employees, Locals, and contractors to lower suicide rates and help employees struggling with substance abuse disorders.

Partners in Progress » October / November 2022 » 3

▪

© Can Stock Photo / huhulin

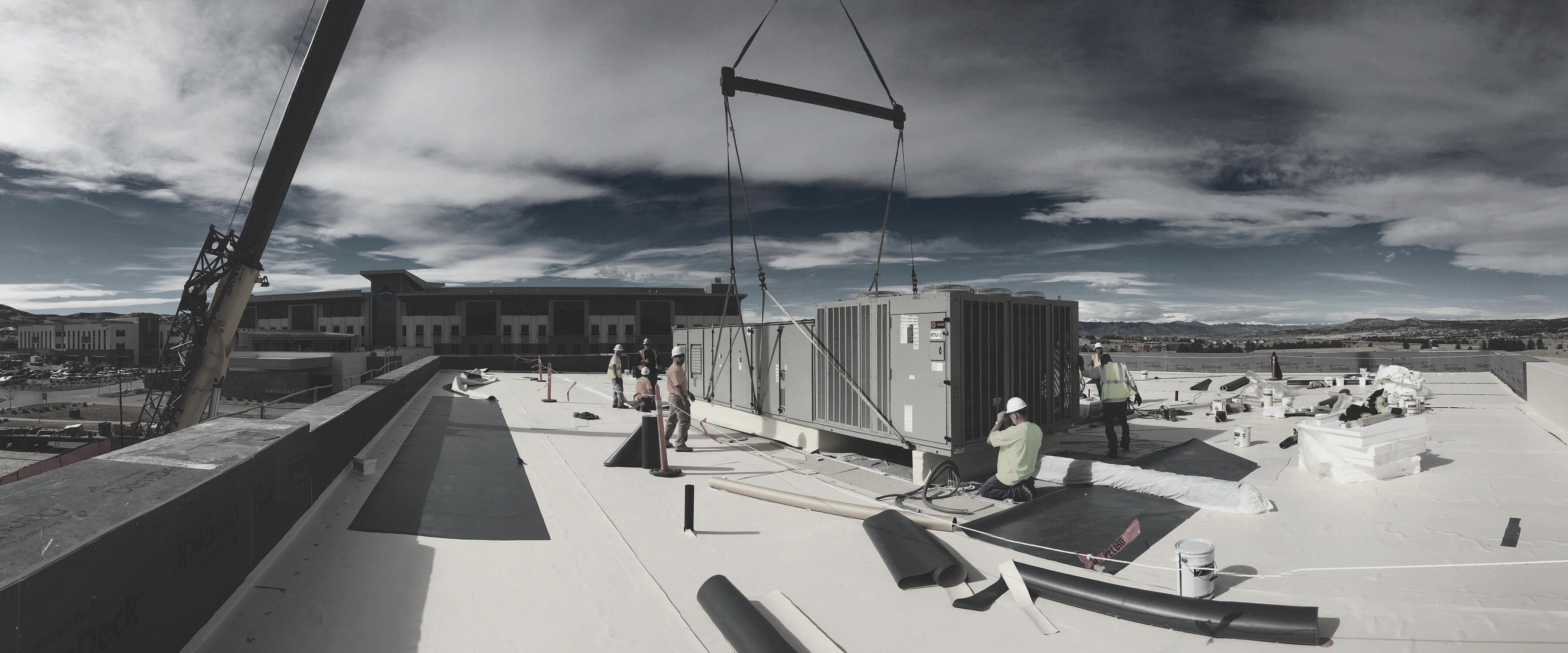

Making History

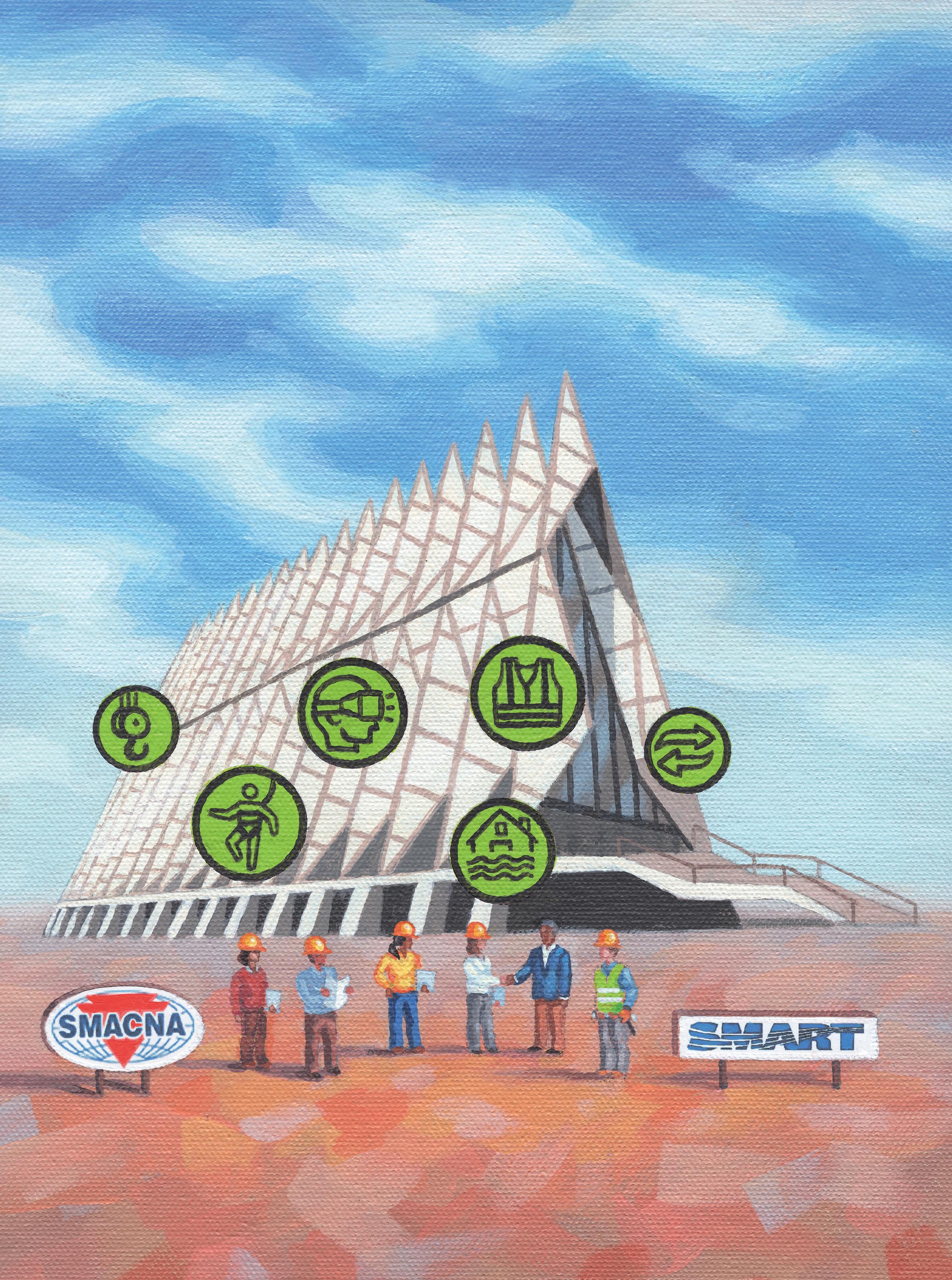

An A. Zahner Co. and Local 9 partnership brings expertise and a can-do attitude to a historic US Air Force Academy project

By Robin Brunet

By Robin Brunet

4 » Partners in Progress » www.pinp.org

When Robert Zahner, senior vice president at A. Zahner Co., discusses his upcoming retirement from the Kansas Citybased architectural sheet metal company, he cites the Cadet Chapel restoration at the United States Air Force Academy in Colorado as his swan song—both because of the project’s major undertaking and because of the collaboration it fostered between A. Zahner Co., Local 9, and the International Training Insitute (ITI).

“SMACNA Colorado’s Nathan Cooper was instrumental in establishing the initial relationship with Local 9, and he has continued to shepherd the process,” Zahner says.

The collaboration began with ITI member Dan McCallum and Local 9 Business Manager Dwayne Stephens. Today, it continues with Stephens’ successor Jon Alvino, as well as Chris Caricato, who was training director for Local 206 in San Diego before joining ITI.

Alvino is enthused about the collaboration. “Our 1,000-plus active members and colleagues in the sector have a real cando spirit, and we have enormous respect for the achievements of Zahner’s company over its 120-year history,” he says. “Normally, our members work in the residential HVAC field, so given that the chapel restoration is a unique architectural sheet metal job, it made sense to pool our resources.”

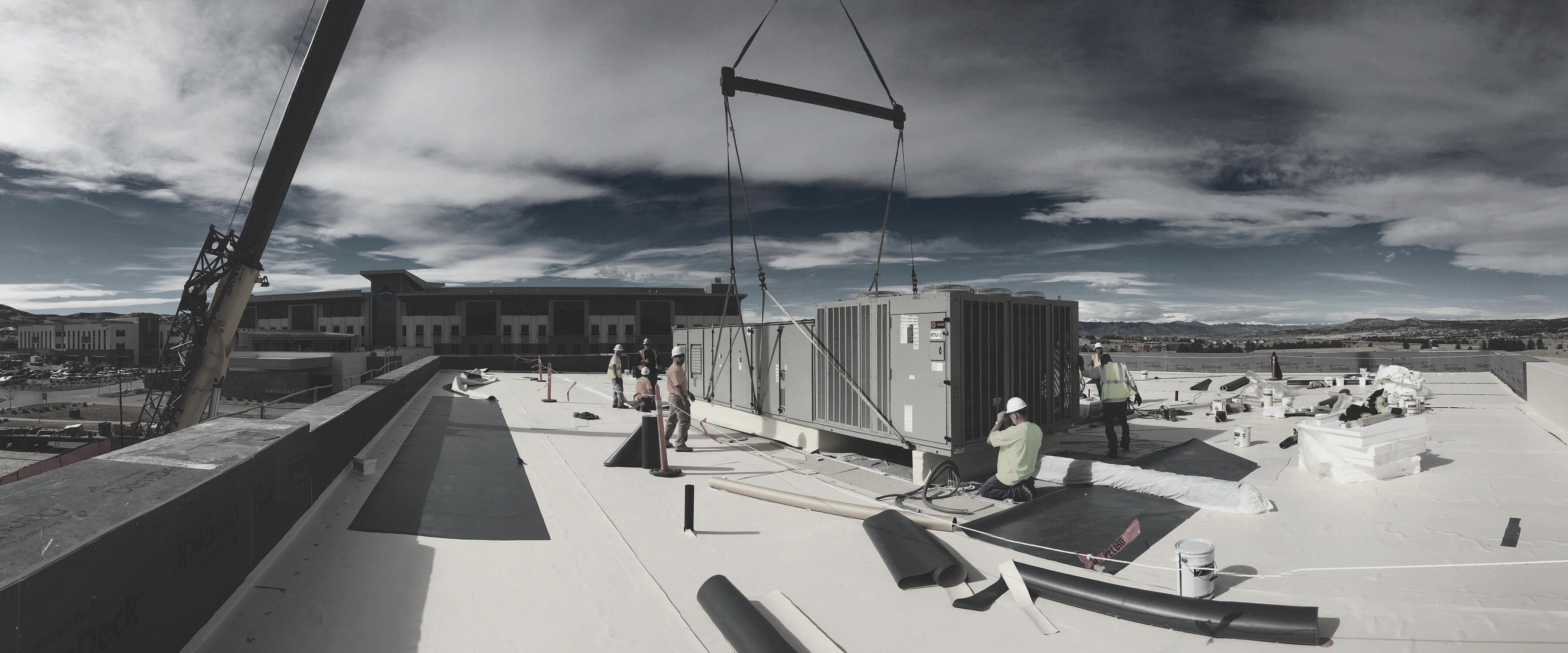

The aluminum, glass, and steel Cadet Chapel features 17 spires that shoot 150 feet into the sky. It is the most visited human-made tourist attraction in Colorado and is considered among the most beautiful examples of modern American academic architecture.

Although architect Walter Netsch Jr. designed an elaborate gutter system to divert rainwater from the structure, during construction in the 1960s, budgetary restrictions meant that caulking was used instead to seal the chapel’s interlocking exterior aluminum panels. From the time it opened, the chapel leaked, resulting in six decades of extensive water damage. The restoration in 2022 encompassed removing the aluminum panels and more than 20,000 Dalle de Verre stained glass units, plus work inside the chapel, including removal and restoration of the pews and two church organs.

McCallum first approached Zahner about the project four years ago. “Our relationship with ITI goes back to the days when it was called the National Training Fund,” Zahner says. “In reviewing what was required for the project, we realized we needed the organization’s buy-in for this to be a success.”

The logistics were especially intimidating given the circumstances of sheet metal work in Colorado. “The Cadet Chapel restoration would require a crew with specific skills,” Zahner says. “The workforce needed to be adept at working at great heights, using significant rigging and exercising accompanying safety skills, for starters.”

In fact, the architecture of the chapel is such that even a special 185-foot lift rented for the job wouldn’t be able to get workers into some corners to remove panels—this

Members from across the southern territory clamoured to be part of the restoration because it’s a once-in-a-lifetime project... [they] would love nothing better than to drive past the facility years from now and tell their kids they were part of the restoration team.

—Jon Alvino, Local 9 business manager

required complex rigging and bosun chairs. “We also needed to accurately locate each of the chapel’s 7,000 anchors to facilitate the reinstallation of the panels, the largest of which is a 12-foot x 12-foot trapezoid,” Zahner says.

The team solved the latter problem with software and hardware that precisely located the anchors via a laser system. Zahner and McCallum held a series of meetings with Local 9 in hopes enough people could be properly trained for the project. “Ultimately, we knew we needed about 30 workers, and we required a program to get them properly trained,” Zahner says. “I was surprised by how amendable the Local was to our proposition, considering the dearth of architectural sheet metal jobs in the state.”

Alvino says the enthusiasm of his organization was understandable. “Members from across the southern territory clamoured to be part of the restoration because it’s a once-ina-lifetime project,” he says. “Our members would love nothing

Partners in Progress » October / November 2022 » 5

”

“

better than to drive past the facility years from now and tell their kids they were part of the restoration team.”

Local 9 wanted to recruit apprentices for the job and Zahner was enthusiastic about the prospect. “He thought it was a great idea because, in addition to the chapel restoration being a great experience, it would prepare the apprentices for the architectural sheet metal work that we intend to pursue in the future,” Alvino says.

ITI quickly got the ball rolling. A fundamental aspect of training was a simulator that would give Local 9 candidates a virtual experience of operating hundreds of feet in the air. “We have two such simulators,” says Caricato, who is now the ITI’s architectural sheet metal specialist and field representative. “We transported one of them in a container from Las Vegas to Local 9’s headquarters in Colorado Springs.”

That simulator was augmented by a 30-foot training tower constructed by A. Zahner Co.

“We also began developing a job orientation program to make available to all Local 9 members,” Caricato says. “We’re confident that certain parts of the training will be incorporated as part of Local 9’s curriculum after the Chapel renewal is completed.”

Restoration work began in 2019 with a temporary enclosure erected around the entire building, but as the general contractor’s crews removed some of the cladding, it was determined that additional asbestos contamination would push the project past its original 2023 completion date. “Our best guess is that the restoration will be completed in 2025,” Zahner says.

The delay has given ITI and Local 9 time to ensure that the training process—which encompasses everything from hoisting and rigging to signalling and fall prevention—will be best in class. “We’ll begin hiring towards the end of this year, starting with leadership positions and following through with sheet metal workers,” Alvino says. “They’ll work in dual shifts when restoration commences in February or March, with staging conducted during the swing shift.”

The Cadet Chapel restoration will be remembered within sheet metal circles for decades to come. Zahner regards it as ending his long career on a high note. Caricato echoes Zahner and Alvino: “The collaboration between us and Local 9 is as special as the restoration itself,” he says. “In order for signatory contractors like Zahner to continue to be successful, a specifically trained workforce is required. Local 9 really stepped up to the plate, and we’re proud to assist in providing that training.” ▪

Robin Brunet’s journalism has been published in over 150 magazines, newspapers, websites, and other media across Canada and the United States since 1982. He is also the best-selling author of two books: Red Robinson: The Last Deejay and Let’s Get Frank, as well as the upcoming The Last Broadcast.

6 » Partners in Progress » www.pinp.org Making History

Soldering Training for Local 80 Workforce

The International Training Institute (ITI) recently facilitated a soldering certification class for members of Local 80 in Detroit. The class, heavily requested by local contractors and facilitated by the JATC, certified 23 members. Eleven were local apprentices.

The ITI partnered with the Copper Development Association (CDA) to develop the unique copper soldering certification

training course, which can be delivered to other members in the United States and Canada.

Contractors requested the class because the skill set is required for many projects in the area, such as the restoration of the Michigan Central Station, the historic former national hub and passenger rail station in downtown Detroit. Built in 1914, the building was purchased by Ford Motor Company in 2018.

Custom Architectural Sheetmetal Specialists (CASS) is one of seven Michigan contractors that attended the training. CASS is currently working on the Michigan Central Station project. Glenn Parvin, owner of the company and a JATC trustee, predicts 35,000 pounds of copper will be used to restore the building’s roof.

“The art or skill set of soldering—and soldering well—has been learned with years of in-field training and practice,” Parvin says. “CASS began targeting copper work early on, and

Partners in Progress » October / November 2022 » 7

The ITI has developed soldering certification for Detroit sheet metal workers

in response to contractor requests

By Jessica Kirby | Photos by the ITI

we have been blessed to have old world craftspeople in the early years, many of whom were known as some of the best in the industry.”

Parvin served six terms on SMACNA National’s architectural steering committee—a group of eight architectural contractors from across the United States who come together to discuss market trends, problems, needs, and educational events for annual conventions.

“One of our first major copper restoration projects, Henry Ford Estates back in 1999, was our first exposure to solder testing and coupon review by outside roof consultants,” Parvin says. “This testing and review morphed and evolved over time and on various projects.”

At the time, demand from specifiers for a reliable soldering standard, consistent training, and proficiency measurement prompted the committee to go to the ITI for guidance. “Dan McCallum and Mike Harris took the ball and kept it rolling,” Parvin says. “Finally bringing the education and testing to the school in Detroit was a feel-good moment.”

The class was instructed by Larry Peters, CDA project manager of building construction, and ITI personnel, including Chris Caricato, field staff and architectural specialist; Mark Van Avery, field staff and welding specialist; and Mike Shields, full-time apprenticeship instructor at Local 12 in Pittsburgh.

“Local 80 wanted to make sure their members obtained the unique skills needed for CASS to be successful on the Michigan Central Station project,” Caricato says. “It was important to both organizations that the work would be performed by Local 80 members working for a local contractor who could proudly say they were part of this significant restoration in their hometown!”

The program includes 24 hours of classroom theory and practical training on techniques and equipment advancements. Students use mock-up structures to learn proper fabrication, layout, and installation techniques, including how to solder a flat lock copper roof system.

The mockups give participants a real-world experience and allow them to accurately hone their skills. Training like this gives the participants a new skillset and allows contractors the opportunity to bid on this type of work where previously they could not, said Matt O’Rourke, training director for Local 80.

“Any time we can add a new little niche of training into our curriculum or into our area of expertise, it makes our members more marketable, improves their skills and gives them confidence,” he added. “We have the ability to come up with other processes if job specifications require it.”

The class also offered a foundation of training that can be continuously built upon, depending on the project requirements. It prequalifies students to take a series of project-specific soldering certifications under the American Welding Society (AWS) B2.3:2018 Specification for Soldering Procedure and Performance Qualification code, which is recognized worldwide.

“This training provides our members with a very rare and highly sought out skillset that has depleted with the Baby Boomer era,” Caricato says. “It provides members with the knowledge to do the work, provides our JATC’s the curriculum, resources and equipment to teach how to do the

Soldering Training for Local 80 Workforce

“It was important to both organizations that the work would be performed by Local 80 members working for a local contractor who could proudly say they were part of this significant restoration in their hometown!”

8 » Partners in Progress » www.pinp.org

—Chris Caricato, architectural specialist, ITI

work, and provides our SMACNA signatory contractors with the personnel to get the work.”

“The training program can also be implemented into the apprenticeship curriculum and journeyperson upgrade training, and delivered based on contractor needs,” he adds.

While plenty of signatory contractors are currently doing this kind of work correctly on new construction and renovation projects, projects that fail because of incorrect procedures threaten market share for everyone.

“These types of roof systems are meant to last well over 75 years without failure,” Caricato says. “Subpar work by uneducated, non-union personnel threatens continued use of this kind of building envelope for use on future projects.”

Parvin agrees. “Copper work is always prevalent in older cities like Detroit,” he says. “While I prefer to be the only contractor in town, as a JATC member, you want the trades to know and install or solder well because that helps differentiate

the union trades. Specifiers can call out certified solder craftspeople on this specialty work.”

Caricato and Parvin agree that labor-management cooperation is key to training development and recruitment. “That starts with trust and understanding the common ground and what’s important to both sides,” Parvin says.

In fact, Local 80 members and SMACNA Detroit contractors proudly brandish truck signage that says, “Together we do it better” boasting labor-management cooperation.

“That’s a whole lot of exposure out on local roads promoting union labor and SMACNA contractors,” Parvin says. “I am active on the SMACNA board, the JATC, and the labor management committee for negotiations. We continue to explore other non-traditional markets that build person hours.”▪

The ITI in Action

The soldering program is just one of several programs the ITI has created specifically for fulfilling existing or anticipated market share.

Strike Force Training

This program was designed to assist contractors who have been awarded work with training opportunities and resources specifically required for a project. The training is focused on project specific materials, equipment, tools, software, installations, and fabrication techniques, as well as required certifications or qualifications.

Strike Force Training is developed by ITI specialists who work with manufacturers, vendors, contractors, and JATC personnel to create a tailored train-the-trainer program that can be delivered to JATC instructors. Afterwards, local JATCs will have all of the resources needed to provide the training whenever requested by contractors or chapters.

Training Grants

The ITI provides grants to JATCs to help offset the cost of the training. Some grants offer as much as 50% reimbursement, up to $20,000. ITI also has other grant programs available to JATCs to enhance training opportunities and develop more skillsets among members.

ITI Developed Trade Curriculum

Current Grant Programs

Spreading the Word

The ITI, SMART, and SMACNA jointly advertise grant programs through industry platforms, including publications, meetings, and conferences. Contractors and chapters that need a workforce with specialized training for a particular project should reach out to the local JATC training coordinator. That person has access to the JATC training committee, union representatives, ITI regional representatives, and industry specialists.

Jessica Kirby is editor-publisher for Point One Media, a small but sturdy family-owned trade magazine creator.

•

•

•

•

•

•

•

•

•

•

Refrigeration • Building Information

• Detailing & Drafting • Signage

Architectural Sheet Metal

Roofing

Indoor Air Quality

Fire & Smoke Damper

Smoke Control Systems • Heating, Ventilation, and Air Conditioning (HVAC)

Lagging

Welding, Soldering, Plasma Arc Cutting

Hoisting, Rigging, and Signaling

Testing, Adjusting, and Balancing (TAB)

HVAC Service &

Modeling (BIM)

•

•

• 3D

•

•

•

•

Autodesk MTP – reimbursement 50% up to $750

Plasma – 75% up to $22,500

Scanner – 75% up to $16,500

3D Printer – 75% up to $1,000

Trimble XR10 HoloLens – 100%

Laser Welder – 90% up to $27,000

Mini-Crane Rental for training (reimbursement up to $1500)

Connect | Facebook @InternationalTrainingInstitute Twitter @iTisheetmetal YouTube @iTi International

Learn more | sheetmetal-iti.org

Trianing Institute

Partners in Progress » October / November 2022 » 9

Contractor of the Year: Jack Knox Partnerships built on trust lead to business longevity

By / Natalie Bruckner

Jack Knox, president of R.F. Knox Company, Inc. in Atlanta, Georgia, may hold an important secret to longevity: “Our success in business for more than 100 years comes down to two things,” he says. “One: embrace new technology, and two: collaborate with your partners.”

As the fourth-generation president in the family-owned straight line sheet metal business, Knox credits a big part of his business’s success to the labour-management relationship that he and his partners at Local 85 have worked hard to build and maintain for all these years. “We honestly couldn’t have succeeded for this long without our labor partner,” Knox says.

Local 85 Business Representative Steve Langley says the same is true when it comes to the success of his organization. “Jack is such a great guy, so easy going,” he says. “We may not agree on everything, but we know that we can talk it out. We have overcome some huge hurdles together. The success of our Local comes down to contractors like Jack.”

It hasn’t always been this way, Knox admits. It takes continued commitment on all sides to maintain this relationship, but he says at the core of it is a great deal of trust. “Maintaining a healthy labor-management relationship starts at the top. When you have trust there, it funnels down and ultimately opens

10 » Partners in Progress » www.pinp.org

up the channels of honest communication at our local level. We trust that we are able to work through difficult times and overcome challenges our industry faces.”

One of those challenges is recruitment, which is something both sides have been working hard at to find solutions. “I honestly don’t know how non-union contractors do it,” Knox says. “We are fortunate to have access to a trained workforce that allows us to tackle those large projects.” R.F. Knox Company, Inc. has a workforce averaging around 225 people.

“Together, we have upped the ante on the quality of apprentices and helpers we take into our program,” Langley says. “New recruits get a 30-day trial period at a company so company supervisors can evaluate each one and determine whether they are the right fit for the industry. They also establish what apprenticeship year the new recruit should enter. This method is working to help us retain quality workers.”

Partnerships like this are essential for securing a skilled workforce into the future, but relationship-building also extends outside the industry. “Last year, we partnered with Georgia High School Association to speak with students before the Friday night football games,” Knox says. “It is a great opportunity to share the benefits of our trade with young folks and their parents. It helps parents realize their child doesn’t necessarily need to go to college. They can go straight into the trades and earn a fantastic living, with zero debt behind them.”

Knox knows that attracting the right kind of candidate is just the start, however, and that retaining those high performers takes a lot of work. “A large part of our workforce will be retiring in the next 10 years,” he says. “Together, we need to consider what we are doing to train the next generation.”

Knox and Local 85 will be reaching out to SMACNA companies in the area to ensure they have the tools they need to be successful, including communication classes and leadership skills.

“Ginger Slaick, executive vice president at GeorgiaSMACNA, is at the forefront of continuing education here and making sure contractors and skilled labor are getting what they need to be successful,” Knox says.

Bringing the team together means engaging the workforce in a meaningful way. At R.F. Knox, Quarterly meetings bring field workers and office staff together to receive an update on the company’s status, projects underway, and upcoming opportunities.

Knox can’t stress enough the importance of making

employees feel valued. “I talk a lot about our Knox family,” he says. We’re only successful because of our people. I have a lot of faith and trust in the men and women that work for us, and whether they are a first-year pre-apprentice or a foreperson, when it comes to the year end, they’re going get rewarded for their efforts.”

The company offers team incentives that focus on the number of hours achieved. “That program has been in place since 2008, and it really helps bring the crew together,” Knox explains. “They work hard for each other and work hard for the company.”

The company also sponsors an annual summer a trip to an Atlanta Braves game and an entire suite that can accommodate 400 people. Staff and their families are invited to attend.

This approach to open communication, along with Knox’s involvement on SMACNA’s Board of Directors—including as president—his legislative advocacy, and service as a trustee on the local industry fund and local pension plan, earned him SMACNA’s 2022 Contractor of the Year award.

“I love this industry,” Knox says. “There are so many incredible opportunities coming up, not just for my company, but for all companies to do well, especially considering the number of mega-projects that are coming down the pipeline here the Southeast. But the only way we can succeed is if we work together.” ▪

Natalie is an award-winning writer who has worked in the United Kingdom, Germany, Spain, the United States, and Canada. She has more than 23 years experience as a journalist, editor, and brand builder, specializing in construction and transportation. When she’s not writing, you will likely find her snowboarding, mountain biking, or climbing mountains with her rescue dog.

Partners in Progress » October / November 2022 » 11

“A large part of our workforce will be retiring in the next 10 years...Together, we need to consider what we are doing to train the next generation.”

”

—Jack Knox, SMACNA contractor of the year

Leading by Example –Take Pride in Your Partnership

Partners in Progress is not just a catchy title for a publication or a conference. And a partnership is not progressive unless that message is conveyed and resonates with all levels and with all members of an industry or membership organization.

SMACNA and SMART know that accomplishing common goals like increasing work opportunities and recruiting for the future is far more effective when labor and management collaborate. National association leaders also know that they must set the bar high and live up to their partnership standards to inspire labor and management at the local and company levels to work together to strengthen the sheet metal industry. That is a compelling reason for SMART and SMACNA to invite one other’s leadership to participate in their most highprofile annual meetings.

In August, SMACNA then-immediate Past President Angie Simon of Western Allied Mechanical filled in for then-President Al Labella at SMART’s Annual Leadership

Forum (previously known as the Business Agents’ conference). This gave Simon an opportunity to share SMACNA’s goals and plans with almost all of SMART’s local leaders. She was able to convey the national association’s commitment to joint labormanagement initiatives, including the B4All program, which is aimed at making the industry more inclusive and welcoming to all who work in it.

New SMACNA National CEO Aaron Hilger was also in attendance. Hilger, who previously managed the SMACNA Rochester Chapter, was well known to the Local 46 leaders that he worked with for a number of years. Attending and presenting at the Leadership Forum gave him the opportunity to meet and introduce himself to union leaders from areas throughout North America. He was also able to share details

12 » Partners in Progress » www.pinp.org

SH EE T ME TA L AI R R AIL TR AN SPO RT AT ION

of SMACNA’s upcoming strategic planning initiative and the priorities he will pursue in his new role.

Simon and Hilger were not simply invited to provide remarks. They were invited to attend the educational sessions hear SMART’s plans to pursue union “Growth Through Unity,” the Forum’s slogan and one of the union’s key priorities. SMACNA representatives were also invited to attend the Forum’s social functions so they could meet union leaders from all over the United States and Canada.

Jason Watson, SMACNA’s executive director of labor relations, was also invited to attend. He could not attend in person, but SMART made it a priority to allow Watson to prerecord his remarks so that he could convey his perspective on industry issues and the importance of a strong SMACNASMART partnership.

Fast-forward to September 2022 when four SMART International representatives showed their commitment to the national labor-management partnership by taking time from their busy schedules to address the contractors and chapter representatives at SMACNA’s Annual Convention and Trade Show.

One of the more popular presentations at the convention is the SMACNA Labor Forum, which features remarks from SMART’s General President Joseph Sellers, Jr. This year, Sellers introduced the other members of his team who were in attendance: General Secretary/Treasurer Joe Powell, and Donna Silverman and Mike Coleman who both serve as assistants to the general president.

Sellers shared his perspective on labor and management initiatives requiring attention at the national and local levels, including making sure the union sheet metal industry is the dominant force in ventilation verification work and ensuring that customers can meet various mandates to lower their carbon footprint.

Sellers noted SMART’s and SMACNA’s commitment to industry diversity and inclusion through Be4All. When the program was launched, there were two other International unions and national contractor associations. Those organizations are no longer participating, but SMACNA and SMART are in it for the long run because of the need to change industry work culture and prevent hate crimes on job sites. Sellers further urged all to communicate labor needs, work to mobilize the workforce on high profile projects like chip plants and automotive industry projects, and do their best to recruit and retain sheet metal workers to meet the needs of current and new industry customers. The Labor Forum concluded with a candid Q&A session.

Sellars and the attending SMART representatives were fully engaged in the SMACNA conference. They attended the educational sessions every day and visited the trade show to keep on top of the latest technical innovations in the industry. They made themselves available to meet with contractors to discuss local market opportunities and challenges, and they

were on hand to congratulate those contractors and chapter executives who earned awards for safety, legislative activity, and outstanding service.

A successful SMACNA-SMART partnership requires buy-in and support from the members of each association. Members need to know why labor and management working together accomplishes far more than the union or contractor associations working on their own.

SMACNA and SMART encourage all local unions, associations, and contractors to make sure their members know why the relationship is so important to future growth and work opportunities. Both organizations want members to know that at times labor and management will not agree on an important issue but they can communicate their views and differences in a constructive manner while continuing work on issues that unite the union sheet metal industry.

Contractors, their associations, and Locals are urged to create opportunities to for members to interact.

Ways to do that include:

• Invite the leaders of your partner union or SMACNA Chapter to participate in one of your membership meetings to demonstrate partnership to your own members.

• Provide an opportunity for your labor or management partner to address an important industry issue from the union or contractor perspective.

• Invite several labor or management partners to attend one or two local events, outings, or recognition functions to allow union members and contractors to interact socially.

• Support each other’s charities and jointly participate in community initiatives.

• Highlight any joint activities to promote the industry in your publications.

If you value your labor-management partnership, be proud of it and demonstrate that to your members.

Partners in Progress » October / November 2022 » 13

“

”

▪

If you value your labormanagement partnership, be proud of it and demonstrate that to your members.

Social Media Gives Air Conditioning a Spike

By Kyle Gargaro Editorial Director, The ACHR News

©CanStockPhoto/cienpies

Have you heard of the Windmill window air conditioning unit? I know as of a few weeks ago, I was not aware of the product. Even if you have not heard of this product at this point, the odds are pretty good that your kids or grandkids have. That is because the product has blown up and gone viral on social media—specifically, TikTok. TikTok is a social media site that hosts short videos from users.

This window air conditioner has all the makings of a social media star. It is a slick looking product, is easy to install, and solves a problem for the younger gneration. One TikTok user posted a short video of the Windmill air conditioner, and it quickly got over 6000,000 likes.

So, that proves that HVAC can be “cool” on social media. See what I did there?

This leads to the next logical question—what are you as an HVAC contractor doing with social media to increase sales at your business?

One interesting company that recently appeared on my radar was Social Jazz. It is a company that automates social media content for your business. It was created when small business owner Paul Baccaro realized that he was so busy with the abundance of tasks needed to run a business that his company had not posted on social media in over two months.

“That is when I got the idea for Social Jazz,” Baccaro said. “It is hard trying to stay on top of things.”

The company provides ready-made content from a growing catalog of posts around IAQ, preventative maintenance, and product change-outs. It combines that with a social media plan for the entire year that automatically publishes.

Of course, it is suggested that HVAC contractors augment those posts with some company-specific posts—items like introducing new employees or photos of company events. Anything that connects you to your audience.

Social Jazz is one way to solve the social media problem, but there are certainly others. While a dedicated position in the company is not feasbile for most contractors, perhaps it could be

part of the marketing employee’s job. Or, since a lot of HVAC companies are family businesses, instead of sweeping floors, maybe the first job of that high-school-aged kid is to run the company’s social media accounts.

There are a few things to keep in mind when contractors, Locals, or chapters are handling social media:

1. If you are going to do it, do it right. You do not need to open an account on each social media platform. That will be impossible to handle. Find out where your audience is and go there. Do fewer social media platforms better. A good rule of thumb is to post two to three times a week to stay relevant and top of mind for your followers.

2. Keep in mind for HVAC that Facebook is still king. Instagram and TikTok are picking up momentum for the younger gnereation and will be more important as Milleniaials gain more buying power. But for right now, there is a pretty good chance your consumers are wasting time on Facebook.

3. Watch the metrics. The vanity metrics are good: numbers of followers, shares, and likes. But also track which sites get customers to contact you. For instance, here at the ACHR News, we track how many people come to our website each month from our respective social media sties. That is much more important to me than any other number.

The important thing is not to be intimidated by the prospects of social media. It is where the majority of your customers are, and it is a relatively cheap form of communication. If it is too much for you, get some help, but make sure your HVAC contracting company is there. ▪

Kyle Gargaro is editorial director of The NEWS. He can be reached at 248-244-1720 or kylegargaro@achrnew.com. Gargaro has been with The NEWS since 2004., first as legislation editor, then managing editor, and now as editorial director. He holds a bachelor’s degree in journalism.

14 » Partners in Progress » www.pinp.org

Is Loyalty a Thing of the Past?

By / Eric Anderton

Photo by Hyppolyte de Saint-Rambert

Construction organizations constantly battle to recruit and retain talented people. In this article, you’ll discover a threestep method to generate loyalty from your employees and members.

Have you ever heard of Hachiko, the golden-brown Akita dog? Hachiko was a familiar sight at the Shibuya train station in Tokyo, Japan. Each evening he would go down to the station to greet his owner Mr. Ueno on his return from work at the local university. One day Mr. Ueno did not appear. He had suffered a cerebral hemorrhage at work and died.

Nearly a decade of commitment

For the next nine years, nine months, and fifteen days, Hachiko went down to the train station, at precisely the time the Mr. Ueno’s train was supposed to arrive, and waited for his master. As the years passed, the dog became famous throughout Japan for his remarkable loyalty.

Here’s what you need to do to generate loyalty from the workforce:

1. Work hard on initial fit.

2. Give your employees opportunities to develop.

3. Recognize and reward high-performance.

Step 1: Work hard on initial fit

The reason some organizations struggle to generate loyalty from their recruits is found in the initial hiring and recruitment process. Desperate to fill open positions, organizations recruit people who are technically qualified but a poor fit with the culture of the organization.

One of my contractor clients has a very competitive culture. The purpose of the business is to “Crush the Competition.” That competitive spirit permeates how they run their business, and they work hard to make sure that they hire people who share that drive to succeed.

They’ve taken time to define their culture. This guides them in the interview process to structure questions that dig into job candidate’s experiences with, and attitudes towards, a competitive environment. The responses to those questions help them to filter through potential employees and identify people who are more likely to fit in with the vibe of the company prior to bringing them on board.

The hiring decision is just the beginning. Immediately following that you have to turn your attention to the second step of building loyalty.

Partners in Progress » October / November 2022 » 15

Step 2: Give your employees and members opportunities to develop

Once you’ve got a cultural fit, you have to make sure you provide opportunity for individuals to develop and grow. Talented people don’t like to stagnate and if they don’t feel challenged, they’ll soon be looking for openings with more dynamic organizations.

Provide “tours of duty” for ambitious people

For example, a contractor might hire someone as a project manager, and after a year or two move them into estimating to provide a taste of what it takes to win projects.

They could even go into the field for a few months as a superintendent to gain a deeper understanding of how to build a profitable project.

Opportunities increase as people’s horizons expand. They not only gain technical knowledge, but they build relationships inside and outside the company. You may also find that as they make progress they emerge as potential leadership candidates.

If you nail initial fit and work on developing your people, they’ll produce great results which will lead to the final step of locking in loyalty.

Step 3: Recognize and reward high-performance

Loyalty skyrockets when people feel appreciated. Savvy leaders not only recognize people for outcomes, such as achieving a sales quota or completing a project, they also reward behaviors that exemplify the values that drive the organization.

When did you last “catch” your employees or members excelling? If your organization is uniquely devoted to customer service or being a team player, for example, make sure you “catch” people when they go above and beyond in these areas. It’s easy to get used to high-performers doing well, and you can slip into neglecting to give them the recognition they deserve. Don’t make this mistake. Genuine, specific,

Loyalty skyrockets when people feel appreciated. Savvy leaders not only recognize people for outcomes, such as achieving a sales quota or completing a project, they also reward behaviors that exemplify the values that drive the organization.

consistent recognition plays a huge part in locking in the loyalty of talented people.

But where can I find the time to do all this work?

Some organization leaders complain that they are too busy with their day-to-day tasks to take the time to go through the loyalty building steps described in this article. This is a very narrow perspective, and it misses one of the most important jobs of a leader: attracting, developing, and retaining talented people.

Focus on the up and comers

One of my clients has been in business for over 25 years, and they intend to continue for at least another 25. That’s why they’ve committed to leadership development classes for up and comers in their company. They’ve also paired them up with a mentor to help them continue their growth in the business.

The battle for talent is not ending anytime soon. Savvy companies understand their future depends on getting, growing, and keeping good people, and they are dedicated to locking in the loyalty of their best employees.

Dogs vs humans

Hachiko stuck around for years waiting for his master, and his loyalty was commemorated with a statue. Dogs and humans are different, and you need to work harder to generate deep commitment from your employees than you will from a friendly mutt. Make sure new recruits fit your culture, get challenged to grow in their careers, and receive the recognition they deserve. ▪

Eric Anderton is a business and executive coach and works with construction executives to develop their leadership. He provides his clients with a tool called the Leadership Dashboard. They use it to help high-potential employees clarify eight key areas that every top performer needs to consider. Access the Leadership Dashboard at constructiongenius.com/leadersdashboard

Reprinted with permission from the author.

16 » Partners in Progress » www.pinp.org

Is Loyalty a Thing of the Past

MY JOURNEY: ALDO ZAMBETTI

Administrator, Sheet Metal Occupational Health Institute Trust (SMOHIT)

I entered the industry through my father, who was also a sheet metal worker. That was more than 40 years ago. The second half of my career has been devoted to education. I was a full-time instructor and apprentice coordinator at Local 19 in Philadelphia for 16 years, and then I was the Occupational Safety and Health Administration (OSHA) specialist for the International Training Institute. Last year, I took on the role of administrator for SMOHIT, which oversees the safety aspect of our trade.

In just the last five years, “safety” in our industry has come to mean far more than it did when I started with SMART. Physical health and safety on the job site through OSHA trainings, PPE, and other tactics, are still very important, but in the last five years, the mental health of our members has become paramount. Men working in construction have one of the highest suicide rates—four times higher than the general population. That means the mental health of our members became our primary mission. While I started because my dad was in the trade, I’m in the trade today to help my brothers and sisters go safely home to their families every night.

In my current position, one day is never the same as another. Lately, I’ve been busy traveling and spreading the word to reach as many SMART members as possible about mental health in our industry—whether it’s speaking at the SMART Leadership Conference, working with the SMOHIT team to provide online or live classes, or attending the SMACNA Annual Conference, I’m working with industry and mental health experts to let our brothers and sisters know they’re not alone. I’ve been collaborating with Justin Crandol, SMACNA director of safety, on various initiatives.

In the upcoming months, SMOHIT will hire a second counselor for The Helpline, which is open all day, every day, to members and their dependent family members. More and more members are taking their mental health seriously, calling for help, and getting the referrals they need—and more will be able to. In an industry known for its strong-and-silent nature, that’s a huge step. Right now, the biggest challenge is reaching members and getting them to realize their mental health is

important. We can’t keep losing brothers and sisters to suicide and substance use disorder. Each and every one of them is valuable to us, their families, and the global community.

For those considering a career in sheet metal, remember that if you’re going to be a part of the sheet metal worker family, there are responsibilities. It’s more than just a job you clock in and out from. It’s a family. We’re all responsible for one another. There are a lot of different titles for sheet metal workers— fabricators, installers, architectural specialists who hang off the side of buildings, instructors, apprentices, welders—but there is one commonality for all of them. Whether you’re a first-day apprentice or a journeyperson on the day of your retirement, you can always help a brother or sister out. It can be as easy as grabbing a tool or a bottle of water on a hot day; asking, “How are you doing?” in the hallway and meaning it; or checking in on someone during a hard time. Sometimes, being present and available to your fellow members, and taking care of yourself in the meantime, is the best thing you can do.

I can do my job more easily because of the ongoing relationship between SMART and SMACNA on the national level and because contractors are empathetic to our members’and their employees’ needs. Contractors contact me regarding SMOHIT materials and resources for their employees, including virtual and live classes and links to valuable information. It is because of the commonality between SMART and SMACNA, those conversations and that sharing of information happens.

▪

Partners in Progress » October / November 2022 » 17

Help Spread Awareness About Careers in Sheet Metal

The SMART SMACNA Best Practices Market Expansion Task Force has launched a recruitment initiative to help address the industry's labor shortage.

The Brand Ambassador program attracts new recruits to the sheet metal trade by leveraging the positive experiences of apprentices, journeypersons, and other members of the industry who love the trade.

Brand Ambassadors spread the word about the advantages of SMACNA and SMART careers to their friends and family on social media.

Anyone interested in being a Brand Ambassador simply uses the hashtag of our recruiting campaign, #MJMG, on their social media accounts. Exemplary Brand Ambassadors will receive $100 Amazon gift cards.

Industrial

Athlete™

GET THE SMART SMACNA BRAND AMBASSADOR PROGRAM STARTED IN YOUR AREA

info@industrialathleteofficial.org @industrialathleteofficial @industrialathltofficial

resources visit

For more details on other recruiting

pinp materials.org

By Robin Brunet

By Robin Brunet