1 minute read

Structural Components

Duct Wall Components

Cell Roof Components

The fork shaped Duct walls were cast vertically using PCE owned bespoke steel moulds so that all the visible faces were formed against the mould faces to provide a high-quality finish. Set into the moulds at standard positions were steel formers for the sinks, toilets and vents. Radii and skirting recesses were also set into the moulds to ensure the accuracy of key important detailing. Cell roof components covering the area of two cells and associated ducts were cast flat on steel tables in their final orientation, ensuring a high-quality finish to the cell ceiling and providing a floated finish to the upper face which formed the plant room floor. Magnetized steel formers were fixed onto the moulds to create the main roof light opening.

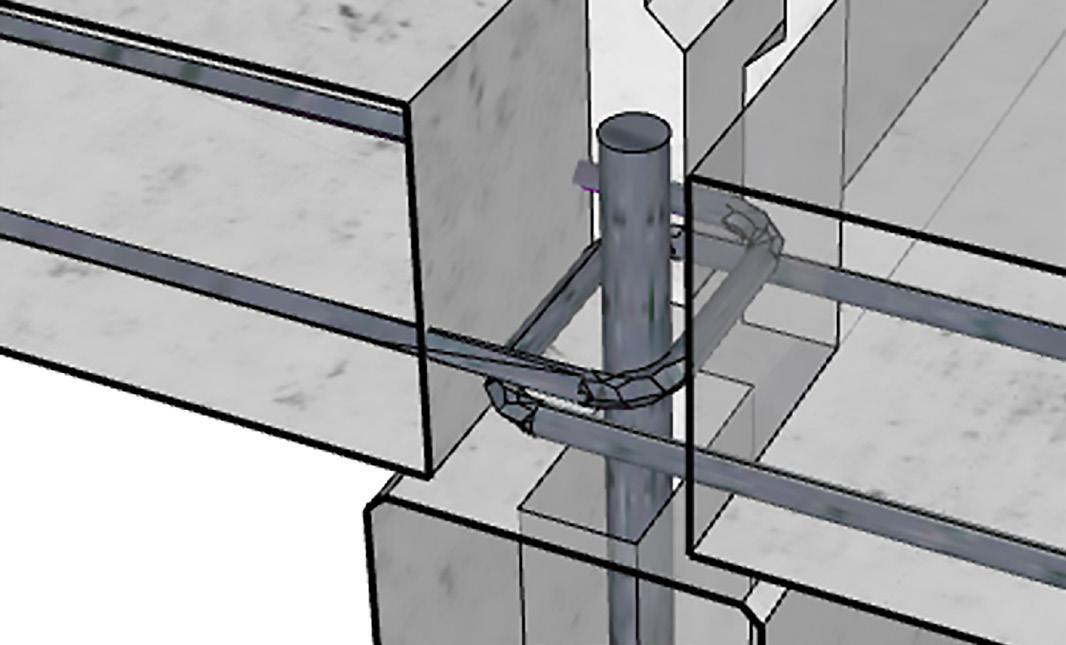

STRUCTURAL COMPONENTS

Corridor Wall Components

The intricate Corridor walls were cast from steel vertical moulds so that all the visible faces were formed against the mould faces to provide the required high-quality finish. The PCE owned bespoke profiled steel formers for the cell and riser door were set into the vertical mouldage at standard positions with specific key positions set within the moulds for containment of them, ensuring they could be positioned accurately and held firmly during concrete placement.

External Wall Components

External walls were cast flat on variable steel tilt tables, ensuring a high-quality finish to the internal cell face and a floated finish provided for the cavity face. Tilt tables were used to minimize unnecessary handling reinforcement that would otherwise have been required to turn the unit vertically into its delivery orientation.