1 minute read

THE ACTIV’ HARVESTING HEAD, THE SORTER AND THE BINS

THE ACTIV' SELF-GUIDED HARVESTING HEAD

The harvesting head automatically aligns in the row via two position sensors. Constant maximum precision, with no intervention from you.

• The movement of the harvesting head is proportional to the ground speed. • The system optimizes the efficiency of shaking, while respecting the trellising and vegetation. • Automation improves working comfort. • Increases the service life of wear parts. • If the ACTIV ’cylinders come to a stop, direction correction indications are provided on

EASY TOUCH.

LARGE CAPACITY BINS

Their large volume, up to 4,000 litres*, means they can be emptied less often. You stay operational longer and gain in productivity.

• The level of the bins* is permanently displayed on EASY TOUCH, allowing you to better manage the work. When the bin is 90% full, the rotating beacon lights switch on. The bin level sensors are present as standard on harvesting heads equipped with SELECTIV ’PROCESS. • The stainless steel distributing auger improves harvest distribution in the bins and optimizes their capacity. The rotational direction of the screws* can be adjusted on EASY TOUCH. • The height of the distributing auger adjusts automatically as the bin fills without penalizing emptying operations.

*Depending on model and options.

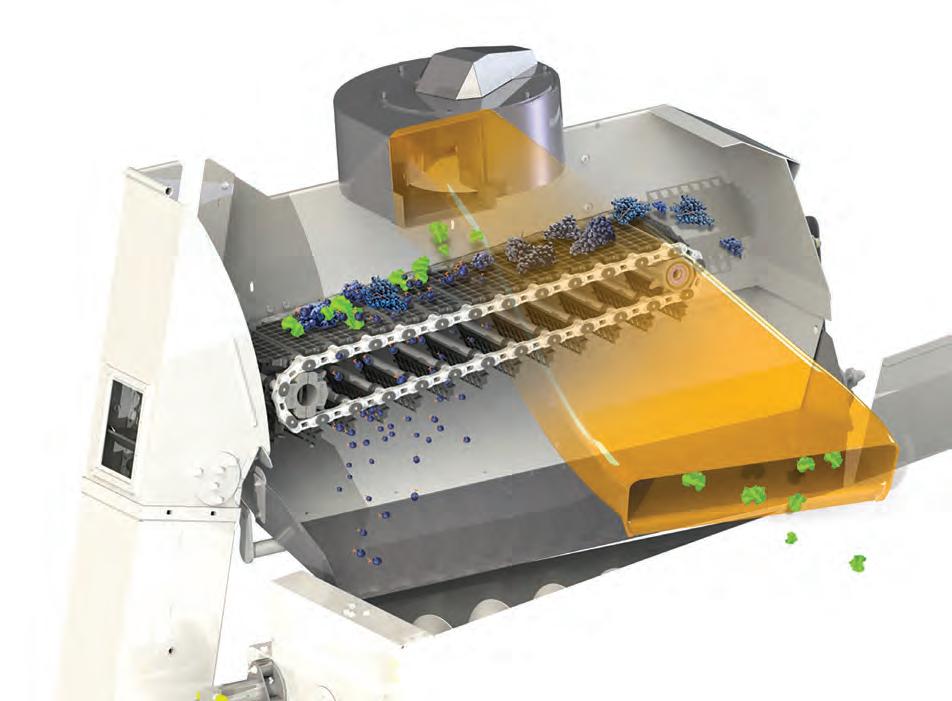

THE HIGH-PERFORMANCE HARVEST SORTER

The system makes it possible to separate and eliminate the leaves from the harvest.

• The juice and destemmed berries pass directly through the slotted conveyor. • No loss of juice. • The suction fan removes only the leaves remaining on the conveyor.

Adjustable power upper suction fan

Direction of the harvest

The slotted conveyor removes the destemmed grapes directly to the bin The suction fan gets rid of plant debris only