INDUSTRY AND TRADES

INDUSTRY IN OUR REGION

FEATURES

Canada’s first first renewable diesel refinery

New technology in the forest and mining industries

SUMMER / FALL 2023

Claire Wilson Glacier Media

SUMMER / FALL 2023

Claire Wilson Glacier Media

Housing starts and investment in residential construction are expected to weaken throughout 2023 and into 2024 as the impact of elevated interest rates cools B.C. ‘s construction industry, according to a new report from BuildForce Canada.

“We anticipate in the short term that there will be a bit of a pullback, in part, because consumers saw interest rates rise rapidly in 2022 and once they adjust their expectations to higher interest rates, we believe that they’re going to get back into the market,” said Bill Ferreira, executive director of the construction industry advocacy group.

This period of decline comes after residential housing starts reached more than 45,000 units in both 2021 and 2022.

Gains in renovations and maintenance investments are expected to offset potential losses in 2023 and 2024. The push to add density in B.C. municipalities as well as the shortage of previously undeveloped land in Vancouver will contribute to this, said Ferreira.

“We see ongoing and growing activity in the renovation market because of those various factors as well as individuals that don’t want to leave their home, want to age in place and will need to upgrade their home to enable them to age in place,” he said.

Residential renovation and maintenance made up roughly 18 per cent of construction employment in 2022, according to BuildForce’s April 28 report. New housing construction accounts for the largest proportion at 34 per cent.

The average annual unemployment rate for the construction fell to under four per cent in 2022. Rising demand and the expected retirement of 38,200 workers over the next 10 years means the industry will need to add 52,600 workers within that period.

“The residential sector is going to be hard-pressed in the next little while, [while] this brief reprieve until 2024 eases some of the pressure that we saw last year. It will actually loosen labour markets,” said Ferreira. “But over time, we’re going to continue to see strong demand for employment right throughout the forecast period, all the way out to 2032.”

Many projects in the major transportation and heavyindustrial sectors, liquified

natural gas developments, pipelines and port expansions will be winding down over the next three to four years. This will work to dampen pressure on the non-residential labour pool, according to the report.

Engineering accounts for roughly 24 per cent of the construction labour market, with 14 per cent working in industrial, commercial, institutional projects and nine per cent in non-residential maintenance.

“There’s a high level of inventory of major projects in the province that will quickly help the industry recover soon after. A lot of them are in the Vancouver area around public transit as well as hospitals, healthcare, but also in Victoria and elsewhere in the province,” Ferreira said.

A2 INDUSTRY & TRADES | SUMMER/FALL 2023

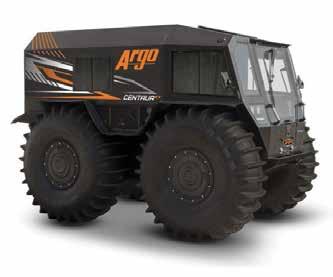

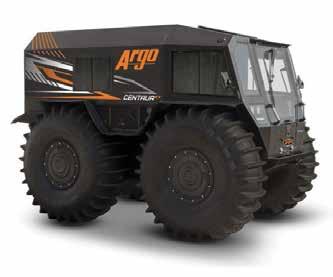

www.forestpowersports.com #120-988 Great Street 250.563.1021 DL30906 @forestpowersport

XT PRO UTV AMPHIBIOUS UTILITY TASK VEHICLE DEFENDER 6x6 LIMITED DEFENDER PRO LIMITED HourS: tueS - Fri 9-5:30 Sat 9-5:00 ©2023 Bombardier Recreational Products Inc. (BRP). All rights reserved. ®, TM and the BRP logo are trademarks of BRP or its affiliates. See your BRP dealer for details. BRP recommends that all ATV drivers take a training course. See your dealer or call the ATV Safety Institute at 1-800-887-2887 (USA) or the Canadian Safety Council at 1-613739-1535 (Canada). ATVs can be hazardous to operate. Y-6+ youth ATVs are meant to be used by children age 6 and older. Y-10+ ATVs are meant to be used by children age 10 and older. Y-14+ ATVs are meant to be used by children age 14 and older. All children must have the right physical and psychological capabilities to use the youth ATVs responsibly and be under an adult’s supervision at all times. Do not ride on public trails with youth ATVs unless permitted by local laws. Carefully read the vehicle’s operator’s guide. Follow all instructional and safety material and observe applicable laws and regulations. Never ride on paved surfaces or public roads. For your safety, the operator must wear a helmet, eye protection and applicable protective clothing. Always remember that riding, alcohol and drugs don’t mix. Never engage in stunt driving. Avoid excessive speed and be particularly careful on difficult terrain. Always ride responsibly and safely. See your authorized BRP dealer for details and visit www.can-am.brp.com.

B.C. construction industry expected to cool in 2023, 2024 amid high interest rates

CENTAUR

A3 SUMMER/FALL 2023 | INDUSTRY & TRADES 505 4TH AVE | 250.562.2441 | @ PGCITIZEN Publisher | Curtis Armstrong Editor | Neil Godbout A DIVISION OF B.C. construction industry expected to cool 2 Canada’s first renewable diesel refinery 4 Northern B.C.’s economy still strong 6 Robots are the wave of digitized forest industry 9 Northern B.C. chief outlines plan for hydrogen plant 10 Indigenous engagement is transforming the future of mining 12 Mining companies use technology for safer work 14 Northern, central B.C. airports get upgrades 14 Artemis Gold investing in mine southwest of P.G. 15 Features Performance you can count on Trucks | EquipmEnT | parTs | sErvicE 7337 Boundary avEnuE 250.562.8171 | 1.888.552.5532 inland-group.com TRUCK & EQUIPMENT

Canada’s first renewable diesel refinery to open in Prince George

diesel refinery, located in Prince George, could enter production this summer.

Once Tidewater Renewables’s $430 million refinery and hydrogen plant is fully operational, it will 170 million litres of lowcarbon renewable diesel per year, company chairperson and CEO Rob Colcleugh said. Construction of the refinery employed a peak of 270 full-time workers during construction and will create 30 high-paying full-time jobs during operation, he said.

“There was no shortage of challenges over the last three years… (But) we’re just about reaching the finish line,” Colcleugh said. “It’s a

very exciting time for us at Tidewater.”

Instead of using crude oil as feedstock, the refinery will use canola oil, tallow, used cooking oil and tall oil to produce fuel, he said. Unlike biodiesel, which is made from similar feedstocks, renewable diesel is “molecularly identical” to convention diesel, Colcleugh said.

While most engines can run on fuel mixtures with fiveto-10 per cent biodiesel, renewable diesel can be substituted for conventional diesel, reducing carbon emissions by 80 to 90 per cent, he said.

Between the new refinery and its existing co-processing

A4 INDUSTRY & TRADES | SUMMER/FALL 2023

Arthur Williams/Glacier Media Canada’s first stand-alone renewable

INDUSTRY&TRADES

Amessagefromyour localMLAs IND SHIRLEY BOND INTERIM LEADER OF THE OFFICIAL OPPOSITION MLA|PRINCE GEORGE-VALEMOUNT 250-612-4181 Shirley.Bond.MLA@leg.bc.ca /ShirleyBondforBC MIKE MORRIS MLA|PRINCE GEORGE-MACKENZIE 250-612-4194 Mike.Morris.MLA@leg.bc.ca /MikeMorrisforBC INDUSTRY&TRADES

uture Amessagefromyour localMLAs IND

Citizen staff photo Tidewater Renewables chairperson and CEO Rob Colcleugh, B.C. Premier David Eby and Prince George Mayor Simon Yu, spoke at the grand opening of Tidewater Renewables’ renewable diesel refinery and hydrogen plant in Prince George.

The Key to Ou rF uture

The Key to Ou rF

diesel plant at the Prince George Refinery, the company will be able to produce 180 million litres of low-carbon fuel per year – 14 per cent of the CleanBC target of producing 1.3 billion litres by 2030.

The project wouldn’t have been possible without the support of the province’s Low Carbon Fuel Standard, Colcleugh said. Under the legislation, Tidewater was awarded credits for increasing the use of lowcarbon fuels.

B.C. Premier David Eby spoke at an opening ceremony for the refinery in June.

“A low-carbon future means high-quality jobs and clean industry for British Columbians, as this investment by

Tidewater in clean diesel refining shows,” Eby said. “By prioritizing reducing carbon pollution, we’re opening B.C. for business and investment, and building healthier communities, while fighting climate change.”

In addition to renewable diesel, the plant will also produce hydrogen using power from BC Hydro’s renewable power supply. There are 24 different hydrogen plants proposed in the province, Eby said, including a project proposed by the McLeod Lake Indian Band and Mitsubishi Power north of Prince George.

The combined potential value of those hydrogen plants is $16 billion, Eby said.

“It’s an exciting time, but we have to be ready to take it,” he said. “Our businesses do rely on affordable, reliable power.”

Prince George Mayor Simon Yu said the refinery will “put Prince George on the map,” as a centre for producing renewable, lowcarbon fuels for the future.

City of Prince George economic development manager Deklan Corstanje said the project provides some welcome diversification for the city’s economy, and is the first in what the city hopes to be several major investments in the clean energy sector in the city.

“It’s all pulling towards where we what we want to be moving towards,” Corstanje said.

A5 SUMMER/FALL 2023 | INDUSTRY & TRADES

“ A

-

PRINCE GEORGE, BC 236-601-5610 www.smprv.ca HOUSTON, BC 250-845-2244 www.sullivangm.com HOUSTON, BC 877-552-6268

low-carbon future means high-quality jobs and clean industry for British Columbians, as this investment by Tidewater in clean diesel refining shows

Eby

Northern B.C.’s economy is still strong, despite forestry industry downturn

Nelson

towns and cities have been affected by major sawmill and pulp and paper mill closures over the last couple of years. A number of closures have happened in recent months and weeks.

But thanks to increased activity and investment in mining and energy, the economies of B.C.’s northern towns are proving resilient, despite a major downturn in the forestry sector. Some are positively booming.

Perhaps not surprisingly, the region of B.C. with the highest unemployment rate – the Cariboo – is one where forestry has traditionally been a major employer. As of March, the region’s unemployment rate was 7.1 per cent, while the B.C. average was just 4.5 per cent.

Houston (population 3,600) once hosted two large sawmills, one of which permanently shuttered in 2014. More recently, Canfor (TSX:CFP) shut down its sawmill there four weeks ago and a planer mill earlier this month, said Houston Mayor Shane Brienen.

“We have about 300-plus employees out of work,” Brienen said, adding the mill closures will also result in job losses for loggers.

A mill the size of the one in Houston spends about $90 million a year on goods and services in the region, he said. That spending is now gone.

“It’s a lot of money out of our local economy in a hurry,” Brienen said.

Fortunately, the Coastal GasLink pipeline project has provided work for loggers and other workers.

A6 INDUSTRY & TRADES | SUMMER/FALL 2023

Bennett Glacier Media Mackenzie, Houston, Chetwynd, Prince George –these northern B.C.

“That ramped up at a fairly good time,” Brienen said. “We were going through the downturn from the last mill when the pipeline came along. There are lots of people in town that work on the pipeline, or out at many of the mining camps in the north or work for CN.”

Similarly, Mackenzie was hammered with Canfor sawmill and pulp mill closures in 2019 and 2020, respectively, but has managed to avoid the hollowing out that might normally happen

with the sudden loss of 400 jobs, thanks to demographics and the restart of mines in the region – notably the Conuma Resources coal mines to the east in the Tumbler Ridge area, and the Mount Milligan gold mine to the west.

“What has been our saving grace – as opposed to when we had a big downtown in 2008-09, and every mill shut down and people gave their keys back to the bank – in 2011 Mount Milligan opened,” said Mackenzie Mayor Joan Atkinson. “And then Conuma Coal, many people in Mackenzie now work at those coal mines. We have 100 families supported by the mining industry.”

Atkinson also noted that many workers who lost jobs were Baby Boomers who took early retirement, so there has not been the kind of exodus one might normally expect with so many job losses.

The biggest impact of the loss of a major sawmill and a pulp mill has been the impact on Mackenzie’s industrial tax base. The town has lost $900,000 a year in taxes just from the pulp mill, which has resulted in a heavier tax burden on residents.

In Prince George, the capital of B.C.’s north, the city is losing 300 jobs with the closure of a Canfor pulp line. With a population of close to 77,000, and a much more diversified economy, Prince George is able to absorb closures and business losses better than smaller, oneindustry towns.

“Prince George is still growing, attracting investment and is very busy,” said Joel McKay, CEO of Northern Development Initiative Trust.

There are several sawmills in Prince George that are

still operating, and the city continues to diversify its economy, including with new clean-tech industries.

“We see the writing on the walls,” said Deklan Corstanje, Prince George’s manager of economic development. “The industry is in transition. And because of our close ties to the industries, we are also sort of in transition.”

One new industry being developed in Prince George is Arbios Bio – a joint venture between Canfor and Australia’s Licella Fibre Fuels to develop a new biofuel plant. Hydra Energy is building a $62 million green hydrogen plant in Prince George, and Tidewater Midstream and Infrastructure – which owns the oil refinery in Prince George – is building a new biofuel plant there.

Last year, Prince George had $250 million in development

permits issued for residential, commercial and industrial projects – a record.

“We have the LNG projects out on the coast, and that will have a regional impact and benefit to our economy,” Corstanje said. “We have our low carbon and fuel projects, and we’re also working on trying to solve our housing challenge in Prince George as well. And hopefully all those things will culminate in stabilizing the growing the economy here.”

Commodities produced in B.C. – from metallurgical coal and copper, to propane and wood pellets – move through the Port of Prince Rupert, which is thriving and growing.

“The economy is strong,” said Prince Rupert Mayor Herb Pond. “As a matter of fact, the challenges we have here are far more around recruitment and retention of both skilled

A7 SUMMER/FALL 2023 | INDUSTRY & TRADES

“ The economy is strong. As a matter of fact, the challenges we have here are far more around recruitment and retention of both skilled and unskilled labour. In Prince Rupert, if you want a job, there are jobs to be had.

Put your MetaL Where the Money Is! $ Call Toll Free: 1-877-566-1177 Mon-Fri: 8am - 4:30pm Prince GeorGe: 302 - 2nd Ave. • 250-562-1177 TerrAce: 5206 KeiTh Ave. • 250-638-6378 NortherN BC’s Largest LoCaLLy owNed sCrap yard! roLL off BiNs • Lugger BiNs piCker truCks Low Beds demoLitioN & yard CLeaN ups Competitive priCes paid serving northern BC, the Cariboo and the okanagan reliable service you can count on www.AllensScrap.com 56 years We Buy MetaL We buy and recycle all types of metals We seLL MetaL used pipe, angle iron, plate DeMoLItIon roll-off bins and on-site equipment Commercia / Indus rial 2020 Readers Choice t d

- Prince Rupert Mayor Herb Pond

and unskilled labour. In Prince Rupert, if you want a job, there are jobs to be had.”

Kitimat is also booming, thanks to heavy industry – specifically aluminum smelting and liquefied natural gas (LNG). About 5,000 workers are employed building the $18 billion LNG Canada project in Kitimat, and about 1,000 are employed at the Rio Tinto (ASX:RIO) BC Works aluminum smelter.

While construction of the LNG Canada plant will start winding down next year, Kitimat Mayor Phil Germuth said there is reason for optimism that the town will continue its boom as work starts on other LNG projects there – Cedar LNG and Phase 2 of LNG Canada.

“There’s definitely some brighter things on the horizon, too,” Germuth said.

Meanwhile, just a 45-minute drive north of Kitimat, the City of Terrace struggles to provide public services. It doesn’t have the multimillion industrial tax base that Kitimat has: $20 million annually from Rio Tinto alone.

Terrace is a service centre hub for the region. With a population of just 12,000, Terrace has some of the same problems bigger cities have – including a highly visible homeless population, and a rental vacancy rate of less than one per cent.

“The businesses in Terrace are doing well because you’ve got the Golden Triangle (mining), the Port of Prince Rupert and LNG Canada (in Kitimat), so there’s lots of work for folks,” said Terrace Mayor Sean Bujtas. “But Terrace itself doesn’t see any industrial revenue, so it makes it a struggle for the community to deal with infrastructure

challenges.

“Last year we had one roadpaving project on the go because that’s all we can afford.”

“Dawson Creek has always been a very stable economy,” said Dawson Creek Mayor Darcy Dober. “There’s a lot going on up here – oil and gas, agriculture, forestry.”

About 450 kilometres north of Dawson Creek, the activity from oil and gas and forestry slows to a trickle. More than a decade ago, Canfor shut down its sawmill and oriented strand board plant there, and while the region experienced some oil and gas activity, most of the investments in oil and gas over the last decade have been further south in the Montney region around Fort St. John and Dawson Creek.

“From Dawson Creek-Fort St. John up to about 200 kilometres on the Alaska Highway towards Fort Nelson, it’s busy,” said Rob Fraser, mayor of the Northern Rockies Regional Municipality. “You go beyond that and the traffic just drops.”

Terrace is one of 21 local governments in northwest B.C. now lobbying for revenue sharing from the province through the Northwest BC Resource Benefits Alliance. The ask is modelled on a revenue-sharing agreement between the province and regional and municipal governments in the Peace region of Northwest B.C.

Dawson Creek is one of the communities that benefits from the Peace River agreement. In addition to getting a share of oil and gas revenue from the province through that agreement, Dawson Creek has a diversified economy – a mix of agriculture, forestry and oil and gas extraction – that has made it less vulnerable to commodity cycle shocks.

The municipality of Fort Nelson and the Fort Nelson First Nation have been trying to revitalize the local forestry sector. The region has a large amount of timber, and Peak Renewables has proposed building a wood pellet mill in Fort Nelson to help revitalize the region’s forestry industry. But for that investment to happen, a Canadian National Railway (TSX:CNR) line between Fort St. John and Fort Nelson needs to be upgraded, and the B.C. government has refused to kick in funding.

Until that happens, Fort Nelson’s economy remains depressed.

“As a transportation community, we’re still doing OK,” Fraser said. “But from the historical resource industries that we’ve had in Fort Nelson, we’re still lacking hugely.”

A8 INDUSTRY & TRADES | SUMMER/FALL 2023

“ Dawson Creek has always been a very stable economy. There’s a lot going on up here – oil and gas, agriculture, forestry.

Built To Last Ride In Comfort P.G. Spring & Accessories Ltd. 2001 1st Ave, PG 250-563-0364 • Toll Free 1-800-722-7001 P.G. SPRING & ACCESSORIES LTD. 2001 - 1st Avenue, Prince George, B.C. V2L 2Z1 Phone 250-563-0364 Fax: 250-563-7004 Toll Free 1-800-722-7001 *Over 140 trailers in stock* TRAILERS Enclosed trailers Flatdeck trailers Pull trailers Gooseneck trailers Utility trailers Dump trailers Car trailers Trailers of all types QUAD Trailers Now in stock Bearing repack Special! Get your holiday trailer ready Air Bags for pickups installed Fifth Wheels Sales and Installation SINCE 1965 P.G. SPRING Serving Prince George since 1965

- Dawson Creek Mayor Darcy Dober

It’s the undeniable wave of the future for forestry companies seeking longterm sustainability in an industry that has come to a high-tech crossroads that will reshape how our forests are managed and utilized.

Rapid advances in remote sensing technology to map, monitor and manage valuable landscape resources are changing how forest health and wildlife activity is measured and the use of remotely-operated robotic harvesting equipment is gaining a foothold in Interior forests. Companies are utilizing new tools to meet goals in environmental stewardship, safety and efficiency.

The ability to operate a crane remotely to load a logging truck means the operator can avoid adverse weather conditions and work safely, day or night. Advances in 5G networks have increased connectivity speed to the point at which real-time virtual control is possible for machine operators using cameras mounted on machines to work wirelessly in the woods.

“We all know forestry is a dangerous business and working around safety and getting people off steep slopes – remote control machines will now allow that,” said UBC forest resources management associate professor Dominik Roeser, who was one of the guest speakers at the B.C. Council of Forest Industries convention in Prince George back in April.

“In the future, you could probably operate your forest machine from your living room, from

of a digitized forest industry future

containers sitting at the top of the hillside, and you’re getting away from this by-yourself operation in the dark to a more communal operation of equipment.”

Machine automation is already being utilized on modern forest machines and Roeser says it’s only a matter of time before there is broad adoption of fully automated equipment in Canadian forests.

Since the 1950s, the number of human-hours it takes to harvest trees has declined almost every year due to advances in mechanical equipment that made harvesting operations more efficient. But that curve has flattened or declined every year since the early 2000s, which Roeser says is a reflection of societal demands for more stringent environmental regulations that have had an impact on logging activities. The evolution of new technologies combined with digitization gives the forest sector hope that trend will be reversed.

Advances as simple as a mobile phone app that instantly determines the volume of a loaded logging truck is an example of supply-chain tracking tools that could save costs for B.C. companies that have long distances to overcome.

“This has been standard on cut-to-length operations for 15 years in Nordic countries and we’re starting this now, and that’s where we should take a step back and think about a lost opportunity,” said Roeser. “I think one of the challenges we’ve always had in B.C. is we’ve had always so much wood, we never had to be superefficient. In Europe, everything

is more scarce and you learn to deal with that scarcity by getting real good and very efficient.”

Until recently, when economically viable tree supplies were abundant in the B.C. Interior, there was no pressing need to innovate.

“Now, with all these challenges we’re seeing, especially in B.C. - the mountain pine beetle and the wildfires - I think we’re forced to think that way and it’s a really big opportunity because the tools are there,” Roeser said. “The context we’re

in doesn’t compare to Europe, where (there is) phone coverage everywhere. But I think having that tool and having that visibility in the supply chain is a gamechanger.”

Technology is already radically changing how forests are mapped. The B.C. government is undertaking a project to map the entire province using LiDAR (light detection and ranging) and its lasers to accurately map inaccessible areas to help professionals manage for a range of values across the entire landscape.

A9 SUMMER/FALL 2023 | INDUSTRY & TRADES

Ted Clarke Glacier Media

The robots are coming to the B.C. forest sector.

Robots

wave

the

... cont. on pg 11 YOUR ONE SOURCE FOR EQUIPMENT NOW OPEN In Prince George 3833 - 22nd Ave. Prince George 250-614-2050 www.sunbeltrentals.com

Glacier Media photo Dominik Roeser, a UBC forest resouces management associate professor, speaks at the B.C. Council of Forest Industries convention, April 6 in Prince George.

Ted Clarke/Glacier Media

An agreement to proceed with a plan to build a $5-7 billion hydrogen plant located on the Kerry Lake East Indian Reserve, 90 kilometres north of Prince George, could be in place by Sept. 30.

Harvey Chingee, chief of the McLeod Lake Indian Band, says negotiations are continuing with Mitsubishi Power to complete the deal and he expects it will be done before that deadline.

Chingee says all the necessary infrastructure to operate the plant is in place at the site, which is about two kilometres east of Highway 97.

“It will be huge, like a big pulp mill,” said Chingee. “We’ve got the electricity, we’ve got the water, we’ve got the highway and we’ve got the railway, and the pipelines are all there.”

The plant will use electricity to split water molecules into their basic elements – two parts hydrogen and one part oxygen – using a process called hydrolysis. The problem with hydrogen is it is the lightest element on earth and it’s not feasible to compress the gas enough for it to be transported.

Northern B.C. chief outlines plan for hydrogen megaproject

The solution is to convert it to liquid ammonia, which would then be shipped in railcars to the port facility in Prince Rupert, which is gearing up with an expansion to be better equipped to handle large-scale ammonia shipments.

“We’re negotiating right now with CN, and we’re also negotiating an agreement with BC Hydro, because it will take a lot of power,” said Chingee.

Chingee does not anticipate opposition from other First Nations whose territory the ammonia shipments will eventually pass through.

“We’ve already got the right-of-way identified,” he said. “They’ve been hauling (petroleum) condensate to Prince Rupert since the 1960s and they’re still doing it and there hasn’t been a spill. The rail is already there, that’s the beauty of it. Existing infrastructure is already there and there’s no need for consultations and all this other stuff.”

A five km rail spur line would be needed to connect to the CN line. The existing BC Hydro transmission line is about two kilometres from the proposed site. Water would

be drawn from the nearby Crooked River.

The plant would produce ‘green hydrogen’ generated from non-fossil fuel sources (electricity) as well as ‘blue hydrogen’ made using natural gas.

A $2 billion straddle reprocessing plant would also be built at the site to recover and refine natural gas products to be fed into the Coastal GasLink LNG pipeline that runs through the area. Construction of that 670-kilometre pipeline which from runs from Dawson Creek to Kitimat is expected to be complete later this year.

The McLeod Lake band is working with Pacific Natural Gas to reactivate its compressor station near Summit Lake and with Pembina Pipeline Corporation to create the pipeline infrastructure needed for the project.

Surveying of the plant site, 32 km north of McLeod Lake, is set to begin July 15 and Chingee says the area will be logged this winter. If an agreement is reached by September he said construction would begin in May 2024, to be completed within two years.

Plant construction will require an estimated 600 workers. A temporary work camp as well as some permanent housing will be built, Chingee said. It will ultimately create 250 permanent jobs, which will have an economic boost to the region, with Prince George as the plant’s service hub.

Because of its potential to produce zero-emission clean energy, the plant is expected to have financial backing from the provincial and federal governments. On May 30, the BC government announced the renewal of an energy and minerals partnership with Japan.

Chingee says Mitsubishi will handle details of the financing needed to get the plant built.

“All we’re doing is leasing the land to them and doing a revenue share off the top,” he said. “We’ll lease the land and it will be secure for 99 years. There’s no risk to the nation and a big upside.”

Chingee says the hydrogen plant will provide well-paying jobs for the people of his area, on a much larger scale than the McLeod Lake band’s forestry/logging/construction firm, Duz Cho Group of Companies.

A10 INDUSTRY & TRADES | SUMMER/FALL 2023

Prince George Citizen file photo McLeod Lake Indian Band chief Harley Chingee speaks at an event in Prince George.

Trade schools are using simulators and video screens to train operators inexpensively without the inherent risks of turning loose inexperienced students at the controls of heavy machinery. The simulators provide live feedback to show what they need to improve to achieve maximize efficiency.

The UBC Forest Science Centre recently became home to the first global state-of-the art Forestry Trimble Technology Lab, which will give students access to the most innovative software and hardware tools available to the forest industry to be used for teaching and research.

Just as the health sector is being transformed with remote interactions between patients and healthcare professionals and doctors and nurses using realtime connections to perform remote procedures such as an ultrasound exams, Roeser says the forest sector also stands to benefit from advanced diagnostics for such purposes as repairing machinery or maintaining equipment.

He says electrification is coming. It’s already happening in places like Finland where hybrid electric harvesters are being used, while in Austria and Germany cable yarders use electric carriages to power electric engines.

Electric trucking fleets with interchangeable batteries are also coming to help companies achieve fuel savings and meet emission targets. But Roeser says B.C. will still have to overcome the challenges of its large distances and remote work sites.

The arrival of ChatGPT, the artificial intelligence chatbot first introduced to the public in late November, has the power to radically reshape the forest sector. The app essentially harnesses the entire knowledge base of the internet to provide detailed answers and articulate responses to user queries and it is already having an effect on the UBC forestry program. Roeser says all his graduate students are already using it in their studies.

“We have to adapt, there’s no way around it,” he said. “It’s making my life so much easier because I don’t have to answer any questions about coding, ChatGPT does that for me. I don’t have to correct papers anymore, ChatGPT does that for me. It’s unbelievable and I think it will change the way we all will be interacting with each other.”

To prepare for his COFI presentation on digitizing in the forest sector, Roeser asked ChatGPT for suggestions on what he should talk about and it came up with such topics as autonomous forest machines, advanced genetic research and biotechnology, 3-D printing with wood-based materials, carbon capture and storage technology and cross-disciplinary collaborations.

“I think this just shows the potential and the opportunities that AI can provide us today,” said Roeser. “But then I asked about what we need to do in B.C. to turn things around in the forest sector, and ChatGPT crashed.”

FenceS

DeckS

PatioS

ScreW

irrigation

SyStemS

Drainage

SoD

A11 SUMMER/FALL 2023 | INDUSTRY & TRADES

UBC photo

A UBC student learns how to use a virtual reality screen to work the controls in a simulation to practice operating a piece of forest harvesting heavy equipment.

Dominik Roeser photo

... cont. from pg 9

A UBC forestry student practices using a video screen and hand controls to simulate operating a piece of forestry equipment at UBC.

Design

• Constru C

tion

•

Maintenan

C e maintenance services that keep properties looking their very best.

Hill • 250.563.7062

Stone Work retaining walls, PonDs & waterfalls

Russ

PileS

SeeDing Landscaping Ltd. Landscaping

MM er C ial & r

D ential QuaLity

&

Co

esi

Favourite Landscaping Company

Lawn Maintenance

Indigenous engagement is evolving, and suppliers are learning new ways to collaborate on the journey towards economic reconciliation

Harold Reimer/Special to Industry and Trades Canada’s mining sector has an extensive history, with minerals playing a vital role in day-to-day life going back thousands of years. Since then, much has changed and the industry has experienced innumerable advancements, including in technology, safety, and sustainability. More recently, one of the most significant developments has been the official recognition of the traditional lands of Indigenous communities that many Canadian mines are located on. The recognition and accompanying legislation give communities better representation and more leverage in the mining process. That is why Indigenous community partnerships are becoming

even more important and the relationship between industry and Indigenous communities is transforming. It helps pave the way towards economic reconciliation.

While the process is new to many, some suppliers are in a unique situation where they can support as a liaison to consult and understand. This allows for a bridging between the industry and Indigenous communities where there is an opportunity to reach out, engage, and educate. What we are seeing is an approach to seek social licence and the discussions taking place are leading to impact benefit agreements (IBAs), capacity agreements, and mutual benefit agreements. It is leading to greater information sharing, better consultations, engagements,

and consent for respective projects.

As minerals continue to play a critical role in dayto-day life, including to support the energy transition with electrification and low-carbon technology, it becomes increasingly important to support our Indigenous communities with their stewardship action plans that are based on traditional knowledge since time immemorial. National Resources Canada states that “Indigenous representation in the minerals sector has increased in the last decade, especially in the mining industry. Working with First Nations Territories can help support the future success of Canada’s mining industry.” Additionally, in 2021, the direct contribution

of Canada’s minerals and metals sector to national GDP was $97 billion, which represented four per cent of Canada’s total GDP.

Shift from duty to consult to right to consent

At the core of this shift are significant declarations. We must acknowledge and understand the United Nations Declaration on the Rights of Indigenous Peoples (UNDRIP) that was adopted in 2007 and given Royal Assent by the Government of Canada in 2021. The declarations state that “Indigenous People have the right to determine and develop priorities and strategies for the development of use of their lands or territories and other

A12 INDUSTRY & TRADES | SUMMER/FALL 2023

Getty Images photo

resources.”

The result is the change from duty to consult to right to consent (Free, Prior and Informed Consent, FPIC). The key difference is that new projects now hinge on the rights of Indigenous Peoples to give or withhold their consent for any action that would affect their lands, territories, or rights. This requires active engagement, strong relationships, and partnerships between the mining industry, the suppliers, and the Indigenous communities. It is helping to shift conversations and involve the local communities at project onset to understand their views and desires and incorporate them into the plan, rather than consult communities at the final stages.

Right to consent has been instrumental in ushering in meaningful engagement between those who are proposing a project and those whose traditional livelihoods could be impacted by that disturbance. With new legislation and rulings placing FPIC in the forefront, there have been significant changes that genuinely see collaboration and the resulting benefits in working with Indigenous communities. So, it is important to get out in the field to identify what is happening and what the implications are for suppliers, industries, and the impacted communities. Establishing good relationships is at the core of every business. Those relationships overlap in communities where we work, live, and play. The pace of change has accelerated in the last 24 to 36 months, and there is now more engagement in environmental assessments, permits, and water licensing as Indigenous involvement and consent is required for every project and proposal.

Building bridges between communities

Deep rooted for generations, Indigenous relationships thrive in person-toperson dynamics and oral communication. Businesses have the honour and privilege to learn from Indigenous leaders, Elders, and Knowledge Keepers. Through this learning, it is possible to understand historical provisions of the land, ceremonial, and spiritual traditions. From a western Canadian perspective, the territory is vast. There are over 300 First Nations communities in Finning’s territory and endeavouring to connect with every community is ambitious. But, by proactively starting the process and engaging one by one and at the beginning of a mining project, this act builds trust and lasting connections.

Many First Nations have already established longterm operations. They operate full economic development teams with a CEO and an established board of directors. Within this structured network, the communication between all the stakeholders is facilitated and flows from economic development through discernment by the Chief and council to the eldership and in some cases to the membership for voting. The systems operate very well and a synergy between industry and community exists. Alternatively, some Nations are at the beginning of the economic development process and desire consultation for the establishment of a strong economic development team and identification of good board of director prospects. Active involvement, consultation, and communication by representatives from all industries leads to the

discovery of a Nation’s unique needs and requirements for projects and future economic development.

Exciting opportunities for the future

This is an exciting time for doing business. Indigenous engagement is evolving, and suppliers are learning new ways to collaborate on the journey towards economic reconciliation. Problems can be overcome together, and opportunities for education, apprenticeship and mentorship can be unearthed. Project legacy is not superficial; it becomes part of the unified statement that honours the territorial, social, and spiritual connection to the traditional lands and provisions. It means that communities are engaged, and their specific needs are met, whether that means waterway and biodiversity protection,

economic and education opportunities, or other specific considerations that help a community flourish.

We are starting to see a future full of opportunities to partner and embrace developments around mineral exploration, hydrogen, LNG, fleet electrification, alternative fuels, and power generation. Better understanding, listening, and engagement leads to more meaningful projects that can become generational building blocks. So, if future prosperity is the end goal for both industry and Indigenous communities, the first place to start is with strong partnerships.

Harold Reimer holds an MBA from the University of Alberta and is the Indigenous business development manager for Finning Canada.

A13 SUMMER/FALL 2023 | INDUSTRY & TRADES

1951 -1st Avenue Prince George,BC Telephone: 250-562-6760 Toll Free: 1-800-663-4344 Fax: 250-562-3407 E-mail: sales@ior.ca REFUELING TANKS FUEL TANK PUMP LOADING RAMPS PILOT CAR SIGNS RACKS&RAILS TO OL BOXES NEW

Mining companies betting on autonomous technology to make dangerous jobs safer

Amanda Stephenson, The Canadian Press CALGARY — Forget about the canary in the coal mine — experts say the day is coming when there won’t even be a need for a human.

Today, companies are employing everything from driverless haul trucks to remote-controlled and robotic drilling machines to remove human labour from some of their most hazardous operations.

Teck Resources Ltd. is already using an autonomous haulage system at its Elkview steelmaking coal mine in British Columbia.

“Automation is changing where a mine actually gets controlled – it doesn’t have to be at the mine site,” said W. Scott Dunbar, head of the mining engineering

department at the University of British Columbia. Productivity is one reason mining companies are making the move to automation. A tele-remote operated mining machine, for example, doesn’t need to take breaks, and doesn’t need to pause for shift changes.

At an investor presentation earlier this year, Imperial Oil CEO Brad Corson said the company’s fleet of autonomously operated heavy-haul Caterpillar trucks at its Kearl oilsands mine in northern Alberta is demonstrating 10 to 15 per cent higher productivity than staffed trucks.

The swift pace of automation is changing the types of jobs available at mine sites, in some cases making software

Northern, central B.C. airports getting upgrades

Nine small airports in northern and central B.C. are receiving provincial grants to support economic development, improve safety and increase access for rural communities.

The provincial government announced $19.8 million in funding for 40 projects at 29 rural and remote airports in B.C. through the BC Air Access Program. Projects include runway extensions, improved runway lighting, pavement improvements, terminal enhancements and better fire

protection.

“The BC Air Access Program helps communities, especially smaller ones, with important improvements to their aviation facilities,” Transportation Minister Rob Fleming said in a statement. “This investment will help move people and goods, improve safety and benefit front-line services, like air ambulance and wildfire fighting, as well as making for more secure access to remote and Indigenous communities.” Projects in northern and central B.C. which received fund-

skills more valuable at some companies than the ability to drive a truck.

Language in the current collective agreement between Teck Coal Ltd. and United Steelworkers Local 7884 — which contains an entire section about “technological change” and lays out the employer’s obligations in the event that “mechanization or automation of duties” leads to job losses — illustrates the nervousness some employees may feel about the prospect of remote-operated equipment and driverless trucks.

Imperial, too, says its former truck drivers haven’t lost their jobs, but have been redeployed to other parts of the organization or retrained to operate other equipment. Mark Crouse, industry

account executive for mining with software giant SAP, said he’s been hearing mining customers talk about the potential for remote and autonomous technology for more than 20 years.

While the industry has only recently started moving more rapidly in this direction, Crouse said, he believes a day is coming when no one will have to go underground at all to mine the earth’s resources.

“Remember how not that long ago people were using flip phones, and how quickly things shifted? It’s not that far off,” Crouse said.

“The capabilities are already there. The technology already exists.”

BUSINESSBRIEFS

ing include:

* 108 Mile - $2 million for runway rehabilitation.

* Bob Quinn Lake - $87,650 for an airport master plan and for a solar-powered weather camera with altimeter and satellite uplink.

* Dease Lake - $88,200 for an airport master plan and new batteries for solar-powered hazard beacons.

* Fort St. James - $2 million for the runway end safety area, lighting improvements and a master plan.

* Fraser Lake - $55,650 for

pavement markings and an upgrade to runway shoulders.

* Kitimat - $511,250 for a greenhouse gas emission audit, and taxiway and apron improvements.

* McBride - $259,000 to rehabilitate runway and airside pavement.

* Vanderhoof - $330,984 for runway and apron lighting.

* Williams Lake - $83,750 for an apron lighting upgrade and two automatic security gates.

A14 INDUSTRY & TRADES | SUMMER/FALL 2023

BUSINESSBRIEFS people, products & partnerships

Canadian Press photo/ Handout-Nutrien Borer Operator cutting from Surface Tele-Remote operating stations at the Lanigan potash mine, in Lanigan, Sask., in an undated handout photo. Today, mining companies are employing everything from driverless haul trucks to remote-controlled and robotic drilling machines to remove human labour from some of their most hazardous operations.

Artemis Gold investing additional $54M into mine southwest of Prince George

Arthur Williams/Glacier Media

Artemis Gold has announced a partnership with Wheaton Precious Metals Corp. to invest an additional $40 million US ($54 million Canadian) into the Blackwater Mine.

The open-pit gold mine, located 160 kilometres southwest of Prince George, is expected to begin production in the second half of 2024. The mine’s working life is projected to be 22 years. The total cost of the project, to get to production, is estimated at $730-750 million.

“Artemis Gold Inc. … announces that as a result of internal engineering analysis, it has committed to additional investments as part of its Phase 1 development of the Blackwater Mine… in order to facilitate the potential fast-tracking of the Phase 2 expansion,” a statement issued by Artemis on Thursday said. “These investments in the Phase 1 initial capital are expected to allow the Company to further optimize throughput in the early years of operation.”

Wheaton Precious Metals Corp. is providing the

additional funding in exchange for approximately 92,000 ounces of gold, to be delivered starting in approximately 2034.

The funding will be used to increase the conveyor belt widths in the crushing circuit, electrical upgrades, upsizing the oxygen plant and other investments aimed at facilitating construction of Phase 2 of the mine.

“We have been exploring these options internally for some time,” Artemis Gold CEO and chairperson Steven Dean said. “This announcement is the logical next step and importantly provides the additional funding to further pursue these optimizations at a low cost of capital with a great partner in Wheaton, without a material dilution of the net asset value per share for shareholders.”

With the agreement, the optimized initial capital for Phase 1 construction of Blackwater Mine is fully funded, the company statement said. Construction was approximately 20 per cent complete as of May 31.

A15 SUMMER/FALL 2023 | INDUSTRY & TRADES

BUSINESSBRIEFS

Artemis Gold photo

Prince George 9341 Rock Island Rd. 250-562-7422 Smithers 3364 Yellowhead Hwy 250-847-3981 www.babinetruck.com Prince Rupert 1600A Prince Rupert Blvd. 250-624-5171

Heavy equipment is parked on the site of the Blackwater Mine in an Artemis Gold undated handout image.

A16 INDUSTRY & TRADES | SUMMER/FALL 2023 Platinum model shown1 3INVENTORY AVAILABLE NOW 2LEASE A 2023 ROGUE SV AWD MONTHLY AT $430. THAT’S LIKE PAYING 4.99% APR AT $99 WEEKLY WITH $3,495 DOWN 24 MONTHS O.A.C. FOR Available Features TAKE CHARGE OF THE EXCITEMENT IN A NEW NISSAN BORN TO THRILL ROGUE® Remote Engine Start System with Intelligent Climate Control Intelligent Around View Monitor Nissan Intelligent Key with Push Button Ignition VISIT NISSAN.CA/OFFERS OR CONTACT NORTHLAND NISSAN northlandnissan.com | 1-888-584-7756 • 1995 - 20th avenue | Prince George, Bc dl# 30757 1Selling Price of model shown (Rogue Platinum Edition) is $46,484. Lease offer available through Nissan Canada Finance (NCF) on approved credit. 2Representative lease offer 2023 ROGUE SV AWD. 4.99% lease APR for 24 months. Monthly payment is $430. All prices and payments include $1,995 freight and PDI; $100 A/C charge; regulatory fees (up to $35); dealer administration fees (up to $621); PPSA fees (up to $139); as well as all other applicable fees, levies and duties (all of which may vary by region and retailer). License; insurance; registration; and applicable sales taxes are extra. $3,495 down payment, $0 security deposit and first monthly payment due at lease inception. Total lease obligation is $13,816. 16,000-kilometre allowance; charge of $0.10/km for excess kilometres. Dealer may lease for less. Dealer order/trade may be necessary (but may not be available in all cases). Conditions apply. Offer valid between July 1ST and July 31,ST 2023, and is subject to change or cancellation without notice. Ask your dealer or visit www.nissan.ca for complete details. Nissan names, logos and slogans are trademarks owned by or licensed to Nissan Motor Co. LTD. and/or its North American subsidiaries. ©2023 NISSAN CANADA INC. 3602 2023 Rogue SV AWD available in Canada as of June 26,TH 2023.

SUMMER / FALL 2023

Claire Wilson Glacier Media

SUMMER / FALL 2023

Claire Wilson Glacier Media