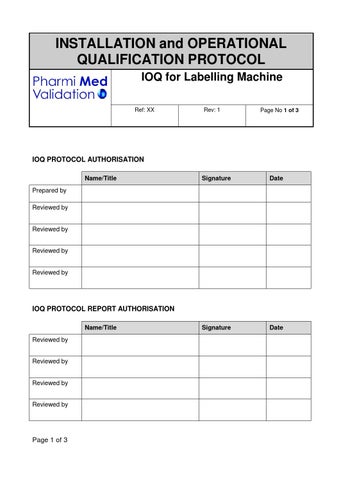

INSTALLATION and OPERATIONAL QUALIFICATION PROTOCOL IOQ for Labelling Machine Ref: XX

Rev: 1

Page No 1 of 3

IOQ PROTOCOL AUTHORISATION Name/Title

Signature

Date

Signature

Date

Prepared by Reviewed by

Reviewed by

Reviewed by

Reviewed by

IOQ PROTOCOL REPORT AUTHORISATION Name/Title Reviewed by

Reviewed by

Reviewed by

Reviewed by

Page 1 of 3

Introduction The Labeller according to GMP, MHRA Annex 15 and FDA guidelines.

Brief System Description and IOQ Rationale The labeller is used to apply a label to a product by transporting the product along the conveyor, aligning and spacing the product, correctly positioning a label on the product, and ensuring that the label is correctly adhered to the product before leaving the labelling machine. All systems shall be challenged in this protocol. Therefore it is imperative that checks are thoroughly documented according cGMP recommendations. All testing will be performed retrospectively, and all tests will be in accordance with Company “Guidelines for the Validation of Manufacturing and Laboratory Equipment and Facilities�.

Scope This protocol covers the Installation & Operational Qualification for the Labeller on Line 5. The scope of this document is therefore limited to the testing for the equipment related to this and to assure that equipment is fit for use in accordance with cGMP. The protocol shall be reviewed and authorised by the stated personnel in the approval box prior to execution of IOQ. The IQ execution shall be reviewed and approved prior to execution of the OQ. Upon completion of the OQ, a final review will be done and sign off.

Objectives The objectives of this Installation & Operational Qualification (IOQ) protocol is to ensure that the labeller on Line 5 has been installed and operates retrospectively and is fit for use in accordance with cGMP and Health and Safety requirements.

Protocol Number: VP-PR-IQ-001 Page 22 of 15

Version 01

Index of IOQ Labeller on Line 5 Test Reference

Test Name

IQ Section 1

Description and Reference Numbers

2

Mechanical, Electrical Checks

3

Critical Components

4

Maintenance and Calibration Checks

5

Availability of Software

6

Documentation Review

7

Health and Safety Checklist

8

cGMP Audit IQ Sign Off

OQ tests for execution 1

Sensor Challenge – Product and Label Detector

2

Rewinder Challenge

3

Memory Challenge

4

Security Challenge

5

Product Challenge

6

SOP Review

7

Training

Protocol Number: VP-PR-IQ-001 Page 32 of 15

Version 01