7 minute read

Heat from Refrigeration, Pt III

from April 2022

Slow at reaching mass adoption, heat pump water heaters can savehomeowners on energyconsumption by 60 per cent. By Greg Scrivener

In the last issue, we discussed some of the fundamentals of heat pumps and how they are being applied in many applications, like clothes dryers, to increase the efficiency of heating systems and decarbonize our energy use. One of the obvious areas where heat pump technology can be applied is in hot water heating. For residential applications, hot water heat pumps have been available for quite a while (see Bruce Nagy’s article in Plumbing & HVAC magazine from January/February 2019). The uptake for heat pump water heaters has not happened quickly even though they can save approximately 60 per cent in energy consumption compared to standard electric water heaters. There are two reasons for this. First, the lower price of conventional equipment and the availability of inexpensive natural gas, are both really just about cost. Compared to a typical electric or natural gas water heater, heat pump water heaters cost two to three times as much depending on specifics. They can, however, be less expensive to install because they don’t require the same size electrical service that comparable capacity electric water heaters do and there is no gas line or venting required. The second reason relates to the fact that context is needed to know whether the energy efficiency can be realized, which is discussed below.

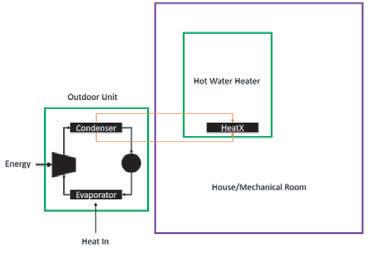

Figure 1 shows a diagrammatic representation of how a heat pump water heater works. Heat is absorbed from the air in the mechanical room or wherever the water heater is located, and a refrigeration system moves that energy into the water at a higher temperature. If you are wondering – wouldn’t this air condition my mechanical room? You are right, it would.

The average Canadian household uses 75L of hot water per day. This means that for a four-person household, the water heater will need to move about 56 megajoules (53 MBH) of energy per day, not counting parasitic heat loss.

Figure 1: Diagrammatic representation

Recall the following from the first article in this series:

For this example, this means:

If we assume some typical operating conditions for an R404A heat pump water heater, this means that about 75 per cent of the energy we put into our water is going to come out of the mechanical room air and 25

This commercial carbon dioxide heat pump was installed over 10 years ago to provide heat to the building.

per cent is going to come from the electricity we put in the compressor.

On a typical day, this water heater would then, on average, take 1,650 BTU/hr from the mechanical room and put it into the water. In the summer, this would help decrease the air conditioning load, but in the winter the house would require more heat to make up for what the water heater took. Whether this is a problem or not depends on your circumstance and in short it depends on whether the heat you take is affecting the rest of the house. In many houses, this amounts to a very small portion of the overall heat and is borderline inconsequential as the mechanical room just balances out to be a little colder (although still deflates the energy

claims a bit). If you have a hot mechanical room because of a hydronic heating system, several deep freezers, or your personal grow-op, for example, the heat pump water heater is a probably nice addition since it will help keep the room cooler. The energy efficiency gain ends up being really good since that extra heat isn’t making its way to your house.

Passive house inspiration

If you are designing energy-efficient housing, and your primary source of heat is electric, there can be a significant disadvantage to these types of water heaters in the winter. For example, a modern “passive-house inspired” 1,800 sq. ft. home in -35C weather only requires about 10,000 BTU/hour of heat. If this heat is coming from an electric resistance heater, then the payback of using a heat pump water heater can be quite poor. In other words,

increasing opportunity to

recover heat from different places.

Continued on page “31”

Continued from page “29”

it may not make sense anymore to spend two to three times on the water heater since you are only getting a benefit in the summer and extra cooling that is “stuck” in the mechanical room is not a good HVAC design.

In order to get around some of these challenges, there have been attempts to build heat pump water heaters with the heat pump located elsewhere. The unit looks very similar to a split air conditioner with the refrigeration heat pump outside and only a water storage tank inside. An added benefit of this design is that it gets the compressor and fan noise outside. Figure 2 shows how a remote evaporator heat pump water heater is set up.

These types of remote systems have typically used carbon dioxide as a refrigerant, and they are uncommon and may even be unavailable or hard to find. These systems have been marketed primarily to passive house-type builders/owners; while they solve one set of challenges, they come with a much higher installation cost because of more expensive equipment, field installation of additional electrical and water piping, and heat trace or freeze protection of the waterline. These types of systems also have some challenges operating in very cold weather and surprisingly (or perhaps not if you work with carbon dioxide much) very hot weather as well.

More options

Once you move out of residential systems, the options for hot water heating equipment and the types of applications in which heat pumps can be used increases substantially. The most important parameter that changes is that there is an increasing opportunity to recover heat from different places.

Consider the hot water heating we discussed above where the average person uses 75L of hot water per day. In residential typesetting (e.g., apartments, hotels, dorms, etc.), the majority of this hot water goes down the drain and is not really “used” so to speak. For a building with 300 people in it, this amounts to putting an average of 125 MBH down the drain constantly. Obviously, the drain water is not “hot” since it is mixed with cold water, so this example is a bit simplistic, but regardless the 75L/day/person of water that is going down the sewer is definitely not “cold.” Capturing this heat directly is difficult but there are, for example, greywater heat exchangers that use the greywater through a heat exchanger to preheat water for the water heater feed water. More useful, however, would be to take the energy out of the sewage with a heat pump.

The challenges associated with air source heat pumps (e.g., cooling the mechanical room, operating in outdoor ambient temperatures, etc.) are eliminated if we have a relatively consistent year-round heat source. And it is even better if that heat source coincides with a demand for heat, which would be the case with using a heat pump to extract heat from the sanitary drain flow to heat hot water. Figure 3 shows a rudimentary schematic of how this would work.

Of course, this example oversimplifies the situation. Sewage requires a combination of separation, filtration, and cleaning in order to protect heat exchangers from plugging. Nonetheless, there are several installations like this in Canada and likely more on the way. In the next issue, we will discuss more commercial heat pump applications and technologies, including some new equipment that can reach higher temperatures than we have seen from factory equipment in past. :

Figure 2: Heat pump water heater with

a remote heat pump. With heat pump water heaters, heat is absorbed from the air in the mechanical room or wherever the water heater is located, and a refrigeration system moves that energy into the water at a higher temperature.

Figure 3: Basic example of how a sewage

heat recovery heat pump could work.

Greg Scrivener is the lead refrigeration engineer and a partner at Laporte Consultants, Calgary, and works throughout Canada and the U.S. He is a professional engineer and journeyperson refrigeration mechanic. He can be reached at GScrivener@laporteconsultants.com.