PACKAGING TECHNOLOGY MATT REYNOLDS | EDITOR, PACKAGING WORLD

Extended Shelf Life Is Key to Lidl’s Latest RTE Line Using a process-in-pack technology, the German grocery giant added shelf life to ready-to-eat meals that will extend their market range.

G

ERMAN GROCERY GIANT Lidl recently launched three ready-to-eat (RTE) meals made with a refrigeration technology that provides a much longer shelf life. Released under its Chef’s Select brand into the Swedish market, the three meals—Meatballs with Mashed Potatoes, Sausage Stroganoff, and Pasta Pomodoro—are made by long-time Lidl partner Smålandskräftan, a Swedish cookery and private-label food producer. Smålandskräftan employed the Micvac method on the ready-made meal applications—a patented method that affords the products a far longer shelf life compared to other ready meals, without compromising on taste, nutrition, or consistency, according to Micvac. The meals are produced and chilled, not frozen, and only require warming by the consumer. “Our ready meals produced with the Micvac method taste as if they’re homemade. We have great faith in this launch, and are also planning to introduce the dishes abroad,” says Alexander Weiss, purchasing manager for food at Lidl. “We were very interested when Smålandskräftan told us about the technology, and the products have not let us down.”

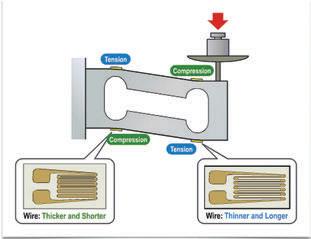

The Micvac method The meals are produced with a microwave application that cooks food in its package. On the packaging and processing line, thermoformed polypropylene (PP) trays supplied by Faerch plast are denested and conveyed to a depositor that fills them with the raw ingredients. Next, the trays are lidded with a PP/PA laminate film. The lidding material is sealed to the tray in a sealing machine from G.Mondini. A specialized valve that allows steam to vent from the package is then applied to the lidding material of each sealed tray, but the mechanism only allows venting to occur after a pre-determined pressure is reached during the next process, which is a microwave cook. When the cooking process is finishing, and the pressure inside the sealed tray reduces, the valve recloses to maintain a barrier for the cooked food. The finished, cooked tray maintains a negative internal pressure. Secondary packaging involves a printed

PHOTO COURTESY OF LIDL

Lidl launched three ready-to-eat meals made with the Micvac method, which provides a much longer shelf life than other ready meals.

paperboard bellyband, which is automatically applied after the tray is sufficiently cooled. Compared with many other ways of making ready meals, Micvac says its method better preserves vitamins and flavor. This means that the artificial E-number additives can be minimized. “For me as a purchaser, it’s extremely important that the products have as long a shelf life as possible without affecting the quality, and the Micvac method makes sure they stay fresh for a very long time,” Weiss says. “Since they were only recently launched, we don’t have any statistics yet, but we believe they’ll reduce food waste.”

Plans for an international launch The products have been well-received on the market since their launch in November 2020, Lidl reports, and the ambition is to launch them on additional European markets moving forward. “I truly believe in the Micvac method, and in the longer term, I hope we can export these dishes to other Lidl countries,” Weiss says. “Taste is of course subjective, but many find that dishes made using the Micvac technology taste delicious—as if they were homemade, even. We have long been looking to develop the ready-meal segment, and with this method we can do so with products of high nutritional content, which also taste great and look appetizing.” Micvac www.micvac.com

Faerch plast www.faerch.com

G.Mondini www.gmondini.com

www.profoodworld.com

0421_PackagingTech.indd 17

| April 2021 | PROFOOD WORLD

17

3/31/21 7:51 AM