7 minute read

Tech Perspective

AARON HAND | EDITOR-IN-CHIEF

Digital Recorder Replaces Cumbersome Paper Charts

With its Paperless Process Recorder and cloud-based Legendary software, Anderson-Negele aims to digitalize—without necessarily reinventing—the recording of process parameters in food and beverage plants.

PAPER CHART RECORDERS have been around for more than 100 years, with one of the earliest examples patented in 1915 for use in environmental monitoring. The chart recorders used back then—colored pens scratching out process data onto a circular paper—are not drastically di erent than the charts still prevalent in food processing plants today, according to Natalee Kau man, sales manager for Central States Industrial (CSI). “Of course, there are digital transmitters that are telling this chart what’s happening, and there’s obviously increased accuracy and things like that,” she says. “But at the end of the day, the principle and the tech itself are not di erent.”

CSI is the authorized distributor for AndersonNegele’s Paperless Process Recorder (PPR), a digital recorder system that can be used in pasteurization, clean in place (CIP), clean out of place (COP), raw silo monitoring, or any other food or beverage application that would typically use a paper chart recorder to monitor process parameters. With the Legendary cloud-based software, the records from the PPRs are securely stored in one location, enabling quality managers or other authorized users to conveniently access, review, annotate, and approve records remotely.

Kau man joined Neil O’Connor, national key account manager for Anderson-Negele, and Nathan Collins, regional director of sales for AndersonNegele, to explain the need in the food and beverage industry for a digital version of the traditional paper chart recorder.

PFW: With as much that has changed in food processing over the past 100 years, why are these paper chart recorders still so much in use today? Kau man: When you think about the advancement in food processing, and even up to the implementation five years ago of FSMA, the Food Safety Mod-

PHOTO COURTESY OF ANDERSON-NEGELE

ernization Act—all that brought to the table as far as everyone coming up to speed at the same time with best practices and cleaning and many other aspects of food processing, to think that we’re still using this tech that is from 1911 is surprising. I think that in many cases, we’re all just victims of ‘If it ain’t broke…’ But what’s sad is that it really is broken. It’s very time-consuming and it’s operationally cumbersome.

Collins: What I’m seeing is that, in this industry, anytime you change anything, there’s a certification process, essentially, that you’ve got to change along with it. If you’ve been doing this for a long time, and there’s a change, there’s a workflow in that process— it’s not just a single person that’s got to buy into this. It’s an entire company. So, what is that process for change? What are the requirements?

One of our campaign slogans is ‘It’s easy.’ It’s so easy, it really is. But it’s change. Is change really ever easy?

PFW: Help me understand how a paper chart recorder typically works. Collins: If everything was running 100% perfect all the time, that’s going to be almost a straight line coming through there. Then when you see a devia-

s The Paperless Process Recorder records process parameters like temperature, flow, and pressure, and uses the Legendary cloud-based software to securely store those records.

tion in that line, that’s going to be a change in the operating condition. Every time you see a change in that operating condition, somebody’s got to make a note on that chart, explaining what that deviation was and why it happened.

So then that operator, if you see a deviation in data, is going to have to take a pen and write down on the chart what the event was that happened. This chart records for a period of time, let’s say 12 hours, and then this chart is taken to a quality assurance supervisor. That quality assurance supervisor goes through and looks at that chart—at all the annotations on the chart—and makes sure all the annotations are correct. A lot of times they’re not. So that quality supervisor then has to take this chart back out to the line supervisor or whoever’s running the line to make that annotation. The quality supervisor can’t make those annotations for the operator; that’s something the operator has to do. Once that chart is fully annotated, then the quality supervisor puts the stamp of approval on that. And these are stored away for audits. I believe they have to be stored for seven years. So you can imagine— one chart every 12 hours for seven years.

Now, dairy plants, juice plants, where these are operating—what happens if you’re out collecting these and you drop one on the floor? The ink disappears, they tear. Just the workflow of going back and getting all of these charts annotated correctly, the potential damage to the charts, and then what happens if you’re audited? So now, I’ve got one of these charts for seven years, and somebody wants to see what happened six months ago. What’s the process that I have to go through—the storage boxes, literally storage units that somebody might have to go out to to find a particular chart is almost an overwhelming task

Kau man: So far, he’s only accounted for the human failure. But there’s lots of mechanical failure. If the pen arm breaks, if the markers don’t work, or they’re dry, then it’s worthless. Mechanical failure is constant. Or they run out of charts.

PFW: What happens with the quality manager after the PPR is in place? O’Connor: Well, their life is a lot easier. With the cloud, they can actually sit at their desk, instead of walking half a mile down the line to get the piece of paper and bring it back and forth. But also they can check everything on the computer to get all the information, and they can improve the charts.

Collins: The process becomes a lot easier. This box right here—physically, this is the box that’s located out with the process equipment. The quality manager, they don’t work o of this box; they work o of a PLC in their o ce. So when that record is ready, that comes to a queue for the quality assurance person. They look that through, and if there’s something that isn’t right on the annotation, they send that back to the box. So the operator at the box now can make those annotations and those changes and then resubmit it to the quality supervisor. So everything is handled digitally now.

So now imagine you’re doing an audit. And instead of going out and looking for a box, you just go to the date and click on your chart. And instead of it coming in a round chart that is hard to read, it’s now a beautiful graph that you could project up onto a screen or email to the client. So now audits are not something that you have to go and prepare for. You can do audits in real time, essentially.

PFW: The Legendary cloud software goes hand-inhand with the PPR, correct? Are customers more open than they used to be about cloud storage? Kau man: Yes, because the only thing we’re not making more of is time. Everyone’s understa ed. So, if for no other reason, what would you do with your operator’s extra time, with your quality manager’s extra time? What would you do with the personnel hours? Because nobody’s in a position that they can spare any of that.

Collins: There might be some pushback to the cloud, but it’s usually not from the IT department. You’ll get it from the operators, you’ll get it from the plant manager. But once you get to the IT department, that’s a di erent conversation because they understand the data integrity and how secure these sites are. At that point, that’s when it becomes less of an issue.

PFW: Are there any particular industries that need PPR more than others? Kau man: Quite simply, if you use paper charts, you’re a candidate for this. It comes back to food safety and product quality.

O’Connor: Everything that they were doing on that paper chart recorder is what we’re doing on a digital recorder.

Kau man: That’s really where the change part becomes less hard. Because you’re not doing something di erent. You’re still collecting the same data. All of those things are the same. You’re still going to annotate a chart, you’re just doing it a better way.

Anderson-Negele

www.anderson-negele.com

Central States Industrial

www.csidesigns.com

INFUSED INSIGHTS

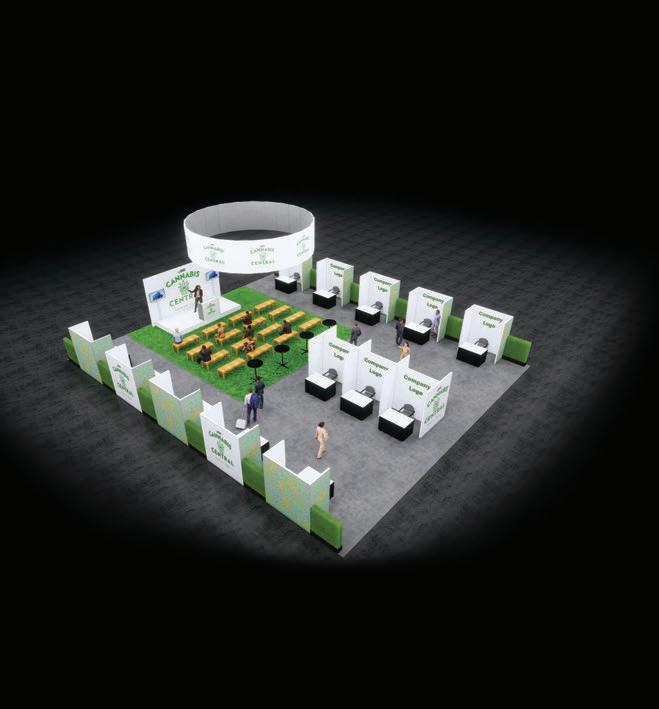

With the popularity of cannabis-infused foods at an all-time high, there’s never been a better time to dig into this budding industry segment. That’s why we’re launching a brand-new pavilion at the Baking Expo™. Drop by Cannabis Central - Powered by Cannabis Products to learn about the unique business challenges and opportunities in this specialized area of legal cannabis and hemp infused product development. Connect with highly qualified and relevant suppliers for expert advice, and spark new ideas through targeted education sessions. Hear from thought leaders on everything you need to inspire business growth, including legal guidelines, regulatory structure, go-to-market strategies, and distribution. Witness this incredible, must-see pavilion for yourself when you join the global baking community in Las Vegas for IBIE 2022.