25 minute read

PACKAGING FOR E-COMMERCE

Health and Beauty Aids: Head & Shoulders CLINICAL Scalp Calming Treatment Tube from Viva Healthcare Packaging (Canada) Ltd. (5) was developed to facilitate the precision application of its formula and provide a striking impact on the shelf. The applicator head is injection molded, then welded onto the cut shoulders of an injection-molded polypropylene tube, the lowest density of commodity plastics. The applicator is made from polypropylene, maintaining a mono-material design. The in-mold labels provide full coverage artwork from shoulders to end of crimp, 360 deg around the tubes.

Industrial/Commercial: RP System from Mitsubishi Gas Chemical Company, Inc. provides manufacturers of sensitive products 24/7 protection from moisture and oxygen damage during shipping and long-term storage. According to Mitsubishi, it’s the only product that offers oxygen and moisture protection in one complete system. The packaging solution has the potential to change production methods and ease the burden of unpredictable parts forecasting in the future.

Industrial/Commercial: TerpLoc Automated Curing & LongTerm Storage Cannabis Pouch from Kinzie Advanced Polymers LLC, doing business as Grove Bags, takes a new approach to the idea of modi ed atmospheric packaging and allows industrial cannabis facilities to maintain up to 37% more terpenes and up to 7% more THC by using the natural moisture of the cannabis plant to support the internal microclimate and keeps packaged product moisture loss below a 1% variance. Industrial/Commercial: The Master Builders Solutions

Tray Pals from Placon holds pouches of activator for construction adhesives. The trays rest on the rim of large steel pails (2 or 3.5 gallons) with either one or two pouches containing an activator, and the trays act as a barrier between the pouches, lid, and liquid chemicals inside. When the pail opens, there is no sticky residue of the liquid chemicals contaminating the pouches or lid. While the design at rst glance appears simple, it innovatively solves a negative customer experience due to the tight tolerance required. The tray’s rigidity holds the bags of activation powder, and the tray’s design prevents liquid from splashing up on the bags of activation powder and the lid.

Medical Device: 3-Web Pouch Design from Oliver Healthcare Packaging was designed with the end-user in mind, offering a “multipack” con guration without increasing the shipping footprint. The surface treatment applied to the product exponentially increases patient safety and has sensitivities to contact materials and environmental conditions. The packaging system needed to accommodate these variables while providing a user-friendly sterile barrier that is easy to manufacture.

Medical Device: CapSure from Becton Dickinson-Surgery is used for a minimally evasive hernia repair procedure.With a

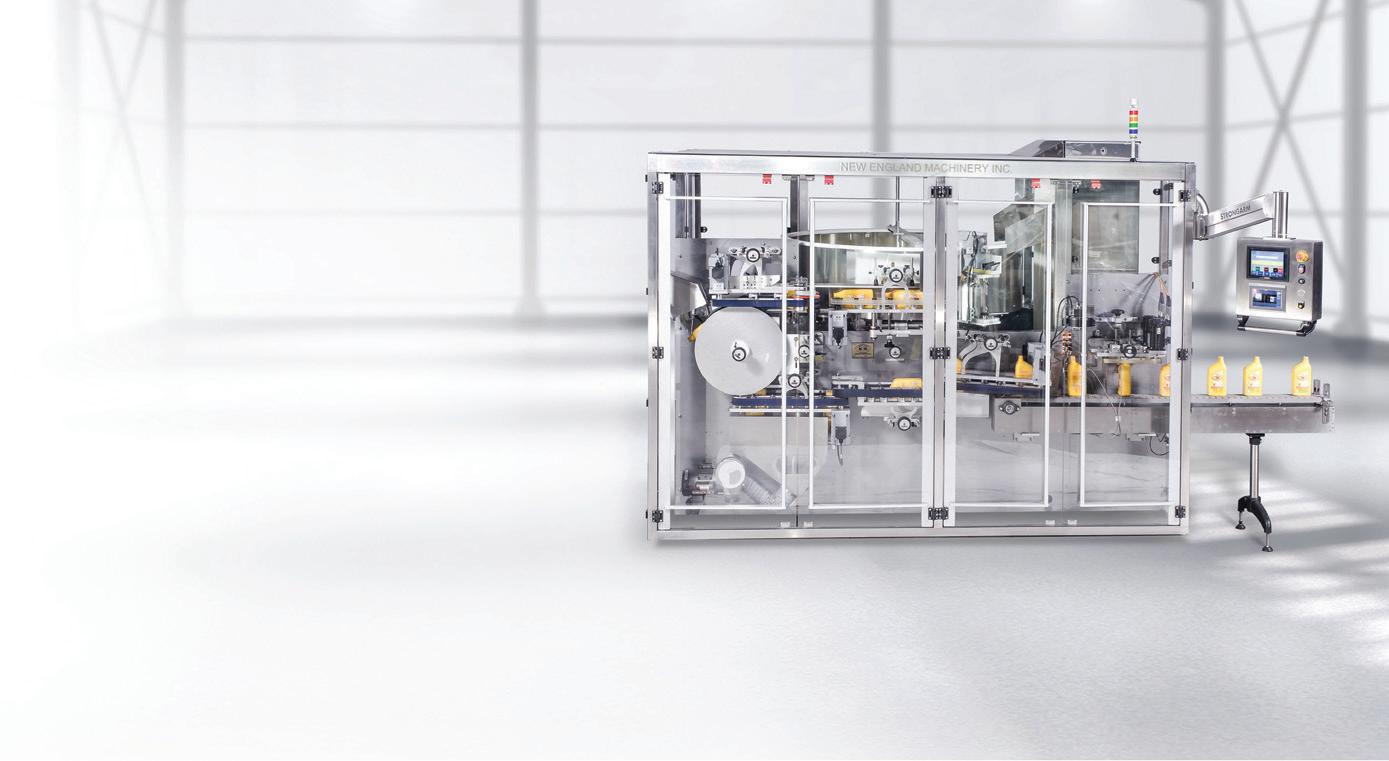

There is a Better Way with New England Machinery.

Thousands of customers worldwide choose NEM to achieve:

Increased ROI Greater Pro ts Smaller Footprint Solutions for Di cult Projects Continued Support & Service

Providing Reliable, High-Performing Packaging Equipment for Over 48 Years.

We upright containers from random bulk. We close containers to speci cation. We orient containers to align on spot & much more!

NEM builds solution-driven machinery including Unscramblers, Cappers, Orienters, Pump Placers, Retorquers, Scoop Feeders and more. We also build lasting relationships. We are here to serve you today, tomorrow, and for many years to come.

NEW ENGLAND MACHINERY A Massman Company

CONNECT WITH US:

Visit us online at NEMinc.com Call today 941-755-5550 Email info@NEMinc.com

miniature-sized retainer called SEEkeyMD, this 1-g retainer allows additional support to the base tray to reduce sheet thickness from 40 mils to 30 mils. The 25% plastic reduction–equal to 295,417 16 oz. water bottles a year–and associated cost savings advanced the project.

Sustainable Packaging: AmSky Thermoform Blister System from Amcor Flexibles Healthcare North America takes a unique approach to recycle-ready blister packaging by using high-density polyethylene (HDPE) in a proprietary formulation to create both the formed blister and lidding, demonstrating a new usage of existing materials. This packaging system presents end users with a seamless, single-stream option for end-of-life disposal.

Sustainable Packaging: Colgate Keep Toothbrush from ColgatePalmolive has a handle that is the rst of its kind, made with aluminum instead of plastic—eliminating 80% of the plastic waste from a typical toothbrush. Keep’s 100% paper-based package allows consumers to recycle the packaging in a single waste stream and eliminates new plastic from being introduced into the environment. Colgate-Palmolive leveraged its expertise in thermoforming to deliver a package that is now fully recyclable at scale and operates well with established packaging lines. Sustainable Packaging: Recyclable Mono-Material Pump – Future from Aptar Beauty + Home and Dermalogica is a fully recyclable mono-material pump consisting of a plastic spring that makes it possible to recycle the bottle and pump as one unit. Because this Future pump is made from polyethylene (PE) only, which aligns with the most common materials used to make bottles—PE and polyethylene terephthalate (PET), the complete packaging, including pump and bottle, is more ef ciently recycled. Sustainable Packaging: SimpliCycle, A Fully Recyclable Valve from AptarGroup, Inc. is a 100% recyclable valve solution for food, beverage, and foodservice products. The valve is comprised of proprietary low-density material that oats, allowing it to be easily separated from the PET stream and then recycled along with the PP/PE ole n stream. Sustainable Packaging: SLIDE, A Liner-Free Closure from AptarGroup, Inc. is unique in that it does not require the application of a foil liner between the cap and bottle. Removing this foil liner component improves the consumer opening convenience, eliminates waste as liners are not recyclable, and reduces greenhouse gas emissions by 16%. To enhance the positive environmental positioning of SLIDE Aptar even further can offer it with post-consumer polypropylene content. —Matt Reynolds

Mid-Range Solution Runs 30-50 wrap-round or tray style cases per minute.

Changeover Assist Faster, more consistent changeover with minimal manual changerover points Intuitive HMI Standard Allen Bradley PanelView Plus with 2-Touch navigation Servo Track Technology Reduces footprint while increasing case output rate.

Experience the NEW M3000 Variable Pitch Case Packer

Filling the gap in our case packing portfolio

Pack Expo International - October 23-26 Join us in booth #5546

Visit the IoPP booth (N-4523) at PACK EXPO International in Chicago, and the Showcase of Innovations (W-20052) to see the AmeriStar winners on display. More at packexpointernational.com.

October 23-26, 2022 ■ Chicago, Illinois, USA

Fresh Food Accelerates its D2C Transformation: A Tale of Two Bakeries

Fresh food, including baked products, has lagged other CPG categories in e-comm adoption for obvious shelf life- and cold chain-related reasons. But increased consumer willingness to use the channel after the onset of the pandemic has bakeries doubling down on D2C programs, and packaging optimization naturally follows.

D2C food maintains cold chain Spoilage prevention tactics

Lots of bakeries had D2C programs before COVID-19, including New York’s Levain Bakery. And at Taartenwinkel.nl in the Netherlands, the business model was predicated on e-commerce. But the pandemic so altered consumer behavior—from the initial wave of ecomm during the shutdowns, to the greater familiarity and adoption of such channels thereafter—those bakeries were forced to fortify their D2C programs.

In the case of Levain, online business tripled during the pandemic. And Taartenwinkel, a producer of cakes meant to feed entire parties, experienced a shift to individual treats like brownies and pastries when the Netherlands halted gatherings of six or more people.

Meanwhile, during lockdowns, consumers were becoming more cognizant of the mountain of packaging that e-commerce produces, intensifying demand for more sustainable formats. Out of this crucible and unprecedented set of circumstances emerged a new attitude toward, and aptitude for, D2C baked products. What follows are the e-comm packaging journeys of just two bakeries that have reacted to the shift, Levain and Taartenwinkel.

An eight-count box of cookies uses two universal inserts to protect the cookies during transit. Vibrant graphics depict the ‘cookie parade,’ with a mix of individuals re ecting the diversity of the neighborhood in which Levain Bakery was founded.

Levain Bakery Builds a Better E-commerce Box

A neighborhood institution turned national brand, New York City-based Levain Bakery is famous for its decadent, freshly-baked cookies. The bakery’s mostly chocolate chip-based cookie assortment has become so popular, in fact, that when COVID-19 shutdowns hit, Levain’s online business rose by 200%. The boost in e-commerce orders prompted the brand to redesign its packaging, resulting in a more operationally ef cient and more vibrant package that also more clearly re ects the brand’s home-grown roots.

Levain Bakery was founded in 1995 as a small bread shop on the Upper West Side of Manhattan by two friends, Pam Weekes and Connie McDonald, both of whom were passionate about baking—and about competitive sports. One day, they created a generously portioned chocolate-chip walnut cookie to give them energy while training for a triathlon. They decided to sell a batch in their bakery, and the palm-sized, 6-oz cookies ew off the shelves. After that, the cozy shop on West 74th

Street became a neighborhood favorite and a destination for epicurious travelers from around the world.

Since then, the company has expanded its brick-and-mortar reach, growing to 10 stores and launching a frozen-cookie retail product, and now offers its decadent cookies online. Prior to the pandemic, Levain packaged its e-commerce orders, available in four-, eight-, or 12-cookie sizes, in cartons that were then placed in corrugated shippers lled with protective packing materials. But the increased demand in online orders required a packaging refresh.

“We were already a growing brand, opening new bakeries, scaling our e-commerce business, and expanding into grocery retailers,” says Levain Bakery CEO Andy Taylor. “The challenge was creating a packaging solution that not only ensured our customers would receive our product in pristine condition, but also improved our ef ciency to better meet demand. When COVID-19 caused New York—and the rest of the world—to shut down, we saw online orders multiply, and we needed a supplier that had the exibility to meet accelerating demand on a greater scale.”

Universal insert protects product, reduces packaging

R.R. Donnelley & Sons Co. (RRD) was chosen for the project by Levain due to its ability to meet the bakery’s package design, printing, and warehousing needs. RRD’s rst task was to design an e-commerce shipper capable of delivering product protection, while reducing excess packaging materials and complexity.

Shares Lisa Pruett, President of RRD Packaging Solutions, “We supplied different iterations of packaging and inserts for the Levain team to evaluate. They then thoroughly transit-tested the prototypes to ensure there would be no tearing or crushing of the packaging, so customers would receive their cookies perfectly protected for the best possible experience.”

The structure selected by Levain is a recyclable, die-cut, roll-end lock-front (RELF) shipper made from 200# B- ute corrugated, tted with a universal corrugated insert that is also 200# B- ute. “The inserts are the same for each pack size,” explains Bill Rizzo, Director of Business Development for RRD. “Having one universal insert for its three different order box sizes—one insert for the four-cookie box, two for the eight-cookie box, and so on—dramatically lowers the complexity of the production process as well as the quantity of SKUs used.”

When the corrugated insert is formed, the structure becomes rigid and builds a lip of material along the bottom that guides the cookies to “ oat” when they are placed inside. In this way, the cookies are not at on the bottom of the package, so when the packaging is moved in transit, the cookies bounce instead of getting smashed. Says Rizzo, this “give” offers left-to-right and front-to-back security. “The inserts also t snugly into the shipper, which limits any movement inside the actual box,” he adds. “Coupled with the insert design, these cookies have excellent protection from breaking.”

The shipper style was chosen, says Rizzo, because it’s extremely easy to assemble: It takes approximately 10 seconds to fold the aps of the shipper and put it together “making this choice a cost-effective option that’s also structurally sound,” he notes. On the logistical side, the shippers can be easily stacked without undermining the strength of the box, which is a signi cant advantage when handling large order levels. And, it’s lightweight, which gives Levain a cost advantage when it comes to paying for shipping.

Lightweight packaging is good, but not if it’s too light, resulting in damage. Says Pruett, “We found that B- ute corrugated was our ‘Goldilocks’ shipper in that it was both lightweight, and the structure held up and performed to our expectations.”

“On behalf of our clients, sustainability and ef ciency is a key focus of our team at RRD,” she adds. “For Levain, we were able to reduce the use of unnecessary materials per order while signi cantly cutting down the time it takes to package and ship the product, improving ef ciency by 50%.”

With the new design, an eight-step process for assembling the box and packing product has been reduced to four steps: The box is formed, inserts are added, cookies—in a cellophane bag hand-tied with a blue ribbon—are placed in the box, and the box is closed. Says Rizzo, “This has much to do with the simplicity of the die-cut mailer shipper style.”

The outside of the box is printed in one color— Levain’s signature blue—with the white of the box creating a ribbon-effect.

New box delivers ‘surprise and delight’

Both the box style and its branding were designed to provide consumers with the “surprise and delight” factor that a successful unboxing experience imparts, Rizzo shares. Graphics for the shipper were designed by Levain in partnership with The Creative Pack and include decoration on both the inside and outside of the box.

On the outside, the shipper is exo-printed by RRD in one color, Levain’s signature blue, and looks as if it’s wrapped with a white ribbon (the white being the unprinted portion of the box) bearing the bakery’s logo. The inside is litho-laminated in four colors plus one PMS color and features an illustration of “the cookie lover’s parade,” with a variety of characters of different ages, abilities, ethnicities, and genders making

their way across the inside ap. Said Pentawards, which honored the design with a Gold Award for E-Commerce, Branding & Consumer in its 2021 competition, “It [the design] presents a more wholesome and inclusive view of NYC, where the bakery is based.”

Regarding the structure’s contribution to the unboxing experience, the shipper is designed with thumb notches that allow the consumer to stick their thumb under the crease and easily open the box. “This is another functional area that contributes to the ‘wow’ factor of the opening experience,” says Rizzo.

Replenishment model saves space

The last part of the project was to address Levain’s limited warehouse capacity. Explains Pruett, a new system put in place by RRD allowed Levain to manage its own inventory and determine a reorder point based on its forecasts, while RRD met the bakery’s warehousing challenge with a replenishment model. “Because of the uctuations in demand during the pandemic, RRD acted as a resource to make sure Levain was always stocked with the packaging they needed, as they needed it,” she says.

This included providing Levain with partial orders as necessary for its rolling shipments of 15 pallets per week. RRD kept the balance of the order in close proximity at an RRD warehousing facility [in Pennsylvania] so Levain could tap into this inventory when needed while not overpacking its warehouses. As demand for shipments increased, so did the frequency of shipments.

Levain’s cookies, baked fresh daily, are available in ve avors: Chocolate Chip Walnut, Dark Chocolate Chocolate Chip, Dark Chocolate Peanut Butter Chip, Two Chip Chocolate Chip, and Oatmeal Raisin. They can be purchased online for shipment anywhere in the U.S. and are priced at $27 for a four-pack, $49 for an eight-pack, and $68 for a 12-pack. —Anne Marie Mohan

Connect with Suppliers Fast

PMMI ProSource is a free online directory with 900 categories of validated suppliers of packaging machinery, materials, and service solutions. With a powerful search engine and the ability to filter solutions by machine feature and package type, ProSource brings vetted suppliers to you. Visit www.prosource.org today.

Protect your products and the planet.

Visit us at Pack Expo International: Booth #22051

Void-fill | Cushioning | Wrapping | Box Lining | Cold Chain | Automated Solutions

Dutch Bakery’s E-Comm Pack Keeps Cakes Cool

Cool packs used by Taartenwinkel are made from a drain safe, plant-based gel, and the paper-based pouch containing the refrigerant is recyclable.

Waved paper pads serve both as blocking and bracing for a delicate cartonboard cake box, and insulation to keep things cool.

A two-side printed paperboard carton cake box delights Taartenwinkel customers upon opening.

Taartenwinkel.nl is a popular Dutch bakery and e-tailer with a single location in Utrecht, Netherlands. Since its entire line of cakes, pastries, and petit fours are produced in-house in a single commissary bakery, the company controls its product completely, and enjoys a lot of freedom to innovate when it comes to pivoting to the latest trends and developments in baking and sweets. While consumers can certainly order a single cake for a family occasion, a large portion of its business is B2B. Businesses can upload logos, photos, or corporate messages that can then be printed onto the cakes, transforming them into marketing tools for clients, rewards for a successful product launch, treats for a company retirement party, or just about any corporate special event you can imagine.

The Netherlands is about twice the size of the state of New Jersey, a manageable enough size that most any e-tailer ought to be able to easily serve the entire nation without air freight. And Taartenwinkel’s Utrecht bakery is mercifully located in the center of the country. Still, freshly baked products aren’t shelf-stable, durable, robust products that other e-comm outlets might be selling and delivering. These are delicate items that need to be delivered promptly and gently, all the while maintaining a certain temperature.

For years, the company had relied on refrigerated trucks to maintain a cold chain temperature not to exceed 7°C (45°F) upon delivery. This system served its purpose well, but in recent years, customers began getting all-too used to the Amazon experience, and its attendant level of order management.

“The refrigerated trucks worked great, but the only thing was they were not able to give us the service that consumers are used to at the moment,” explains Eric van Noort, Taartenwinkel’s owner. “If you order something from Amazon, you want to know where it is at any moment, and if it is on time. All of that is very important to our customers ordering cakes for an special occasion. And refrigerated trucks couldn’t give us that.”

That’s why two years ago, van Noort selected courier service PostNL, a central European mail, parcel, and e-commerce delivery corporation, to transport product. Soon after, he upgraded to a new secondary packaging system by Ranpak, Recycold, and Akarton Innovative Packaging.

“This system makes it possible to deliver the cakes, on time, with the e-commerce standards people expect,” he says.

First tries

It took a bit of trial and error to arrive at Taartenwinkel’s current, entirely recyclable and waste-free packaging format. The company began with a secondary packaging format more familiar to catering businesses: expended polypropylene (EPP) thermal regulation boxes. These large, black boxes are intended to be returned for repeated use.

“They use EPP a lot in the Netherlands to deliver food,” van Noort says. “The only the thing is you need a whole big warehouse to store all of them. And for the system to work, the boxes have to return to us.”

The returns piece of the equation was a big drawback for Taartenwinkel’s courier partner, as that added layer of return logistics was fraught with extra work, requisite storage, and potential error. And EPP boxes that weren’t returned were simply lost inventory of a durable asset.

Finally, when the EPP boxes were thankfully returned, they required extensive cleaning, equating to expensive (and wasteful, van Noort argues) water usage.

Return logistics headaches aside, where van Noort really drew the line was in EPP boxes’ impact on product quality. It quickly became evident that using the same boxes repeatedly (even washed) to deliver fresh baked, one-off products wasn’t good for the cakes’ avor and aroma. Fresh baked products—especially those with whipped cream—can both emit and pick up strong smells. The EPP boxes began to carry odors of their own; not of the fresh butter, cream, or shortening used in the fresh-baked product they presently contained, but of all smells the materials picked up over the lifetime of the EPP. And then there was potential for the many-use boxes to impart their own odors to the fresh product they contained, especially whipped cream cakes. Van Noort even cited smoking as a worst-case scenario—if someone was smoking next to a whipped cream cake, that cake will pick up the smell, and then that’s introduced into the boxes that carry the cakes that also can pick up odor. To van Noort, the EPP solution wasn’t feasible for freshly baked cakes and pastries. “Our [delivery] partner said, ‘I want to deliver for you, but I don’t want to do it with these boxes,’” van Noort recalls. “I said, ‘Me neither.’”

REGISTER TODAY!

Interested in cutting-edge, e-commerce focused packaging design solutions for your product? Don’t miss PACK EXPO International 2022 to see the latest packaging design solutions engineered specifically for e-commerce applications. Visit packexpointernational.com for more information.

October 23-26, 2022 ■ Chicago, Illinois, USA

A better solution

Going back to the drawing board, van Noort got in touch local Dutch company Recycold Cool Solutions, a thermal refrigerant company that uniquely produces entirely recyclable cold packs for thermal transport of food, ingredients, and pharmaceuticals. Recycold introduced him to Ranpak and its WrapPak Protector system, designed to insulate a package’s contents and maintain a prescribed temperature in concert with cold packs like Recycold’s. In fact, in December 2021, Recycold was acquired by Ranpak, though the two were still separate entities during this project.

The Ranpak system includes a physical installation of semi-automatic WrapPak Protector equipment. This rollstock-fed kraft paper converting system creates waved paper pads, good at trapping insulating empty space, at programmable sizes and increments. For ful llment centers interested in box lining, the wide paper pads produced on the system can cover an entire

box surface with just one insert. Wrapping, blocking-and-bracing, and interleaving are also possible with the pads.

According to Ranpak, the features listed above mean the WrapPak Protector unit can replace a wide range of existing packaging materials that a company like Taartenwinkel might’ve chosen instead, including dunnage, aluminum-coated plastic lms, tapes, and inserts. The WrapPak Protector converter is also highly programmable to match evolving needs, and it’s small enough to use at a pack table, either in-line or as a standalone unit, according to the company Functional and sustainable

Taartenwinkel ended up adopting the format it still uses today, which includes Recycold cool packs, the Ranpak WrapPak thermal insulation, and a custom printed corrugated shipper box from local converter Akarton. This secondary packaging system accommodates the two-side printed paperboard carton cake boxes, one element of packaging that the bakery didn’t have to change.

“It works well, we’re really happy with it,” van Noort says. “It functions as simply as paper that is printed out of a machine. There’s a lot of air in [the resulting waved paper pads], but we needed it [to maintain] the right temperature, so we did some tests. We tested the product rst in temperature chambers to check if it works, that was step one. And we also did it in real life. For example, on one the hottest days in the

summer, it also works. So, that’s really good.” At the time of pack-out in the Taartenwinkel facility, the cakes are kept at an ambient temperature of 2°C, so that’s the starting point. These cakes exit the facility at 9 p.m. every evening, and most are delivered to their destination by 1 p.m. the following day, if not earlier. The Ranpak and Recycold system successfully maintains the temperature without breaking 7°C, until after 6 p.m. Knock on effects of the packaging system are that it provides Watch the WrapPak a dramatic unboxing experience. Cakes are usually ordered for festive occasions, so printed secondary packaging with visually Protector appealing branding—Taartenwinkel uses white on kraft corrusystem in gated—gives consumers a sense of opening a present. action. And for the sustainability-minded consumer, which describes a lot of Dutch folks, the entire system—from printed paperboard cake box to cold packs, from waved paper insulation to printed corrugated shipper box—entirely recyclable in the Netherlands. No cleaning of reusable shippers means far less water used in the operation, so, van Noort says, “there’s no waste at all.” Based on the success of this format, Taartenwinkel bought a second Ranpak WrapPak Protector system—not for increased capacity, rather for redundancy in the case of breakdown. “My whole business would shut down without it, so, we have one extra,” van Noort says. “But the rst one works so great and we’ve never had to use it before.” —Matt Reynolds

Redefining precision. Streamlining material detection. Simplifying commissioning.

UC-F77 Ultrasonic Sensor with IO-Link

Highly adaptable: Adjustable sound beam width and ability to ignore unwanted reflections Precise and reliable: Detects even the most di cult materials, such as transparent films or high-gloss labels Real-time parameterization and control: Simplified setup and enhanced sensor communication with IO-Link

www.pepperl-fuchs.com/F77

Black-Owned Brewing Co. Opens Up Underserved Market

In an era when subservient, racially charged mascots are being shown the door, Moor’s Brewing ushers in a royal depiction of the untold story of Africa’s massive contribution to current craft brew culture.

Graphic design Emerging brand challenges Demographic shift

By Matt Reynolds, Chief Editor

When you think of demographics making up the craft beer market—both its consumers and its producers—a suite of social stereotypes likely leaps to mind. If people were forced to describe or sketch a craft brew persona, most would likely come up with a casually dressed, outdoorsy, and oftentimes bearded or tattooed white Gen X man with disposable income. That’s not necessarily a value judgement or an indictment on the industry; a trip to the annual Craft Brewers’ Conference bears out this rule of thumb. By and large, that’s just who has traditionally represented the craft beer industry. The Craft Brewer’s Association knows this, and is working to become more diverse—both because it’s the right thing to do, and because they need to address changing demographics to stay relevant.

At the Craft Brew Conference last year in Denver, Craft Brewers Association economist Bart Watson revealed that in 2019, the number of young women who drink surpassed the number of young men who drink. This doesn’t take volume into consideration—young men drink more in volume. But you have to wonder what craft beer might do for women, who have historically been groomed for wine, and who now have options in the RTD spirits beverages alongside seltzers and other non-beer options?

Also, according to a study by Rabobank that Watson referenced, “Spending [in alcohol] is increasingly female, and spending is increasingly BIPOC (Black, Indigenous, and People of Color).” Some might say that overall U.S. demographics are doing the same, but those spending increases were happening even faster than that. Craft brewers are asking themselves, “how can we get out to those ‘new’ markets that have greater buying power?”

The Association is convening the BRU (Brewing, Respect, Unity) Coalition, designed to foster an equitable and inclusive brewing community. Read more about these and other programs from the Brewers Association at pwgo.to/7500 but suf ce it to say they are largely aimed at social equity and inclusivity. The craft brewing industry as a whole is aware of its demographic makeup and is working to become more inclusive.

Read about another black-owned brewery, Crown’s and Hops in Inglewood, Calif., and how race, politics, and inclusion intersect over a lager at an upscale neighborhood brewhouse.

Meanwhile, in Miami…

Damon Patton, who attended the University of Illinois at Urbana-Champaign (and for the purposes of the demographics in question, is a young black man) was enjoying the weather in South Florida and making his own hours as an Uber driver. His concept of who makes up the craft brew market matched the one we just described, but it wasn’t something he thought much about—at least until one Uber delivery got him thinking. “I delivered an order of beer to a party in an upscale villa on Miami Beach,” Patton says. “I wasn’t expecting it, but enjoying the beer there were 30 to 45 black people. And I was dropping off a bunch of beer—it was at least 12, maybe 15 cases. I just asked the question, ‘Is this beer for you guys?’ They said, ‘Yeah, why wouldn’t it be for us?’ It was at that point that I thought, ‘I think we can probably sell beer [to the black community].’”

Patton reached out to college friend and entrepreneurial collaborator Jamhal Johnson, a fellow young black man and U of I grad, to kick off the idea. The black community has been traditionally underserved by the craft brew market, but Johnson and Patton are seeking to change that. And they don’t mean to do so by asking the existing market to better cater to black people. Instead, they’re diving into the craft brew market, as a black-owned business, to help make a market and build a business that they themselves control.

An early hurdle was overcoming the dismissive reason why the mar-