PORTFOLIO OF XU YAO

SELECTED WORKS 2012-2024

XU YAO

Address: 10 River Road, New York, NY 10044

Email: yaoxuarch@gmail.com

Phone: (215) 921-0672

EDUCATION

2022 - 2024

2017 - 2018

2012 - 2017

Harrisburg University of Science & Technology

Master of Project Management

School of Design, University of Pennsylvania

Master of Science in Design, Advanced Architectural Design

School of Design, University of Pennsylvania

Bachelor of Architectural

PROFESSIONAL EXPERIENCES

02/2023 - Present

Project Manager, O'Neil Langan Architects, New York, NY

Glossier: Las Vegas,NV (SD-CA); Manhattan,NY (CD-CA); Boston,MA (CD-CA).

Fireclay: Manhattan,NY (SD-CD); Snata Monica,CA (SD-CD).

Bond Vet: Fairfield, CT (DD-CA); Rittenhouse, PA (DD-CA).

Burberry: Manhattan, NY (DD-CD).

04/2019 - 02/2023

Assistant Project Manager, O'Neil Langan Architects, New York, NY

Bond Vet: Lynnfield, MA (CD); Watertown, MA (DD-CD); Fairfax, VA (DD-CD); Alexandria, VA (DD-CA); Washington, DC (DD-CD); Capitol Hill, DC (DD-CD); Edgewater, NJ (DD-CA); Prototype Project.

Moose Knuckle: Manhattan, NY (SD-CD); Roosevelt Field, NY (SD-CA); Central Valley, NY (SD-CD); Vancouver, CA (SD-CD); Calgary, CA (SD-CD); North York, CA (SD-CD); Beijing, CN (SD-CD); Nanjing, CN (SD-CD); Jiangsu, CN (SD-CD); Jing’an Temple, CN (SD-CD); Qiantan Taikooli, CN (SD-DD); Xi’an, CN (SD-DD);

Lotte Incheon Terminal, KR (SD-DD); Shinsegae Centum City, KR (SD-CD); Gyeonggi-Do, KR (SD-DD); Miyashita Park, JP (SD-CD);

SPACE NK: Brooklyn, NY (SD); Manhattan, NY (SD); Pasadena, CA (SD); Norwalk, Ct (SD).

12/2018 - 01/2019

06/2018 - 08/2018

Part-time Design Assistant, DLR Group, New York City, NY

Kosovo National Stadium (SD)

Architectural Intern, ERAY/CARBAJO Inc. Brooklyn, NY

Gastronomi Center: Food court design (SD)

“Urban Rural V.2”: High-rise Residence Competition (SD)

407 Tompkins Ave, NY: Residential Renovation (Site Survey)

SKILL

Software Fabrication

Language

2D: Adobe Creative Suites, Auto CAD, Revit

3D & Rendering: 3Ds Max, Rhino, Maya, Sketchup, Grasshopper, V-ray, Lumion, KeyShot

Hand-Crafted, Laser cut, 3D Printing, Hand Drafting with ink and markers.

Proficient in English & Chinese Mandarin.

01 Glossier - Las Vegas

Role: AOR / Project Manager

Resposbility: SD(Partial), DD, CD, CA

Location: Las Vegas. NV

Gross Area: 3164 SQ.FT.

Project Stastus: Built

Project Date: 10/2023 - 05/2024

The Glossier Las Vegas store project aims to provide customers with a completely unique experience by creating a friendly sci-fi atmosphere. Key design elements include playful furniture integrated with lighting and interactive buttons, fostering an engaging and interactive environment. These features collectively create a futuristic yet welcoming shopping experience at Glossier’s Las Vegas store. “We were looking at casinos, slot machines, and ornate hotel carpeting. This is a retro, futuristic version of Glossier that felt right for Vegas,” said Chitra Balireddi, Glossier’s chief commercial officer.

LINEAR LED LIGHT STRIP AS REQUIRED.

HOLES FOR VENTILATION ON TOP.

J-BOX DROP FROM CEILING.

STRUCTURAL OPENING.

CLEAR ACRYLIC DIFFUSER SURFACE.

SELF TAPPING SCREWS

ALUMINUM CHANNEL. 2" DYNAMIC LED NODES.

STRUCTURAL OPENING.

EX'G DEMISING WALL.

0'-0" A.F.F. FINISHED FLOOR 13'-2 3/4" A.F.F. [V.I.F.] B.O. LOBBY CEILING LINEAR LED LIGHT STRIP AS REQUIRED.

CLEAR MOUNTING SURFACE, TYP 2" DYNAMIC LED NODES.

DYNAMIC LED NODES.

Selfie Room South Elevation

Store Photo: Overall View

Store Photo: Slanted Focal Wall Store Photo - Merch Display Unit

Glossier - Manhattan

Role: AOR / Team Member

Resposbility: CD, CA

Location: Manhattan, NY

Gross Area: 7261 SQ.FT.

Project Stastus: Built

Project Date: 06/2022 - 02/2023

Area

Storefront

Wet Bar Room

Selfie Room

5/8" MDF PANEL; PAINT IN [PT-01].

RADIATOR COVER MANUFACUTRE: ADVANCED ARCHITECTURAL GRILLEWORKS CONTACT: PAUL @ 516-488-0628 PATTERN: AAG717 CLOVER LEAF (43 % OPENING) FINISH: POWDER COATED WHITE. FINAL FINISH TO MATCH [PT-01] BY GC. MOUNTING: FLUSH MOUNT WITHOUT SCREW HOLES (DROP IN). THICKNESS: 1/8" THK.

2-1/2", 20 G.A. METAL STUDS AS REQUIRED. 3'-3" A.F.F [V.I.F.], T.O. WINDOW SILL

8 GYPSUM WALL BOARD TYPE 'X'. PAINT IN [PT-01] TEXTURE PAINT.

3 7

EXISTING RADIATOR TO REMAIN AND PROTECT. GC TO FRAME AROUND THE RADIATOR. NO ELEMENT TO TOUCHING THE RADIATOR DIRECTLY.

PROVIDE 2" HEIGHT AIR GAP ALONG THE WINDOW SILL.

2"

Glossier - Boston

Role:

Resposbility:

Storefront

Selfie Room

02 Moose Knuckle - Manhattan

Role: Designer | Assistant Project Manager

Resposbility: SD, DD, CD

Location: NYC - SOHO, NY

Gross Area: 3876 SQ.FT.

Project Stastus: Built

Project Date: 05/2019 - 11/2019

The first U.S. flagship store for Canadian outerwear brand Moose Knuckles, located in the heart of SoHo, showcases a masterful blend of historical and modern elements. The two-story boutique preserves original features such as aged pillars scattered throughout the space. Contemporary additions, including fur-upholstered ottomans, were integrated to embody the brand’s luxurious and rebellious spirit, creating a distinctive and inviting atmosphere.

Ground Floor Plan

SEE STRUCTURAL DRAWINGS FOR DETAIL.

TROLLEY SYSTEM. BY FC.

[MT-01] CLADDING. BY FC.

[PVC-01] PVC STRIP WITH [MT-01] TRIM ALL FOUR-SIDED. SEE DETAIL. BY FC.

LIGHT PANEL AS SCHEDULE BY FC.

SHEETROCK CALD OVER LIGHT BOX BY GC.

T-ANGLE. WHITE FINISH. BY FC.

LIGHT BOX AT TOP BY FC. GC'S CEILING TO RECEIVE AND COORDINATE WITH FC AND SHOP DRAWINGS FOR HEIGHT.

[PT-01] WALL PAINT. BY GC.

[PT-01] WALL PAINT.

LIGHT BOX BY FC. GC TO COORDINATE WITH FC AND SHOP DRAWINGS FOR HEIGHT.

WHITE METAL FINISH TRIM BY FC.

LIGHT PANEL AS SCHEDULE. BY FC.

GC TO EXTEND UP GYPSUM BOARD TO HOUSE FC'S LIGHT BOX.

[PT-01] WALL PAINT. BY GC.

[PVC-01] PVC STRIP WITH [MT-01] TRIM ALL FOUR-SIDED. SEE DETAIL.. BY FC.

ALL VISIBLE SURFACES OF THE TROLLEY TO MATCH [MT-01] FINISH. BY FC.

[MT-01] CLADDING. BY FC.

TROLLEY SYSTEM. BY FC.

FIN. FLOOR.

[B-01] METAIL 1" REVEAL AT BASE. BY FC.

[MT-01] METAL PLATE IN BETWEEN GLASS AND PVC PARTITION. BY FC.

LIGHT PANEL AS SCHEDULE. BY FC.

HEAD TO COORDINATE W/ FC. COORD. W/ FC.

LIGHT BOX AT TOP BY FC. GC'S CEILING TO RECEIVE AND COORDINATE WITH FC AND SHOP DRAWINGS FOR HEIGHT.

[PT-01] WALL PAINT. BY GC.

[PT-01] WALL PAINT. BY GC.

LIGHT BOX BY FC. GC TO COORDINATE WITH FC AND SHOP DRAWINGS FOR HEIGHT.

LIGHT PANEL AS SCHEDULE. BY FC.

LIGHTING AS SCHEDULE. BY FC.

[MT-01] METAL PLATE IN BETWEEN GLASS AND PVC PARTITION. BY FC.

SPRINKLER

[MT-2] FINISHED STEEL PLATE ANCHORAGE

[FA-1] LEATHER STRAPS SUSPENSION

[MT-2] 1 4 CASING. INTERIOR POWDER COATED WHITE.

[FA-1] LEATHER SLEEVE

SIDE

[MT-2] ANCHOR PLATES x2 [MT-1] WASHER AND KNOTS

[FA-1] STEEL STRAP ENCASED WITH LEATHER. SEE 7/G-1 FOR DETAIL.

[MT-1] WASHER AND KNOTS.

G-1

[MT-2] 1 4 CASING. INTERIOR POWDER COATED WHITE.

LED LIGHT BEYOND [MT-2] HANG BAR

A HOLD

VARIES. SEE EACH FIXTURE DWG

IN-CEILING FRAMING & REINFORCEMENT TO SUPPORT HUNG FIXTURE AND FULLY LOADED MERCHANDISES.

[FA-1] STEEL STRAP ENCASED WITH LEATHER. SEE 8/A-9.0 FOR DETAIL.

[MT-1] WASHER AND KNOTS

CONCEALED POWER SOURCE BEYOND STRAP. CORD TO MATCH STRAP FINISH.

[L04] FULL LENGTH LED STRIP.

[P-1] CASE INTERIOR IN WHITE TO REFLECT LIGHT. [MT-2] INTERMEDIATE CROSS BRASSING CONNECTOR.

[MT-2] VERTICAL CONNECTOR WELD TO HORIZONTAL CONNECTOR ABOVE AND HORIZONTAL HANG BAR BELOW. GRIND SMOOTH NO SEAM. TYP.

HANG BAR

Moose Knuckle - Roosevelt Field,

Moose Knuckle - Calgary, Canada

Moose Knuckle - Roosevelt Field, NY

Moose Knuckle - Roosevelt Field, NY

Moose Knuckle - Calgary, Canada

Storefront Photo

Storefront Photo

Store Photo

Store Photo

Storefront Rendering

Storefront Side Rendering

Fitting Room Rendering - off Fitting Room Rendering - on

Storefront Rendering

Moose Knuckle - Qingdao, China

Moose Knuckle - Qingdao, China

Moose Knuckle - Miyashita, Japan

Moose Knuckle - Miyashita, Japan

03 Bond Vet - Fairfield

Role: AOR / Project Manager

Resposbility: SD(Partial), DD, CD, CA

Location: Fairfield, CT

Gross Area: 3104 SQ.FT.

Project Stastus: Built

Project Date: 04/2023 - 06/2024

Storefront Photo - In Construction

Storeside Elevation

Storefront Elevation

1. SEE FIXTURE PLAN AND FIXTURE DETAILS FOR FIXTURE INFORMATION.

2.SEE REFLECTED CEILING PLAN FOR SOFFIT AND LIGHTING INFORMATION.

3.NOTIFY ARCHITECT IMMEDIATELY OF ANY INCONSISTENCIES OR DISCREPANCIES WITH PLANS IS RELATIONS TO EXISTING FIELD CONDITIONS.

4.WRITTEN DIMENSIONS TAKE PRECEDENCE OVER SCALE ON THE CONSTRUCTION DOCUMENTS. DO NOT SCALE.

5.DIMENSIONS ARE FROM THE FACE OF FINISHED WALL (GWB) TO FACE OF FINISHED WALL (GWB) UNLESS OTHERWISE NOTED ON PLANS.

6.ALL MANUFACTURED ARTICLES, MATERIALS AND EQUIPMENT SHALL BE APPLIED, INSTALLED, CONNECTED, ERECTED, USED, CLEANED AND CONDITIONS IN ACCORDANCE WITH THE MANUFACTURER'S WRITTEN SPECIFICATIONS OR INSTRUCTIONS.

7.ALL WORK SHALL BE EXECUTED IN A MANNER ACCEPTABLE TO THE OWNER.

8.UNLESS NOTED OTHERWISE, THE GENERAL CONTRACTOR SHALL PROVIDE ANY PAY ALL LABOR,

13. GENERAL CONTRACTOR TO COORDINATE ALL MILLWORK WHIP LOCATION AND CONNECTION WITHIN THE MILLWORK CABINETS WITH MILLWORK CONTRACTOR.

14. ELECTRICAL CONTRACTOR TO VERIFY IF SERVICE PROVIDED IS ADEQUATE, IF NOT, GC TO NOTIFY ARCHITECT IMMEDIATELY.

SYMBOLDESCRIPTION REMARK GROUNDED 20 AMP DUPLEX RECEPTACLE TYP. GROUNDED 20 AMP QUAD RECEPTACLE TYP. GROUND FAULT INDICATOR 20A DUPLEX RECEPTACLE TO BE USED IF LOCATED WITHIN 36" OF WATER SOURCE

GROUNDED 20 AMP DUPLEX RECEPTACLE MOUNTED W/ USB CHARGER

GROUNDED 20 AMPQUAD RECEPTACLE W/ USB CHARGER

ISOLATED GROUND 20 AMP DUPLEX RECEPTACLE. (ORANGE)-DEDICATED OUTLET ISOLATED GROUND GROUND FAULT INDICATOR 20A DUPLEX RECEPTACLE (ORANGE)-DEDICATED OUTLET

SPEAKER OUTLET FOR SONOS SPEAKERS LOCATED AT 6" BELOW FINISHED CEILING J-BOX OR POWER WHIP FOR FIXTURES GC TO COORDINATE

FLOOR OR CEILING MOUNTED J-BOX.

Lobby Elevation

Halway Elevation

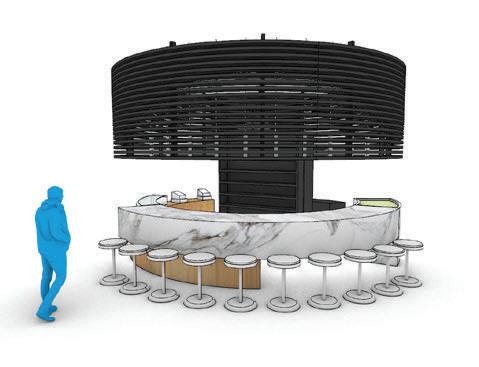

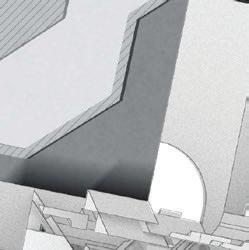

04 GASTRONOMI CENTER

Food Court Design

Role: Intern Designer

Resposbility: SD

Location: Istanbul, TR

Gross Area: 29070 SQ.FT.

Project Stastus: Conceptial

Project Date: 06/2018 - 08/2018

According to the requests of clients, this food court is not only a restaurant but also a combination of a restaurant and a market. The purpose of the design is to create a releaxed dining environment where people could learn and have fun. The food court is located on the ground floor of a mall which is located in Turkey. The colums of the food center use arched structures to divide the space and the food pavilions for providing different foods are arranged in the site evenly. The roof of the food centre features round ceilings and lights, which echos the arched columns.

Fine Dining Room

Food Pavilion

Food Pavilion

Food Pavilion

05 2050 Dubai Expo Pavilion

Sustainable pavilion Design

Graduate Design Studio

Instructor: Joe MacDonald

Location: Dubai, UAE

Team Mate: Long Ye

Date: Fall 2018

The pavilion is designed using sand as the primary building material, reflecting the local climate. Positioned to overlook the expo’s development and distant sand dunes, the museum employs 3D printing with local sand to highlight the balance between nature and technology, aiming to reduce the carbon footprint. A secondary layer of wire mesh, woven with metal pipes, serves both structural and functional purposes. This mesh condenses humidity from the air, with the pipes acting as an irrigation system to cool the building. Additionally, the structure extends underground to access cooler temperatures, ensuring sustainability in the harsh daytime heat.

Under Water Gallery

Second Floor Center Well View

Second Floor View

Terrace View

Northwest Plaza View

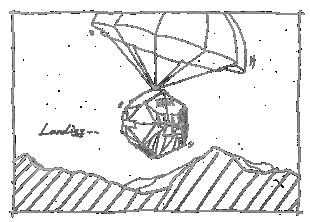

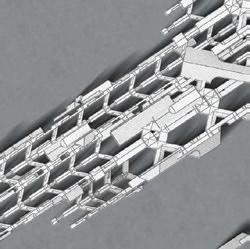

06 IO Mission

Space Mining Project

Graduate Design Studio

Instructor: Matias del Campo

Location: Jupiter

Team Mate: Zihao Fang, Xing Zhang

Date: Spring 2018

The space mining project is inspired by the growing demand for mineral resources due to industrial and technological advancements and the finite nature of Earth’s resources. Our proposal envisions a fully automated mining colony using robots to extract raw materials from asteroids or moons of other planets. This colony would include mining robots and factories. The robots would be deployed to explore ore bodies, analyze their composition, extract raw materials, and transport them back to the colony’s factory. Some of these raw materials would be used to develop the mining factories, while the rest would be transported back to Earth.

Mineral Storage

Robot Repairation

Connecting Tunnel

Mining Unit & Under Ground Chamber Section Detail

Physcial Model

View From Mining Robort

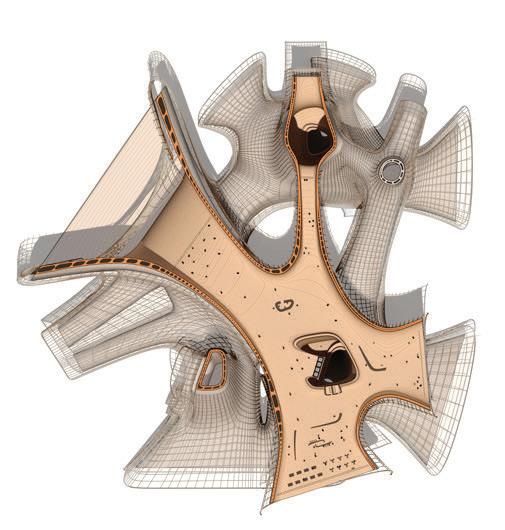

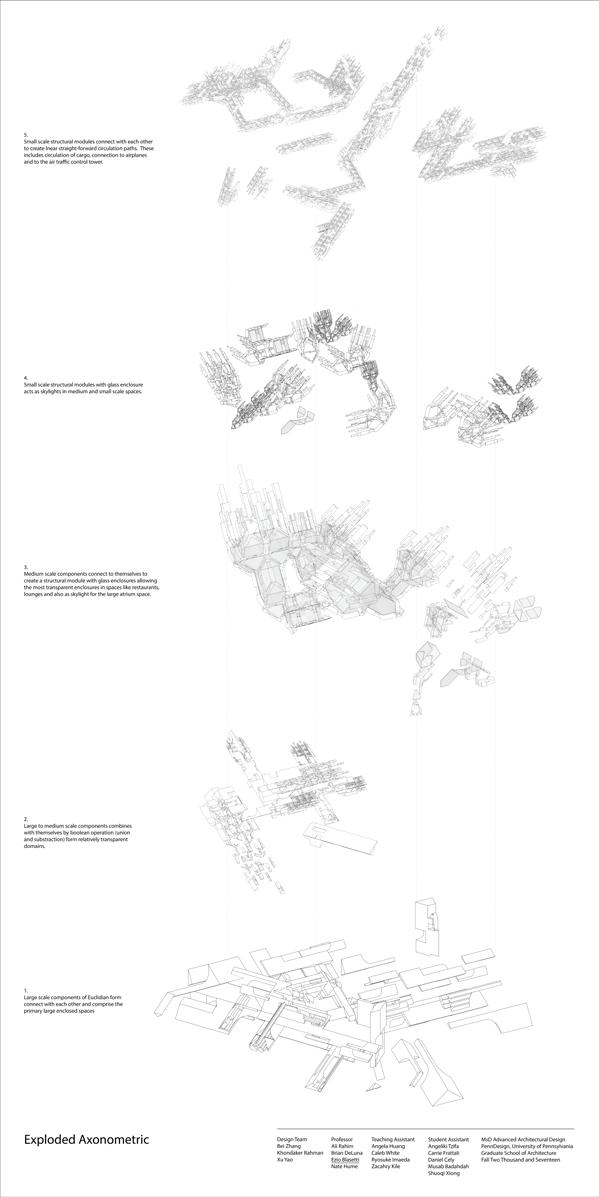

07 JFK Future Airport

Integrated Passanger & Cargo Terminal

Graduate Design Studio

Instructor: Joe MacDonald

Location: Dubai, UAE

Team Mate: Bei Zhang, Onie Rahman

Date: Fall 2018

The design process started with an examination of bifurcating vector structures as wireframes, which led to the concept of discrete architectural elements. By integrating these wireframes with various components, we developed a system capable of accommodating spaces of different scales, qualities, and functions.

Large-scale components connect to form enclosed spaces, while connections between large and medium components create geometrical transparency. This transparency increases with smaller components, resulting in highly transparent glazed enclosures for restaurants, lounges, and atriums. Further scaling down forms linear paths for cargo circulation, gate connections, and channels to the air traffic control tower.

Our discrete elements enable the transition from Euclidean geometry to a machine aesthetic for the façade. This transformation allows for replaceable building elements, making the structure not only resemble a machine but also function like one. As a result, the airport’s design evolves through the continuous replacement and rearrangement of its components.

Departure Plan

08 The Flowing Mountain

Undergraduate Design Studio

Location: Shanghai, CN

Individual Work

Shanghai Art Museum Design The design concept draws inspiration from the nearby Huangpu River, the city, and the surrounding mountains. The building’s form mimics the waves, while its irregular pore structure imitates the spray and foam of splashing waves. The connection between the two buildings resembles the mountains. This design not only offers visitors a modern experience of nonlinear architecture but also gives the sensation of shuttling through the waves.

Date: Fall 2016

09 Green Regeneration

Undergraduate Design Studio

Location: Chongqin, CN

Individual Work

Date: Fall 2015

Graphic Information Center Renovation The project aims for renewable design to support a low-carbon economy with minimal intervention and transformation, preserving the integrity of old industrial buildings. We adhere to green ecological principles, treating these structures as living organisms to develop a comprehensive design that enhances their metabolic mechanisms and improves breathing efficiency. Our goal is to enable these buildings to “re-breathe” and eventually transform them into a state of continuous “breathing” in the future.

10

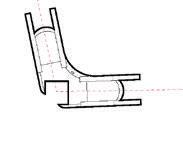

Techinical, Morphology of a Pavilion

Depoloable Pavilion Design

Graduate Structure Elective

Instructor: Mohamad Al Khayer

Location: University of Pennsylvania, PA

Team Mate: Class of ARCH-732

Date: Spring 2018

The primary objective of this project is to construct a deployable pavilion prototype that showcases the practicality of building a full-scale pavilion. The pavilion comprises three main components: the bone structure(sissor), joints, and fabric. The structural framework is crafted from multi-layer MDF panels, cut into the desired shapes. These structural elements are connected using 3D-printed joints. Translucent fabric is employed to create enclosed spaces where necessary.

yaoxuarch@gmail.com

Phone: