Issue 1, Volume XXXIV, January/February 2023

The machinery only journal for processing & packaging | www.machineryupdate.co.uk

INSIDE NEWS

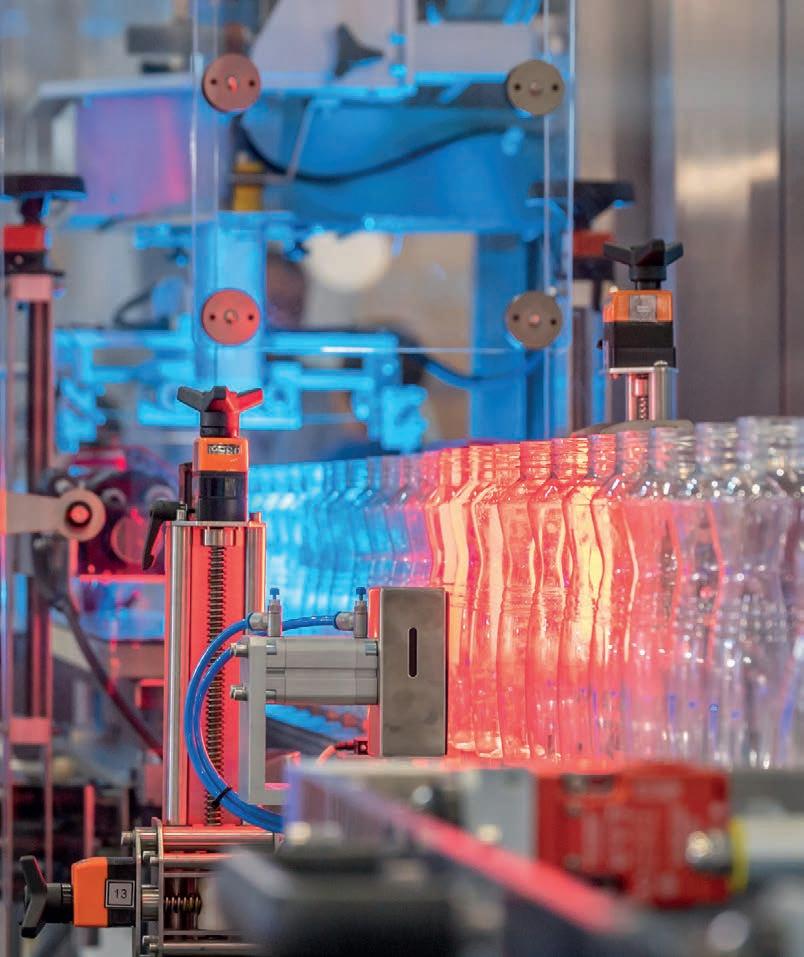

Securing production

Our feature this issue covers technologies that ensure product safety that when installed, help to avoid any product recalls caused by flawed products/packaging

Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod tincidunt ut laoreet dolore magna

PPMA Group of Associations appoints James Causebrook as its new chairman, taking over from David Barber who has steered the trade association safely through the pandemic

NEW MACHINERY

A condition monitoring sensor, which is described as a rugged bolt-on device, delivers real-time, continuous service data from electric motors, pumps, fans and conveyors in harsh environments Find out more on page 18

INSTALLATIONS

A weighing and packing solution delivers a sustainable option for carrot snack packs

NEWS PLUS

There are three opportunities to attend the fundamentals of field service PPMA training course that runs over 2 days charlotte.paget@ppma.co.uk

FEATURING:

Where the processing, packaging & logistics sectors meet

Informing, inspiring and connecting the industry

We look forward to this April when the industry comes together at the UK Food & Drink Shows, encompassing Foodex Manufacturing Solutions, Farm Shop & Deli Show, Food & Drink Expo and National Convenience Show.

This is a trade

Register for FREE: foodex.co.uk

event. No under-18s will be admitted.

January/February 2023

7 NEWS

This magazine has been shortlisted for a Publication of the Year award from a record number of entries…

12 NEW MACHINERY

Opening the twelve pages of new machinery is ABB’s smallest ever industrial robot for wearable uses

26 INSTALLATIONS

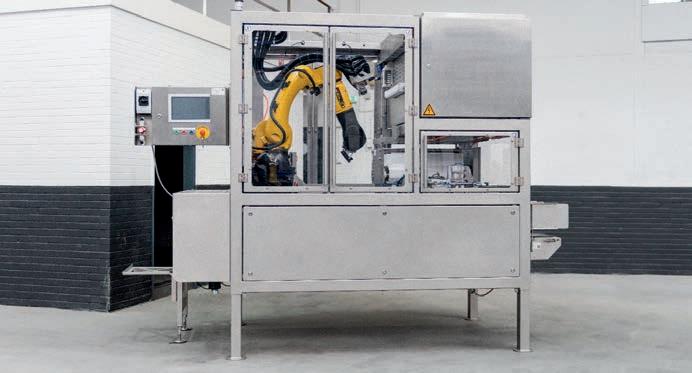

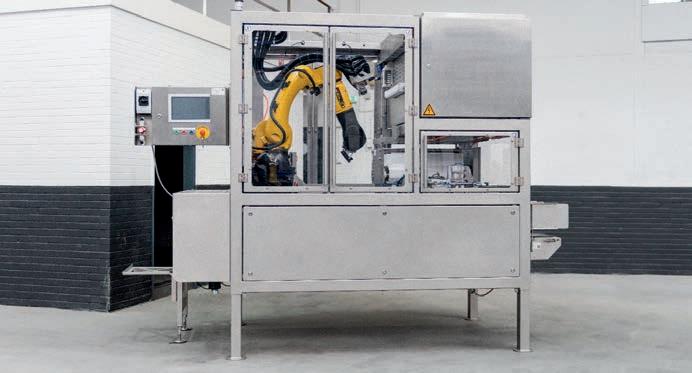

Cama has delivered a robot-based secondary packaging machine to handle chocolate covered tea cakes

30 SPECIAL FEATURE SECURITY

Our feature this issue covers the many technologies that deliver product security to users and that help to avoid any product recalls, any cyber-attacks and also that keep equipment operators safe

30

REGULAR FEATURES

10 REGULATIONS

This issue we cover fire prevention and protection compliance.

TÜV SÜD explains how vital it is that machinery end users have an appreciation of ISO 19353 as it describes in detail the methods for identifying a machinery fire hazard and also, how a corresponding risk assessment should be conducted. It also describes the basic concepts and methodology of the technical measures needed for fire prevention

EDITOR:

Gail Hunt

gail.hunt@ppma.co.uk

PUBLISHING MANAGER:

Bill Lake bill.lake@ppma.co.uk

ARTWORK CONTRIBUTOR:

Barry Heath

HEAD OF PUBLISHING:

David Chadd david.chadd@ppma.co.uk

A PPMA PUBLICATION

PPMA Ltd

New Progress House, 34 Stafford Road, Wallington, SM6 9AA

TEL: +44 (0) 20 8773 8111

E-MAIL ADDRESSES: publishing@ppma.co.uk show@ppma.co.uk technical@ppma.co.uk

WEBSITE: www.machineryupdate.co.uk

APPLICATIONS FOR FREE COPIES of Machinery Update are considered from specifiers, managers and purchasers of processing and packaging machinery in the UK.

ANNUAL SUBSCRIPTION: £35 (UK), £50 (Continental Europe), £65 (rest of world).

ISSN 0969-4145

42 COMPONENTS

Rockwell Automation showcased the power of data, cybersecurity and sustainability at SPS 2022, showing how its hardware and software solutions enable users to become even more productive

44 WHO WHAT WHERE People, events and diary dates

46 MACHINERY FINDER Machinery and also services

PRINTED BY: John Good Ltd, Progress House, Butlers Leap, Rugby CV21 3RQ Tel: 02476 652800

The Processing and Packaging Machinery Association assumes no responsibility for the statements or opinions, whether attributed or otherwise, in Machinery Update.

This publication is copyright under the Berne convention and the International copyright convention. Apart from any fair dealing for the purposes of research or private study, as permitted under the Copyright, Designs and Patents Act 1988, no part of this publication may be reproduced, stored in a retrieval system or transmitted in any form or by any means in any form without prior written permission of the publishers.

Publishers: PPMA Ltd

www.machineryupdate.co.uk JANUARY/FEBRUARY 2023 MACHINERY UPDATE 3

21

Contents

THE BENEFITS OF OVERWRAPPING: Excellent appearance On-pack promotion with printed film

& paper IMPROVE OVERWRAP your products Over 10,000 machines sold world-wide!

sollas.com your sales, Sollas MU S-O 2021 artwork

Cost reduction Closed packaging No heat radiation Efficiency Ease of operation Flexibility Low maintenance Easy opening with tear tape Biodegradable film

01256 896930

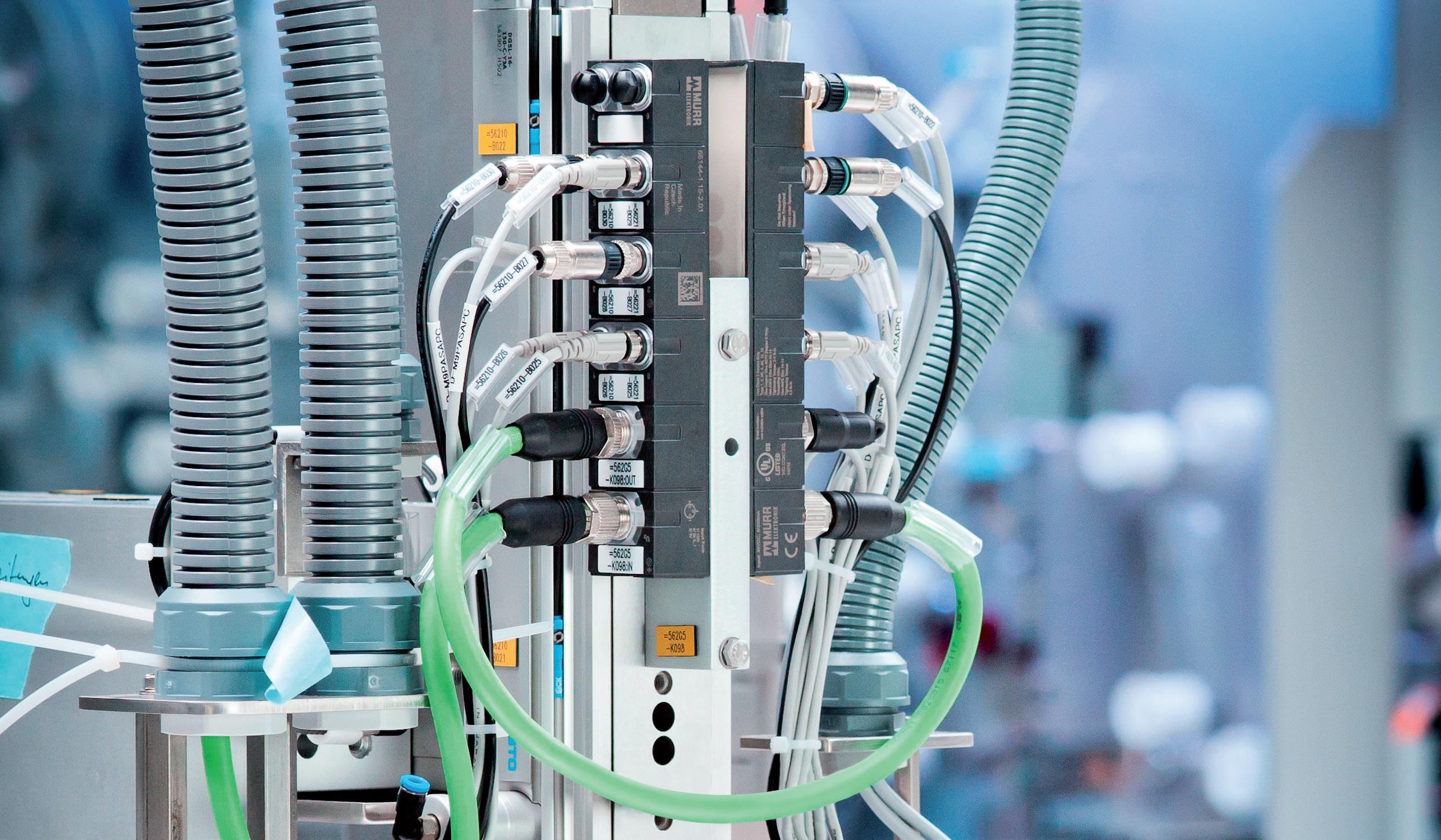

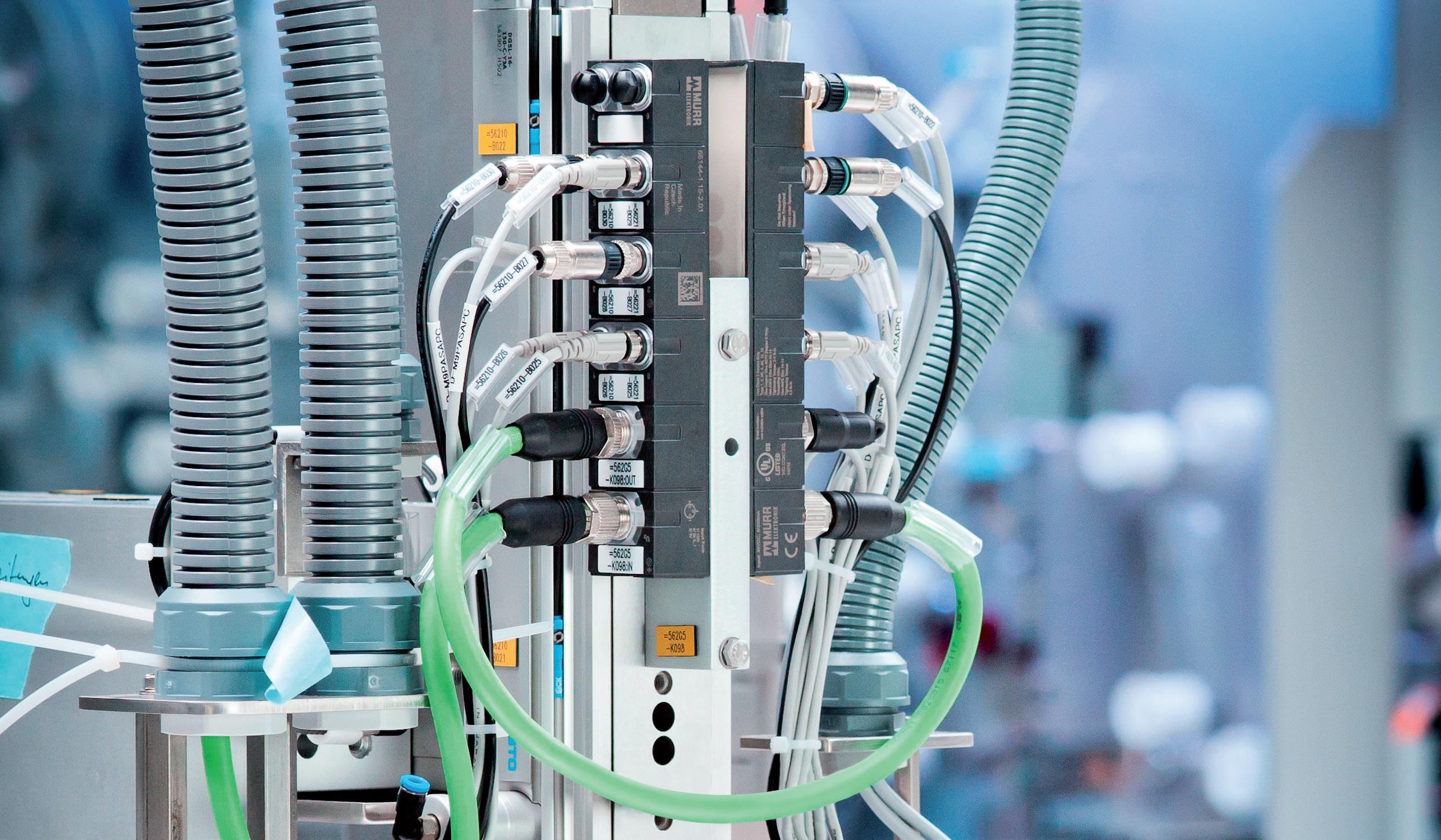

Compact. Modular. Flexible.

Cube67

by Murrelektronik

The perfect I/O system for decentralized installation concepts

Cube‘s flexibility creates the best solution for every application – all the way from the controls to the on-machine I/Os.

Cube solutions offer the best value for your money during the engineering phase, commissioning phase and maintenance phase. Maximizing uptime and productivity.

www.murrelektronik.uk

Automation must work for all partners…

This my first column as the new chairman of the Processing & Packaging Machinery Association, or the PPMA, and I thought it would be useful to set out some of our plans for the trade association during the coming year as they are all designed to benefit you, our customers, as well as the members of our trade association.

There is no doubt that all of us need to do more to stop UK PLC being the slowest to adopt automation, in all its forms, if we are ever going to compete successfully in these turbulent times. If there is an upside to the current labour shortages then let’s hope it is the adoption of more automation, and I don’t just mean robotics. I also don’t necessarily mean multi-million-pound projects … I mean automation that is not over-specified, or under specified. I mean the correct level of automation. There’s no point selling a crane to a customer for which a step ladder would be the best solution. The correct levels benefit everyone. As does properly trained staff on any systems being installed.

The PPMA will be facilitating collaborative partnerships to help UK PLC use the correct automation

The PPMA is therefore going to be concentrating on helping companies to adopt the correct level of automation to meet their needs, while also helping to upskill their personnel to support it. And we are putting our money where our mouth is in investing in our trade association to speed up our response to these challenges.

To do this, we are recruiting new people (see page 7), we are running new events this year, our marketing team will be promoting the accessibility of automation and we will be engaging with government and stakeholders. Our successful training department will also be engaged in this enterprise.

Our Automation UK event in June is a new exhibition that will be highlighting the importance of automation, robotics and systems integration to the future growth of the UK economy and will run alongside the established Machine Vision Conference for two days. This unique event will highlight the latest industrial products and services, robots, robotic systems, systems integration, automation control parts and systems, sensors and machine safety.

I believe that this new show will bring together a diverse range of technology and talent that can only help in meeting the automation needs of UK PLC. And it will also help foster more collaborative partnerships between our members and the end user which surely is the key for all of our businesses going forward. n

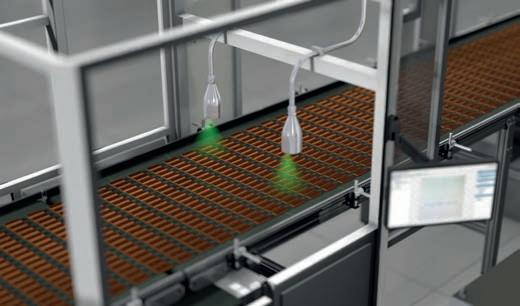

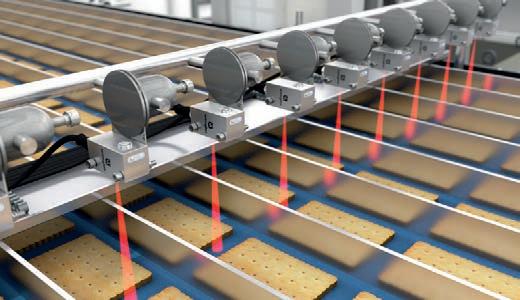

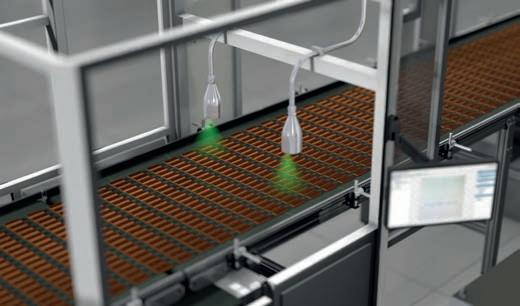

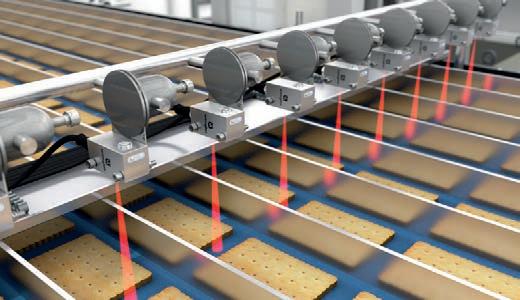

CleaningResistant and Robust Sensors

The sensors for the washdown area are ideal for use in washdown applications in the food, beverage and packaging industries. The high-quality stainless steel 316L housing makes them robust and corrosion-resistant

Height and Angle

Measurement of Ice Cream Cups via 2D/3D Profile Sensors

Detection of Cookies with Reflex Sensors with Background Suppression

Detection of Food Trays with Reflex Sensors with Background Suppression

Color Control of Baked Goods with Vision Sensor

www.machineryupdate.co.uk MACHINERY UPDATE 5

PPMA matters

James Causebrook

CHAIRMAN, PPMA GROUP OF ASSOCIATIONS (INCORPORATING PPMA, BARA AND UKIVA)

wenglor sensoric ltd. Unit 2, Beechwood | Cherry Hall Road | Kettering Business Park Kettering, Northants NN14 1UE +44 1536 313 580| info.uk@wenglor.com

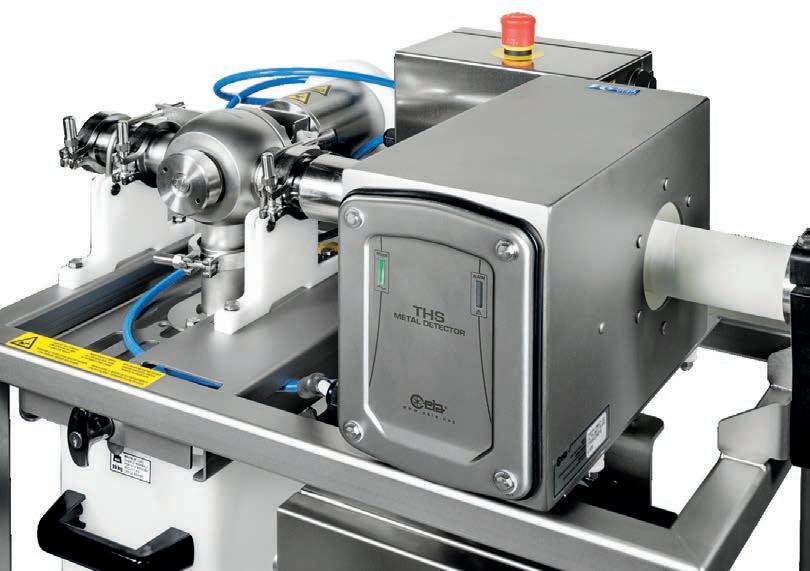

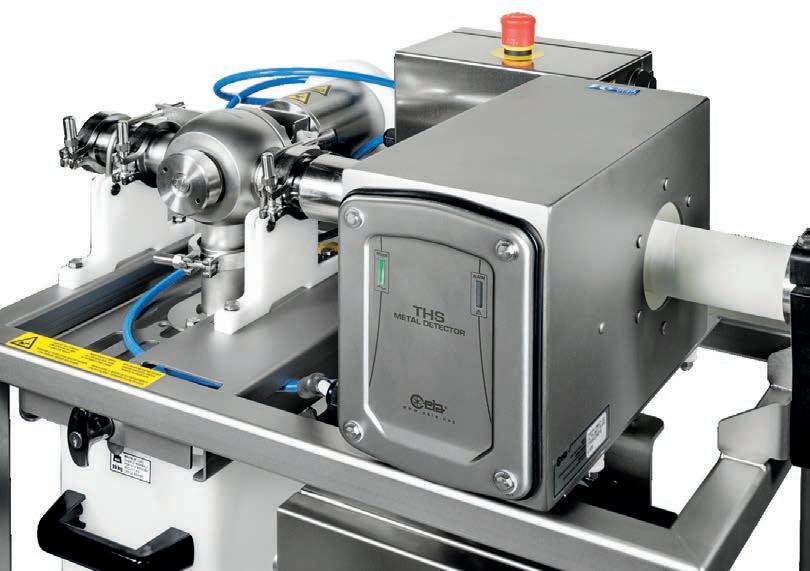

KEY FEATURES

• HIGH SENSITIVITY TO ALL METALS

• INTEGRATED CONTROLS for line speed and rejection

• HIGH IMMUNITY to environmental interference

• AUTOMATIC LEARNING & TRACKING of product effect

• DIGITALLY ADJUSTABLE BELT SPEED

• RUGGED AISI 316L stainless steel CONSTRUCTION and food-compatible plastic parts (EU, FDA COMPLIANT)

CEIA CONVEYOR INSPECTION SYSTEMS PIPELINE INTEGRATED SYSTEMS IXC AND WEB-SERVER FUNCTIONS www.mds.org.uk UK FULL SERVICE AND TECHNICAL SUPPORT ∂ 24-7 Help Line and Assistance ∂ Metal Detector Validation and Retailer Code of practice training CEIA AUTHORISED DEALER ∂ Contact us on: 0161 286 8750 ( TECHNICAL) - 0161 286 8755 (SALES) metal detection services

Three new appointments at the PPMA will strengthen its remit

James Causebrook, managing director at Grunwald UK, is the new chairman of the PPMA, taking over from out-going chair David Barber who steps down after his two-year term. Causebrook was elected to the board of directors in 2018 and has held the vice-chairman role throughout 2022.

During the chairman’s lunch in December, Causebrook and the PPMA reflected on the outstanding job that Barber had done in the last two years, facing unprecedented challenges especially throughout the COVID-19 pandemic. Against all odds in the lockdown years, Barber oversaw the PPMA growing its membership and helped to plan for its future.

As the new chair, Causebrook is looking to hone the efforts of PPMA members and staff to ensure that the association continues to offer

members the valuable support needed for them to sell products and services, all the while encouraging new, and existing members to take full advantage of their membership.

“I believe that our members want an association that speaks up for them and is there to help them improve their businesses, so building vital links and connections with our affiliate partners will be of paramount importance,” says Causebrook.

At the same time, the PPMA Group of Associations has announced two new positions to help drive it forward. These include a new chief executive officer (CEO) being added to its

executive team and a new director to the board.

Peter Williamson, managing director at PPMA member RARUK Automation will now be helping to shape the future of PPMA. He takes up his position as CEO of the PPMA while continuing to be md of RARUK Automation, and a director of the trade association. He will spend two days a week in this role, helping to shape the strategy behind operations in 2023.

Meanwhile, group director at RMGroup Rosie Davies is joining the board of directors. Both Williamson and Davies will be aided by PPMA chief operating officer David Harrison, who will assist in their transition to the PPMA.

busy this year with the upcoming Automation UK, Machine Vision Conference, and PPMA Show

This magazine is shortlisted for a Publication of the Year award

Machinery Update has been shortlisted in the Publication of the Year category in the 2023 Trade Association Forum Awards.

THE

BRITISH SALES SUBSIDIARY HAS 15 EMPLOYEES

Enjoying 20-year landmark

Schubert UK, the British sales subsidiary of the German packaging machine manufacturer Schubert, celebrated its 20th anniversary at the end of last year. The business started with a small team of four people and twenty years later, under the management of Mark Stepney, the 15-strong team works on a range of packaging solutions for customers and generates 16.4 million euros in sales.

Held annually, the awards recognise associations that have delivered for their members, their sector or made outstanding contributions over the previous year. Our magazine has been selected from a record number of entries and, according to judges, is a huge testament to the quality of work over the past year.

A series of shortlisting panels met last December, and the final judging panel meets

this January to decide on the winners. The results will be announced at a ceremony to be held at the Brewery in East London on 23 February.

www.machineryupdate.co.uk JANUARY/FEBRUARY 2023 MACHINERY UPDATE 7 News

James Causebrook is the new chairman

2023.

MachineryUpdate INSIDE NEWS Loremipsumdolorsit ingamet,consectetueradipiscelit,seddiamnonumutmynibheuismodtincidunt laoreetdoloremagna NEWS PLUS NEW MACHINERY Issue 3, Volume XXXIII, May/June 2022 UKIVA’s Machine Vision Conference and Exhibition Milton Keynes proved be a very popular in-person event once more, having been an on-line forum for two years The UK Pavilion Gulfood Manufacturing in Dubai this November can be booked through the PPMA Group janette.lane@ppma.co.uk Thenewpackagingalternative fromKHS,whichwrapsdrinks cansinpaperinsteadoffilm, can now also be retrofitted to existingmachineswhilealsoswitchingbetweenmaterials Find out more on page 16 The machinery only journal for processing & packaging | www.machineryupdate.co.uk Sustaining the sector The dairy sector is facing an almost perfect storm of increasing costs, labour shortages and consumer pressure for sustainability, as our feature explains INSTALLATIONS A line conversion tooknewprovideformats just two usingdayslatest remote solutions

Industry-leading

Peter Williamson is the new CEO

Z

Rosie Davies is now on the board

Visitors to Chicago exhibition were increasing automation

Back after four years, the industry came together at PACK EXPO International in Chicago last October with over 44,000 attendees to the event.

The show opened its doors with the industry ready to do business after years of consistent growth, reported show owner and producer PMMI, The Association for Packaging and Processing Technologies. “The success of PACK EXPO is a testament to our industry’s continued growth as well as PMMI’s commitment to bringing the industry together to share cutting-edge innovations,” says Jim Pittas, president and ceo, PMMI. “No other event this year showcased so many end-to-end solutions, offering attendees everything they need to compete in a changing marketplace.”

LABOUR SHORTAGES

According to The Future of Automation in Packaging and Processing report produced by PMMI and released during the event, labour shortages are driving consumer packaged goods (CPG) companies to adopt automated solutions.

The report highlights how CPGs are looking to enhance and optimise their production, storage, and distribution processes using automated solutions including automated guided vehicles, industrial robots, collaborative robots and mobile robots, with some of these technologies being supported by artificial intelligence (AI) and advanced vision tools.

According to the report, eCommerce is fuelling the automation trend, moving companies toward more agile modes of distribution.

• Our PACK EXPO Review can be found on pages 24-25

News 8 MACHINERY UPDATE JANUARY/FEBRUARY 2023 www.machineryupdate.co.uk

Tel: 0 1865 8 9 1466 Email: info@cap c ode r.com To d is cover mo re a bo u t th e m ac hi ne s th at cou l d t ran sform you r comp any please v isit: www. ca pc ode r.com

Automation leaders address challenges during Open House

Over 600 visitors attended the annual Fanuc UK Open House event in Ansty park, Coventry in November as the industrial automation community sought to address some of the key challenges and opportunities facing manufacturers today.

Attendees saw expert speaker presentations, case studies, panel discussions, hands-on training, robotics demonstrations and an exhibition of more than 40 companies.

“A German worker is about 30% more productive an hour than we are, because of their increased use of automation,” said Fanuc UK md Tom Bouchier at the event. “Let’s keep the UK at the forefront of the manufacturing revolution and raise our productivity by increasing the uptake of automation.”

Industry personality has passed away after illness

It is with great sadness that we report on the passing of former Group chairperson of Bradman Lake Graham Hayes at the end of last year, following a lengthy illness.

Graham was a largerthan-life character within the packaging industry who was generous with his time, contacts and industry knowledge to all he met. These traits were reflected in him being named on influential people lists and winning packaging personality of the year in the Starpack awards. He was a keen networker throughout his time at the PPMA and EAMA and spent much time lobbying and campaigning for the packaging industry as a whole, as well as working hard at his day job where he helped to develop Bradman Lake into a global business.

He started his career in 1966 as a trainee at Kliklok in the US, and after three years, he returned to the UK and

Graham Hayes was an industry advocate

worked at BP Plastics before moving to Engelmann & Buckham, where he honed his sales and marketing skills. Graham then put his entrepreneurial ideas to the test by setting up his own packaging machinery business called Starpack Design Systems. It was then that he first discovered Bradman Lake, became a successful sales agent for

the engineering company and in 1976, he was appointed a director and bought his first stake in the company. In 1990, he was appointed chairperson of the UK business when the factory was located in Brislington, Bristol. He was also chairperson of the US business. In 2004 Bradman Lake acquired three businesses from GEI Packaging Machines which included the well-established brands Autowrappers and Europack.

Hayes ended his long association with the packaging machinery manufacturer after its acquisition by engineering firm Langley Holdings, a business that continues to be a leading provider of integrated packaging technology to this day. He had a passion for golf and lived in Gerrards Cross overlooking Stoke Park golf course. He leaves his wife Suzanne, and children Eliott, Paul and Danielle.

The first ever Grant Jamieson Engineering Scholarship has been bestowed on a University of Portsmouth PhD student

Joshua Wright, a mechanical engineering graduate, has become the first recipient of the Grant Jamieson Engineering Scholarship launched in 2021 by the then PPMA chairman David Barber in recognition of Grant’s service to the PPMA and in support of his passion to aid the re-generation of future engineering talent. Jamieson sadly died in March of last year. This annual grant of up to £5,000 is awarded by PPMA BEST to an outstanding

individual who has shown both interest and potential in a field of engineering relevant to PPMA member businesses. Joshua, who is now enrolled on a PhD programme, was nominated for the award by the Head of the Mechanical and Design Engineering School at the University of Portsmouth

metal additive manufacturing technologies – essentially looking at using metal AM to create textures and surfaces which will change the characteristics of products, for example increasing hydrophobicity or reducing drag characteristics.

“I’ve always been interested in engineering as for me, it was the perfect blend of science, maths and design –and this was only reinforced by my parents who work in engineering and education.

www.machineryupdate.co.uk JANUARY/FEBRUARY 2023 MACHINERY UPDATE 9

Over 600 visitors were at event

Joshua Wright (centre) at the PPMA Total Show

Dr Jovana Radulovic. His PhD topic is creating functional surfaces using

Fire prevention and protection compliance

ISO 19353:2019 – Safety of Machinery – Fire Prevention and Fire Protection defines ‘fire’ as: “Independent combustion, which can occur as controlled combustion or as uncontrolled combustion.” The standard is directly relevant to machinery manufacturers, and health and safety bodies, such as the Health & Safety Executive in the UK. However, it is vital that purchasers and end users of machinery understand their machinery supplier’s responsibilities in this area, including employers, employees, in-house maintenance staff or a maintenance service provider.

As a designated standard (B-Type), ISO 19353 satisfies the relevant essential safety requirements (ESRs) where the relevant hazards have been identified during the design risk assessment stage. Compliance with it therefore gives a ‘presumption of conformity’ with the Machinery Directive in the EU, and The Supply of Machinery (Safety) Regulations for the UK. Products demonstrate their compliance by having a CE mark (EU) or UKCA mark (GB) affixed by the manufacturer and the drawing up of a Declaration of Conformity.

ISO 19353:2019 is the third edition and has therefore replaced the previous edition, ISO 19353: 2015. The updates from the previous edition are not however, significant.

ISO 19353 is a type B1 standard as stated within ISO 12100. This means

Darren Hugheston-Roberts HEAD OF MACHINERY SAFETY

Paul Laidler BUSINESS DIRECTOR FOR MACHINERY SAFTEY AT TÜV SÜD PRODUCT SERVICE

Paul Laidler BUSINESS DIRECTOR FOR MACHINERY SAFTEY AT TÜV SÜD PRODUCT SERVICE

that it relates to specific safety aspects of machines, describes general safety aspects and provides relevant solutions, such as the design of appropriate controls. Type B1 and B2 standards are laterally interlinked, but type B2 standards relate to specific products, such as EN 13850 (Emergency stop function – Principles for design). They include notes on the design and testing of safety components, which both the product manufacturer and machine designer must take into account.

is the means of firefighting, which includes fire detection. Overall, this would include the technical, structural, organisational and fire suppression measures to be considered, and it can be implemented through a single measure or a combination of measures.

Overall, the protective measures that are dealt with in ISO 19353 include:

• Inherently safe design measures such as minimising the use of flammable materials and liquids.

Machinery end users should be aware of ISO 19353 as it describes basic concepts as well as methodology

ISO 19353 therefore specifies methods for identifying the fire hazards presented by machinery and the methods for performing an appropriate risk assessment. It includes fire protection measures for the design and manufacture of machinery. It also gives the basic concepts and methodology of protective measures for fire prevention and protection to be taken during the design and construction of machinery. The measures consider the intended use, as well as the reasonably foreseeable misuse of the machine.

The third area that must be considered for machinery safety against fire, in addition to prevention and protection,

• Safeguarding/technical protection measures such as spatial containment (encapsulation).

• Complementary protective measures such as integrated fire alarm and extinguishing systems, including:

• Pre-fire alarm systems

• Fire alarm systems

• Manually release fire suppression equipment and systems

• Automatically released fire suppression systems

• User information. However, the standard does not cover every machine type and is not applicable to:

• Mobile machinery.

• Machinery designed to contain controlled

combustion processes (eg internal combustion engines, furnaces), unless these processes can constitute the ignition source of a fire in other parts of the machinery or outside of this.

• Machinery used in potentially explosive atmospheres and explosion prevention and protection.

• Fire detection and suppression systems that are integrated in building fire safety systems.

• Machinery or machinery components manufactured before the date of the Standard’s publication.

In conclusion, it’s vital that machinery end users have an appreciation of ISO 19353 as it describes the methods for identifying a machinery fire hazard and how a corresponding risk assessment should be conducted. It also describes the basic concepts and methodology of the technical measures for fire prevention, protection and fire-fighting that should have been taken during the design and construction stages of machinery. Therefore, with knowledge of its application users can be assured that their machine has reached the required level of fire safety according to its intended use, as well as any reasonably foreseeable misuse.

i For more information contact W www.tuv-sud.co.uk TÜV SÜD Product Service is the PPMA’s technical and legislative partner

10 MACHINERY UPDATE NOVEMBER/DECEMBER 2021 www.machineryupdate.co.uk

Regulations

It is vital that end users of machinery understand their machinery supplier’s responsibilities when it comes to designing and producing machinery with fire prevention and protection in mind…

10 MACHINERY UPDATE JANUARY/FEBRUARY 2023 www.machineryupdate.co.uk

26-28 SEPTEMBER 2023 NEC, BIRMINGHAM

PPMA Show is the UK’s largest event for processing equipment, packaging machinery, industrial robots and vision systems

FREE TO ATTEND

REGISTER YOUR INTEREST NOW

www.ppmashow.co.uk

Smallest industrial robot offers electronics benefit

ABB has launched its smallest ever industrial robot, offering new possibilities for faster, more flexible and high-quality production of wearable smart devices. With its compact size, payload and accuracy, the new IRB 1010 offers electronics manufacturers the opportunity to increase their production of devices including smart watches, earphones, sensors, and health trackers through adopting automation.

“The market for wearable smart devices is accelerating rapidly, with projections estimating double digit growth between 2022 and 2028,” said Rui Liang, managing director of ABB Robotics’ electronics business line. “To meet this growth, companies are demanding compact robotic solutions that are suited to narrow production spaces in electronics manufacturing lines and that can accurately handle the small components used in wearable devices.

“As the most accurate robot in its class for 1.5 kg payloads, our IRB 1010 meets these demands, enabling companies to maximise output and productivity while maintaining the highest levels of product quality,” he claims.

The IRB 1010 is designed to suit the narrow spaces and special purpose machines typical of electronics production environments. With a reach of 370 mm and a footprint of 135 mm by 250 mm,

the IRB 1010 is 30% smaller than ABB’s current smallest robot, the IRB 120. These compact dimensions increase the number of cells that can be fitted into production spaces, enabling manufacturers to boost output through higher density factory layouts.

Capable of handling loads up to 1.5 kg, ABB says its IRB 1010 has the highest payload in its class, with the ability to lift up to three times more weight than comparable robots. This increased payload capacity – coupled with a larger diameter air hose that provides added power for vacuum suction – enables simultaneous handling of multiple objects, allowing more objects to be processed per hour. It also opens opportunities for new applications including film peeling, materials handling, assembly, gluing and inspection.

T 01908 350300

W www.abb.com/robotics

Flow wrapper stable is extended to meet all customer needs

Ilapak has been appointed as the official UK agent for IMA Record, taking on exclusive responsibility for sales and servicing of all Record flow wrapping machines across the UK.

Companies in the bakery, fresh produce and other food industries with existing Record equipment can now rely on Ilapak for all their servicing, spares and technical assistance requirements, and Ilapak will also handle all sales of new Record flow wrappers.

This agreement gives users of Record’s flow wrapping technology access to Ilapak’s technical support capabilities, including 24/7 back-up from the largest team of flow wrapping engineers in the UK and a £1 m readily available UK-based spares inventory, says Ilapak.

IMA Record was acquired by the IMA Group in October 2020, joining the IMA FLX Hub –a collective that was created within the IMA Group to maximise the synergies and expertise. Ilapak can now offer three flow wrapper brands to support any product from any size of end user in any industry.

020 8797 2000

W www.ilapak.co.uk T

New Machinery 12 MACHINERY UPDATE JANUARY/FEBRUARY 2023 www.machineryupdate.co.uk

The robot offers accurate handling

Riggs MU M-J 2022

Pasteurising solution benefits organic exfoliants processing

The continuous pasteuriser from Holmach and Revtech Process Systems of France is being used in the cosmetics industry for processing the bio-degradable fruit stone and nutshell grit that is now being used as an exfoliant within natural creams and serums. Offering potential as a profitable by-product for fruit processors, the kibble can require pasteurisation to ensure the eradication of harmful microbial flora including Listeria monocytogenes and Salmonella which is naturally occurring in the environment.

MAXIMISING SHELF-LIFE

To retain the organic nature of the exfoliant while maximising product shelf-life, Holmach and Revtech Process Systems offer the heat treatment solution in the form of its continuous pasteuriser. Revtech’s technology sees the fruit by-product being indirectly pre-heated in a controlled environment, prior to the use of a steam flush to achieve the wet kill. Condensation is carefully controlled to ensure there is no regrowth of micro-organisms and the treated grit can be delivered directly to manufacturers for immediate use or be stored in a clean environment in sacks or bulk bags after cooling.

Managing capacities from 200-5,000 kgs an hour, the system is independently validated to 5 or 6 log reduction with destruction of pathogenic micro-organisms. The unit is fully electrically powered, ensuring it can run solely on renewable sources.

T 01780 749097

W www.holmach.co.uk

Do more with Domino Cloud

Domino understands that integrating innovative, new equipment into the toughest production lines requires reliable, compliant products, simple integration and a consistent global support infrastructure. Domino’s latest technology offers in-built future-proofing to keep pace with customers’ increasingly intelligent factories.

Seconds of downtime could mean lost revenue. Domino’s portfolio of cloud, vision and automation solutions allow you to increase accuracy, quality, and reliability.

Domino are trusted by a wide range of food, beverage, life sciences and industrial manufacturers, as well as global packaging machinery manufacturers who partner with us to offer fully-integrated and engineered solutions.

www.machineryupdate.co.uk JANUARY/FEBRUARY 2023 MACHINERY UPDATE 13

More Insights More Uptime Learn more: www.domino-printing.com

More insights More uptime

Upgrade offers efficiency gain

tna has added the new tna auto-splice 3 to its packaging portfolio which is designed to be the perfect pairing with the tna robag 3e vertical form, fill and seal (VFFS) packaging system.

The development helps food producers address labour shortages and rising resource costs.

REAL-TIME BENEFITS

“The ‘Perfect Pair’ speaks to the challenges our customers face and represents an evolution of our portfolio that will deliver real-time benefits,” explains Alf Taylor, md & ceo at tna. “Connectivity is king, and intelligent communication between packaging systems and their auxiliary equipment will allow operators to make their lines work even more efficiently, improving their ROI,” he says.

The simplicity of the tna robag 3e VFFS system makes it easy to operate, service and maintain. This latest unit reduces cabling infrastructure

by 20%, enabling easier servicing and lower total installed costs. The tna robag 3e also shares common core components with tna roflo distribution conveyors and the tna intelli-flav seasoning system, reducing the need for additional spare parts stocking, while its smart diagnostics and remote connectivity allows real-time communication for faster global servicing support.

Fast, simple and flexible, the tna robag 3e features integrated control and a refined design for easy control and maintenance on-the-go.

Designed for seamless cohesion with the tna robag 3e, the tna auto-splice 3 is a compact solution that splices packaging film automatically, with no downtime or interruption to the packaging process. The new rotary reel swapping feature makes it easier to access and replace the film roll without having to stop the packaging system.

T 0121 628 8900

W www.tnasolutions.com

New case packer is a compact unit

The latest case packer from Lan Handling Technologies has been redesigned with an even more compact footprint. In addition to its high capacity (currently up to 160 trays per minute) and accurate product placement by the 6-axis robotic arm, the company says its new design delivers significant benefits.

For instance, the height and width of the robot cell have been reduced, making this machine easy to fit into existing factories with limited available floor space or height. Benefits include simplified on-site transport through

existing wicket doors and placement of this compact case packer on or under a mezzanine floor. In addition, the control cabinet is also easier to access due to its new placement at a working height. These case packers are used for a wide product range that include flow packs, nets, bags, top sealed and vacuum packaging which can be loaded into both crates and boxes. Depending on the product type, the robot tool is equipped with vacuum or mechanical grippers.

T 00 31 2040 72040

W www.lanhandling.com

WATCH THIS SPACE FOR VMECA’S NEW AND IMPROVED VACUUM CONVEYOR

BRINGING PNEUMATICS AND VACUUM TOGETHER

• Dustless conveying of your dry powder or granular produce

• Convey food materials, pharmaceuticals, chemicals, plastics and other free flowing granular products

• Clean, safe compressed air driven multistage vacuum pump, pre delivery ATEX approval upon request

• Low maintenance with self-cleaning filtration, yet high level of capacity from 0.6TPH to 9TPH

New Machinery 14 MACHINERY UPDATE JANUARY/FEBRUARY 2023 www.machineryupdate.co.uk

The case packer from Lan Handling can be installed on or under a mezzanine

01299 877770 sales@simmatic.co.uk www.simmatic.co.uk Unit 11, Sandy Lane, Stourport-On-Severn, DY13 9QB

VMECA product specialist and UK agent for over 20 years. Vacuum challenges? Simmatic has the solutions.

NEW COMINGPRODUCTS SOON

Programmable roll handling option replaces manual work

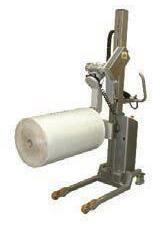

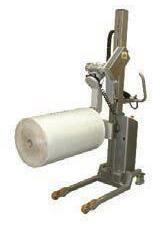

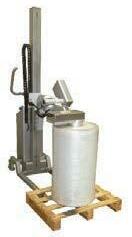

New from Packline

Modular designs

Materials Handling is an automated, robotic, and programmable roll handling solution that has been designed to lift and rotate rolls independently and automatically with no manual handling or operator intervention. Constructed from stainless steel, this roll handling solution is suitable for clean room high care environments such as those found in the food, drinks, pharmaceutical and medical industries.

This new solution has been designed to lift and rotate rolls independently and automatically with no manual handling.

It features programmable automated controls to lift, rotate and accurately place rolls of film or foil, and the preprogrammed settings enable the operator to simply press the ‘start’ button to initiate the roll handling procedure.

Unit replaces any manual handling

The lifting solution includes a fully powered vertical spindle lifting and rotating attachment which is fully motorised to provide powered drives for both the roll gripping and release as well as the roll rotation to and from the vertical to horizontal orientations.

The rolls are securely gripped by the core which enables the operator to lift and transport rolls with complete confidence.

T 01202 307700

W www.packline.co.uk

New Machinery 16 MACHINERY UPDATE JANUARY/FEBRUARY 2023 www.machineryupdate.co.uk

Kenos® foam grippers info-uk@piab.com 01509 857010

New denester is boosting output

MPE UK is launching a new range of denesters that it says, are compatible with nearly all types of packaging materials and machinery.

This compact model is capable of integrating into any production line, denesting different sizes and shaped trays with a simple five-minute magazine changeover.

It is easy to operate and capable of running large format trays, including cardboard packs, while taking up minimal factory floor space, due to its small footprint.

The robust MPE denesters are built from food grade materials, and they can load about 200 trays a minute before filling.

The self-regulating system can be used with any flat blue belt or indexing conveyor with full control over speed. MPE can also create a bespoke mount for any new machines requiring this speedy solution. Developed and manufactured in the UK, MPE’s denesters can be bespoke to a customer’s requirements for speed and accuracy at the beginning of a process. “Our equipment can help customers achieve their objectives including increased productivity and packaging accuracy,” MPE’s technical director John Hodgkiss tells Machinery Update.

T 01663 732700

W www.mpe-uk.com

Cartoner upgrade will deliver flexible lock-style technology

With lock-style technology, Syntegon is launching the latest upgrade of its proven Sigpack TTM cartoner platform. The lock-style process involves forming completely glue-free cartons and trays from carton blanks. Trays can be produced from 100% recyclable materials since they do not require any further gluing steps to securely close the carton. By eliminating adhesives during forming, maintenance efforts are significantly reduced which

enables manufacturers to lower their energy, maintenance, and also their materials costs.

Companies can choose between two options when integrating the lock-style technology into their production: they can order it together with a new TTM top load cartoner or retrofit existing machines to benefit from the higher pack style flexibility of their equipment.

T 01332 626262

W www.syntegon.com

www.machineryupdate.co.uk MACHINERY UPDATE 17

The denesters bring operational benefits

Regenerative braking can save energy

Motion control and robotics company Yaskawa has developed a solution for the recovery of robot braking energy and offers this feature as standard on its larger Motoman robots with a payload upwards of 50 kg.

Its latest YRC1000 robot controls are able to convert kinetic energy from the down and sideways movements directly into 400V AC at 50 Hz and feed in back into the grid. Depending on the movement pattern of the application, this means the robot’s energy requirements can be significantly reduced.

In applications such as handling, palletising, joining and processing, industrial robots make many down or sideway movements during which the servomotors dissipate energy while potentially generating electricity. Unlike previous options, using the Yaskawa solutions allows the electric energy to be fed back into the operator network – without the need for additional hardware so it can be re-used.

The extent of savings obviously depends on the specific application and the robot’s individual movement patterns, although realistically, savings ranging from 8 to 25% can be anticipated which may result in annual feed-ins of about 2,800 kWh, equivalent to about 1600 kg CO2 and £1200 savings.

T 0330 678 1990

W www.yaskawa.eu.com

Bolt-on sensor offers condition monitoring

Sick has launched its MPB10 Multi-Physics Box condition monitoring sensor, which it describes as a pioneering and rugged bolt-on device designed to deliver realtime, continuous service data from industrial machines, including electric motors, pumps, fans and conveyor systems, even in the harshest industry environments.

A first condition monitoring sensor from the company, the MPB10 is an all-in-one device designed to make it easy to monitor and interpret vibration, shock and temperature measurement data delivered right from the heart of machines. The MPB10 provides service data to enable more cost-efficient predictive maintenance practices that can improve plant availability, maximise operating life, and protect product and also process quality.

The MPB10 measures vibration, shocks and temperature that can be the tell-tale signs of approaching machine failure. Users are

provided with pre-processed, concise and easy to interpret information that can be customised for the machine and process.

A stand-alone MPB10 can transmit data over IO-Link to a machine control or output a simple alarm-based switching signal. With wide-ranging measurement parameters, the sensor can be set up according to the type of machine to alert, for example, when values exceed pre-configured thresholds.

Users also have the option to visualise real-time and historic data from the

MPB10 on easy-to-interpret, customisable dashboards using the Monitoring Box digital service.

“The Sick MPB10 is a rugged little instrument with the potential to add huge value to industrial machines and processes,” says David Hannaby, Sick’s market manager for presence detection. “Maintenance effort and costs are reduced because reactive interventions can be avoided, and time-consuming routine preventative inspections can become less frequent.”

T 01727 831121

W www.sick.co.uk

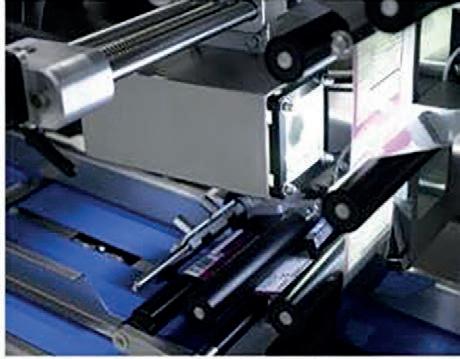

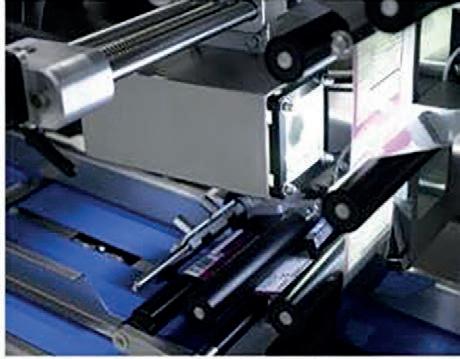

Direct web printer portfolio is extended to deliver variable data on tray sealers, flexibly

Multivac has developed the DP 245, a new, direct web printer for its X-line series of tray sealers that although operate at a fixed working height, can automatically adjust to possible differences in the height of finished packs.

“With this new process and IP65 protection, we are taking direct web printing to a new level,”

Even trays with different product protrusions are marked safely, reliably, and precisely thanks to the new technology. The printing position on the pack can be easily and conveniently adjusted using handwheels, so that batch changes require only minimal downtime.

This variable data, such as the best-before date or a batch number, is printed with the Multivac TIJ 10.

T 01793 425800

W www.multivac.co.uk

New Machinery 18 MACHINERY UPDATE JANUARY/FEBRUARY 2023 www.machineryupdate.co.uk

explains Michael Reffke, product manager for marking technology at the company.

The MPB10 from Sick is protected by a rugged IP68 stainless-steel housing

Energy costs are now reduced

The DP 245 has an optional washdown version

COMPLETE END-OF-LINE PACKAGING SYSTEMS HIGH-SPEED PACKAGING LINES SHRINK WRAPPING SLEEVE WRAPPING TRIMSEALING CASEERECTING &CASETAPING PALLET WRAPPING E-COMMERCE AUTOBAGGING FLOW WRAPPING FEEDING& SEPARATION SYSTEM SPIRAL WRAPPING www.adpak.co.uk 3PENDLESIDE,LOMESHAYEINDESTATE,NELSON,LANCS,BB96RY Tel:01282601444 | Fax:01282612201 | info@adpak.co.uk ADPAKCANDELIVER ENDOFLINE PACKAGINGSOLUTIONS THATARERIGHTFORYOU

Kensal

Handling Systems

• Stainless steel conveyor systems

• Standalone units or fully integrated

• Robotic and end of line equipment

• Bespoke engineering capabilities

• Turnkey and standalone solutions

• Integration and project management

• Service support and upgrades

• Partnered with Lita Palletising Systems for over 30 years

www.kensal.com | sales@kensal.com | tel: +44 (0) 1 582 425 777 Kensal Handling Systems Ltd, Kensal House, President Way, Luton, LU2 9NR

New Machinery

Expanded gripper range offers all round benefits

Laser coding range delivers maximum marking resolution

Macsa ID UK has introduced a newly simplified modular laser platform to deliver maximum marking resolution on a wide range of substrates which is easy to install and operate, is cost effective, versatile and reliable.

The clean and energy efficient SPA 2 series of modular laser coders boasts a modular design and can be easily integrated with any production line or application to provide high quality marking on a range of packaging materials such as wood, thermal labels, board, metallised board, glass, ceramics, metals, rubber and also plastics.

There are two basic SPA 2 printheads available to users for different speed and quality needs.

T 01462 816091

W www.macsa.com/en-uk/

Following the acquisition of vacuum gripping solutions company Joulin last year, Piab has integrated three of Joulin’s gripper ranges into its Kenos portfolio, while products for heavy duty industries including the wood industry continue to be marketed under the Joulin brand.

The Kenos MiniGrip is suitable for the FMCG, food and beverage and automotive industries. It is a foam gripper that can be adapted to tight clearance applications in end-of-arm tooling (EOAT). Its foam surface offers the versatility to pick a variety of different objects without adjustment. While in the case of uneven layer heights, it can be equipped with level compensators without needing to change the existing mounting device.

THE COMPLETE SOLUTION FOR:

SHRINK WRAPPING MACHINERY

SHRINK FILM

STRETCH WRAPPING MACHINERY

STRETCH FILM

E-COMMERCE PACKAGING

& SERVICE

Suitable for the food and beverage, automotive and construction sectors is the new Kenos FlexiGrip. This vacuum foam gripper can be used as a single gripper on robots as well as on cobots or combined into an EOAT for use with industrial robots. With its foam surface, it offers the flexibility to pick a variety of different products without adjustment. Its modular design provides the flexibility for fast and easy set-up in case of product changes as well as simple integration into existing equipment.

Finally, the Kenos Safe&Light can be used in applications such as packaging, warehousing and end-of-line production. Thanks to its carbon fibre structure holding a foam made body, this lightweight product allows users to make maximum use of the robot or cobot payload. It is a robust and simple solution for a broad range of purposes, particularly for palletising applications in rugged and also dusty environments.

T 01509 857010

E info-uk@piab.com

www.machineryupdate.co.uk JANUARY/FEBRUARY 2023 MACHINERY UPDATE 21

Piab can deliver custom options across a wide range of technologies and for various sectors

Printer heads are easily switched

SUPPLY THE FILMS SPARES & SERVICE P CHANGE OLD MACHINE SUPPLY A MACHINE Contact us today T 01484 715111 E info@yps.co.uk W www.yps.co.uk

SPARES

YPS MU J-A 2021 ARTWORK

Danish equipment will bring a range of user gains to UK

Equipment built by Danish company the VARO Group can now be purchased in the UK from the packaging division of Friedheim International.

Martin Howells, UK sales manager for Friedheim’s packaging division believes the new Varo range of equipment which includes a pallet unwrapper and the E-Com packer will be a great benefit to UK users.

The Varo E-Com packer offers a 50% minimum saving on cardboard consumption and speeds of up to 1,800 packs per hour which will reduce packaging costs and help with current labour shortage issues while the Varo pallet unwrapper allows customers to reduce breakages, decrease forklift truck movements and removes the stretch film for immediate recycling.

T 01442 206100

W friedheimpackaging.co.uk

Flexible laser marking system brings benefits

Murrelektronik says that as a complete system of hardware, software and accessories, the MurrSystems LM-3 laser printing system provides a cost-effective solution for producing quality, non-durable labels for a variety of applications. This can include the identification and security marking of wires, cables, components and control panels.

As laser marking has become faster and more accurate, the technology is often now the preferred method for permanent marking of metal and plastic labels in a diverse range of industry sectors.

“I’m very confident that laser marking technology will continue to get more precise and more cost effective in the future,” explains Tim Bradbury UK sales and technical engineer at the company.

“The LM-3 is already at the forefront of this technology and offers a complete laser marking solutions for companies and organisations

A more accurate process of producing inhouse labels

looking for a faster, more accurate process of producing inhouse labels and ID tags.”

The LM-3 can label onto polycarbonate, polypropylene, adonised aluminium, stainless steel or laser foils and produces durable labels that are UV, acid, oil and chemical resistant. The system can function under extreme environmental conditions and does not require any additional consumables such as printer cartridges, ink, thermal transfer ribbons or even toners. The whole inscription process is completed by laser, inside the unit.

Automated batch processing

to perform at a high output. The magazine filling aid mp-LM B enables a smooth and time-optimised labelling process due to parallel preparation of the magazine loading. The mp-LM carrier plates are used to flexibly hold various MurrSystems labelling materials.

Labelling material can be stacked directly in the labelling magazine, as can separator plates to allow mixed loading in one batch.

T 0161 728 3133

W www.murrelektronik.co.uk

22 MACHINERY UPDATE JANUARY/FEBRUARY 2023 www.machineryupdate.co.uk

New Machinery

The E-Com packer is now offered

www.machineryupdate.co.uk JANUARY/FEBRUARY 2023 MACHINERY UPDATE 23

04-10 May 2023 Düsseldorf – Germany Booth 13/a33

Inspection systems are tailored to

Pack Expo Review

Visitors were keen to see new technologies

Back in Chicago after 4 years, PACK EXPO saw over 44,000 attendees come together for the most comprehensive packaging and processing event of the year, according to organisers PMMI. Over 2,200 exhibiters greeted visitors last autumn, and here, we highlight just some of the products on show from PPMA members stands at this major international exhibition…

Barry Wehmiller group showed latest technology on offer

BW Packaging Systems showcased several customer-focused solutions from Accraply, BW Flexible Systems and BW Integrated Systems at PACK-EXPO. This year’s stand highlighted the shared progress BW Packaging Systems and its customers have made solving prominent industry challenges through ongoing dialogue about labour shortages, sustainability and food safety standards.

MID-SPEED PALLETISER

BW Integrated Systems’ Maximus mid-speed case palletiser, which meets increased customer demand for a flexible high-level palletiser, made its first appearance on the stand, while BW Flexible Systems’ Hayssen ISB vertical form, fill and seal machine, returned to PACK EXPO after its successful debut at PACK EXPO Las Vegas in 2021. Leveraging the latest technology in intelligent, sanitary bagging for food, this solution includes several improved features that have been added after a year of conversations with end users.

Accraply’s new MK6 pressuresensitive/TE band labelling solution was also on display. With Accraply’s SmartLink HMI as a standard feature, the MK6 brings together labelling and tamper-evident sleeving in a single solution. It is specifically designed to meet the demands of fast-moving, highly flexible production lines.

W www.accraply.com

W www.bwflexiblesystems.com

W www.bwintegratedsystems.com

Self-support and helpdesk printer services are offered

Markem-Imaje introduced its MiVista connected printer services at PACK EXPO, which is designed to streamline and improve daily coding operations across the printer fleet. Using a tested and proven IoT platform –developed with knowledge gathered across 17,000-plus software installations and honed by analysing data from over 4,000 printers in the field – the services provide manufacturers with continuous insight and support.

MiVista services empower customers to:

• Operate efficiently: Realtime visibility and printer alerts provide increased self-sufficiency and automated risk monitoring… anytime, anywhere.

• Improve continuously: Predictive analytics, automated improvement alerts and proactive prevention advice from Markem helpdesk experts deliver 360-degree printer performance insight which

increases uptime and also reduces costs.

• Resolve quickly: Advanced remote diagnostic capabilities allow Markem’s helpdesk technicians to streamline root cause determination and quickly identify the best way to get production up and running.

“The benefits of the new MiVista will further enhance our customers’ service experience,” said Mark Hathaway, product marketing manager, connected devices & solutions services at MarkemImaje. “This connected printer services offering is available in

various levels of functionality to suit the operational style of each customer individually.”

MiVista works seamlessly with Miva (intelligent, selfsupport solution) and along with Remote Video Support is an integral part of the company’s comprehensive remote services offering. Markem says that when used to its full potential, this new service suite will make the break/fix scenario an exception rather than the rule, delivering peace of mind across the printer fleet.

T 0161 864 8111

W www.markem-imaje.com

Group demonstrated a range of end of line equipment as well as case packer options

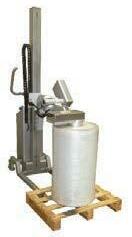

Robopac and OCME demonstrated its end of line packaging solutions at PACK EXPO that the Aetna Group has developed to effectively meet the needs of different product sectors.

Among the technologies on show was the Robot S7, the flexible, standalone unit with stretch film and R-Connect technology, in line with all industry 4.0 requirements and ideal for handling products of any size, shape and weight.

There was also a Technoplat, for fully automatic pallet wrapping; a Masterwrap HD, a semi-automatic rotating arm wrapping machine, ideal for stabilising unstable and heavy loads as well as the new Orbit R horizontal stretch

wrapper with rotating ring, which can be added to integrated work cells or lines.

OCME showed TopTier palletisers, available with integrated stretch wrapping, and intralogistics solutions that, with laser guided LGVs, reduce labour costs and, at the same time, improve production efficiency.

T 01234 825050

W www.aetnagroup.com

The new MiVista platform on show features advanced security protocols

The Robot S7 was shown

24 MACHINERY UPDATE JANUARY/FEBRUARY 2023 www.machineryupdate.co.uk

Solid dose ranges can be handled on integrated line

At PACK EXPO, Uhlmann presented the first bottle line for solid dose products with an integrated serialisation unit. This bottle line IBC 150 with integrated metal detector in a compact monoblock is billed as a world first.

The serialisation unit S 500, which has been optimally adapted to the bottle line, was also on show.

Visitors to the stand could experience the entire packaging process for solid dose products in bottles –from bottle unscrambling to 100% correct figures, feeding of solid dose products and desiccants, sealing, labelling and serialisation of bottles. The focus was on the enhancements in the packaging line IBC 150 – including the new bottle unscrambler BU 300, the first metal detector integrated in a monoblock, the single tablet reject function and the serialisation platform S 500 for the serialisation of bottles. Highly automated,

Uhlmann presented the entire IBC 150 bottle line at the show in Chicago diameter can be converted to a different one in just six minutes. The entire line is controlled in a standardised manner via the user-friendly SmartControl operating system – from the new bottle unscrambler BU 300 to the integrated bottle centre 150 through to the serialisation platform S 500. All bottles are handled carefully and gently.

networked and flexible – the IBC 150 is designed to pack small to medium sized batches of solid dose products in bottles. The monoblock line, measuring about five metres, processes on average up to 150 bottles and 24,000 tablets or capsules per minute. Rapid product changeover and short ramp-up phases also make the line attractive for CMOs, CDMOs and manufacturers of food supplements.

For example, the bottle

T 01252 743120

W www.uhlmann.de

• Increases shelf life (for up to 3 days)

In brief

A VERSATILE PORTFOLIO

Syntegon presented a broad brand portfolio of versatile processing and packaging solutions at PACK EXPO including a new intelligent direct handling pick-and-place system, two packaging lines for confectionery and bakery products; flexible solutions for replacing plastics with alternative packaging materials; individual service agreements and a special software solution. Visitors to the stand found insights into robotic handling solutions, automation technologies, as well as advanced and sustainable system concepts.

W www.syntegon.com

SOLUTIONS FOR PHARMA

Marchesini demonstrated new systems for the pharmaceutical industry including the Compact 24, a monobloc machine for filling and capping tablet, capsule or pill bottles. This solution covers multiple operations with a single machine and ensures high levels of efficiency in the crucial counting and capping phases. The monobloc is equipped with a transport system that employs magnets to overcome the limits generally associated with standard transport systems.

W www.marchesini.com

• Medical, Pharma, Parts

• Greener packaging options

• Food-to-Go and Convenience packs

• Less food waste

www.machineryupdate.co.uk JANUARY/FEBRUARY 2023 MACHINERY UPDATE 25

FROM SINGLE PACK MANUAL TO HIGH SPEED LINEAR AUTOMATIC MACHINES 2 YEAR RETURN-TO-BASE WARRANTY SOKENENGINEERINGISPARTOFTHEJENTONGROUP

QUALITY

HEAT SEALING MACHINES FOR SANDWICH, WRAP, SALAD AND READY MEAL PACKS

P A C K S E A L S E L L www.sokenengineering.com 01525 376 000

Robotic system handles teacakes gently, accurately and with speed

High speed, high accuracy and gentle handling combine on an advanced robot-based secondary packaging machine that Cama devised for a customer in Peru to handle chocolate covered teacakes. With their thin delicate skin of chocolate, the teacakes present an interesting challenge from a packaging perspective, says Cama, a challenge which is compounded by the speed and volume by which they are normally manufactured.

In addition to these product and volume challenges, Cama was also unable to deploy a counterflow system (often

preferred in these types of applications) and instead had to develop and modify one of its co-flow solutions.

“Due to the layout constraints at the plant, the only option was to deploy a co-flow layout that was tailored to precisely fit the limited space,” explains Alessandro Rocca, group sales director at Cama Group. “Counterflow is preferred in these fast-moving lines, as there is less chance of un-picked products exiting off the end of the conveyor.

“Indeed, the order criteria actually included a maximum figure for unpicked products.”

However, Cama was

confident that its equipment would be capable of meeting this challenge because it uses in-house developed robotic solutions. “These are robots with one single purpose – secondary packaging in a Cama machine – it’s perfect machine/robot synergy,” says Rocca. “In fact, by enhancing the common working envelope of the robots, we have actually minimised the chances of products being missed – even at these throughput speeds.”

The co-flow line, where products and cartons move at the same speed and direction, comprises two primary interconnected modules, namely FA series two head box-forming machines and IG Series multi-Delta, visionguided robotic loading units. In operation, the teacakes exit a cooling tunnel at a rate of

400 products per minute, in multiple rows on a main transport conveyor. On entry to the IG series packaging machine, a vision system ascertains the individual product’s positions on the belt and this data is fed to the central PLC for disbursement to the eight robots in the packaging area.

The products, which are still at 20deg C, are gently picked and placed into cartons (preassembled by the FA series machines) running on a track parallel to the main conveyor. A subsequent vision system is used to ascertain optimum filling, before two more robots are used to close and seal the cartons in multiples based on the format count.

T 01793 831111

W www.camagroup.com

26 MACHINERY UPDATE JANUARY/FEBRUARY 2023 www.machineryupdate.co.uk

Installation News

Teacakes can be tricky to handle

Packline Ltd • Unit 28 • Newtown Business Park • Ringwood Road • Poole • Dorset • BH12 3LL T: 01202 30770 • E: info@packline.co.uk www.packline.co.uk ■ Bespoke Design ■ Stainless Steel Construction ■ Compact and Manoeuvrable ■ Lifting Capacity up to 300kg ■ Interchangeable Attachments ■ Handle Reels of Film or Foil, Drums and Barrels

Cama says its in-house developed robotic solutions deliver operational gains

Packline third

High shear mixer has developed protein bar

In preparation for the launch of a new protein bar ready-to-mix product, Winkworth has recently worked with a whey ingredient supplier to strengthen its capabilities within the category.

The customer needed a pilot size mixer that could conduct trials during its development phase to replicate large scale industrial

production methods. The customer’s bakery mixers, used for similar pilots, were not able to mix the dense ingredients of the whey protein isolate and dairy proteins sufficiently to be effective.

The company required a high torque kneading and folding mixer that could effectively mix 5 kg batches and Winkworth recommended its stainless steel MZ10 high shear mixer. Featuring twin heavy duty Z blades and a manually operated hydraulic tilting mechanism, the 10 litre capacity of Winkworth’s range of laboratory and pilot mixers are small enough to reduce waste, yet large

enough to be representative of production reality. This accurate representation of production performance typically provides a scalable outcome prior to full capital investment.

“Throughout this smooth process we had good support from Winkworth –the mixer is ideal for our requirements and is delivering what we hoped for,” says the customer. “We are frequently showing the mixer to our customers who, like us, are very impressed with its overall capabilities.”

T 01256 305600

W www.mixer.co.uk

Triple finishing equipment purchase is improving flexibility and staff options

Print, direct mail and fulfilment specialist

RNB Group has praised the impact of a triple finishing equipment purchase from Friedheim International, revealing that the investment has helped to significantly improve production flexibility.

The company installed a Hunkeler unwinder UW6, Spedo 8500 E stacker with tray (second user) and Spedo 2600 pinless cutter 2600 a few months ago and as well as offering flexibility, they will also allow the company to expand further.

“The devices have allowed us the flexibility to produce more with less down time, while they have also helped to streamline our paper-to-envelope

time,” explains RNB’s project and account manager Dave Martin.

T 01442 206100

W www.friedheimpackaging.co.uk

• Proven technology

• Sturdy robust design

• Quick and easy set up between size formats

• Supplied in either tape or hot melt application

• Various options available

• UK engineering support/install

The installation has now helped to free up staff

www.machineryupdate.co.uk MACHINERY UPDATE 27 Machinery Southern Manufacturing Review Installation News

Being able to mix small batches makes it ideal for pilot studies and product trials

Lantech

17 Elizabeth Court, St Neots, Cambridgeshire, PE19 8PF T: 01480 382739 M: 07764 772965 E: andrew@maters.co.uk www.maters.co.uk CS1000H

C1000/2000 case erector from Lantech

modular case erector capable of up to 30 erected cases per minute

Latest robotic pre-roll packaging system is ordered for cannabis

CME’s latest export contract will provide in-house developed automation for the cannabis sector in Canada.

Under this latest contract, CME will provide a robotic pre-roll packaging system to a Canadian customer. This flexible, stand-alone system will be using two SCARA robots to pick up pre-rolled cannabis joints, which are presented in a random fashion on a vibratory feeding system. The products are then transferred and placed in a set configuration and orientation within a tray.

Off the shelf technologies were used

This compact and costeffective system can process up to 60 pre-rolls per minute with the vision system being used for product identification, position, and orientation, before the SCARA robot selects the product and transfers it to the packaging. Full sensor monitoring is also included for product quality and materials supply.

The system is designed to be quickly adjusted to operate across five different packaging formats and product quantities.

Developed using a combination of different off the shelf technologies, CME says the system provides both consistency in the way product is handled, predictable productivity levels, and a minimum of operator intervention.

T 01460 269500

W www.cme-ltd.com

Installation News 28 MACHINERY UPDATE JANUARY/FEBRUARY 2023 www.machineryupdate.co.uk

Tel: 0 1865 8 9 1466 Email: info@cap c ode r.com To d is cover mo re a bo u t th e m ac hi ne s th at cou l d t ran sform you r comp any please v isit: www. ca pc ode r.com

Ready meals factory is using a retort unit for gentle cooking

The Kirsty’s ready meals brand is now using a second Lagarde retort unit, supplied by Holmach, to meet increased demand for its healthy, flavourful foods.

The initial retort was purchased to deliver a short gentle steam cook to the sealed tray, neutralising any bacteria to extend shelf life while also sealing in the flavour and nutrients. The increased shelf life provided wider distribution opportunities. Hence the second purchase which has increased capacity to 40,000 meals a day.

“Holmach’s Lagarde retorts have not only reduced our carbon emissions and minimised the risk of food being wasted, but it has also increased our capacity,” says company founder Kirsty Henshaw.

T 01780 749097

W www.holmach.co.uk

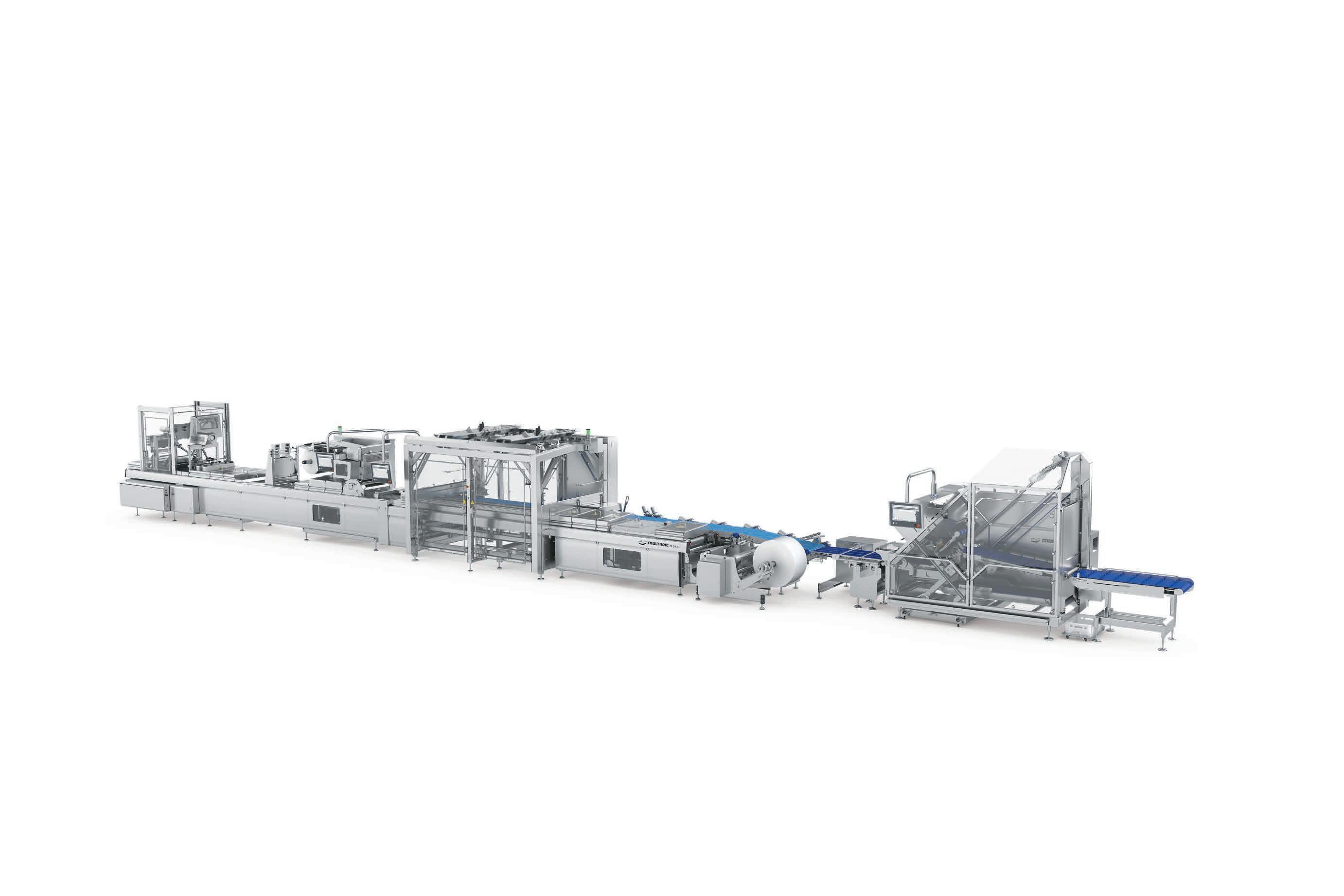

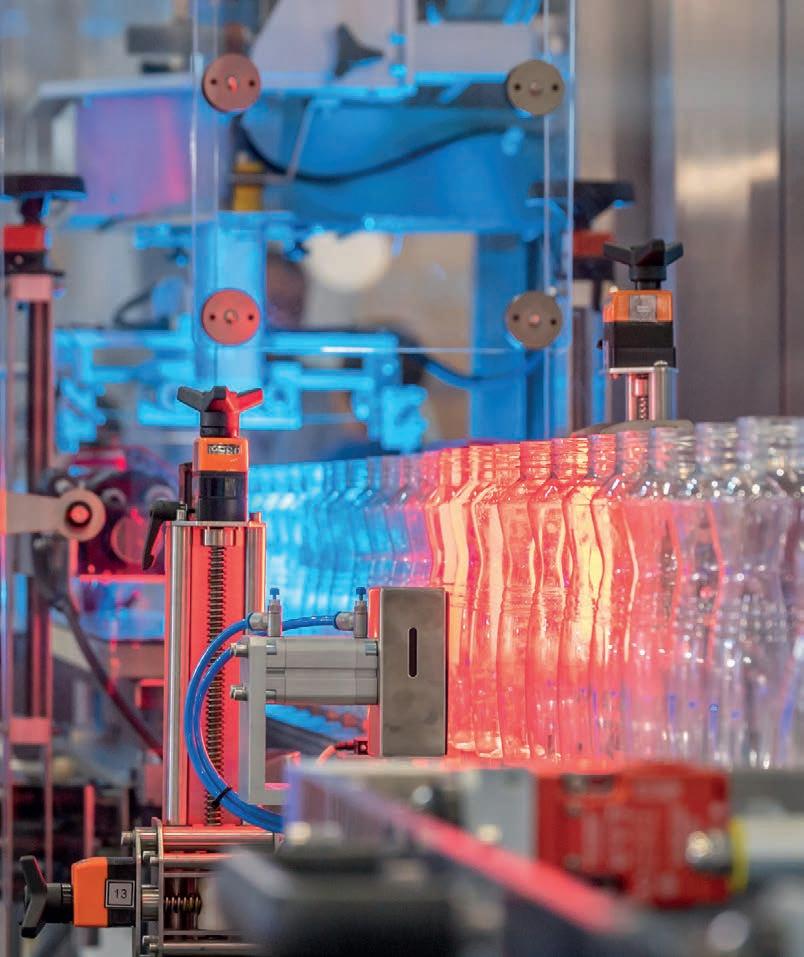

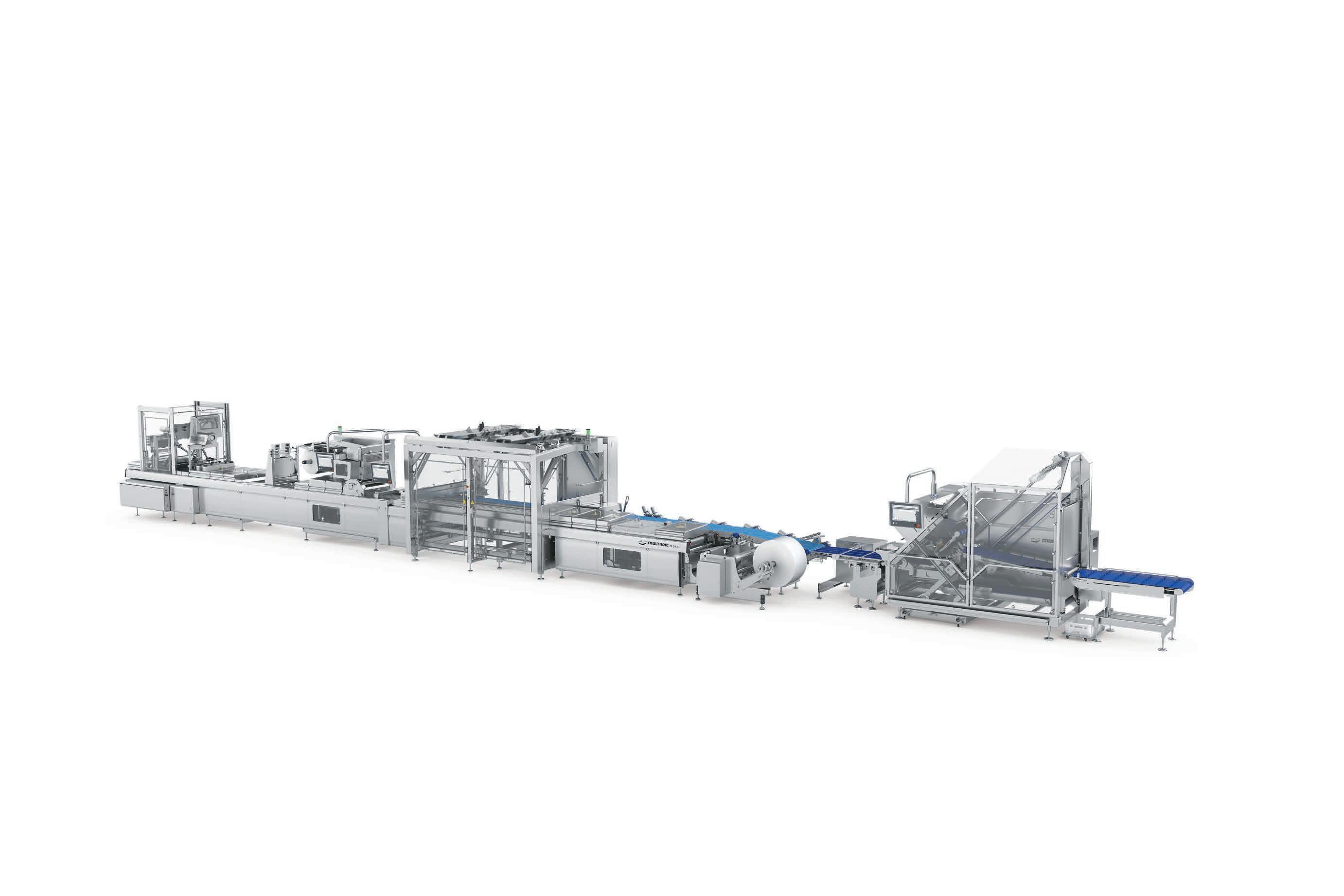

New weigh/pack solution brings accurate efficiency

Danish vegetable production company

DanRoots has invested in Newtec’s weighing and packing solution for its snack carrots in 500 g and 200 g bags to optimise production in a sustainable way.

The new weighing/packing line consists of Newtec’s weighing machine, model 4015B2, which is designed for accurate weighing of smaller portions and two Redpack machines for packing the snack carrots in recyclable 200 g bags.

To meet the root vegetable producer’s sustainable goals, the foil consumption on the packaging machines has also been adjusted so that there is no waste in the form of a ‘snip’ or too large a bag. By minimising waste, offering precision of portion size while reducing energy consumption without compromising product quality, the Newtec weighing/packing solution delivers on DanRoots’ overall green initiatives.

The company says that it

now uses less energy on the new weighing/packing line while better food quality is ensured by not damaging the product.

The company says that the biggest optimisation it has experienced when installing the weighing/ packing technology, is the subsequent reduction of labour requirements.

“By reducing the possibility of human error and the reliance on manual labour, our new line helps preserve the quality of the product and ensure production is at the highest

level with minimum giveaway rates,” says Lone Kondrup, project director at DanRoots. “This means less waste in terms of product, energy, and also cost.”

The advantages of automation are also evident with regards to Newtec’s optical sorting machines installed at the company, which grade products according to size, shape and quality, thereby customising production and optimising product selection.

T 01406 426526

W www.newtec.com

Bagging and palletising solutions are helping to optimise the workflow at a building materials and aggregates firm

RMGroup has supplied bagging and palletising solutions to Dumfries-based building materials and aggregates supplier J&J Currie to increase efficiencies and reduce labour costs. The project included an MB-400 manual bagging machine and a robot palletiser, followed by a BB-215 bulk bagging machine.

J&J Currie, who supply an extensive range of sand and decorative gravels, began their search for a manual bagging

system and robot palletiser earlier in the year, principally to alleviate manual handling labour requirements and their associated costs. Having secured a number of quotes for the required

solutions, the company found RMGroup’s equipment prices to be more competitive and placed an order.

The installation of the initial system, required to pack and bag all types of aggregates, consisted of an MB-400, RMGroup’s most popular bagging machine, and an ABB IRB 460 palletising robot, which was installed to automate the palletising. The MB-400, capable of filling pre-made bags up to 400 bags an hour, comes complete with

a 5 m 3-tonne hopper, rubber trough conveyor feed belt, electronic load cell bag clamp, weigh indicator, 4 m filled bag conveyor complete with guide panels, and an SH1000 continuous heat sealer.

More recently, J&J Currie also purchased RMGroup’s complete bulk-bagging system, the BB-215, the installation of which occurred within three weeks of the order being placed.

T 01686 621704

W www.rmgroupuk.com

www.machineryupdate.co.uk JANUARY/FEBRUARY 2023 MACHINERY UPDATE 29

All the products have been awarded the international certification for food

The BB-215 was installed in one day

The retorts have delivered gains

Security against more than just cyber-attacks…

Industrial security not only includes the protection of data, but at the same time also guarantees the integrity of safety functions and measures.

If a production worker starts up a plant, for example, even though they are not authorised to do so, this is already considered a security incident. This manipulation, even if unintentional, endangers the safety of other employees. This makes it even more important to consider safety holistically – because it also plays a key role in questions of liability, explains Pilz.

Compared with the more tangible topic of machinery safety, industrial security still appears to be more of an abstract concept. Many people primarily associate it with external cyber-attacks, but security is relevant down to the smallest machine in a production facility. Security encompasses safety, ensuring its integrity and thus the protection of human and machinery. With the new European Machinery Regulation, security measures will become obligatory from 2025. But companies are already working to ensure the safety of personnel, machinery and data.

If management fails to implement general organisational measures and instructions when structuring work, it can be held liable for this. Problems such

as near-accidents or the occurrence of new risks at the workplace must result in suitable measures. Regular checks identify any need for action in good time.

Employee protection goes hand in hand with liability protection: The operator of the plant or machinery is responsible for the protection of its employees and must take appropriate measures.

A third area that is becoming increasingly relevant is, of course, data protection. Security is often associated with this and there is great concern that an attacker could manage to access a

company’s network. Data and expertise must be protected against external attacks as well as from danger originating within the company.

These areas are not only relevant for reasons relating to liability, but they also have a major influence on a company’s productivity. And so, to ‘play it safe’, security precautions must be regularly scrutinised and adapted to the current conditions. An holistic risk analysis indicates possible weaknesses and includes both safety and industrial security. Based on this analysis, appropriate measures can be taken, and the machinery retrofitted, if necessary.

Comprehensive identity and access management, meaning the regulation of accesses and entrances, could be an adequate solution for a manufacturer. If an access permission system PITreader is used, only authorised people are issued an RFID key with their individual permissions for plant and machinery on which they carry out work. They only achieve the desired access after they authorise themselves on the machine by inserting their key into the PITreader.

Authorisations can be issued and managed centrally. If there is however a safety incident or manipulation, the system can be used to track who last worked on the machine.

30 MACHINERY UPDATE JANUARY/FEBRUARY 2023 www.machineryupdate.co.uk

Compared with the more tangible topic of machinery safety, industrial security still appears to be more of an abstract concept says Pilz, but a more holistic approach to safety should be taken

Feature: Security

▸

The Branson GSX has the latest data security

Feature: Name here

or individually, data about component parts, and data about the quality of individual ultrasonic welds, including the day, time and operator in charge.

A related upgrade to the Branson GSX ultrasonic welding platform gives it the latest encryption technology that ensures the integrity and security of data transfers. After authenticating the identity of the data recipient, this technology ensures secure data transfers from welders on the manufacturing floor to local or remote enterprise quality management systems, or to customer systems. The authentication process ensures that the data is coming from a reliable source (the welder) and that the welder is not sending data to an unidentified fraudulent attacker. This secure data-transfer process delivers Industry 4.0/industrial internet of things (IIoT) capabilities while supporting everything from secure, in-field system software upgrades and patches to remote data analysis and remote system troubleshooting and diagnostics.

With cybersecurity becoming more of a focus, Phoenix Contact says the introduction of IEC62443 and a shift from a product only approach to an holistic way of thinking, means it has the ability to cover cybersecurity needs.

If machines are to be protected against unauthorised access and manipulation, an industrial firewall such as SecurityBridge from Pilz also offers protection. It monitors the data communication within an industrial automation network. To protect the data flow of a production facility, switchable and activatable products can also be an appropriate measure to lock out attackers. And these measures can be easily integrated or retrofitted into an industrial application.

Safeguarding the integrity of manufacturing systems and data is a critical responsibility for every equipment producer, says Tom Ayars, software engineering manager for Branson Welding and Assembly at Emerson. “Because we recognise the operational impact of cyber events – the potential costs of downtime, scrapped production, and lost or corrupted data – we adhere to a ‘secure-by-design’ approach for our manufacturing technology,” he explains. This approach embraces industryrecommended standards of cyber protection throughout a product’s life cycle. Emerson’s product development is based on International Electrotechnical Commission (IEC) 62443, the global standard for the security of industrial

automation control systems and networks.

The secure-by-design approach is embodied in the company’s latest ultrasonic welding platform, the Branson GSX, which has been upgraded to provide data security and integrity features modelled on frontline computers and servers that connect directly to the internet.

The GSX welding platform can now support the stringent data-integrity and security requirements of the U.S. FDA’s CFR 21 Part 11 medical device regulation.

FDA requirements include validating users for system security, creating audit trails capable of identifying data manipulation, and delivering data to meet FDA traceability regulations. Traceability requirements extend to all forms of manufacturing data: data that provides a complete audit trail, data that can trace finished devices by lot

With Phoenix Contact’s new mGuard family, not only can users protect their network, but it also makes it future proof with Gigabyte throughput over the firewall, meaning the protection is not giving users a bottleneck at the most crucial point.

Data is the new oil of this world, says the company, everyone wants it, everyone needs it but not everyone is a cybersecurity expert, nor have they the means to pay for a full-time specialist. Phoenix Contact can help with its Firewall assistant. This feature reads in a network using PCAP data, while the network is in full operation and then recommends firewall rules. This way, companies can allow and deny network paths easily.