The machinery only journal for processing and packaging; robotics and vision systems

This issue, our feature looks at the meat, poultry, fish and protein sector, examining the role that product data can play in lifting quality and boosting the bottom line

Early March saw the very first UK Automation Forum round table event streamed, with its prestigious panel showing the momentum growing around automation in manufacturing

Sidel’s latest filler for PET is said to improve hygiene and product quality, while still remaining simple in design and compact with features that enhance sustainability Find out more on page 15

Carlsberg has invested in can filling and a Snap Pack gluing system for its smaller multipacks

Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod tincidunt ut laoreet dolore magna NEWS PLUS

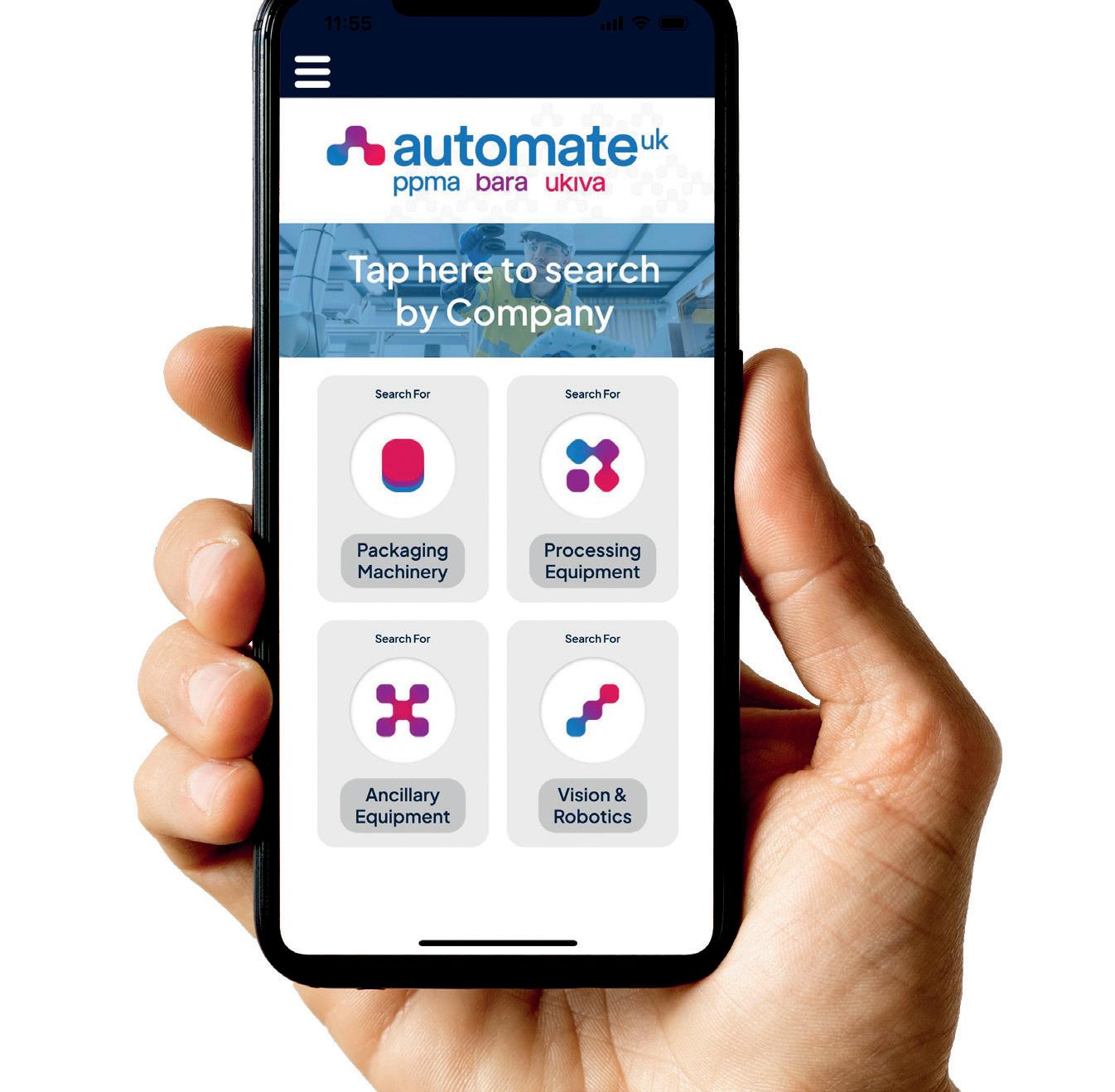

Check out the new branding for Automate UK on the website and learn more about the goals of the renamed association www.automate-uk.com

Being a driver of industrial digitalisation, our mission is to make outstanding optical technologies available to companies of all sizes. This also applies to vision sensors, which, as the “eye” of Industry 4.0, play a significant role in the implementation of digital evolution. Our vision: cutting-edge technology, available to all!

7 NEWS

14 NEW MACHINERY

18 INSTALLATIONS

Automate UK members are supplying systems to process and pack animal and plant proteins in ways that allow brands to stand out on shelf

EDITOR:

Paul Gander

paul.gander@automate-uk.com

PUBLISHING MANAGER: Bill Lake bill.lake@automate-uk.com

HEAD OF PUBLISHING: David Chadd david.chadd@automate-uk.com

BUSINESS DEVELOPMENT

EXECUTIVE:

Stephen Badgery stephen.badgery@ automate-uk.com

AN AUTOMATE UK PUBLICATION

PPMA Ltd

Progress House,

12 REGULATIONS

The PUWER regulations can far too often be taken for granted or thought of as being too complex to comply with, but can be approached in a logical, straightforward manner. Risk assessments are required on all types of work equipment, both at the time of installation and then at regular intervals, with any records being kept up to date

42 COMPONENTS

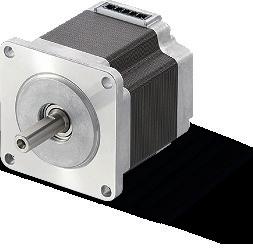

Motor condition monitoring can be a valuable weapon in the battle to detect failures before they trigger unplanned downtime, and OMRON has servo, in particular, covered

47 WHO WHAT WHERE People, events and diary dates

48 MACHINERY FINDER Members’ machinery and services

One day, we won’t need special daysCausebrook

f like me, you work with many brilliant, talented and astute women in your own workplace, at your suppliers and at your customers, you must share in my frustration that we still have to consider it a ‘thing’.

Of course, this is easy for me to say, as a man who runs an engineering business, but the sad fact is that despite progress in gender equality and growing interest over the last decade, women continue to be under-represented in STEM fields. And my frustrations are not just about how few women are found in manufacturing roles, but also how those that are involved can sometimes be treated. I have worked on many projects over the last year in which female participants have made the most telling contribution, and yet these ideas have subsequently been hijacked by male colleagues or at least their input has had to be ‘validated’ by the blokes on the teams. Why is this still happening? Surely, in 2024, we should be celebrating the success of the individual and not the success of the gender of an individual across our society.

However, in 2023, the gender gap in STEM remained significant, with women making up less that 30% of the global STEM workforce. This is obviously why there is still a need for the annual International Day of Women and Girls in Science that promotes awareness and dialogue to celebrate the accomplishments of women and girls in STEM and encourages young people to consider a future career in these fields. This year, it took place in February and Automate UK members got involved (see page 8).

To help provide a brighter, more diverse future in the STEM world, Automate UK – through its Automate BEST charity –runs STEM days designed to show why engineering is a great career choice, as well as providing bursaries, grants and annual engineering scholarships to attract girls and boys to our sector. Indeed, a woman from Middlesex University won last year’s scholarship.

I am also proud to say that one of the key drivers behind the formation of the brand-new UK Automation Forum was a female director from the Automate UK board. This new forum held its first event in March (see page 7) and saw a panel of experts discuss how greater automation adoption would benefit UK PLC. Oh yes, and it was hosted by a woman. n

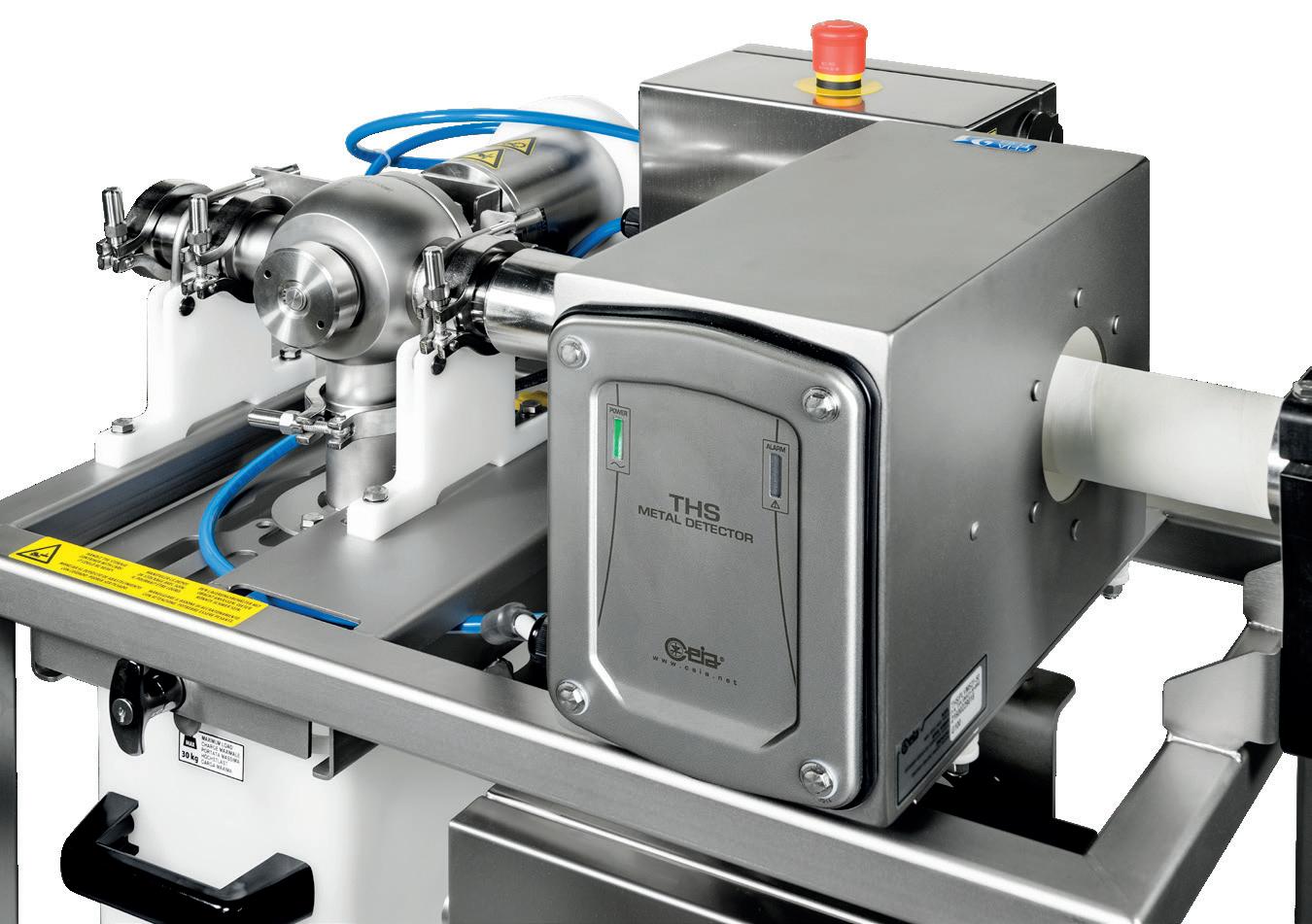

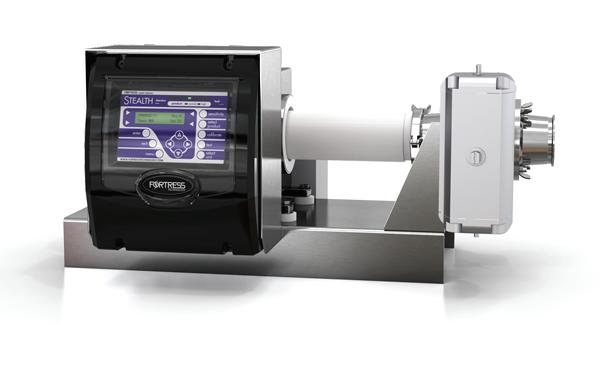

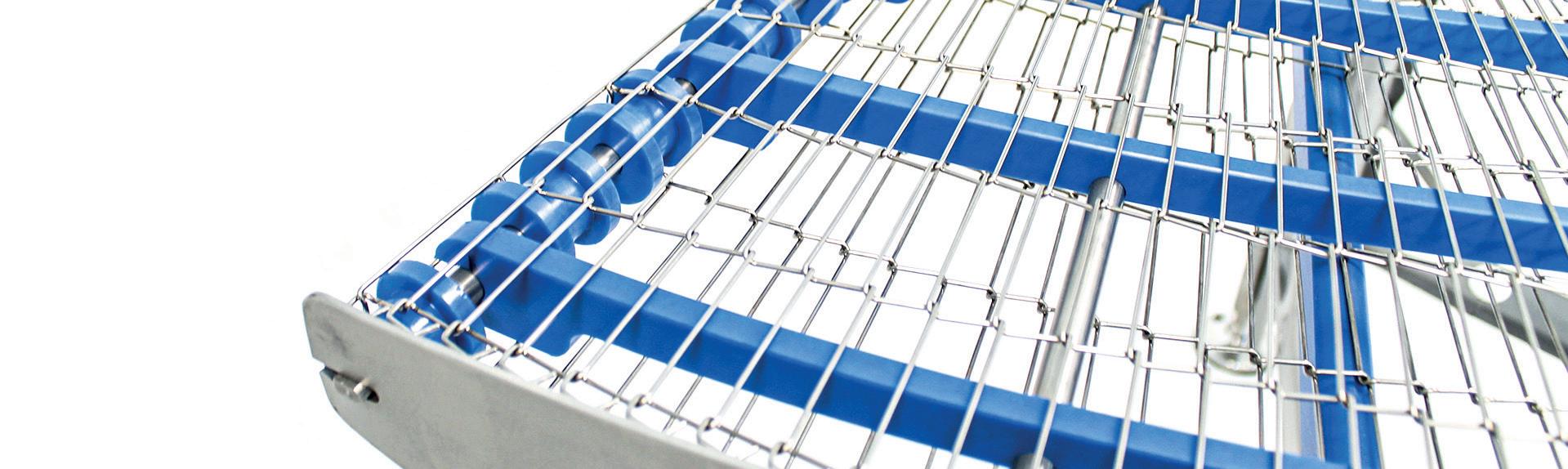

• AUTOMATIC LEARNING & TRACKING of product effect

• DIGITALLY ADJUSTABLE BELT SPEED

• RUGGED AISI 316L stainless steel CONSTRUCTION and food-compatible plastic parts (EU, FDA COMPLIANT)

The opening of its new 35,000sq ft headquarters and manufacturing site in Sunderland brings robotics and automation specialist Yaskawa UK closer to customers including Nissan UK, but the company predicts growth across many sectors, including food & drink and packaging.

“This represents a huge vote of confidence in the UK, and our new location in the North East is a significant driver for major industrial investment,” says MD David Walsh.

The company says it also plans to increase the size of its workforce during 2024.

The location is close, too, to the International Advanced Manufacturing Park.

With the first

UK Automation Forum event going live in early March, and Peter Williamson taking up a formal role within Make UK alongside his position as CEO in a stronger, more influential Automate UK, a new national landscape in manufacturing automation is taking shape.

Schubert Business Development (SBD) is joining with automation specialist Weiss in new robotics startup pssbl. (pronounced ‘possible’), with easy access and open systems a priority.

Williamson joined representatives of the manufacturing and equipment supply sectors, of Make UK, the Manufacturing Technology Centre (MTC) and Manufacturing Technologies Association (MTA), in evaluating the current state of UK manufacturing and how further automation could benefit the sector.

“The aim is to use our combined voice to influence

Cobalt Systems has moved to a new manufacturing facility in Wardle, Cheshire. The site includes a visitor centre, demonstration suite and expanded manufacturing capacity. “This means reduced lead times from order to delivery and significantly improved manufacturing efficiency,” says MD and founder Tony Hunt (pictured, centre). Investment includes on-site CNC machinery.

government and policy,” says Williamson, who is now chair of the affiliate partner board at Make UK.

“We are creating a community of leading experts and businesses to ensure that all members of the industry have a voice,” adds Mike Wilson of the MTC, chair of the new Forum.

The first roundtable, hosted by Gail Hunt of Automate UK, can be viewed at: www.ukautomationforum.com

For the second year in a row, Germany’s Mosca GmbH has been named Best Mechanical Engineering Company by Focus Money, as part of its ‘Company of the Year 2024’ study, outperforming higherprofile businesses such as thyssenkrupp.

“Being named Company of the Year once again demonstrates that we are well-positioned with our solutions, and continue to live up to the high level of trust our customers place in us,” says CEO Timo Mosca.

It has made strong progress in service, innovation and sustainability.

“The spectrum of activities that people will be able to use robots for in the future is very broad,” comments SBD partner Gerald Schubert. The plan is to launch robots with open control systems and intuitive programmability.

“Strategic partnerships that benefit everyone involved are very important to us,” adds pssbl. MD Tobias Frank. “We want to move away from silo thinking.” Weiss and SBD hold equal shares in the company.

Industrial camera manufacturer

IDS Imaging Development Systems GmbH says it saw 15% growth in its business in 2023, compared with the previous year, outperforming the sector as a whole in Germany. Innovation has been a significant driver of growth, says the company, and further launches are planned for the coming year.

Cama Group is a leading supplier of advanced technology secondary packaging systems continuously investing in innovative solutions.

www.camagroup.com

cama-UK@camagroup.com

e rightly celebrate events such as International Women’s Day in March, and International Day of Women and Girls in Science in February, say women in industry, but still need to do more to address gender inequality in science, technology, engineering and maths (STEM) disciplines.

Last year’s World Economic Forum Gender Gap report put the proportion of women in STEM-related fields at 30% globally. Nationally, figures for the US sit at 24%, 17% for the EU, 16% for Japan and 14% for India.

Carole Noutary calls out inequality

“This inequality is concerning, as it leads to a lack of diversity and inclusion and ultimately will limit the potential of the STEM industry,” says Carole Noutary, Beyond Printer director at Domino Printing Sciences. Wendy Tonks, lead system test engineer at OMRON Europe, underscores the benefits of being part of a diverse Dutch R&D team. “It results in different ways of thinking, which can be really helpful when solving problems,” she says.

Autonomous mobile robots need to be able to navigate evolving surroundings

ABB has acquired Swiss start-up Sevensense, with its expertise in AI-enabled 3D vision navigation technology for autonomous mobile robots (AMRs).

The company was founded in 2018 as a spinoff from Swiss technical university ETH Zurich. It joined ABB’s innovation ‘ecosystem’ in 2021, the same year that ABB acquired ASTI Mobile Robotics. Pilot projects have already taken place in the automotive and logistics sectors.

President of ABB Robotics and Discrete Automation Sami Atiya points out that each

Tooling up for successful training

Automate BEST funds new tool set

Line Equipment apprentice Ben Rose has used an Automate BEST grant to buy new tools. Company owner John Blashkiw says this will help him to improve his skills. “He’s an excellent trainee, who enjoys engineering,” he adds.

AMR can work autonomously in a rapidly-changing environment, differentiating between fixed and moving objects.

“This marks a significant step towards our vision of a workplace where AI-enabled robots assist people, addressing our customers’ needs for greater flexibility and intelligence, amid critical skilled labour shortages,” he says.

According to the company, the market for mobile robots is expected to grow at 20% CAGR through 2026 to reach a global value of $9.5 billion.

Germany’s Possehl Identification Solutions (PID) has acquired a majority stake in Advanced Labelling Systems (ALS).

The company, based in Thame, was founded in 1997 by Noel Donaldson. Current directors Phil Donaldson and Ian Turner explain: “Being part of a larger European group of labelling and marking companies allows us to give our products a wider reach, while bringing our expertise into the group.”

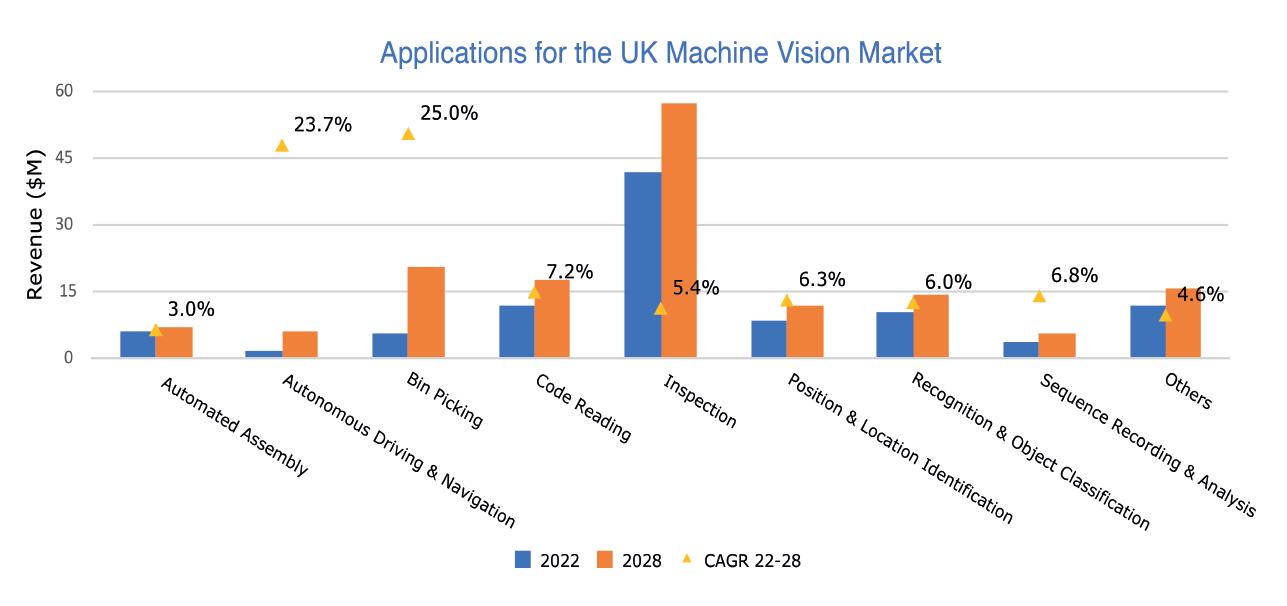

Data from Interact Analysis forecasts that the UK machine vision (MV) market will rebound from negative growth last year to outstrip rates for global markets up to 2028. Lead analyst Jonathan Sparkes tells Machinery Update that MV markets in the UK were worth $100.5 million in 2022, but declined to $95.5m last year. A small bounce back up to $98.2m is expected

for 2024. Compound annual growth (CAGR) of 7.6% is forecast to 2028, taking market size to $156.2m.

Inspection is expected to remain the largest single application, but bin picking is likely to show highest growth (25%). CAGR for autonomous driving is put at 23.7%.

Global growth over this period is put at 6.4%.

Asia Pacific accounts for the largest market (34.5%), followed by EMEA (28.4%).

Eriez has announced the inauguration of a new research and development (R&D) hub, Eriez at sbarc, at Cardiff University in Wales, with the company’s R&D team now operating primarily from this site.

The supplier says mutual

co-operation progressed from membership of an advisory board to a successful Engineering and Knowledge Transfer Partnership (eKTP) up to 2022. What resulted from this was a “groundbreaking” series of metal detectors, scheduled to launch this year, and an

ongoing Artificial Intelligence (AI) feasibility study, supported by Innovate UK.

Executive vice president of global technology Mike Mankosa says: “Joining forces with Cardiff University has been instrumental in driving innovation at Eriez.”

Medical device contract packing company Riverside Medical Packaging has announced the demerger of its equipment business unit Shawpak.

First created in 2014, Shawpak was always intended to grow as a medical device packaging machinery business to the point where it could operate as a standalone company, says chief executive David Shaw. The strong collaboration with – and innovation support for –Riverside will continue, he adds.

Equipment includes rotary thermoforming, three side seal pouch-making and tray-making. The machinery business has an installed base in 25 countries and a subsidiary in the US.

Machinery safety is much broader than compliance with the Machinery Directive (EU) or the Supply of Machinery (Safety) Regulations 2008 (UK). The Work Equipment Directive, which has been implemented in the UK by The Provision and Use of Work Equipment Regulations 1998 (PUWER) and The Li ing Operations and Li ing Equipment Regulations 1998 (LOLER) must also be considered.

PUWER applies to all work equipment regardless of its age, regardless of the machinery being CE or UKCA marked or not.

PUWER describes what an employer needs to do to protect employees in the workplace and is applicable to all work equipment. If work equipment is used in a li ing operation, then LOLER applies in addition to PUWER. It is therefore the responsibility of machinery owners to ensure that they meet these regulatory requirements.

While many machinery end-users may think that they have PUWER compliance covered, we continue to see common hazards and issues that have not been adequately addressed. Meeting the requirements of PUWER can be complex, but if a logical and practicable approach is adopted it doesn’t have to be unworkable.

PUWER provides a link to

The Management of Health and Safety at Work Regulation and requires users of work equipment to carry out a risk assessment and provide work equipment that is suitable for its intended task, and which can be used without putting people at risk. PUWER covers any machine, appliance, apparatus, tool or installation for use at work (whether exclusively or not).

PUWER assessment is an ongoing process that must be repeated at appropriate intervals, and should always refer to the latest standards, not the standards that were applicable when a machine was rst brought into service.

As an overview, inspections should be carried out:

• A er installation and before being put into service for the rst time; or a er assembly at a new site or in a new location to ensure that it has been installed correctly and is safe to operate;

• A er work equipment has been exposed to any conditions causing deterioration, which is liable to cause a dangerous situation;

• At suitable intervals; and

• Each time that exceptional circumstances have occurred that are liable to jeopardise the safety of work equipment.

The results of inspections have to be documented and kept until the subsequent inspection is recorded

Regulation 6 of PUWER also requires that inspections must be repeated ‘at suitable intervals’ if machines are exposed to conditions that may lead to deterioration. In reality, every machine is exposed to conditions that will lead to deterioration, so the requirement e ectively means that they must all be periodically inspected. The results of these inspections have to be documented and kept until the subsequent inspection is recorded. This means that there should be a current inspection report kept on le at all times.

PUWER also requires machine users to ensure that the CE or UKCA marking process has been properly carried out through Regulation 10 of PUWER, “Conformity with European Community Requirements”. Therefore any equipment subject to a Product Directive or Regulation should meet all applicable Essential Health and Safety Requirements (EHSRs) that apply to it.

In total, there are 39 PUWER regulations plus 17 LOLER Regulations. While some of them are rather lengthy, it is possible to construct a simple checklist to determine

the necessary actions for compliance. If this process reveals that a potential hazard exists, then a risk assessment must be carried out, with the implementation of appropriate control measures documented.

So ware is available to help you automate this checklist process, and the suppliers of the best packages will be happy to adapt them as necessary to deal with special requirements. It should also store results locally or in the Cloud and produce appropriate reports to con rm that the work has been carried out with due diligence, as well as generate a list of any outstanding action points.

While machinery safety is a complex process, the guidance that is widely available means that there is no excuse for getting PUWER wrong. A thorough and correct risk assessment should therefore be completed before any new machinery goes into operation and if substantial modi cations are made, to ensure that machinery meets all requirements. If in doubt, seek expert advice as the safety of your employees and the reputation of your business may depend upon it.

The perfect partner for the entire value stream

Having launched its Cigno traysealer, G. Mondini is extending the capabilities of the range with the addition of a skin pack variant, the Cigno Skin, which combines gas ushing with skin application.

The company stresses the compact design and ‘plug-and-play’ simplicity. Changeover is also straightforward, with tooling changes taking as little as 2 minutes to perform. The single-lane machine is designed with hygiene in mind, and is fully washable.

The servo-driven system can run at 25 cycles a minute with gas ush and 15 cycles a minute for skin packs.

The Cigno and Cigno Skin are supported by an augmented reality tool, combining the best of the virtual and real worlds. This system o ers advanced remote assistance, rapid diagnosis alarms and 3D visual-based training, including easy-to-follow tutorials, says Mondini.

The tool allows other media such as drawings, pictures and videos to be viewed alongside the machine section under analysis.

Regarding the Cigno product line as a whole, the company says that the ergonomic design means downtime is kept to a minimum, with die-change systems which can be interchanged quickly and easily to accommodate multiple pack formats.

Last year, G. Mondini UK launched The Cigno Roadshow, which allows the machinery supplier to demonstrate the bene ts of its system on-site at customers’ own facilities. Since the entire ‘show’ can be set up in just 15 minutes, says Mondini, teams can experience the system rst-hand with minimal disruption to their schedule.

T 01785 812512

W www.gmondini.com

AM Labels has for the first time demonstrated its LabelPack COMPACT WA automatic bottle applicator and the Afinia Label x350 digital roll-to-roll press.

The LabelPack COMPACT WA applicator is designed to apply labels to bottles, jars and cans. Meanwhile, the Afinia Label press, which can be sourced directly from AM Labels, is a high-volume labelling and flexible packaging press suitable for use in various industries including food, beverage and the chemicals sector. LabelPack applicators now straddle the range between entry-level models and highperformance print-and-apply systems, says AM.

Both systems were shown for the first time at the Packaging Innovations 2024 Show in February in Birmingham. 01536 414222 W www.amlabels.co.uk T

Carton

feeder extends machine running times while fitting in with a modular approach and compact footprint

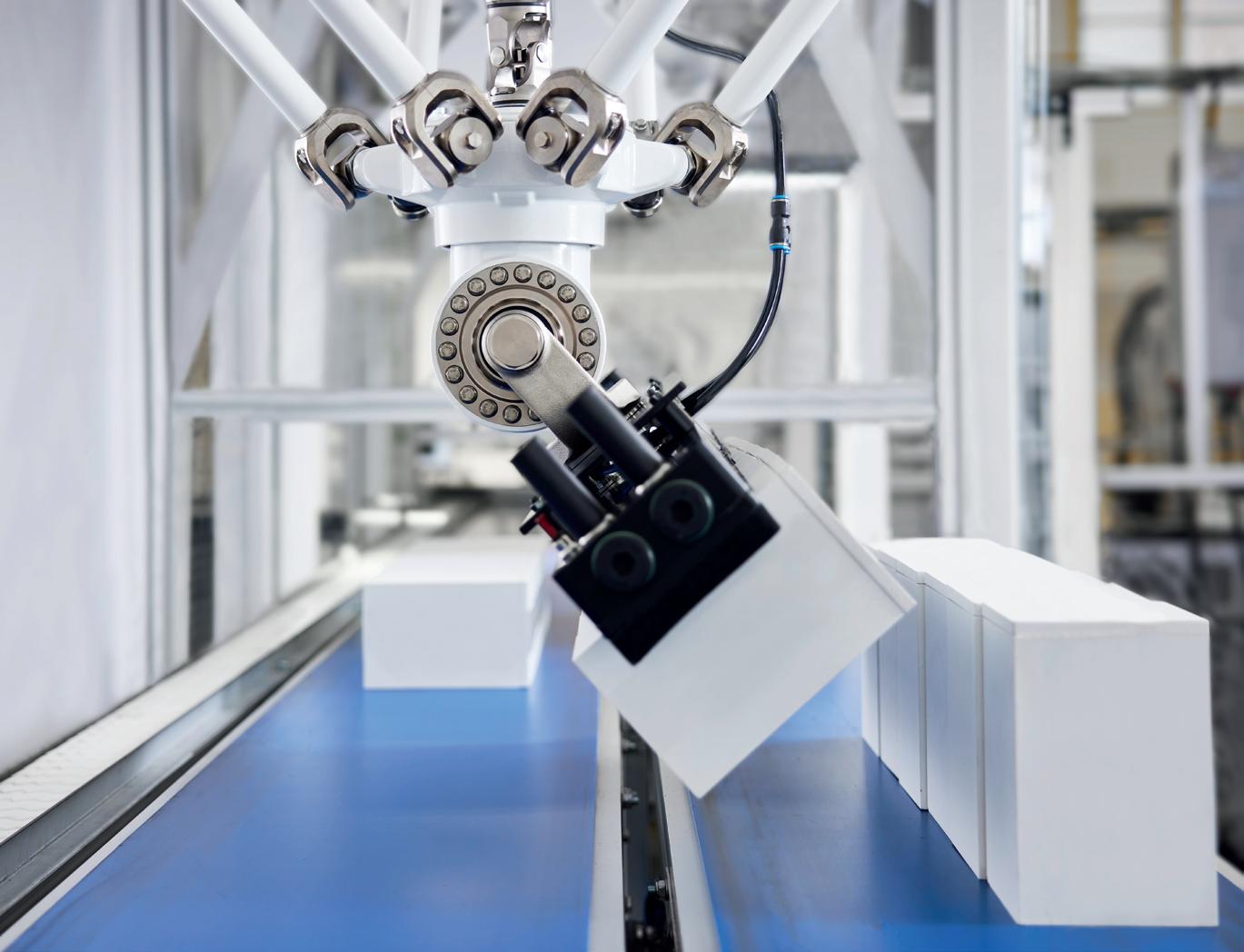

In response to industry pressures such as higher energy and raw material costs, as well as labour shortages, Gerhard Schubert has introduced a compact system which automates the feeding of carton blanks to its TLM packaging machine, while keeping the process on a modular, expandable basis. The TLM Comfort Feeder addresses the problems commonly caused when the blank magazine repeatedly empties, causing delays in

production. The system, which uses an F4 robot to pull each precut, unglued carton

blank from the magazine while a camera monitors its quality, allows the machine to operate at up to 60 cartons per minute. It will run for up to 5 hours without requiring replenishment with a new pallet load of blanks. Alongside minimising

human intervention, a further advantage of the Comfort Feeder is that it ts with Schubert’s ‘Power Compact’ machine concept. This means that the system is designed to be compact while o ering high output.

A er the infeed, the A6 erector transports each blank to the gluing and folding stations, before placing the erected carton onto the transport system.

T 01676 525825

W www.schubert-uk.co.uk

Acompact filler from Sidel is said to offer improved hygiene and final product quality levels while also showing sustainability benefits and helping to reduce total cost of ownership (TCO).

The EvoFILL PET offers rated production speeds of up to 90,000 bottles per hour on a footprint that is 15% smaller than comparable systems. Sidel notes that in countries such as China, India and Turkey, bottled water is the fastest-developing category for PET.

Product manager for filling at Sidel Tommaso Tegoni underlines the stripped-down design of the EvoFILL PET. “Its simplified configuration, which includes a reduced number of starwheels and a more compact front table and process unit, makes it easier to operate, maintain and clean. These factors contribute to optimal hygiene, which is very important to all our customers.”

According to Sidel, the ergonomic design helps

and can be completed in under five minutes. The filler can be integrated within the company’s Combi and Super Combi complete systems, with the option of linking to its Evo-ON ‘digital intelligence platform’. This allows manufacturers to monitor and optimise all filling and overall performance parameters.

to ensure a consistent repeat performance and accessibility to operators of different skill levels. The reduced filler enclosure creates a controlled environment for contactless flowmeter filling. This again helps to deliver safety and quality in the final product. At the same time, gentle neck handling is designed to safeguard bottle integrity. Sidel’s EvoFILL PET, said to be designed to reduce total cost of ownership

Models can be equipped with between 24 and 144 filling valves, with various pitch and diameter options. Line speed and bottle size –in the range 0.1 to 10 litres – can be tailored to the needs of the specific product.

Whether in manual or automatic mode, format changeover has been simplified, says Sidel,

It is not only changeovers which have been streamlined. In an effort to improve productivity still further, Sidel has made the filler more readily accessible. This allows for faster cleaning as well as changeovers, all of which helps to reduce downtime. The integrated clean-in-place (CIP) system is said to reduce energy usage by 25%, while also cutting water and chemicals consumption by 12%, when it comes to external cleaning.

The improved design, lower operational costs and reduced planned downtime all add up to a lower TCO, Sidel claims.

T 01707 292820

W www.sidel.com

Materials & machinery for the complete solution

Transit & display packaging

Fully-recyclable, sustainable, anti-fog, barrier, MAP packaging and more...

High-speed equipment for demanding environments

Supported by expert engineers, across the UK & Ireland

• Proven technology

• Sturdy robust design

• Quick and easy set up between size formats

• Supplied in either tape or hot melt application

• Various options available

• UK engineering support/install

Penn Packaging is offering the SPM 50 horizontal spouted pouch-making machine for the first time in the UK, explaining that this is a new system developed by German engineering company SN Maschinenbau and Südpack.

The technology, which is suitable for free-flowing and viscous products such as fruit purees, smoothies and yoghurts, is said to be a sustainable and economical alternative to prefabricated pouches. The ability of the system to utilise monomaterial polypropylene for both spout and pouch material is in line with current trends towards recycle-ready formats.

“This is an attractive alternative to using high-priced ready-made pouches, the processing and filling of which often involves a lot of logistical effort,” says Südpack product manager Lutz Neugebauer. “Film can be processed from the roll, which leads to a variety of advantages in terms of efficiency and cost-effectiveness, without having to compromise on quality.”

Pre-made pouches are traditionally supplied on rails, which have to be

W www.penn-packaging.co.uk The

separated out before they can be fed into the filler. But director of global sales at SN Thomas Fuest talks about the SPM 50’s “significantly improved ergonomics of spout and rail handling, as well as high flexibility in terms of different pouches and spout shapes”.

The machine can produce up to 4,200 pouches per hour, or more than 30,000 over an 8-hour shift with a single roll of film. Pouches can be filled and sealed on existing machines, says Penn, with different barrier options available, and are suitable for hot-filling and pasteurisation.

T 01473 893990

TAWI, part of the Piab group, is launching its Container Unloader vacuum lifting system in what it says is a substantial contribution to workplace safety.

The company says its system offers a safe and efficient way of unloading and sorting items within confined spaces, and is especially suited to logistics applications, where it is designed to reduce injuries and associated costs, while enhancing operational efficiencies and minimising staffing requirements.

“The introduction of our Container Unloader marks a pivotal moment for TAWI and the industry at large,” says UK sales manager Matt Baker.

AS FAR AS YOUR EYES CAN SEE: INFINITE OPTIONS FOR PACKAGING FOOD. BROUGHT TO LIFE WITH SCHUBERT.

Being flexible is good, being fast and flexible is even better. Schubert packaging machines are leading the way. Intelligent control and precise robotics can now replace complex mechanics to ensure maximum flexibility in all packaging processes. In fact, 80% of the leading FMCG companies count on us and our flawless packaging combined with the lowest possible consumption. In line with our Mission Blue Sustainability Initiative: A winning proposition – for our planet and for you. www.schubert.group/en/food.html

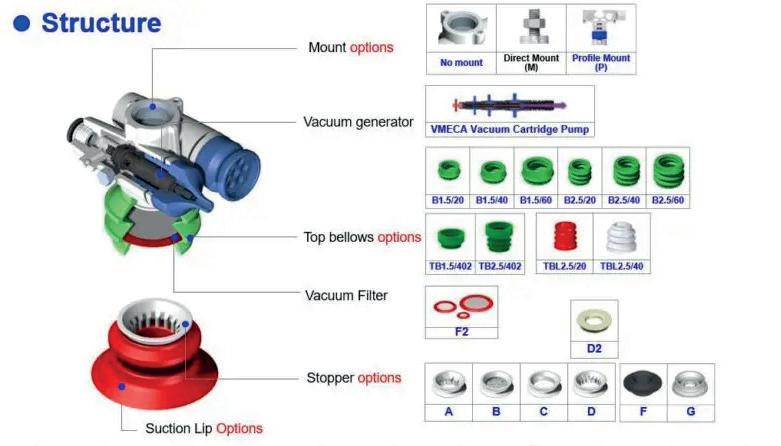

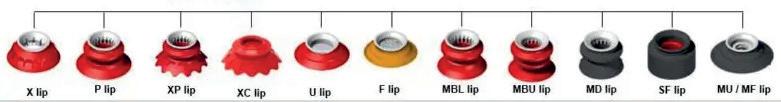

• Detectable suction cups

• FDA and EU compliant

• Wide range of shapes and sizes

• Suitable for different food objects from bread, fruits and pralines to frozen, raw or prepared foods.

erman company Rottendorf Pharma has introduced the FactoryTalk PharmaSuite manufacturing execution system (MES) from Rockwell Automation, with its ability to provide comprehensive batch recording.

According to the contract development and manufacturing organisation (CDMO), the move to this MES suite will provide greater accuracy, quality, efficiency and repeatability in its operations, while also creating a solid foundation for further digitalisation.

The integration of the MES system with central weighing operations is said to offer easy access to consistent data, and is the first step towards ensuring end-to-end electronic batch recording over the company’s entire value chain.

Peter Teszner, Rockwell’s regional vice president for central and eastern Europe, emphasised the challenges of handling multiple batches and formulations at any one time. “By starting at the beginning of the process, the company will have a strong platform from which to expand its transformation,” he said.

IT manager at Rottendorf Arne Groneick added:

“We needed a software platform that was not only pharmaindustry specific, but also demonstrated full validation in the face of widespread, differing and evolving global legislation.”

The CDMO operates under Total Process Ownership (TPO) and Total Technological Mastering (TTM) principles, aiming to reduce customer management resource requirements – and costs.

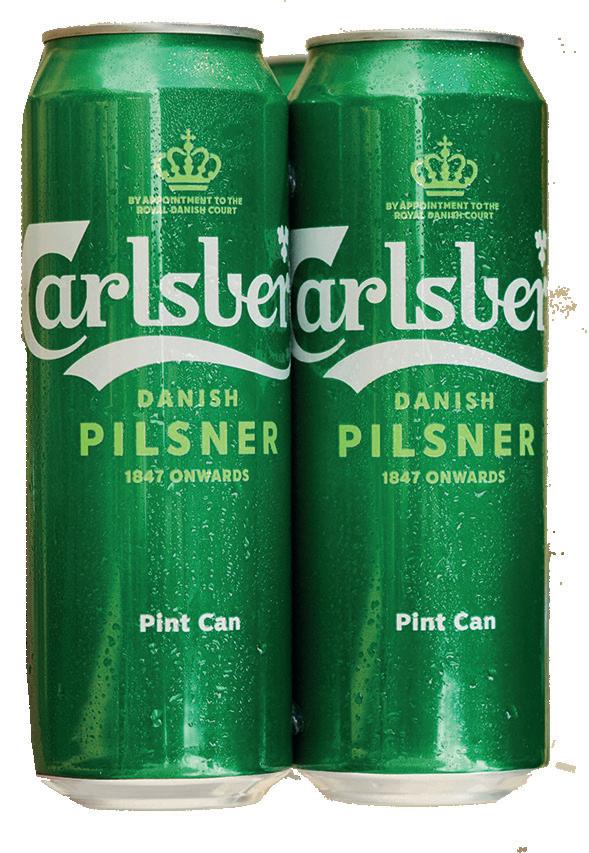

The Carlsberg Brewery in Northampton has invested over €11.5 million (£10 million) modernising its can filling and multipack operation, with new equipment including a KHS Innofill Can DVD filler and Kisters Nature MultiPack (NMP) system.

Alongside the energy efficiency of the filler, benefits are said to include reduced water consumption and the elimination of plastics collation wrap. Instead of plastics, Carlsberg Marston’s Brewing Company (CMBC) applies the Snap Pack NMP technology, which holds the can multipack together using hotmelt glue dots.

cans per hour, and will fill 0.33, 0.44 and 0.5-litre volumes. Executive vice-president for Europe at KHS Edgar-George Petsche emphasised the “trust shown in our flexible can filler” and the company’s “pioneering packaging system”.

The Innofill Can DVD boosts efficiency and operational reliability on

the line, says KHS and will work in tandem with an FS14 Ferrum can seamer, which features a dual infeed for lids. The hygiene zone is particularly compact, ensuring an optimum, targeted flow of sterile air through the enclosure, the company adds. The filler has a rated output of 90,000

For the past five years, CMBC has marketed the NMP system as Snap Pack in the UK, and by the end of 2022, 65% of small multipacks from the Northampton brewery were created this way.

Across the three machines acquired in the upgrade, CMBC estimates that it could reduce its annual water consumption by 10%, or 18 million litres per year.

Vaccine manufacturer Sanofi has relieved the strain of manual case palletising at its Marcy-l’Étoile site near Lyon, France, by introducing a robotic alternative from OMRON: TM12 collaborative robots (cobots). The 9kg weight of each box, as well as the repetitive nature of the operation, convinced Sanofi of the need for automation. The TM12 was chosen because of its performance, range, payload capacity and compact footprint, says OMRON.

Working with materials flow specialist FlexLink, OMRON is able to support Sanofi in all of its locations worldwide. The ability of the cobots to work safely alongside human operators is an important plus.

T

01908 258258

www.industrial.omron.co.uk

ABB Robotics has entered into a strategic partnership with technology and artificial intelligence (AI) specialist XtalPi in order to apply its GoFa collaborative robots (cobots) to the creation of automated laboratories targeting the Chinese market.

The intention is that the new automated laboratories will boost the productivity of the R&D process in industries including biopharmaceuticals, chemical engineering and new energy materials.

Manager of the service robotics product line at ABB Robotics Jose-Manuel Collados said the collaboration with XtalPi marked a further milestone for the company’s cobots in the life sciences sector. “ABB Robotics and XtalPi will radically advance lab research and development through automation that works side-byside with people,” he added. “By enabling pharma and biotech companies to develop new drugs faster and with

less cost, ABB is helping to further research into disease prevention, creating healthier societies.”

The GoFa cobot can perform a range of functions in an automated laboratory over 100 of the cobots in 2022 for its own test facility in Shanghai. This year, it officially launched its XtalPi Intelligent Automation brand.

The lab automation market is important for ABB Robotics. Collados linked the new venture with the recent opening of ABB’s Open Innovation Lab for Life Science and Healthcare in Zhangjiang, Shanghai, which complements its Life Sciences and Healthcare Lab in Houston, Texas.

XtalPi, meanwhile, is very familiar with ABB’s GoFa technology, having bought

Director of automation product management at XtalPi Chenxi Zhang explained that the partnership with ABB would help to improve lab efficiency by implementing the human-robot integration model. “We hope to combine XtalPi’s intelligent software system and industry experience with ABB’s expertise in robotics to bring more innovative solutions

to the pharmaceutical sector.”

According to ABB, workstations can be customised to meet specific process requirements, with different modules available to complete the various research steps. By working non-stop to perform repetitive manual tasks, the GoFa cobots help to boost the efficiency of the ‘design-make-test-analyse’ research cycle, said ABB, and provide a firm experimental basis for the application of AI to science.

XtalPi integrates the cobots into different roles, from dilution, filtration, reaction and glovebox workstations to sample warehousing, automated guided vehicles (AGVs) and automated mobile robots (AMRs). GoFa cobots not only perform a multitude of process functions, but also – when mounted on an AMR – transfer samples between workstations, further helping to increase efficiency and reduce costs.

T 01908 350300

W www.abb.com

Consumers like – and expect – paper packaging for flour, but they also want that packaging to be dust-tight, and this was the challenge that Syntegon successfully addressed when the company installed a bagmaker and casepacker at German milling group Roland Mills United.

Matthias Karrenbauer, head of production and technology at Roland Mills, had a set of exacting requirements as he replaced one particular packing machine that had been in operation for 40 years. “Our goal was to find a future-proof line solution that combines sustainable primary and secondary packaging,” he said. “However, this was no easy task, as the line had to fit a limited space.”

After a selection process, Roland Mills opted for Syntegon’s Package Maker PME 4081 BS in combination with its Elematic 3001 WAH casepacker.

Unlike in conventional flour bag making, roll-fed

The Syntegon

uncoated paper enters a specialised module on the PME 4081 BS. Here, 14 timecontrolled nozzles apply the sealing medium to the top, bottom and vertical seams. Because the rest of the package remains unaffected, there is no interference with moisture exchange, helping to optimise the flour’s shelflife. The fibre content in the bag also remains at over 95%,

at Roland Mills United had to fit into a tight space meaning it can be recycled as a monomaterial through the paper waste stream. The advantages do not stop there, as senior sales manager at Syntegon Uwe Pfander explained. “Our solution reduces downtime to a minimum,” he said. “With the exception of short interruptions for cleaning and paper changes, the machine runs

continuously, achieving an effectiveness of 97%.”

Comparable systems from competitors typically only achieve 75% effectiveness, at best, he claimed.

Roland Mills was equally demanding when it came to the secondary packaging. “We want to offer our dusttight flour bags in premium retail, which is why we invested in a Syntegon casepacker that packs them in a sustainable display carton,” said Karrenbauer.

The Elematic 3001 WAH is capable of packing 100 flour bags per minute, while minimising the use of adhesive, and so again contributing to the recyclability of the fibre-based packaging.

Roland Mills is one of the leading grain mills in Europe, working from three sites in Germany. The family-owned business processes more than one million tonnes of flour per year.

T 01332 626262

W www.syntegon.com

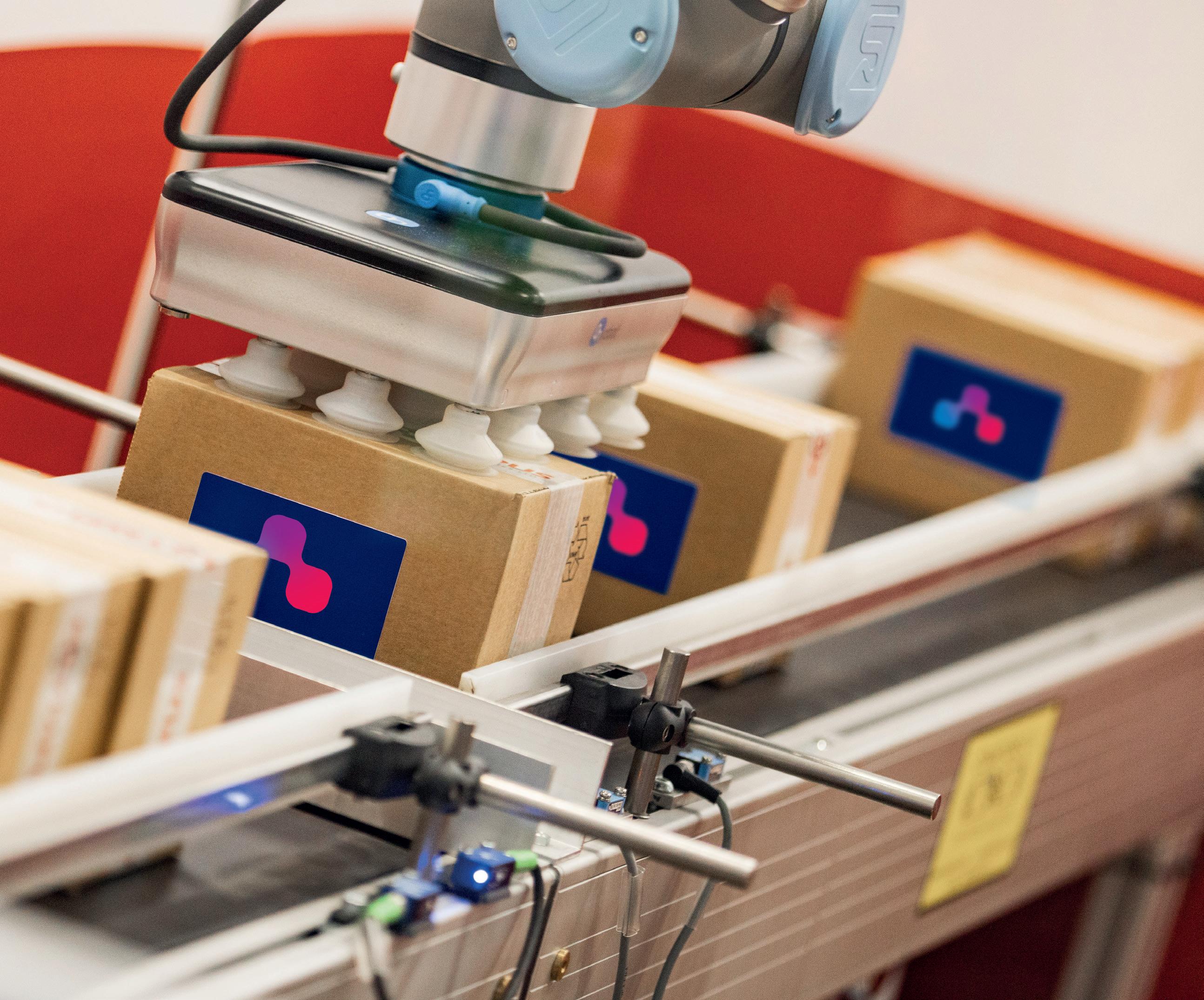

SEE has installed its I-Pack Void Reduction System for corrugated transit packaging at Finnish logistics provider and e-commerce distributor

Inex Partners, automating the right-sizing of packages for items in a wide range of sizes and doubling productivity.

Inex, which handles e-commerce fulfilment and distribution for one of Finland’s largest retailers, packs and sends out a variety of products from clothing to personal care items and

VP consumer goods logistics at Inex Pasi Siilmaa summarises the challenges. “Varying product weights and dimensions can lead to overpackaging and wasted space in boxes,” he says. “Our goal is to avoid this, as it isn’t sustainable and can negatively impact end-customer satisfaction.”

Uniform packaging systems can also add to costs and contribute to levels of damage to products, Inex points out.

SEE explains that I-Pack

a mechanical sensor plate to process boxes and, depending on size, can pack between 400 and 900 boxes an hour. Its knife-free technology reduces potential hazards for operators.

“SEE’s automated packaging solution has enabled us to double productivity in picking and packing,” says Siilmaa. The overall system was developed and installed by Ferag Nordic.

T 01480 224000

W www.sealedair.com

Process control specialist Promtek has re-engineered an entire factory for St Gobain in Mexico, speeding up materials handling, reducing energy consumption and improving capacity at the plant, which produces abrasive pads and wheels for a range of industrial uses.

The turnkey operation fills boxes with a predetermined weight of product, utilising a trolley dispensing system. Here, around 50m of track links no fewer than 250 material locations arranged in two rows. Two laser-guided trolleys each have two weigh scales, one for fine and one for coarse materials. Overall,

There are two loading points and 10 unloading points, and the system can travel at a maximum speed of 10m per second.

“Previously, a total system had been designed for a smaller factory in Stafford,” said Promtek md Charles Williams. “Despite this factory being one of the smallest in the group, it was

The Mexican plant handles a range of abrasive materials

with the engineers, designers and everyone else involved.”

St Gobain’s Jaime Guzman

must be millimetre-accurate and precise, and with the expert engineering support available at Promtek the system has been completely reliable since completion,” he said.

The project included the construction of a full working 1:10 scale prototype in the UK.

Subcontractor Aptech Powder Handling Systems contributed the mechanical design for ingredients handling and, together with Promtek, worked to ensure the overall design resulted in leaner maintenance, reduced downtime and improved workforce utilisation.

Meat, poultry, fish and other proteins depend on quality

There have been moments over the past few years when doomsayers have foretold the death of consumer markets for red meat and poultry in the face of a vegan and flexitarian plant-based onslaught.

So far, that has not come to pass in the UK. Recently, the main pressures on all types of higher-value food items have had more to do with the cost of living crisis than any macro trend to or from one category or another.

Government data from last year suggested you would have to go back 50 years to find a time when households ate less meat and poultry than now. The same figures plotted a 12% decrease in consumption since 2012.

But in many ways, meat continues to hold the line when it comes to consumer demand, with Mintel putting the 2023 retail value of processed poultry and red meat main meal components at £4,145 million. This compares with a figure of £523m for ‘meat substitutes’.

Fish and shellfish are not immune from these challenges. Mintel estimates that the category saw a 4% volume decrease and 2.9% value decline in 2021 alone.

Meanwhile, Frost & Sullivan’s analysis forecasts global growth in demand for plant proteins to 2030, and puts CAGR in Europe between 2022 and 2030 at 8.4%.

With regard to meat and fish, processors will always hope that economy options will shore up any slippage in consumer demand. But for most retailers, that can only ever be one part of a tiered and nuanced strategy. With many consumers eating less animal protein, but more willing to select premium product when they do

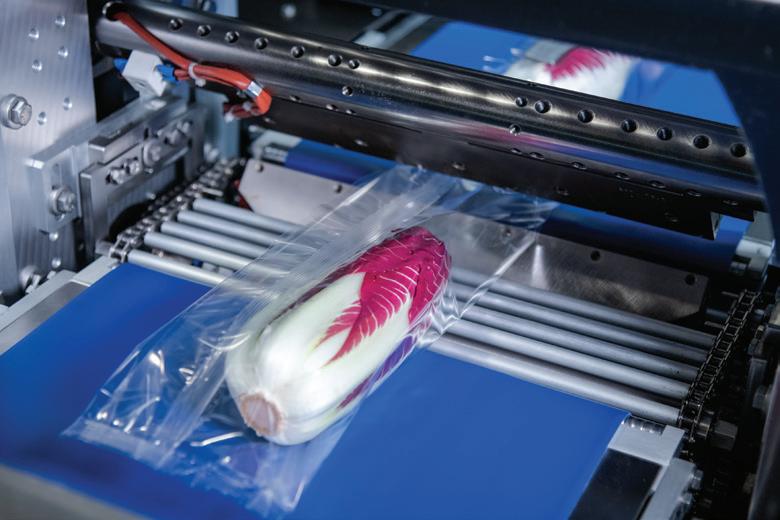

In the first quarter of this year, four PFM Scirocco machines are being installed at meat producers to flow-wrap their mince

buy it, there is a clear opportunity to differentiate meat and fish in terms of quality and presentation.

Any quality distinctions have to be based on data. Under normal circumstances, lack of contaminants is assumed to be a given by retailers and consumers alike. But a new generation of x-ray equipment, for example, is claimed to do a much better job of detecting even relatively small bones in fish, allowing processors to potentially make new claims for fillet ranges. X-ray can also be deployed to inspect for unwanted waste such as shell fragments in plant proteins.

As Multivac demonstrates (see p. 34), new smoking and spray marination systems for fish allow costs and quality to be far more closely controlled than with traditional approaches.

At the same time, weighing system developments mean that

relatively costly ingredients can be dispensed more accurately than in a manual operation, and giveaway on the protein itself can be pared back to a minimum.

Clearly, packaging, too, can play a leading role in differentiating protein products, and this can be as much about sustainability as premiumisation.

At PFM UK, for instance, MD Chris Bolton says: “We’ve noticed a trend towards flow-wrap packs at the expense of more traditional tray-with-lid and thermoform formats.”

On products such as mince, he adds, this can use around 45% less material.

The latest design of the PFM Scirocco has been particularly successful in this type of application among the UK’s main meat processors, with four machines due to be installed in the first quarter of this year. n

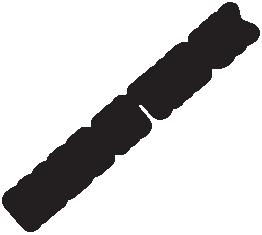

The operations happening either side of the central processing or packing of a meat, poultry or fish product can be the ones which deliver key results and meet critical customer requirements.

With increasing numbers of brandowners and retailers reducing their use of plastics and, in many cases, maximising paper and board usage, lines need to be able to handle the new pack formats.

Partners in Packaging (Machine Systems Ltd) has installed its C Series servo denester-placer to handle both plasticslined board trays and more traditional PET trays for meat and poultry.

The UK’s largest meat processor has said the system is one of the simplest to install. “The machines have been so well received by production that we have purchased more for our other factories,” says the customer’s engineering manager.

The denester integrates two Mitsubishi

to be transported and manipulated even in confined spaces.

The attachment has electric lift and lowering functions, offers a sideways rotation of 90 degrees to either side, and a hinged mechanism facilitates sideways loading on to packaging equipment.

Maximum lift capacity is 70kg, and reels are securely gripped by the core, with a torque limiter to ensure this function is not too tight but always secure.

After packing and sealing, labelling is another essential operation for meat and fish products, and ALTech UK has installed a new ALbelt D-wrap labelling machine at a leading seafood customer in Grimsby. The system applies full wraparound labels to trays and skin packs at speeds of up to 150 labels a minute.

servo motors and three pick heads.

Designed specifically for the highcare, cleanroom standards of the meat processing industries, the stainless manual hinged vertical spindle attachment introduced by Packline Materials Handling allows rolls of film

The equipment adapts to handle a variety of product shapes and incorporates the ALritma L 300mm labelling head. This allows more labels per roll compared to other tray labelling formats, says the company.

The system can also adapt to shaped labels and offers options such as printers, coders and remote machine management.

The Grimsby installation includes a ‘non-stop’ configuration designed to eliminate downtime on the line.

W www.altech-uk.com

W www.packline.co.uk

W www.partnersinpackaging.com

Gluing made simple with the new EasyLine. Exclusively for applications requiring up to 2.5 l/h hot melt. NEITHER

The denester is able to handle trays combining board and plastics

Meat and fish processors can halve both plastics consumption and power usage on their packaging lines by utilising a flow-wrapper such as the Fuji Alpha 8, according to Paramount Packaging Systems.

The 50% cut in plastics the company talks about is in comparison with traditional packing methods such as thermoformed trays.

“Reducing plastics packaging in the meat and fish sector is a commendable goal that aligns with broader global efforts aimed at addressing environmental concerns about plastics pollution,” says sales director Aaron Bessell.

Paramount recommends the following:

• Consider alternatives to conventional plastics, such as compostable or biodegradable polymers;

• Use Modified Atmosphere Packaging (MAP) which, by lengthening shelflife, adds to overall sustainability by cutting food waste – and can be delivered even at high speeds on the Fuji Alpha 8;

• Educate and communicate with consumers;

• Implement and champion recycling programmes for plastics;

• Forge strong partnerships with your suppliers, not only on the materials side but when it comes to equipment, too, meaning you can always leverage our extensive expertise in, for example, alternative materials;

• Keep yourself well-informed and compliant with Government regulations regarding packaging.

T 01252 815252

W www.paramount-packaging.co.uk

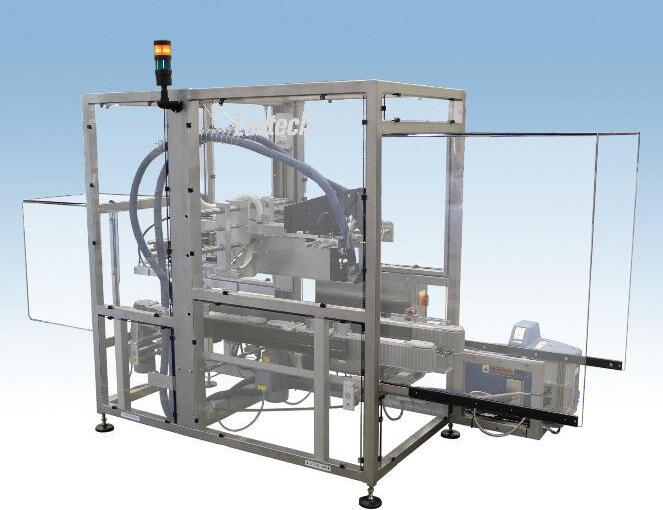

Fishmeal is a protein-dense product with a characteristic powdered consistency which can create challenges in a bulk weighing and bagging process, but these are challenges that Concetti overcame in a recent installation on a producer’s site.

The fully automatic system, weighing and bagging 1,200 x 25kg bags of high quality fishmeal an hour, was Concetti’s response to the customer’s objective of not only automating the process but also increasing the output of the packaging line.

The supplier emphasises the highly unusual consistency of the product as a semi-free-flowing mix of coarse and fine powders. The particular challenges it involves include a tendency to clump, but Concetti was attentive to the specific needs of the product and the customer, according to sales manager Trevor Mitford.

“Choosing Concetti means partnering with people who listen, having many years’ proven experience of protein and nutrition applications,” he says. “Automatic product and format changes

in less than 90 seconds, flexibility of applications and easy-clean features are just a few benefits of our lines.”

The Italian company, which produces palletising as well as weighing and bagging systems, also boasts broader experience of products with a variable density. The equipment recommended included the proven belt-fed NET/N weighing scale, combined with an intermediate discharge belt. This belt is said to accurately regulate the flow of product to the bag-holder, which is designed for rapid filling.

Because the system reduces air contained in the bag, this makes for a longer-lasting and more easily-stackable pack.

Concetti emphasises the versatility of the IGF 1200 bagging machine, meaning that a single system can fill and “perfectly” close pillow or gusseted bags in a 10-50kg weight range, whether paper, PE or WPP.

PLC-assisted format change is fully automatic and can be carried out in just 60 seconds, says Concetti.

T +39 075 801561

W www.concetti.com

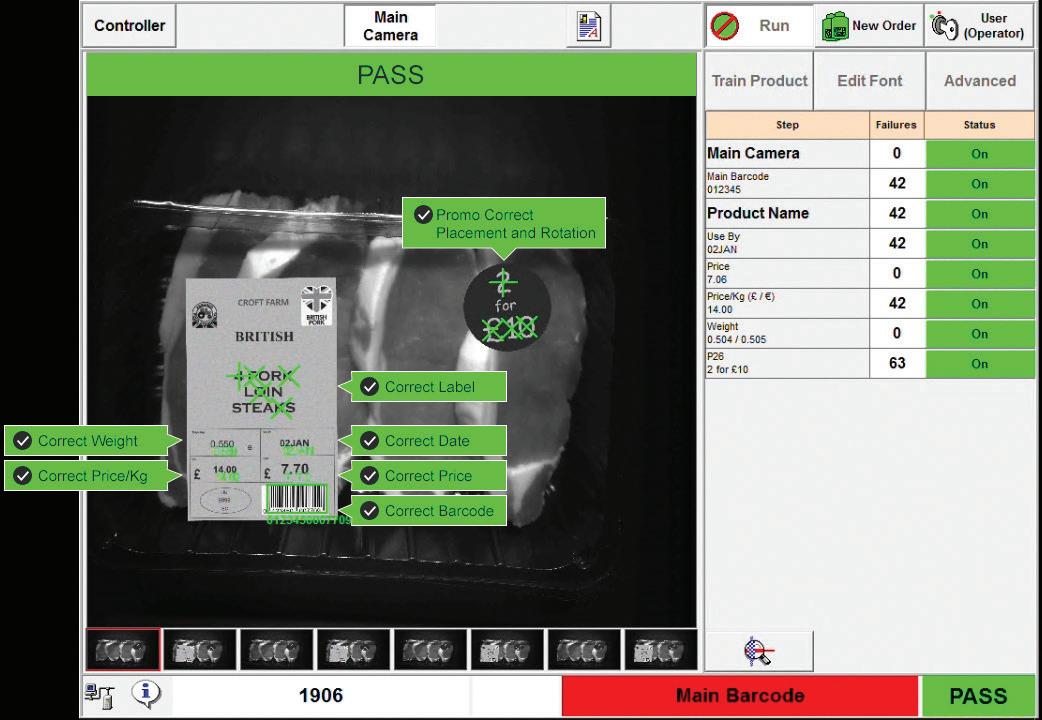

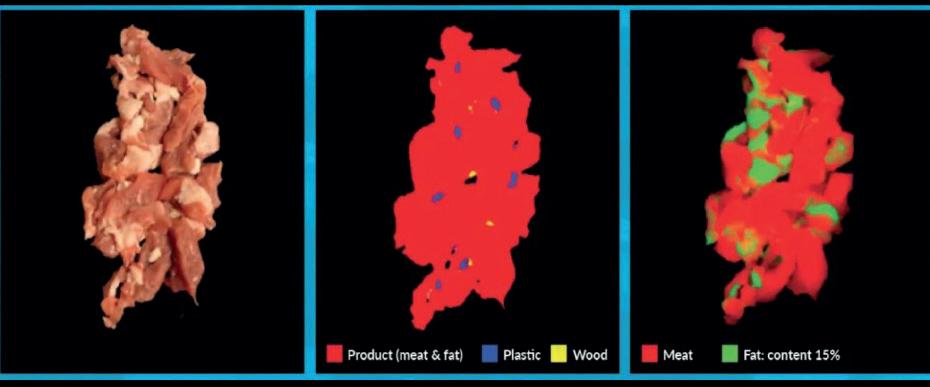

With meat processors focused on multiple aspects of quality, Quantum Design offers a new approach

Quantum Design UK and Ireland is supplying hyperspectral imaging cameras sourced from Specim, allowing OEMs to build this versatile technology into their systems, and enabling end users to scan meat and other food products in real time both for contaminants and, for instance, quality assessments of fat or water versus protein content.

Quantum cites the example of Inndeo, a Spanish company founded in 2016, which produces industrial hyperspectral imaging systems under the Inspectra brand, incorporating technology from Specim, part of Konica Minolta.

Emilio de la Red, chief technical innovation officer at Inspectra says: “The main reason we decided to implement hyperspectral imaging technology in our equipment was that no other technology was able to detect particular contamination and defects

and

in the products, and also characterise different quality parameters in the food.”

Significant processing power is required to convert the image into a pixel-by-pixel analysis and representation of the chemical composition. According to Quantum, the technology has already been applied to inspecting for: contamination (such as fat) in the seals of heat-sealed packs; contamination on seafood lines; freshness in meat, fish and vegetables; and the composition analysis of meat.

The company makes the point that many other vision systems are not able to go beyond comparing a colour palette, when it comes to detecting defects. Specim cameras operate on the ‘push-broom’ model, which means that product is imaged line-by-line to build up a full 2D image. They are designed to operate in specific bands across the VIS-IR (visible-to-infrared) spectrum between 400nm and 12µm.

Those interested in the technology can hire Specim FX10 or FX17 cameras from Quantum for a week, a month or possibly longer. If the customer then opts to purchase a camera within 9 months, a portion of the loan cost will be taken off the final purchase price.

T 01372 378822

W www.qd-uki.co.uk

Protect your brand with inspection solutions that enhance food safety and weight compliance for meat processing lines.

Image

analysis from Specim and (above) the Inspectra system

Image

analysis from Specim and (above) the Inspectra system

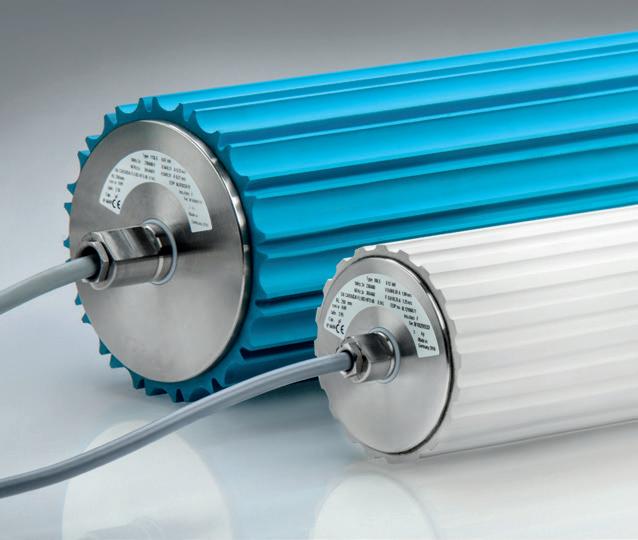

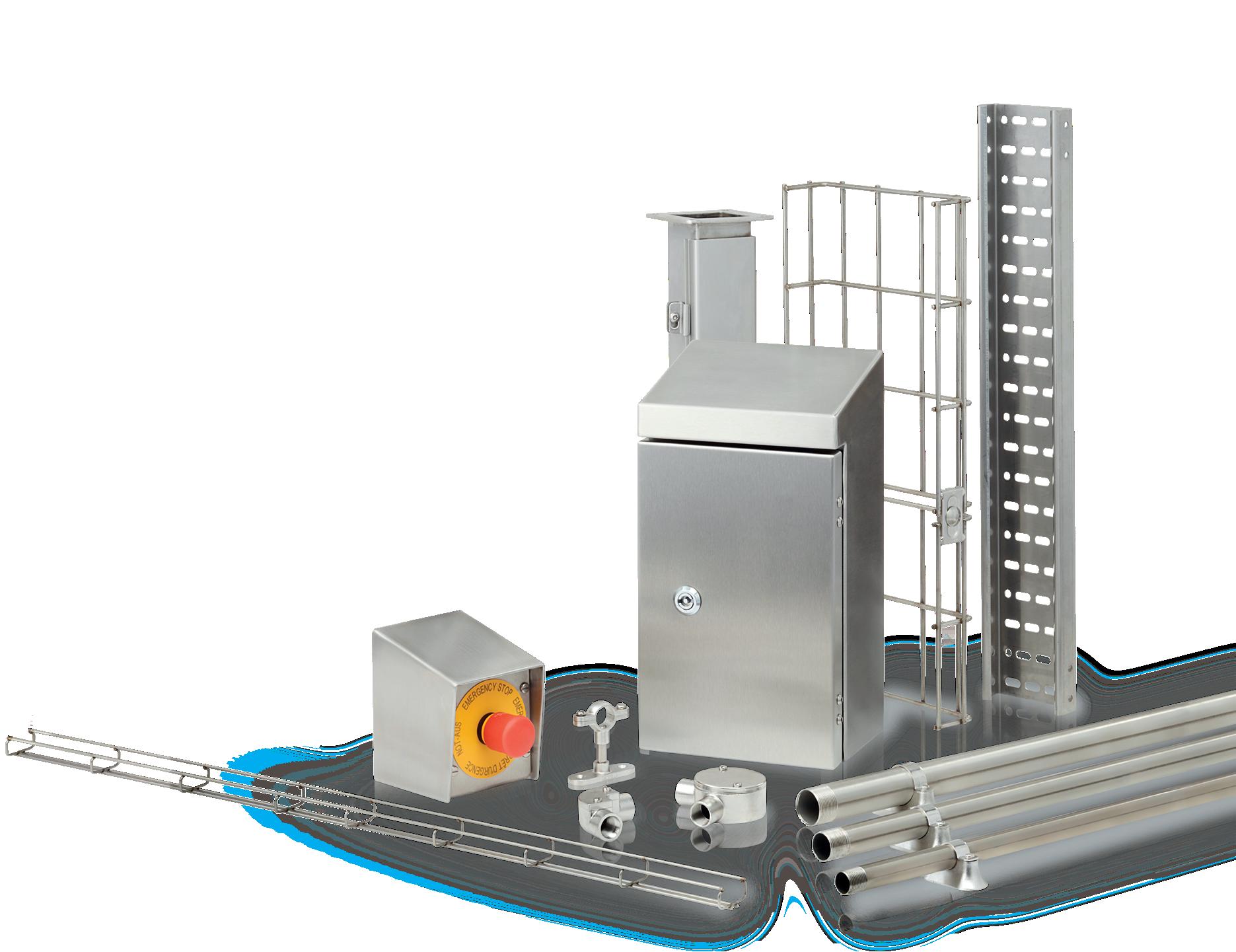

If meat and poultry processing can make multiple demands on a plant, fish can deliver an even longer list of hygiene, safety and other requirements. Line conditions are harsh, with constant exposure to ice-cold water and daily washdown routines.

Catchment zone can also be an issue with the nuts and bolts that hold equipment together, and WDS Components has addressed many of these challenges with its range of fasteners with European and US approvals for hygienic applications.

Lafert worked with a major fish processing company which needed to upgrade its conveying systems. These had previously been driven by conventional motors and gearboxes, but they were prone to failure due to water ingress and corrosion. Downtime seriously impacted on the company’s throughput of 40 tonnes of fish per hour.

The situation is much improved, says Lafert, thanks to the customer’s adoption of its IP67K stainless motors from the supplier’s Marlin range, resistant as they are to water ingress and any consequent corrosion. IP66 versions are also available.

The units are easy to clean, says the company, with smooth body design, no cooling fins or other potential catchment zones. As proven clean-in-place (CIP) systems, they can be pressure-hose cleaned in situ.

Hygiene needs do not stop at major line elements such as motors and gears.

The nuts and bolts, ranging in thread size from M4 to M16, use 316 stainless steel to prevent corrosion, and are certified by both the European Hygienic Engineering and Design Group (EHEDG) and the Food and Drug Administration (FDA). They also feature an hygienic sealing washer. Meanwhile, in-process contamination of product can be a concern, even for the most diligent manufacturer. While the presence of metals will, in general, be picked up by end-of-line inspection systems, plastics typically will not. Detectamet is among those companies offering a metal-detectable and x-rayvisible polymer, with applications to date including gloves and scoops, but involving a range of other accessories, too. The metal-detectable polymer is relevant to food and drink, but also the pharmaceutical industry, says Detectamet.

W www.detectamet.co.uk

W www.lafert.com

W www.wdscomponents.com

Kawasaki Robotics

Tel:+44-1925-713-000

www.kawasakirobotics.com/uk/

Vegan alternatives to meat have their own weighing and inspection requirements, Minebea Intec explains

Trends towards lower consumer consumption of meat, poultry and fish show no signs of disappearing, and the competition among brands eager to fill that meat-free gap is equally as intense as ever.

The battle for market share involves dedicated start-ups, traditional meat producers and multi-nationals such as Nestlé and Unilever, says equipment supplier Minebea Intec, with every business having to struggle with supply chain bottlenecks and inflated energy costs, among other challenges. High levels of efficiency, and the monitoring and safeguarding of resources at every stage of the supply

chain, are of critical importance.

Where plant-based alternatives to meat and poultry are being marketed as a ‘straight swap’ with a meat-based product, huge efforts are made to ensure that the item comes as close as possible to the steak, burger or nugget it imitates in terms of shape, consistency, flavour, smell and mouthfeel. Recipes can consist of more than

Installed Novego weighing module

30 individual components, including flavourings, protein and fibre from seeds, pulses and other vegetables. Food companies are using automated mixing systems equipped with high-precision weigh cells from Minebea Intec to ensure that these complex recipes are formulated in the correct proportions, global product manager Yannick Salzmann explains. “Our weighing solutions guarantee accurate, continuous, fast and flexible ▸

dosing processes and minimise material losses,” he says. “Our Novego weighing module was developed specifically for tank and process vessel weighing in the food and pharmaceutical industries. The hygienic all-in-one solution offers a variety of innovative features for easy, error-free installation, as well as maximum resistance to lateral forces.”

As well as accuracy and reliability, Novego is said to allow for fast cleaning. Corrosion resistance is exceptional, says Minebea Intec, while overall design follows the guidelines laid

down by the European Hygienic Engineering & Design Group (EHEDG).

Once the mixing process is complete, product is formed and placed on the conveyor, says the company, where a different type of weighing comes into play.

“With the help of dynamic checkweighers, companies can optimise their production processes, improve material and resource management and increase the accuracy and consistency of processes,” says product manager Lars-Henrik Bierwirth. Minebea Intec claims its Flexus checkweigher not only checks product weight or completeness but can help to optimise filling and sorting processes more broadly.

The wide range of ingredients typically blended in plantbased meat alternatives increases the likelihood that unwanted parts of one ingredient or other – such as shells – may find their way into a batch of product.

Naturally, x-ray systems can be – and increasingly are – installed at end-of-line to inspect packaged products.

Minebea Intec’s Dylight and Dymond models have been developed for a range of different pack types.

A recent addition to the company’s x-ray range is

the Dypipe, which is again designed to EHEDG standards to inspect viscous and liquid products, including vegan mince, for example.

Dypipe is fitted with a system to allow specimen insertion and verification during live operation, meaning that operators

can always be sure that the system is working as it should be.

T 0121 779 3131 W www.minebea-intec.com

Meeting rising demand for Shelf Ready-(SRP) and Retail Ready packaging (RRP) in the food and beverage, logistics, pharma & cosmetics or consumer packaged goods industry needs a robot to match.

With fast performance, greater dexterity and flexibility, find out how ABB’s IRB 390 FlexPacker can transform your productivity and help you grow your business.

Visit: https://bit.ly/IRB390FlexPacker

Multivac says the spray marination it is offering exclusively in the UK courtesy of partner Metalquimia and the intense smoking process available from Schroeter Technologies are providing significant efficiency benefits in fish flavouring.

The Metalquimia system involves introducing brine directly into the flesh of the fish as microparticles. These stick to the muscle fibres and are retained in position until the product is ready to eat, says the company. The system can be used to deliver flavours as diverse as citrus into salmon or sea salt and pepper into haddock.

fish processors more flexibility in terms of flavour profile, with what it calls its “woodchip style generator” able to create aromas such as apple or cherry wood. The flavour can be deepened by combining this with spray marination.

The equipment delivers a range of flavours

Data regarding UK fish markets says that salmon remains the most popular seafood species in UK retail, but that sales volumes slipped significantly over the past year. This is thought to mirror overall national fish sales and consumption, says Multivac. With higher fish prices playing into the wider cost of living crisis, more efficient processing combined with enticing new flavours could help to rekindle consumer interest.

Exclusive UK smoke house partner Schroeter has equipment which drives a laminar channel of smoke directly into the core of the fish. The company has reported reductions in smoking times from as long as five hours to just 15 minutes, using this approach in trials with UK customers.

Schroeter says its technology gives

Traditional approaches would typically involve soaking fish in brine, with little control over penetration or final quality, and exposure to smoke for many hours. The Multivac UK Curing and Smoking division offers alternatives for higher output and improved margins.

T 01793 425800

W www. multivac.com

Film From Below

• Reduce plastic by 50% compared to traditional packaging methods • Energy-e cient

• Reduced power consumption by 50%

• Compatible with recyclable, biodegradable & compostable films

• Simple product changeover

• Easy maintenance

• Customisable – From hand fed to fully automated high speed feed systems

Poultry and meat products can certainly make some specific demands, not all about hygiene

When using suction cups in any type of food handling, the prime challenge is to ensure that they adapt and seal properly across the surface of the product, limiting leakage as much as possible, while avoiding damage to the item.

But as Piab explains, the wide range of suction cups that the company offers the food industry means that there is – literally – likely to be a good fit with any category of product, including meat and poultry. They have metal detectable powder content and a blue colour to ensure detectability by cameras. They comply with all relevant FDA and EU safety regulations.

Specifically, the FCX50 cup, though originally designed for fruit, has multiple lips and flexible bellows which make it suitable for picking items such as nuggets or burgers, offering a secure grip

loads of up to 270kg, each system can be customised to integrate seamlessly with existing production lines. This bespoke element means that efficiency is maximised and the workflow never compromised, says the company, which is part of the Piab group.

even on irregular surfaces. The piSOFTGRIP, on the other hand, is ideal for delicate products such as chicken breast or sausage rolls.

TAWI says its stainless steel vacuum lifters are well-suited to the demanding

With these systems, a routine such as the retrieval of frozen meat joints from storage can be turned from a two-person job into a task for a single operator, says TAWI.

Of course, handling of meat and poultry takes many forms. Rollon has a range of linear motion components, all designed to ensure the non-contamination of product and able to withstand the most intense cleaning regimes.

The company’s MiniRoller Rail is a linear guide with an adaptive design for easy installation. Radial roller bearings glide on induction-hardened raceways between 58 and 62 HRC (Rockwell hardness). Driven actuators and systems from Rollon include the Plus System series. The ELM linear axis is a linear belt actuator using extruded aluminium profiles.

W www.piab.com

W www.rollon.com

W www.tawi.com

TAWI says automated handling can help efficiency

TAWI says automated handling can help efficiency

CAPTURING THE VERY BEST OF

Visitor registration is now open for the much-anticipated Machine Vision Conference, taking place on 18-19 June 2024 at the CBS Arena in Coventry. It is renowned for bringing together the machine vision industry, from leading brands showcasing cutting-edge solutions to industry experts sharing their vast knowledge. Plan your visit and register now for your free ticket!

COVENTRY BUILDING SOCIETY ARENA COVENTRY

COVENTRY BUILDING SOCIETY ARENA COVENTRY

You too can ensure that your end-of-line and upstream systems are fit-for-purpose, says Fortress Technology

Inspection systems can be integrated almost anywhere along a meat and poultry processing line. Most commonly, processors will choose end-of-line locations for checkweighing and contaminant inspection, after meat products have been prepared and packaged. At that stage, there is virtually zero possibility of new contaminants being introduced.

But as Fortress Technology Europe points out, if product is rejected at this point in the line, the costs incurred as a result of wasted food, labour and packaging can be exponentially higher than if contamination is

Managing director Phil Brown underlines the paramount importance of ensuring that products are safe for consumption, and the vital role played by the identification of Critical Control Points (CCPs) and of the best route to Hazard Analysis and Critical Control Point (HACCP) compliance.

“Inspecting products after packaging, using an end-ofline metal detection or x-ray system, is the most important CCP, and is also a retailer code of practice (CoP) requirement,” he says. For that reason, upstream in-line inspection equipment can only ever supplement what must be installed at the final stages

“However, in meat processing, a conveyor metal detector with a bigger aperture may be used to ensure that no metal is fed into the grinder, where it could damage equipment,” he says. “X-ray equipment may also be utilised to detect non-metallic contaminants such as bones. This is more common in premium meals or prepared foods targeted at young children or the elderly. A pipeline metal detector or x-ray is also quite typical in meat processing to inspect soft meats and pastes, such as sausage meats.”

Although metal detection offers superior sensitivity on foil, product effect common

Early inspection can reduce costs

potentially limit the variety of contaminants it can find.

“It’s critical to understand that the product effect for each type of meat – minced, large joints, cooked, frozen, and so on – can vary and behave differently in a metal detector,” says Brown. Equally, he adds, x-ray systems can be technically challenged on high-speed processing lines. Establishing your greatest

most cost-efficient CCPs and inspection options all help to ensure a robust HACCP-compliant food safety strategy, the company advises, delivering maximum profitability and avoiding costly waste.

As meat and poultry processors know all too well, the nature of foreign bodies in these products is slightly – sometimes radically – different from other food types. While imported meat may contain the usual contaminant culprits, including metal, glass, plastics, wood or stone, they also contain bones or fragments of bone. If a product is sold as ‘boneless’, these intrinsic foreign bodies are considered undesirable and potentially dangerous.

Additionally, other processes involved with handling the produce, such as cutting, trimming deboning, mincing or grinding, can potentially introduce contaminants, Fortress points out.

By law, meat products packed to set weights need to have those weights verified, and end-of-line options now

go well beyond the triedand-tested integration of checkweighing and either metal detection or x-ray on the same conveyor.

Where multiple machines appear to be a requirement, due to upstream output, Fortress recommends closely examining the options,

such as multi-lane systems or multiple product lanes through a larger aperture.

T 01295 256266

W www.fortresstechnology.co.uk

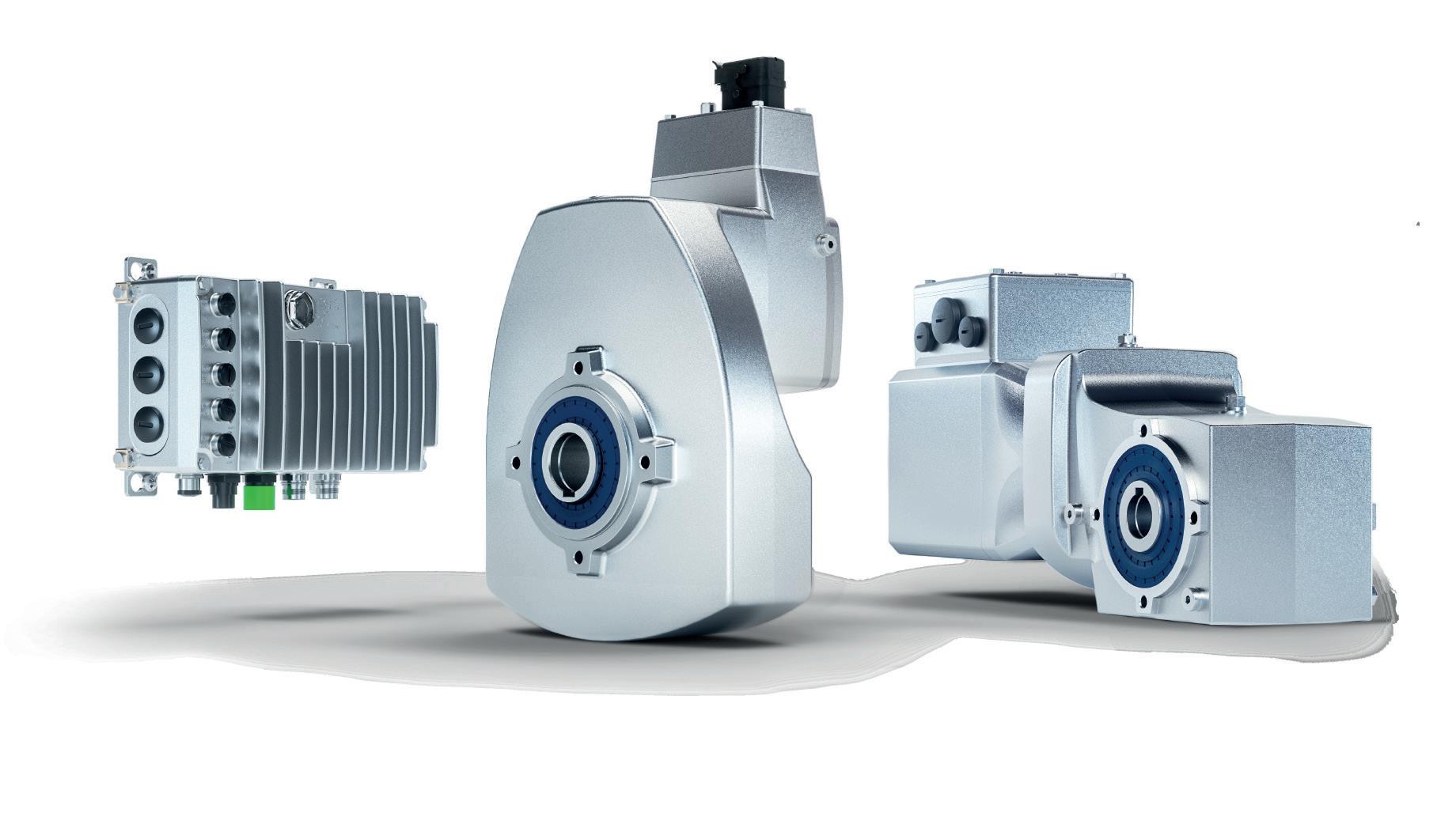

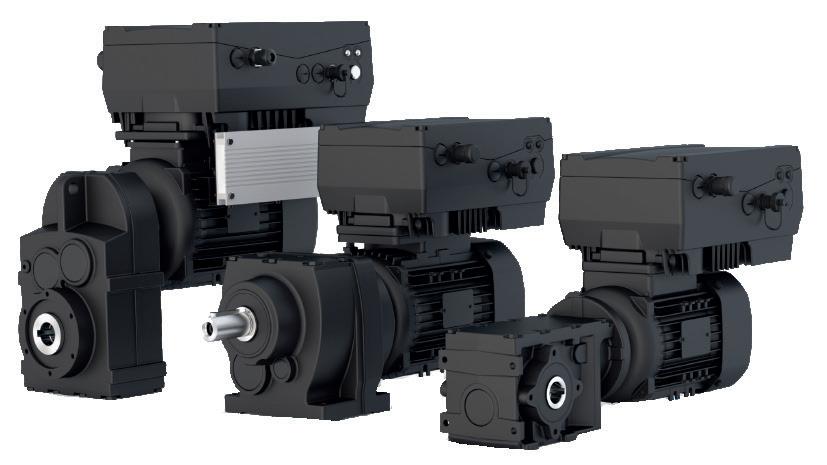

• Flexible, modular range of high efficiency, robust gearboxes with output torques up to 250kNm.

• Motors with efficiency levels up to IE5+.

• Intelligent frequency inverters with PLC onboard and parameter

When an important new customer insists you invest not only in x-ray but in a specific manufacturer’s system, you may feel you have little choice but to comply.

This is what happened to Pápai Hús, a long-established supplier of smoked ham in the west of Hungary, but with a range which now encompasses ham, bacon, sausage and even vegan products.

A new customer in Japan had specific demands. “It wasn’t even, ‘Choose an x-ray machine’,” explains Benedek Szabolcs, technical director at Pápai Hús. “They specifically directed us to order an Ishida x-ray machine.”

Ishida’s IX-GN-2443 was supplied

and installed in standalone mode by the equipment company’s Hungarian agent.

Speciality products such as disznósajt combine various pork meats, and can contain unwanted traces of bone or cartilage.

“We realised that Ishida’s x-ray can easily be programmed to identify any packs containing these traces, allowing us to reject them before they leave the factory,” says Szabolcs.

Currently, the equipment is used to check not only every pack of disznósajt, but also black pudding and cubed bacon.

The system is capable of detecting contaminants down to 0.3mm in size. According to Ishida, its Genetic Algorithm technology can deliver maximum sensitivity and reliability. A menu of saved settings allows for easy changeover, given that the likelihood of finding bone or cartilage varies from product to product.

T 0121 607 7700

W www.ishidaeurope.com

■ Dedicated After Sales Team: industry leading service and spare parts support

■ In House Training Facility: bespoke training for your team on our premises or yours

■ Privately Owned Family Business: flexible solutions to meet your needs

■ Complete customer satisfaction guaranteed Our

Ishida’s x-ray system can be set up very easily

Ishida’s x-ray system can be set up very easily

Automate UK is the leading trade association for automation suppliers and end users of technology across processing, packaging, robotics and machine vision. Providing everything from networking opportunities and world-class events to technical advice and training support. Helping you make smarter technology decisions to maximise productivity, efficiency and sustainability.

Visit automate-uk.com to find out more.

For exclusive benefits, events, networking and support, become a member today.

With a focus on specific applications, NORD Drivesystems has designed its NORDAC ON frequency inverters with the needs of horizontal conveyors in mind, while the high efficiency of its IE5+ synchronous motors makes them especially suitable for food and drink installations, as well as for intralogistics.

The family of decentralised frequency inverters includes an integrated multi-protocol Ethernet interface, IIoT (Industrial Internet of Things) capability, full pluggability and a compact design, says NORD. The NORDAC ON+ version is expressly designed to combine well with the IE5+ motor.

The IE5+ synchronous motor achieves a 95% efficiency rating, outperforming even the highest defined efficiency class, IE5, and is integrated into a helical gear unit.

T 01235 534404

W www.nord.com

Smart 2D profile sensors developed by Baumer are proving invaluable in providing a range of realtime data on an automated sandwich-making line capable of producing 70 completed rolls or sandwiches an hour.

According to Baumer, its OXM 2D sensor offers greater versatility than many of the better-known sensing technologies such as optical, inductive, ultrasonic or camera-based systems.

Key parameters on the sandwich line, engineered by Weber Maschinenbau in Germany, include the exact positioning of the roll on the line in terms of height, centre, alignment and evenness of the edges. This level of detail allows accurate and damagefree robotic handling of each item using suction pads.

Head of automation at Weber Marco Nichau explained the importance of minimising the time and effort required for integrating sensors. “Because the OXM sensor transmits all the

position information directly to the machine controller, we don’t need an additional controller, saving space and reducing costs,” he added. “As the sensor is very compact and easy to connect, we were able to parameterise it via the intuitive web interface.”

The system is especially suitable for this type of application, Weber said, because it is unaffected by

ambient light and surface variations.

Along with the information on the bread, the sensor also determines the lateral position and height of sausage and cheese slices on the belt. This is essential when ensuring the gripper positions each slice accurately on the bottom half of the sandwich.

T 01793 783839

W www.baumer.com

able management specialist icotek has introduced a new split cable entry frame, suitable for cables up to 35mm in diameter, o ering a seal to meet IP65 standards.

Two new hygienic angle seat valves from Schubert & Salzer add to its range of systems for sterile and aseptic applications, respectively o er shut-o and control functions.

On the KEL-ER-BL frame, IP65 protection is achieved thanks to the injected seal and the use of single grommets. These are placed into compartments and securely xed to the frame during assembly. Once assembly is complete, the end cover is screwed on. Cables are also strain-relieved, in accordance with DIN EN 62444. The frame is said to suit standard cut-outs for 10-, 16- and 24-pin heavy duty connectors. An ability to accommodate cut-out sizes up to 46mm, rather than 36mm, means that cables with larger

connectors can also use the entry frame. The KEL-ER-BL-B option is based on a 46 x 46mm cut-out size, suitable for controllers and meters.

The single-row KEL-ER-BL-E version o ers a space-saving design ideal for more con ned spaces and for cables with at connectors.

Typical applications of the KEL-ER-BL, in its bright blue colour, would be in those areas of food processing and packaging where there is no direct contact with product.

T 0161 222 3454

W www.icotek.com

The shut-o valve type 7015 and the control valve type 7025, with its integrated digital positioner, can be applied to product streams, water, gases such as CO2 and nitrogen, sterile steam or sterile air, for example.

Each valve design has been optimised in terms of dead space, with all wetted stainless steel surfaces capable of being manufactured with a surface roughness of less than Ra 0.8µm. The new valves in nominal sizes of DN15-50 are tailored to the pressure class PN 40 and suitable for product temperatures of between -30 deg C and +170 deg C. Specially adapted versions are available to handle the temperature range -50 deg C to +180 deg C.

All batch numbers of wetted stainless steel parts

are traceable, and all wetted plastics are FDA-compliant and conform to both EC Regulation 1935/2004 and the EU Plastics Regulation 10/2011. Both valve types comply with the Technical Instructions on Air Quality Control (12-2021) and EN ISO 15848-1:2017. T 01952 462021

W www.schubert-salzer.co.uk

Readers will evaluate a wide range of 1D and 2D codes and text even in difficult lighting and from uneven substrates

Multicode readers now available from ifm electronic are able to assess and read multiple 1D and 2D codes and texts from a single image and send the results via an IO-Link, allowing them to be readily integrated into control and supervisory systems.

According to ifm, the readers in the new 02I4xx range operate reliably, even when there is variability in lighting conditions or in the surface on which the codes or text are printed.

This is said to make them an ideal choice for production and logistics applications where data needs to be checked for quality or accessed for product tracking.

The readers are ready to use as supplied and setup is fast and easy, the company claims. In most cases, each unit will only need to be taught the codes it is going The multicode reader’s setup is said to be easy

to monitor. In more demanding applications, a range of advanced functions –including focus – can be con gured using ifm’s free-touse Vision Assistant so ware. The range includes multicode readers with an integral RGBW light source, with other versions o ering red light and infrared options. Any data blocks larger than 32 bytes are automatically divided before transmission.

T 020 8213 0000

W www.ifm.com

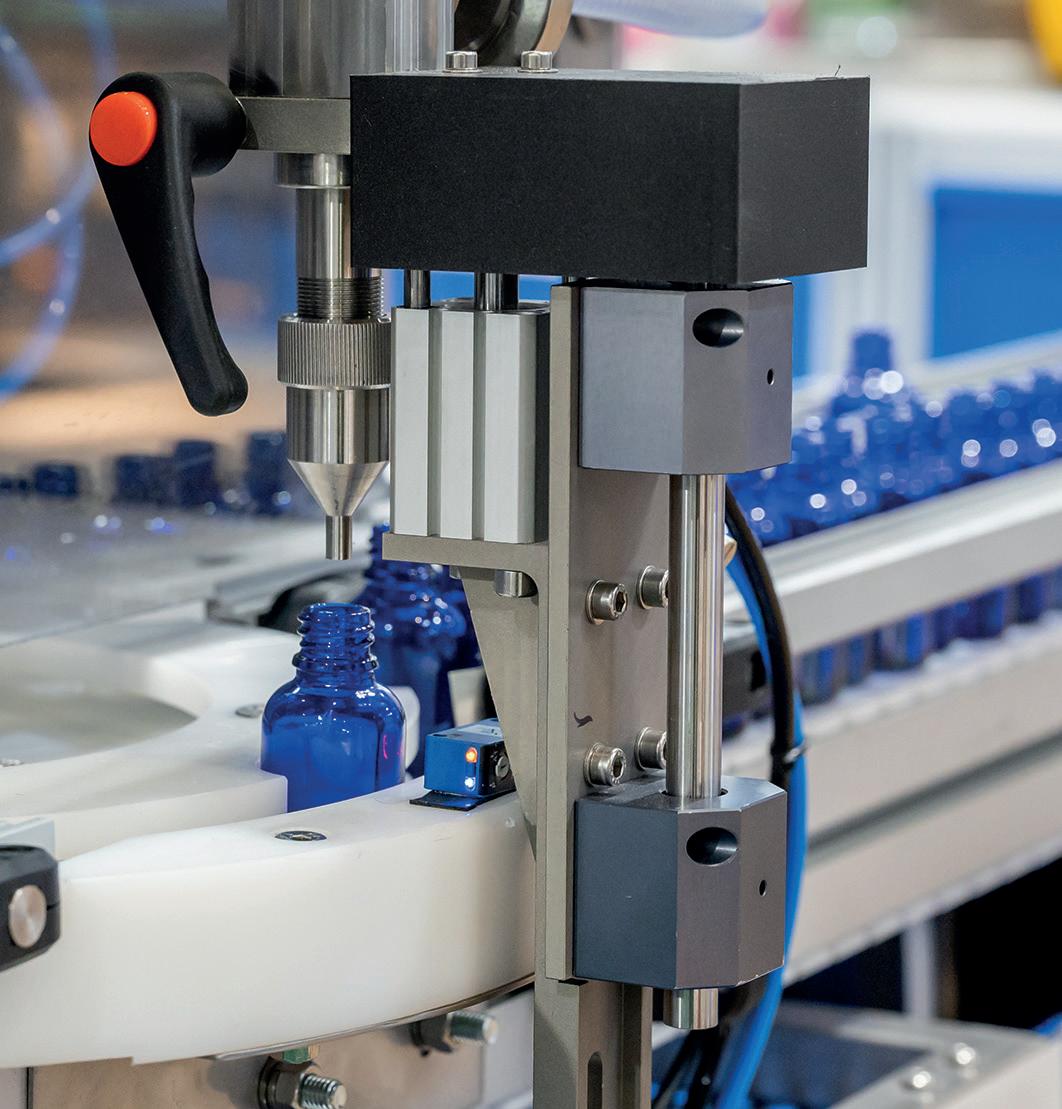

The FIT5X from Hottinger Brüel & Kjaer (HBK) is a digital load cell specifically designed to transform rotary filling and dosing, thanks to its fine control, a hermetically sealed construction, simplicity, reliability and ‘seamless’ integration with digital technologies and Industry 4.0, says the manufacturer.

The cell will interact intelligently with valves

HBK claims the cell outperforms legacy single-point or analogue load cells, due to its filling and dosing algorithm with a control weighing function. Digital inputs and outputs also mean that the FIT5X will interact intelligently with triggers and actuators such as valves. This in turn is said to facilitate reliable automated process control.

The quality of the sealed design is an improvement on its predecessor the FIT5A, says HBK, effectively

eliminating the risks associated with outside exposure and minimising contaminant accumulations. Here, the simplicity of the design also comes into play, it adds. At the same time, HBK calls the load cell “the obvious choice for Industry 4.0”.

With its complementary PanelX software allowing in-depth data analysis, the company says the FIT5X redefines the standards expected across the industrial weighing sector.

T 01223 389800

W www.hbkworld.com

Leveraging the clear benefits of applying frequency inverters to universal drive machines, KEB Automation has extended its range of asynchronous geared motors to include models with integrated MU series inverters.

KEB emphasises the benefits of using frequency inverters to optimise running the motor at different speeds, smooth start-up and braking. Decentralised as well as central drive controllers are now available, twinned with geared motors in the power range 0.37 kW to 7.5 kW. Product manager for motors at KEB Daniel Lehmann spelled out the benefits. “The inverters are mounted directly on the motor as decentralised devices,” he said.

“This saves important space in the control cabinet. Users also benefit from high performance and easier installation.”

But this is a customised rather than a one-size-fits-all option. “Asynchronous geared motors can be combined with different frequency inverters and technical

The combined units offer different specifications

The integrated frequency inverters are available in 10 sizes for mains voltages of 230V and 400V, and motors can be specified for the different operating points 87, 100 and 120 Hz, allowing flexibility in customisation.

T 01933 402220

W www.keb.co.uk

An advanced motor condition monitoring device from OMRON, designed to automate the detection of abnormalities and potential failures across manufacturing, is particularly suitable for servomotors, with their frequent speed change.

The K7DD-PQ series will analyse over 400 different values derived from current and voltage measurements, and is able to detect specific failure modes such as worn blades, chip entanglement or deteriorating bearings in machine tool spindle motors, says OMRON. The aim is to reduce manual inspection requirements and eliminate any reliance on the experience and intuition of skilled operators.

Data processing on the K7DD-PQ is said to be accurate and comprehensive, based on high-speed 2.5-µs sampling technology able to capture even the most fleeting of anomalies. According to the supplier, the 6-channel simultaneous/continuous operation capability means data can be processed without omission or deviation.

The system will effectively monitor servo and induction motors, detecting anomalies caused by gaps between the rotor and stator or by changes in torque. By offering self-contained condition monitoring, says OMRON, the device eliminates the need for complex installations or cloud-based alternatives.

T 01908 258258

W www.industrial.omron.co.uk