Issue 2, Volume XXXIV, March/April 2023

The machinery only journal for processing & packaging | www.machineryupdate.co.uk

Sustainable formats

This issue sees a drinks feature as well as a preview of the global exhibition interpack – both cover new technologies that meet customers’ sustainable needs

INSIDE NEWS

Lorem ipsum dolor sit amet, consectetuer adipiscing elit, sed diam nonummy nibh euismod tincidunt ut laoreet dolore magna

interpack returns to Düsseldorf in May following an enforced 6-year break due to COVID-19. Nearly 3,000 companies will be launching new products, as our 26-page show preview attests

NEW MACHINERY

A new Stretch Hood system is said to guarantee total protection against humidity, rain and dust as it envelopes palletised products from above to the base. It is now available from Pace Mechanical Find out more on page 21

INSTALLATIONS

A complete packing line has been key to the launch of a new healthy snack product

NEWS PLUS

This year, Machinery Update will publish sector eBulletins covering robotics, palletising and labelling/coding/marking www.machineryupdate.co.uk

PALLETISING SOLUTIONS The Complete Portfolio Come and visit us at INTERPACK 2023 Stand G74 / Hall 11 Düsseldorf, Germany, May 4 - 10 Clever design based on the latest technologies In-house manufacturing Seamless project management & install 50+ years of experience www.scottautomation.co.uk +44 (0) 1384 210 278 info@scottautomation.co.uk Layer and robotic palletising systems Pallet and case conveying systems Turnkey solutions Local maintenance services 24/7 support

Contents

7 NEWS

12 NEW MACHINERY

22 INSTALLATIONS

30 SPECIAL FEATURE iNTERPACK PREVIEW

In our 26-page preview of the returning interpack exhibition, you will find details of the very latest equipment to be launched

56 SPECIAL FEATURE DRINKS

Several PPMA members across a range of technologies have developed equipment for drinks manufacturers to enjoy benefits that have ultimately delivered new options to their consumers

56

REGULAR FEATURES

10 REGULATIONS

For any machine, that includes electrical or electronic components, to comply with the UK’s Supply of Machinery (Safety) Regulations 2008, it must also meet (EMC) Electromagnetic Compatibility Regulations 2016. These set out the requirements that must be met before products can be placed on the Great Britain (GB) market, with some changes for Northern Ireland. We outline the responsibilities.

EDITOR:

Gail Hunt gail.hunt@ppma.co.uk

PUBLISHING MANAGER:

Bill Lake bill.lake@ppma.co.uk

ARTWORK CONTRIBUTOR:

Barry Heath

HEAD OF PUBLISHING:

David Chadd david.chadd@ppma.co.uk

A PPMA PUBLICATION

PPMA Ltd

New Progress House, 34 Stafford Road, Wallington, SM6 9AA

TEL: +44 (0) 20 8773 8111

E-MAIL ADDRESSES: publishing@ppma.co.uk show@ppma.co.uk technical@ppma.co.uk

WEBSITE: www.machineryupdate.co.uk

APPLICATIONS FOR FREE COPIES of Machinery Update are considered from specifiers, managers and purchasers of processing and packaging machinery in the UK.

ANNUAL SUBSCRIPTION: £35 (UK), £50 (Continental Europe), £65 (rest of world).

ISSN 0969-4145

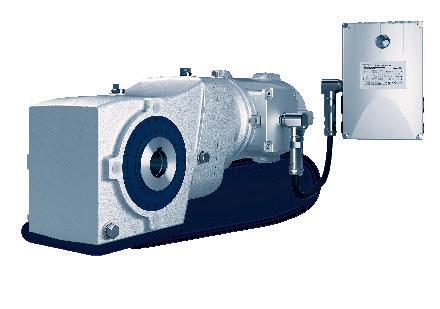

62 COMPONENTS

Nord Drivesystems has introduced the Nord Eco service to help firms to optimise overall energy savings potential hidden in their electric drives usage by finding the most efficient solution for applications

64 WHO WHAT WHERE

People, events and diary dates

66 MACHINERY FINDER

Machinery and also services

PRINTED BY: John Good Ltd, Progress House, Butlers Leap, Rugby CV21 3RQ Tel: 02476 652800

The Processing and Packaging Machinery Association assumes no responsibility for the statements or opinions, whether attributed or otherwise, in Machinery Update.

This publication is copyright under the Berne convention and the International copyright convention. Apart from any fair dealing for the purposes of research or private study, as permitted under the Copyright, Designs and Patents Act 1988, no part of this publication may be reproduced, stored in a retrieval system or transmitted in any form or by any means in any form without prior written permission of the publishers.

Publishers: PPMA Ltd

THE BENEFITS OF OVERWRAPPING:

Excellent appearance

On-pack promotion with printed film

Cost reduction

Closed packaging

No heat radiation

Efficiency

Ease of operation

Flexibility

Low maintenance

Easy opening with tear tape

Biodegradable film & paper

sollas.com Sollas MU S-O 2021 artwork

www.machineryupdate.co.uk MARCH/APRIL 2023 MACHINERY UPDATE 3

March/April 2023

12

OVERWRAP your products

IMPROVE

Over 10,000 machines sold world-wide!

01256 896930 your sales,

Widening our impact will help everyone

As the MD of an engineering SME that has been a member of the PPMA Group of Associations for years; and as a member of its board for the last six, I am confident that my appointment as its new CEO from this March is going to see me hit the ground running.

Our association has a long and rich history of success but is probably still most recognised for our PPMA Show/PPMA Total Show that run at the NEC, Birmingham each autumn. We also publish this magazine, deliver training courses and offer overseas exhibition support, but we need to be more relevant to a host of organisations, whether this be to government; other industry bodies and stakeholders; in education, or through more STEM days run by the charitable incorporated organisation PPMA BEST.

The UK Government, and the devolved administrations, need to understand what our sector can offer

There’s a growing competition for talent – and we have to play our part in ensuring our sector – and all of you, our customers –remain attractive places for young people to want to build their careers. It’s also more important than ever that we step up our political engagement and build the profile of our sector. As the UK Government – and devolved administrations –finally get to grips with the needs of our economy post-Brexit, automation and robotics become ever more important to building this economy, raising productivity and also to levelling up… we need them to understand what we can offer and how businesses can get fit for the future using our kit.

I also believe that our members will be key to delivering sustainability and building a low carbon future and we need to be influencing the debate – supporting our customers as they change and invest to become net zero businesses while educating the sector as well.

We believe that as an organisation, we are already facilitating the needs of members and end users in the fast-developing areas of our industry by offering a new event that will cover all things automation and robotics this June. And Automation UK (see page 7) will join the established Machine Vision Conference, or MVC, to highlight the changing nature of equipment that is required across manufacturing sites in Britain.

But there’s more to do, and I am looking forward to making the PPMA a more authoritative voice for the packaging and processing machinery, robotics and vision systems sectors going forward which will surely benefit all of us. n

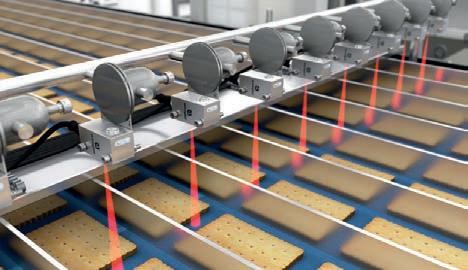

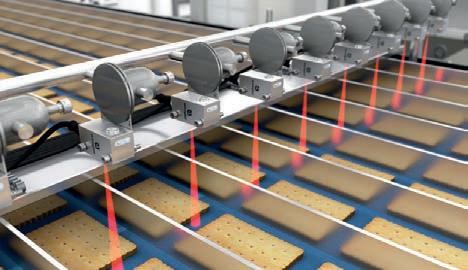

CleaningResistant and Robust Sensors

The sensors for the washdown area are ideal for use in washdown applications in the food, beverage and packaging industries. The high-quality stainless steel 316L housing makes them robust and corrosion-resistant

Height and Angle

Measurement of Ice Cream Cups via 2D/3D Profile Sensors

Detection of Cookies with Reflex Sensors with Background Suppression

Detection of Food Trays with Reflex Sensors with Background Suppression

Color Control of Baked Goods with Vision Sensor

www.machineryupdate.co.uk machinery update 5 PPMA matters

Peter Williamson

CEO, PPMA GROUP OF ASSOCIATIONS (INCORPORATING PPMA, BARA AND UKIVA)

wenglor sensoric ltd. Unit 2, Beechwood | Cherry Hall Road | Kettering Business Park Kettering, Northants NN14 1UE +44 1536 313 580| info.uk@wenglor.com

• Stainless steel conveyor systems • Standalone units or fully integrated • Robotic and end of line equipment • Bespoke engineering capabilities • Turnkey and standalone solutions • Integration and project management • Service support and upgrades • Partnered with Lita Palletising Systems for over 30 years www.kensal.com sales@kensal.com | tel: +44 (0) 1 582 425 777 Kensal Handling Systems Ltd, Kensal House, President Way, Luton, LU2 9NR Kensal Handling Systems

New premises will improve processes and cut lead times

After nearly 40 years, Pennine Industrial Equipment has moved into new business premises which has expanded the production and office space by 50%.

As well as more space, the building has been fully customised to allow for improved operational flow and increased production output. The new premises were selected as they are less than 3 km from its previous site to allow maximum retention of experienced production and valuable sales staff.

“Having a new purpose-built facility will allow us to improve production processes and provide shorter lead times for our customers,” says Pennine’s sales director Graham Womersley.

interpack is back to offer visitors a host of new developments

The international exhibition that is interpack is opening its doors again in Düsseldorf this May, following a COVID-19 enforced six-year hiatus with aims to celebrate the long-awaited reunion of the global packaging industry.

Greeting visitors to the seven day event (4-10 May) will be about 2,700 exhibitors representing key players and newcomers from around the world. Many of these participants will, say organisers Messe Düsseldorf, show how to change the game when it comes to sustainability, processing and packaging technology for a better life, or efficient production processes that are less resource intensive.

Organisers believe the show will deliver the most international industry meeting of the processing and packaging sector for

Co-located events will answer today’s manufacturing needs

Save the date – 20-21 June –for the new Automation UK exhibition from BARA to be held in Coventry which will be co-located with the established UKIVA Machine Vision Conference (MVC) that is relocating from its usual one-day residency in Milton Keynes.

years, and to complement the exhibits, new special areas and promotions include ‘Spotlight talks & trends’ which each day, will have a different focus topic including the circular economy, logistics, sustainability, digital technologies, product safety and also eCommerce.

W www.interpack.com

• A 26-page interpack preview includes new products on show along with ticketing details

Call for entries for the young woman engineer of the year

To mark 2023’s International Women’s Day in March, the Institution of Engineering and Technology (IET) launched the call for entries for its 2023 Young Woman Engineer of the Year Awards by the submission deadline of 3 July 2023.

PRE-BOOKED

GIVE BEST CLIENT OUTCOMES

Getting on board for results

E sales@apexdynauk.com

The awards celebrate women working in modern engineering – and aim to help change the perception that engineering is predominantly a career for men, and seek to find role models who can help address the UK science and engineering skills crisis by promoting engineering careers to more girls and women.

W youngwomenengineer.theiet.org

This new exhibition will showcase products from leading robotics and also automation companies during the two days at the CBS Arena in Coventry, while MVC has over 40 technical seminars as well as an exhibition showcasing the latest innovations in industrial vision technology.

W www.automation-uk.co.uk

W machinevisionconference.co.uk

STEM day success continues this year

Stretford High School is one of the latest secondary schools to enjoy a STEM day delivered by PPMA Business Education Skills and Training. Its science teacher and STEM coordinator Abdul Hamza felt the delivery was exceptional, well timed and engaging for his pupils.

W www.ppma.co.uk/ppma-best

www.machineryupdate.co.uk MARCH/APRIL 2023 MACHINERY UPDATE 7 News

VISITS

Apex Dynamics is taking The Gearbus on the road around the UK this year to provide a novel solution to tackling customers’ motion control problems. It was borne out of an idea for a convenient demo facility that could go directly to customers, and it is now out and about taking problem solving options straight to their premises.

Automation UK is a new exhibition

The Düsseldorf show has 18 halls

The new facility is bringing gains

Pupils were inspired by the day

MVC will now run across two days

Customised customer events are offered across industry segments

Rovema is planning a series of customised customer events for various sectors of the food industry this year which will take place at the company’s headquarters based in Fernwald, Germany.

The company is rethinking its traditional trade show participation and will no longer be exhibiting at interpack this May, and will be concentrating on these bespoke events instead.

Customer days will run all year

The German manufacturer of packaging machinery which offers sustainable packaging solutions will start a series of events in spring 2023 individually adapted to different sectors of the food industry. The series kicks off in March – 21, 22 or 23 – from 10 am until 5 pm, and will cover the coffee sector.

Other forums, including those for the confectionery and powder industries, are also planned for 2023.

Guests will be offered intensive personal advice and support from company personnel, live demonstrations as well as specific industry lectures and presentations on topics such as sustainable packaging or product protection.

Interested parties can send a request to participate to:

E events@rovema-experience.com

W rovema-experience.com

News 8 MACHINERY UPDATE MARCH/APRIL 2023 www.machineryupdate.co.uk

Tel: 0 1865 8 9 1466 Email: info@cap c ode r.com To discover more about the machines that could transform yourcompany please visit: www. ca pc ode r.com

Training from the PPMA meets all engineering needs

The need to upskill the talent pipeline to meet today’s business needs becomes more crucial, and the PPMA training department is offering a range of face to face or online training to cover even more technical and soft skills.

For instance, the 2-day Professional Communication Skills for Service Engineers course was designed by an engineer with over 30 years’ experience to provide participants with insight into the skills required. The course offers a highly interactive programme with many practical activities, with each session designed to transfer learning into actions and results.

The next course is on 25 - 26 April 2023 at the PPMA HQ in Wallington, Surrey. W www.ppma.co.uk/ppma/ training-seminars.html

Conference showcases automation capabilities

The Manufacturing Technology Centre (MTC) is hosting a two-day conference to drive the uptake of robotics and automation throughout UK industry in which BARA (the British Automation & Robot Association) will also be sharing its expertise with the participants.

The Robotics and Automation – A New Perspective 2023 event at the MTC (Pilot Way, Coventry CV7 9JU) on May 10 and 11 will explore the future of automation and demonstrate the opportunities available to UK industry. Delegates from a wide range of industries from construction to agriculture and food production will get the chance to share insights into the transformational benefits of robotic technologies and learn how automation can improve productivity and drive global competitiveness for UK businesses.

The free event will build on the recommendations of a report by MTC robotics

BARA council members will be on hand to help delegates learn about robots or simply network with likeminded individuals. They can also talk to BARA council members that will be on hand throughout the two days for practical advice on how to get started on the automation journey.

experts and the Industrial Policy Research Centre at Loughborough University which called for more knowledge-sharing across the robotics community. It also highlighted the need for support for developers and early-stage adopters, an emphasis on skills, as well as a greater understanding among the investor and finance community of the business benefits of automation.

Delegates can listen to inspiring talks by industry experts, join educational workshops, discover innovative technologies

The BARA representatives represent robot suppliers and systems integrators which, as well as offering impartial advice to visitors, will also be speaking on the second day of the event.

W www.eventbrite.co.uk/e/ robotics-and-automationa-new-perspective-2023tickets-504718716267

www.machineryupdate.co.uk MARCH/APRIL 2023 MACHINERY UPDATE 9

Lamonde Automation Limited Quality Products: Expert Advice sales@lamonde.com | www.lamonde.com | +44 (0)20 3026 2670 Built-in Option Module Slot(s) RJ45 Ethernet and Micro-USB Ports RS-232 and RS-485 Serial Comms Built-in Micro SD Port Built-in WLAN/Bluetooth IIoT Ready thirdpageland_ppma_marapr23_clickplus.pdf 1 03/03/2023 15:01

Many new courses are offered

Keeping compliant with EMC obligations

If the control system of a machine experiences electromagnetic interference it may malfunction and create a dangerous situation, while conversely, if the electrical and electronic systems fitted to a machine generate a high level of interference, it may also cause other equipment nearby to malfunction.

Therefore, for any machine, that includes electrical or electronic components, to comply with the UK’s Supply of Machinery (Safety) Regulations 2008, it must also meet the Electromagnetic Compatibility Regulations 2016. These Regulations set out the requirements that must be met before products can be placed on the Great Britain (GB) market, with some requirements differing for the Northern Ireland market. For example, qualifying Northern Ireland goods can be placed on the GB market with the European Union’s CE and CE UKNI conformity marking.

EMC RESPONSIBILITIES

Machinery manufacturers are responsible for ensuring EMC compliance. Before placing apparatus on the GB market, they must ensure that it has been designed and manufactured in accordance with the essential requirements in Schedule 1 of the 2016 Regulations.

The essential requirements state that:

a) equipment must be designed and manufactured to ensure that the electromagnetic

Paul Laidler BUSINESS DIRECTOR FOR MACHINERY SAFTEY AT TÜV SÜD PRODUCT SERVICE

Ian Wright CHIEF ENGINEER

Ian Wright CHIEF ENGINEER

disturbance generated does not exceed the level above which radio and telecommunications equipment or other equipment cannot operate as intended, and

b) the equipment has a level of immunity to the electromagnetic disturbance to be expected in its intended use which allows it to operate without unacceptable degradation of its intended use.

trade name or registered trademark, a postal address, and the type batch or serial number. If it is not possible to affix these details or the UKCA marking to the machinery, this information can be placed on the packaging and the accompanying documents. Any instructions must also be supplied in English.

It is worth noting that until 11pm 31 December 2024, machinery that conforms to European Union requirements

Regulations. They must therefore take account of any changes in electrical equipment design or characteristics, and any change to a relevant harmonised standard or any technical specifications which are referred to in the Declaration of Conformity.

UNNECESSARY CHANGE

The machinery manufacturer must also have a relevant conformity assessment procedure carried out and technical documentation drawn up. Once this is completed, the manufacturer is also required to draw up a declaration of conformity. This is a document which declares that the product is in conformity with the relevant statutory requirements applicable to the specific product. Any technical documentation and the declaration of conformity must be kept by the manufacturer for 10 years after the machinery was first placed on the GB market.

The UKCA marking must then be affixed to the machinery. The manufacturer must also label machinery with its name, registered

may be placed on the GB market. So, until that date any new machinery which displays the CE marking is acceptable. Therefore, if an individual fully manufactured product is placed on the European Economic Area or the UK market (either in Northern Ireland or Great Britain) before this time on 31 December 2024, the 2016 Regulations do not apply. This means that such machinery can continue to circulate on either market until they are deemed to reach their end of use.

Over time, as adjustments are made to the manufacturing process and new or updated components included within a machine, the manufacturer must ensure that procedures are in place for it to remain in conformity with the 2016

However, products which are repaired, refurbished or exchanged without changing their original performance, purpose, or type, are not considered ‘new’ and therefore do not need to be recertified and remarked. This includes if the product is exported for repair. Any new spare parts can comply with the same conformity assessment requirements that were in place at the time the original product or system they are ultimately intended to repair, replace or maintain was placed on the market.

While EMC may appear to be complex, it doesn’t mean that machinery manufacturers can ignore their legal obligation to ensure their products meet the requirements of the 2016 Regulations. Neither should machinery end-users plead ignorance, making the assumption that their supplier is doing the right thing.

i For more information contact W www.tuv-sud.co.uk

TÜV SÜD Product Service is the PPMA’s technical and legislative partner

10 MACHINERY UPDATE NOVEMBER/DECEMBER 2021 www.machineryupdate.co.uk

Regulations

There can be no doubt about the need for machinery electromagnetic compatibility (EMC) to prevent potential machine malfunctions or nearby machinery failures. Here’s a reminder…

10 MACHINERY UPDATE MARCH/APRIL 2023 www.machineryupdate.co.uk

Machine builders must ensure that a machine has been designed and manufactured to meet requirements

26-28 SEPTEMBER 2023 NEC, BIRMINGHAM

PPMA Show is the UK’s largest event for processing equipment, packaging machinery, industrial robots and vision systems

FREE TO ATTEND

REGISTER YOUR INTEREST NOW

www.ppmashow.co.uk

Latest OCR capabilities improve quality control

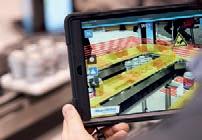

Cognex has expanded the capabilities of its In-Sight 2800 vision system to include optical character recognition (OCR) which is designed to improve quality control and traceability.

The new ViDi EL Read tool, powered by edge learning technology, deciphers humanreadable characters on reflective, low-contrast and non-flat surfaces with ease.

“The In-Sight 2800 with edge learning redefines ease of use, allowing anyone to deploy AI-based applications regardless of experience level,” says Lavanya Manohar, Cognex vice president of Vision Systems. “ViDi EL Read replaces complicated programming with examplebased training, making it simple to set up OCR models to read characters on challenging surfaces and even multiple lines of text simultaneously.”

The easy-to-use OCR solution helps food and beverage producers to easily read expiration dates, even on curved surfaces, to verify

In operation, accuracy of the results is measured by a confidence score proper routing and prevent the need for rework.

freshness and also prevent consumer recalls. Medical device and pharmaceutical companies can verify dates and lot codes to ensure vaccine efficacy and compliance with medical standards.

Meanwhile, electric vehicle manufacturers can quickly locate and read the alphanumeric text laser etched on the bottom sides of EV batteries to improve traceability, and logistics facilities can decipher codes and text on a variety of package types to ensure

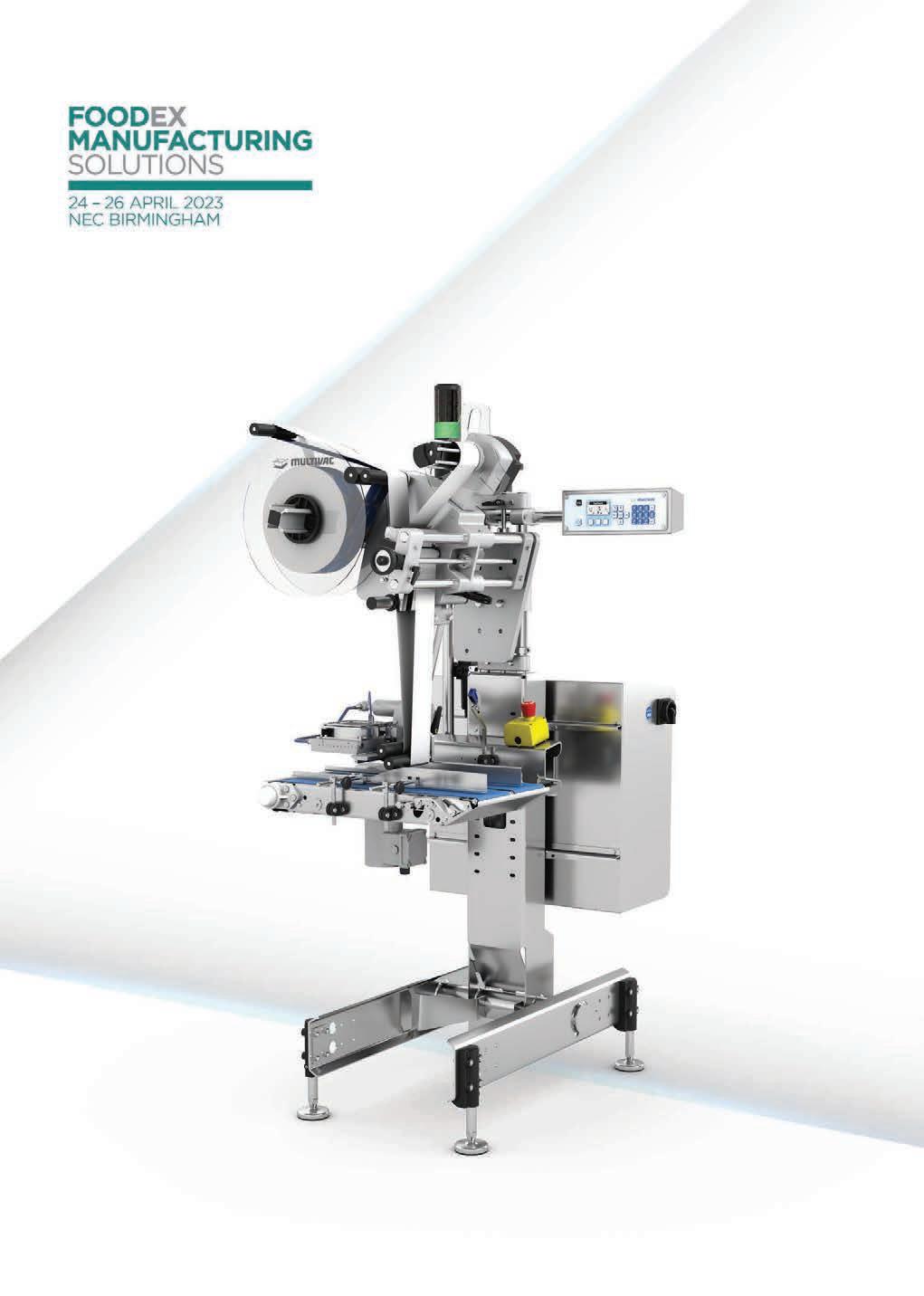

Print and apply unit can now work easily with legacy software

Markem-Imaje is introducing dual language support to its print and apply 2200 series.

The upgrade allows for full operation with both Markem-Imaje’s proprietary CoLOS solution or direct communication with ZPL emulation which, for the first time, facilitates immediate integration of the 2200 series into legacy software systems. This dual language support enables customers to directly connect to existing architecture with the ZPL emulator.

OCR applications can be time-consuming to set up, requiring hours of programming by highly trained engineers, preventing many companies from automating this type of inspection, says Cognex. Using the ViDi EL Read tool, models are set up and deployed directly on the device in minutes with as few as ten sample images.

T 0121 296 5163

W www.cognex.com

The 2200 series offers a broad range of end of line print and apply labelling solutions from simple case and pallet labelling through to high-speed front of pack or multi-side. With full GS1 compliance, the 2200 series has been recognised as an operator friendly solution, supporting optimised efficiency with a simple user interface, a minimised label change time of 40 seconds and competent operation with less than five minutes training.

T

0161 864 8111

W www.markem-imaje.co.uk

SHRINK WRAPPING MACHINERY

SHRINK FILM

STRETCH WRAPPING MACHINERY

STRETCH FILM

E-COMMERCE PACKAGING

SPARES & SERVICE

New Machinery 12 MACHINERY UPDATE MARCH/APRIL 2023 www.machineryupdate.co.uk

SUPPLY THE FILMS SPARES & SERVICE P CHANGE OLD MACHINE SUPPLY A MACHINE Contact us today T 01484 715111 E info@yps.co.uk W www.yps.co.uk

YPS MU M-A 2021 ARTWORK

THE COMPLETE SOLUTION FOR:

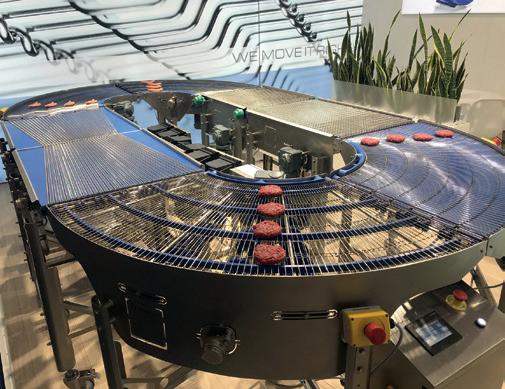

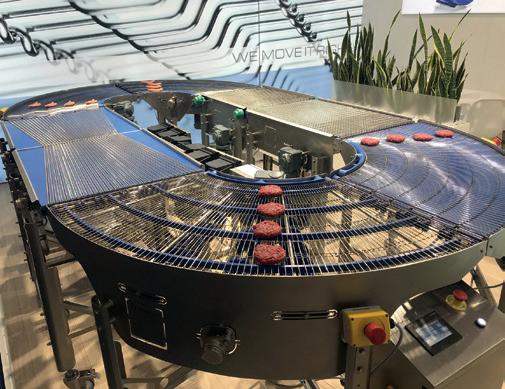

Retail-spec conveyor delivers future-proof promise to users

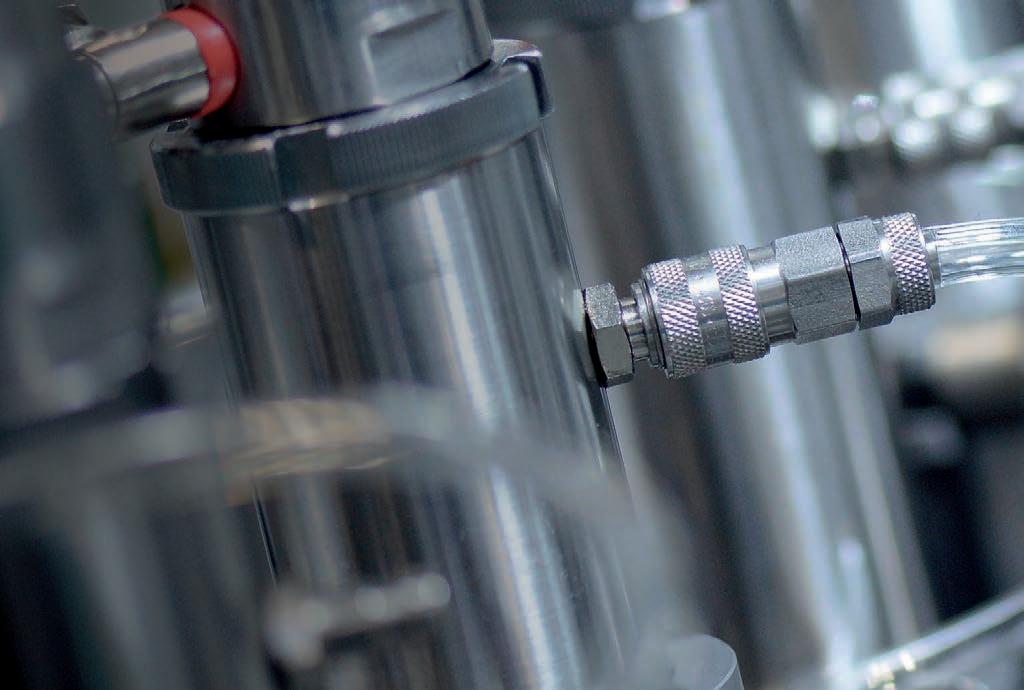

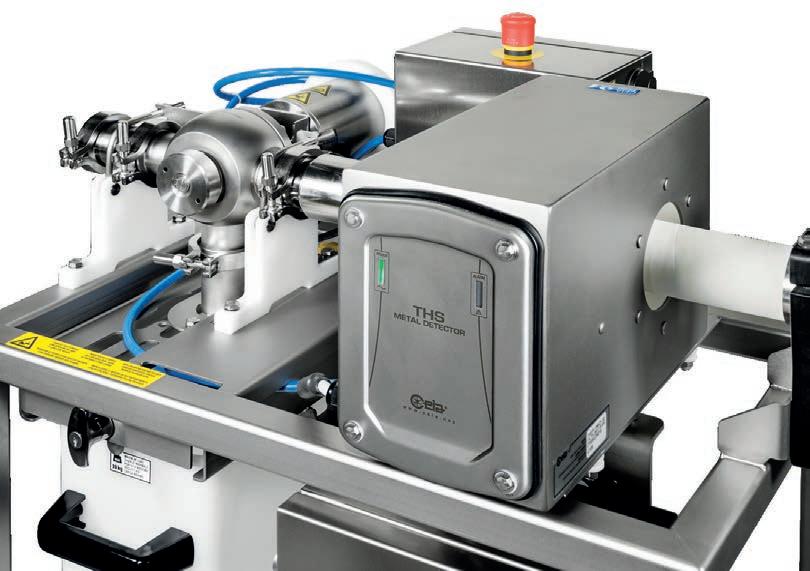

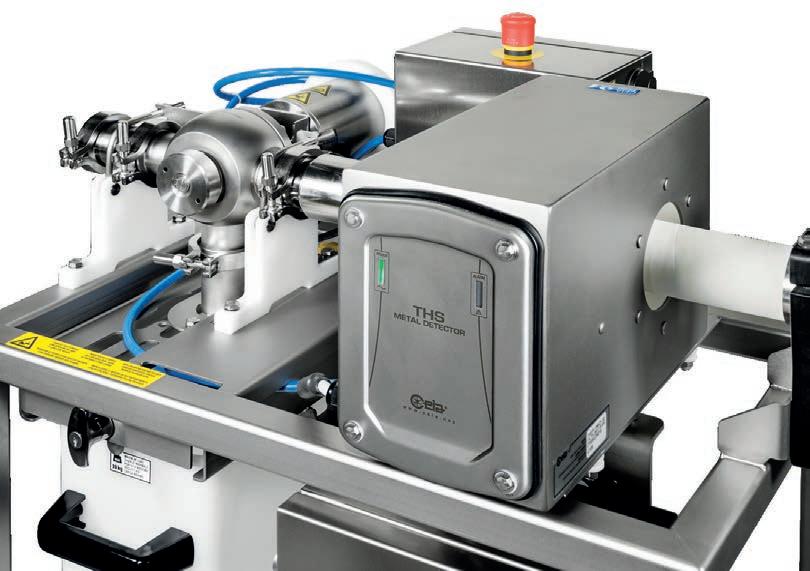

Fortress Technology has engineered a retailer-spec conveyor system that ticks all of the due diligence requirements for all product and application requirements.

Fully compliant with British Retail Consortium, HACCP and GFSI food safety standards, the Fortress all-in-one retail-spec conveyor includes ARM micro processing power and the latest infeed, outfeed and reject sensors.

Fortress believes that purchasing a conveyor system with fully integrated technology, including retailer Codes of Practice (COP), is a failsafe way of ensuring that the metal detector will function at peak performance levels and meet retailers’ current and future inspection performance requirements.

Conveyors/rejects can be customised

The latest conveyor is less about conveyor belt size or configuration, but more linked to the placement of smart sensors confirms Fortress sales manager Jaison Anand.

Describing the sensors as the brains of the retailer-ready metal detector, Anand says: “Built to the stringent M&S Food standards, the rationale for creating our retailer spec conveyor was to address this minefield and provide customers with future-proof functionality.”

T 01295 256266

W www.fortresstechnology.com

www.machineryupdate.co.uk MARCH/APRIL 2023 MACHINERY UPDATE 13

BLH Series Oriental Motor (UK) LTD www.oriental-motor.co.uk – info@oriental-motor.co.uk – 01256 347 090 EZS Series AZ Series CVK Series BLE2 Series KIIS Series DGII-Serie KIIS Series Angle Gearboxes STEPPERMOTORS BLDC MOTORS AC MOTORS ACTUATORS We have the solution. Position. Transport . Rotate

Cooling pouches in more eco way

Holmach is now offering the new Mini Flex Chill-Flow cooler for the rapid cooling of single serve sachets through to large food service pouches from Lyco Manufacturing. Using 80% less water and energy compared to traditional tumble chillers and offered in the smaller 2.4 m and 3.6 m sizes, Lyco has addressed the challenges of maximising production levels and minimising environmental impact, alongside restrictions on factory square footage.

Traditional tumble chillers dump water after every batch, whereas the new Mini Flex design can hold the water for as long as a week. This results in lower water usage and lower energy costs,

New robots for heavy payloads

while achieving fast cooling times following the hot fill of soups, sauces, condiments and pouched meals.

Patented technology ensures a uniform cooling process that, says Holmach, is up to twice as fast as other systems.

The robots in the KR Fortec ultra family from KUKA are a heavy payload range from 480 kg to 800 kg. Designed for high payloads and moments of inertia, they are billed as meeting the new production requirements of the electromobility sector.

This first in first out process achieves cooling levels of 4.4deg C and can be managed in various modes including batch, continuous and oscillating.

T 01780 749097

W www.holmach.co.uk

Five variants are available to meet specific application needs. The KR 800, for example, handles payloads up to 800 kg while the two KR 480 variants reach up to 3,700 mm. The high inertia options called KR 640 and KR 560, significantly increase the maximum permissible mass moment of inertia with extended grippers.

“We developed the robots of the new KR Fortec ultra family in close cooperation with our customers,” explains Wolfgang Bildl,

portfolio manager at KUKA. “They are our response to the automotive industry’s changing requirements, with bigger vehicles, heavy batteries and very large components for electric cars.”

The range’s double link arm design reduces weight but ensures rigidity and accuracy. This results in higher dynamic performance, optimal cycle times, less energy consumption and an overall lower CO2 footprint.

T 0121 505 9970

W www.kuka.com

New Machinery 14 MACHINERY UPDATE MARCH/APRIL 2023 www.machineryupdate.co.uk

The clever double link arm design reduces weight

A two-way flip top feature enables efficient cleaning

ACOPOS 6D

Creating new dimensions of adaptive manufacturing.

ACOPOS 6D allows you to move products freely through an open manufacturing space –unbound by the limits of one-dimensional production flow. Magnetic lev itation prov ides six degrees of freedom for unprecedented processing density on a fraction of the floorspace. br-automation.com

B&R | A member of the ABB Group

Learn more

Flexible screw conveyor agitator offers user gains

Spiroflow has re-designed its existing flexible screw conveyor (FSC) agitator with an updated version that can be easily dismantled in place for cleaning. The new design can also be retrofitted to existing machines in place of the current standard agitator unit if required.

Used to ensure a consistent flow of product, the agitator can be fitted as an optional extra on Spiroflow FSCs when needed, and used to break down bridging material in the flexible screw inlet. Many products being conveyed are not free flowing, so the agitator helps to create material flow within the equipment.

The standard agitator design has been in use for over 20 years and required the use of tooled intervention to remove it and take it apart; whereas the new version can be stripped down easily and reassembled in situ safely as required.

“In certain situations, it’s important for our customers

This version of the Spiroflow agitator can be retrofitted to existing FSCs

to have the ability to quickly strip down the agitator to be cleaned by the operator safely, and without the use of tools,” says Spiroflow’s technical sales manager Chris Brennan. “With the new agitator design, all access is protected by safety interlocks and the gearbox and motor remain in place.

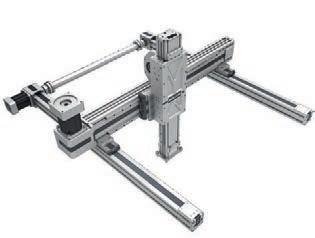

EtherCAT models are added to i4L SCARA robot series

Omron has announced the availability of new EtherCAT models to the i4L SCARA robot series which, it says, means these compact i4L robots now offer even stronger performance at the lowest total cost of ownership.

“There is no need to have plugs and sockets or heavy lifting to facilitate its removal, so cleaning can be done on the line, thereby saving time in the process,” he continues. “The additional benefit of the new agitator is that it can be retrofitted to existing FSCs.”

T 01200 422525

W www.spiroflow.com

Thanks to a compact design and small footprint, the i4L SCARA is simple to install and offers easy integration with Ethernet or EtherCAT connectivity in the base. And together with the robotic integrated controller, users can deploy multiple robots while reducing set up complexity and programming time. Its speed makes it ideal for material handling tasks, while freeing human resources for other tasks that maximise productivity for a company.

“Thanks to the EtherCAT models, we have taken our SCARA robots to the next level,” says Fernando Vaquerizo, fixed and cobots product marketing manager at Omron Europe.

01908 258258

W www.industrial.omron.co.uk T

New Machinery 16 MACHINERY UPDATE MARCH/APRIL 2023 www.machineryupdate.co.uk

Riggs MU M-J 2022

Handling punnets in multi materials

Different materials are handled on the same machine using easy to deploy recipes and package specific end effectors

Brillopak has launched its new TrayPAKer, a high-speed robot-based packaging solution that offers multi-material handling capabilities to make it ready for any changing material trends.

“The primary driver behind the machine’s development was from our customers in fresh produce,” explains David Jahn, sales director at Brillopak. “In this market, efficiency is everything.

“The prices are set by the supermarkets, and so our customers have to find economies in all the steps prior to final delivery,” he continues. “This machine is more than capable of meeting current demands and deploys a technological solution that will enable users to support what they don’t know will happen tomorrow.”

The new machine helps companies keep pace with the rapidity of modern supermarket supply chains; its flexibility, speed and throughput deliver higher performance than manual labour it is designed to replace, and its modular design and small footprint makes it adaptable to restricted spaces.

from plastics to cardboard punnet packaging.

The 150 punnets-per-minute machine combines robotics and vision systems with patented servo-driven end effectors and then deploys them in a pick-and-place operation that is said to address many of the challenges companies face when automating this traditionally manual process.

In operation, an accumulation conveyor manages the build-up of punnets before feeding them into the pick-up area. In the pick-up area one delta robot picks and places the packs onto the conveyor in a layer pattern, which is then indexed, oriented and gently compressed to the dimensions of the crate or container. A second delta robot with a different end effector then picks up the whole layer and lowers it into the crate or the container being used.

Brillopak says this wholelayer approach addresses misalignment issues created by single-punnet pick and place and delivers a neater shelf-ready appearance.

T 01622 872907

W www.brillopak.co.uk

www.machineryupdate.co.uk MACHINERY UPDATE 17

DRIVES NORD Gear Ltd | Abingdon | OX14 3NB Tel +44 1235 534404 | GB-Sales@nord.com nord.com Reliable. Versatile. Global. THE MOTOR Smooth surface High efficiency IP69K THE VARIABLE SPEED DRIVE Compact design Easy setup and implementation IP69K No paint to flake off Stainless shaft and fixings NORD 4.0 READY!

WASHDOWN

Maximising performance of safe doors

Designed with the food and beverage sector in mind, the HS9120G and HACCP-accredited HS9120GHY high-speed doors from Assa Abloy Entrance Systems are billed as meeting the efficiency and speed as well as the hygiene and safety requirements that users need to boost performance and protection.

“By accelerating the flow of people and goods, the highspeed industrial doors can dramatically improve operational efficiency,” explains Paul Dale, marketing officer at Assa Abloy. “Designed for fast-paced, high-cycle environments, the systems are highly durable, meeting the demands placed on them – even in round-the-clock manufacturing facilities.”

Meanwhile, the addition of the new door curtain also helps to reduce noise levels and improve energy efficiency. Designed to enhance performance, the high-speed door systems contribute to reduced downtime in manufacturing environments.

Safety features such as LED traffic lights, a safety light curtain, soft bottom profile and a break-away system make the doors suitable for busy environments. And by effectively separating areas, the doors can also help to maintain more comfortable climates, creating suitable manufacturing conditions while enhancing the comfort and wellbeing of staff.

T 0330 094 5620

W www.assaabloyentrance.co.uk

A robotics-enhanced line handles cosmetics range

Shemesh is launching the TKS-C60 roboticsenhanced packaging line for cosmetics that has been built to handle the entire process – feeding, filling, capping, labelling, case packing and palletising products of all shapes and product sizes.

The TKS-C60 is a seamless, uninterrupted bottling line for a range of products from creams and foundations to fragrances and nail polish and runs at a rate of 60 bottles per minute. The line consists of three ABB Delta robots – one on the product unscrambling station, one for accurate multi-capping and one for case packing – as well as an integrated advanced vision system.

The line’s two lanes offer greater flexibility, with the capability to pack different products on the same line simply by setting up the requisite recipes via a smart HMI screen. The linear rather than rotary feed means there are fewer parts for faster

and easier changeovers and cleaning. It can identify cap types of any dimension –screw caps, snap-on caps, pump/spray caps and more.

For shaped products, the line can also include puck loaders and unloaders to offer maximum flexibility.

ETNA, the line’s automatic bottle unscrambler, uses an ABB/FANUC spider robot to provide precise bottle orientation, covering virtually all bottle types common to the cosmetics sector.

The robotic elements ensure no change parts are required (except in some cases for the robot grippers) when unscrambling multiple different bottle shapes.

Adapted to work with corrosive products as well as flammable liquids, such as nail polish remover, the TKS-C60 is Industry 4.0 ready and offers ATEX protection standards in explosive atmospheres.

T 0758 428 1707

W shemeshautomation.com

Latest throughbeam photoelectric sensors offer quality benefits to packaging films

The new LS25CI throughbeam photoelectric sensor from Leuze is powerful and flexible and can transilluminate even metallised and dark films to meet the stringent requirements of the packaging industry.

As packaging films vary greatly, they can be a challenge for photoelectric sensors to reliably detect the position of

the objects in the packaging. With the LS25CI, Leuze is introducing a throughbeam photoelectric sensor that it

says can transilluminate any type of film.

System operators can pick from two models:

The LS25CI.XR1 high power can transilluminate dark films as well as identify individual transparent films, while for even tougher requirements, customers can specify the LS25CI.XX superpower which transilluminates metallised and dark coloured films, even if they are multi-layered.

T 01480 408500

W www.leuze.co.uk

New Machinery 18 MACHINERY UPDATE MARCH/APRIL 2023 www.machineryupdate.co.uk

Creams and foundations to fragrances and nail polishes can now be handled

Door ranges can be customised

This latest new sensor is powerful and flexible

FEATURING:

Where the processing, packaging & logistics sectors meet

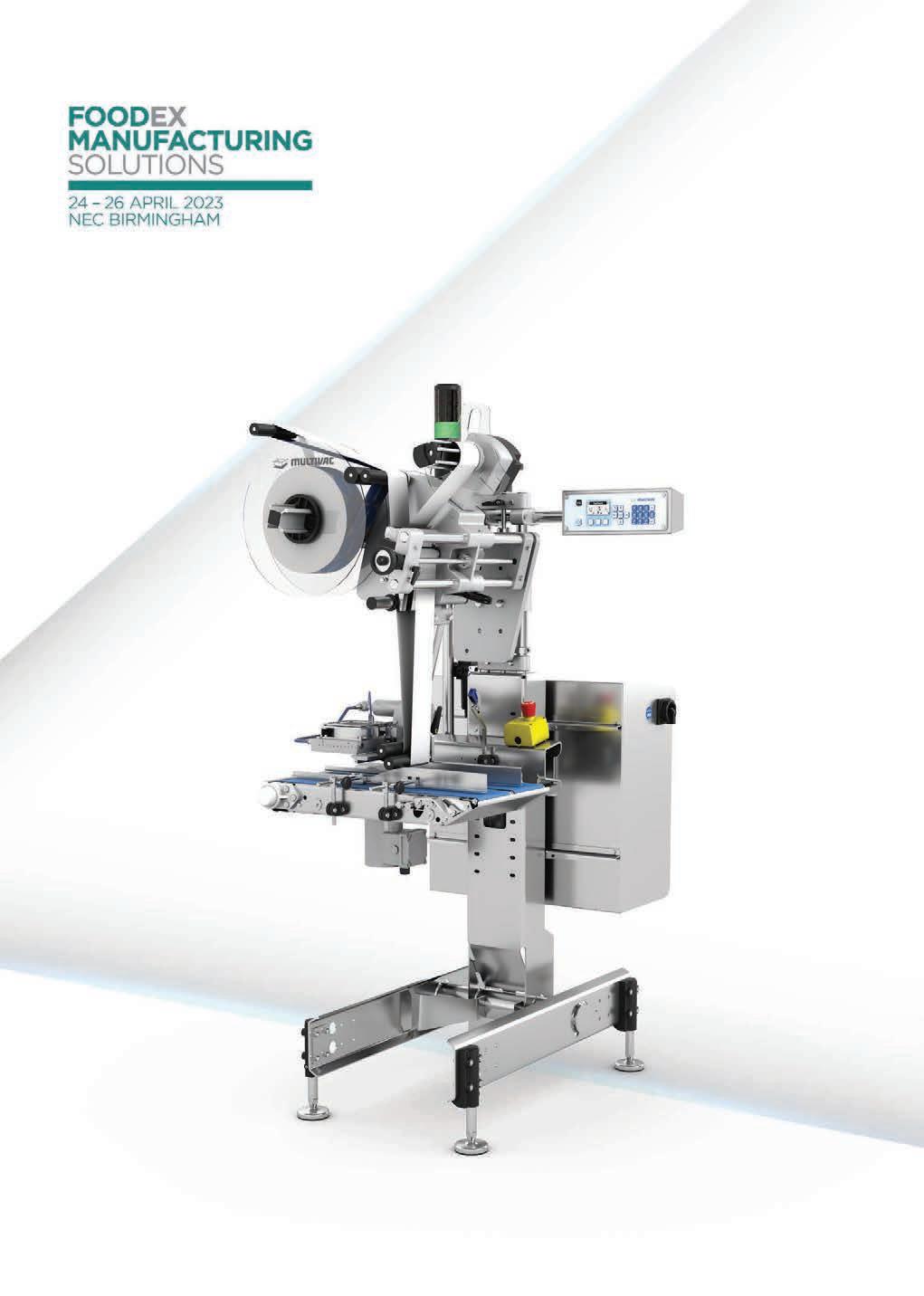

Informing, inspiring and connecting the industry

DOORS OPEN NEXT MONTH

After a five-year hiatus, Foodex Manufacturing Solutions will return to the NEC, Birmingham next month (24th – 26th), as part of the UK Food & Drink Shows.

The must-attend event unites Foodex Manufacturing Solutions (incorporating Ingredients), National Convenience Show, Farm Shop & Deli Show and Food & Drink Expo under one roof, giving food and drink professionals 2023’s most comprehensive snapshot of the latest products, key insights and developments across multiple industries.

Register for FREE: foodex.co.uk

This is a trade event. No under-18s will be admitted.

COMPLETE END-OF-LINE PACKAGING SYSTEMS HIGH-SPEED PACKAGING LINES SHRINK WRAPPING SLEEVE WRAPPING TRIMSEALING CASEERECTING &CASETAPING PALLET WRAPPING E-COMMERCE AUTOBAGGING FLOW WRAPPING FEEDING& SEPARATION SYSTEM SPIRAL WRAPPING www.adpak.co.uk 3PENDLESIDE,LOMESHAYEINDESTATE,NELSON,LANCS,BB96RY Tel:01282601444 | Fax:01282612201 | info@adpak.co.uk ADPAKCANDELIVER ENDOFLINE PACKAGINGSOLUTIONS THATARERIGHTFORYOU

New Machinery

Stretch hood pallet wrap system is available in UK

New feature allows robot collaboration

ABB has enhanced its RobotStudio robot programming and simulation software with cloud-enabled functionality.

The new RobotStudio Cloud enables individuals and teams to collaborate in real-time on robot cell designs from anywhere in the world, on any device. New features such as automatic version control increase transparency and productivity across teams. And the software’s simplified interfaces and intuitive navigation allow users of all skill levels to work on robotic projects.

FLEXIBLE SOLUTIONS

“At ABB Robotics, we continue to develop flexible solutions to help businesses overcome challenges, respond to changing customer needs and thrive in an age of increasing digitalisation,” says Marc Segura, president of ABB Robotics division.

“New web-based tools like RobotStudio Cloud bring a new level of agility and flexibility to manufacturers in how they plan and design their robotic automation solutions.

“RobotStudio Cloud helps to increase collaboration and reduce complexity, enabling both novices and experts to push the boundaries of robotics programming,” he concludes.

New features in RobotStudio Cloud include version control, which allows users to keep track of changes and have full transparency of any amendments, who made them and when.

T 01908 350300

W www.abb.com

Pace Mechanical Handling has been appointed as the first UK representative for Innova’s stretch hood pallet wrapping system.

Established in 2001 and headquartered in Castellón, Spain, the Innova Group specialises in end of line strapping and wrapping packaging machinery including its Stretch Hood system. New to the UK market, the Stretch Hood system guarantees total protection against humidity, rain and dust due to the tightness of the wrapping and properties of the Stretch Hood film, which envelopes palletised products from above to the base.

As well as being the only system that delivers completely waterproof protection, Innova says it uses the minimal amount of film, reducing material and energy costs.

Until now, Innova has focused on North America, Mexico and Brazil but turned its attention to the UK after another Spanish

packaging machinery manufacturer – TMI Sl – introduced the company to Nick Cesare at Pace Mechanical Handling.

“Stretch Hood is unlike anything else available in the UK, and we are confident it will replace traditional stretch wrappers due to the way it protects products and reduces both film and energy use,” explains Cesare managing director and sales director at Pace. “We think it will be popular with packers of all sizes across several sectors, including agriculture, food and beverages, chemicals and cement.

“Stretch Hood complements our range of robotic and automated packing lines in the same way as Ilerbox does, so we are very excited to be appointed as the sole representative for the Innova Group in the UK.”

Commenting on Pace’s appointment, Sergio Llido, CEO of Innova Group, said: “We chose Pace for their experience, technical team, market know-how, and all their expertise in packaging and end of line projects.”

T 01775 630900

W www.robotpalletizing.co.uk

A safety light curtain system for Smart Box Detection enables continuous material flow

Sick has launched what is billed as an industry-first safety light curtain system for Smart Box Detection, designed to enable the continuous safe material flow of cartons or cuboid goods at the entry or exit points of protected areas, while safeguarding people from materials handling, conveying or packaging machinery.

The system is a plug-andplay automation solution for the Sick deTec4 safety light curtain. It uses intelligent

pattern recognition to detect cuboid objects, and even some cylindrical goods that produce a cuboid-shaped silhouette and differentiates them

from people. Unnecessary stoppages are therefore avoided, for example at the in- and out- feeds of packaging machinery, or close to loading and unloading machinery in intralogistics facilities. The protected area above the material remains safeguarded by the light curtain at all times.

The productivity gains, cost and space saving offered benefits both machine builders and also end users.

T 01727 831121

W www.sick.co.uk

www.machineryupdate.co.uk MARCH/APRIL 2023 MACHINERY UPDATE 21 Installation News

Stretch Hood demands the minimum of film

Cost and space savings are offered

Increased agility and flexibility

Complete system delivers cost savings to snack firm

tna solutions worked in collaboration with the US pork snack company Benestar Brands to develop a highly efficient processing and packaging line for its bespoke rinds and cracklings.

The new line helped Benestar Brands improve its product quality tenfold, while significantly reducing energy use and enhancing efficiency.

“tna solutions has been a fantastic partner throughout the process,” explains Jose Gomez, chief technical officer at Benestar Brands. “The company’s experts have a deep understanding of our industry, while being open to listening to our specific challenges and finding out-of-the-box solutions.

“The accommodation of our specific needs, from footprint restrictions and frying demands to intricate

The tna robag 3e VFFS machine provided benefits

seasoning, helped facilitate our partnership with tna and develop an excellent product to satisfy every pork fan.”

Working collaboratively since 2005, Benestar Brands and tna’s engineers say they have developed the world’s most advanced approach to pork rind manufacturing. Every piece of the process, from feeding and frying to distribution systems and packaging, is optimised

Robotic & Automation Solutions

Automated production solutions individually designed and built for manufacturing sectors, including automotive, FMCG, food & drink, electronic components, medical devices.

to ensure better products and also a faster return on investment. The tna batch-pro 12 frying technology reduces rejects to less than 3%, while the special fryer design minimises oil use, contributing to product and materials savings.

In addition, the tna batch-pro 12 fryer system provides direct-fire heating for improved energy efficiencies and lower operating costs, while the accurate and flexible tna intelli-flav OMS 5.1 seasoning system allows for consistent coverage without costly ingredient losses, which further contributes to a healthy bottom line.

Finally, the tna robag 3e, vertical form, fill and seal (VFFS) packaging system enabled Benestar Brands to efficiently pack both pork rinds and cracklings on the same line at a high speed.

T 0121 628 8900

W www.tnasolutions.com

Financing package has allowed firm to save on energy costs

Taking into account Calder Textile’s cash flow, profitability and plans for the future, Siemens Financial Services (SFS) has supplied a 5-year lending facility that covered equipment, technology and infrastructure. “SFS were so dependable and knowledgeable throughout the process,” explains Greg Bedford, md at Calder. “Even in the case of delays in the supply chain, the team was happy to keep the approval in place which definitely made things easier for us.”

With the new facility and combined heat and power unit now in place, Calder can efficiently produce energy onsite giving the business greater control and crucially, also the oversight of its use.

01753 980078

W www.siemens.co.uk T

Installation News 22 MACHINERY UPDATE MARCH/APRIL 2023 www.machineryupdate.co.uk

Family-run firm is back in control

Gripple Automation Ltd, Unit 24 Orgreave Place, Dorehouse Industrial Estate, Sheffield, S13 9LU T +44 (0)114 553 6250 E info@grippleautomation.com W www.grippleautomation.com ■ Robotics ■ 6 Axis ■ Delta ■ Scara ■ CoBots ■ Programming ■ Vision Systems ■ Inspection ■ Assembly ■ Picking ■ Packing ■ Proof of principle

KEY FEATURES

• HIGH SENSITIVITY TO ALL METALS

• INTEGRATED CONTROLS for line speed and rejection

• HIGH IMMUNITY to environmental interference

• AUTOMATIC LEARNING & TRACKING of product effect

• DIGITALLY ADJUSTABLE BELT SPEED

• RUGGED AISI 316L stainless steel CONSTRUCTION and food-compatible plastic parts (EU, FDA COMPLIANT)

CEIA CONVEYOR INSPECTION SYSTEMS PIPELINE INTEGRATED SYSTEMS IXC and WEB-SERVER FUNCTIONS SEE US ON STAND D 59 - HALL 7 www.mds.org.uk UK FULL SERVICE AND TECHNICAL SUPPORT ∂ 24-7 Help Line and Assistance ∂ Metal Detector Validation and Retailer Code of practice training CEIA AUTHORISED DEALER ∂ Contact us on: 0161 286 8750 ( TECHNICAL) - 0161 286 8755 (SALES) metal detection services

Installation News

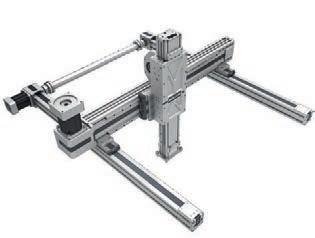

Multi-line palletising solution future proofs tortilla handling

Scott Automation has designed, manufactured and delivered a multiline palletising system that is not only meeting a food company’s existing needs, but that is also capable of doubling its current capacity.

Scott designed and installed this automated multi-line palletising system for Poco Loco, a leading Belgian producer of tortilla wraps, chips and snacks who are part of the Finnish Paulig Group. The system was installed last year in a new building in Roeselare and handles

the output of several new production lines. The solution covers all processes from conveying and accumulating the packs on buffer tables, to palletising them using the latest version of the company’s palletiser PAL 4.0 full pallet wrapping, labelling and conveying to the high bay warehouse.

The customer ultimately opted for the Scott multi-line solution over the single-line option offered by other suppliers as it is designed to enable further expansion that will accommodate double

the current palletising capacity of up to 50 pallets per hour.

The first phase covered four tortilla packing lines, sending filled cartons and display boxes to the buffer tables and one central PAL 4.0 palletiser. As soon as enough product is buffered to fill a complete pallet, it is summoned by the system, and then transported to the palletiser and the pallet is created.

Product infeed is at high level (of about 3.5 m) which frees up the access flow on the floor between production lines. Scott says this multi-line solution brings considerable benefits to the food giant, ranging from the low cost of ownership, reliability, space utilisation, high performance and high standards of hygiene and operator safety.

The PAL 4.0 is suitable

for a wide range of products including plastics trays, shrink wrapped packs, cartons, shelf ready and display boxes and has a user-friendly interface for creating new pallet layouts which simplifies setup and reduces changeover times.

T 01384 210278

W www.scottautomation.com

multihead weigher, a bagmaker and a checkweigher has delivered for new snack

A packing line solution comprising

An Ishida packing line solution comprising a multihead weigher, bagmaker and checkweigher has been instrumental in the launch of a new healthy snack from snacks specialist Good Food Products, Poland’s largest manufacturer of rice and corn wafers, crackers and also popcorn snacks.

Corn A’petit waffle snacks are produced from corn kernels and are baked with no added fat, preservatives or gluten and with reduced

The customer wanted the best snacks solution salt, making them a healthy alternative for snack fans. Because they are 45mm in

diameter, compared to traditional wafers which are 90 mm, Good Food Products was seeking a new production line that was able to cope with this specification. “When we were choosing our line supplier, we did thorough market research and Ishida turned out to be the optimal choice,” said Łukasz Wawrzyniak, engineering

department manager at Good Food Products. “We wanted to have the best solution for our new product, which we consider as a breakthrough on the snack market.”

The integrated Ishida solution features the company’s 14 head CCW-RVE multihead weigher combined with its Inspira bagmaker. The bagged snacks then have a final weight check on Ishida’s DACS-G checkweigher.

T 0121 607 7700

W www.ishidaeurope.com

a

24 MACHINERY UPDATE MARCH/APRIL 2023 www.machineryupdate.co.uk

Display boxes of tortillas transfer from the buffer tables to the palletiser

The pallet elevator conveys two full pallets

Auto bag placer helps throughput

RMGroup has supplied one of its new automatic bag placer systems, the BP-600, to animal feed specialist WE Jameson & Son who wanted to improve staffing levels at its mill. The new equipment includes an automatic bag stitching unit, label application and an ABB robot palletiser.

Delivering an efficient and cost-effective method of automatically placing sacks/bags onto the bagging unit, the BP-600 replaces existing manual operations, thereby maximising bag filling production efficiencies. Previous bag presentation issues are also eradicated

Pump provides quality savings

The new pump that Packo, part of The Verder Group, has supplied to Airedale Chemical for emulsifying soap in a consistent manner has saved the company time and also money.

with a consistent flow of bags to the filling head.

The system provides speeds of up to 10 bags a minute and its small footprint means that the configured layout enabled installation in the space provided, without impairing the customer’s ability to fulfil production demands. Designed to accept sacks up to 950 mm in length, the bag placer comprises a suction cup vacuum system to pick up bags before being transported on a chain belt, then opened to allow paddle arms to present to the filling head in operation.

T 01686 621704

W www.rmgroupuk.com

As the initial product is granular, the company’s existing pump could not completely emulsify the particles consistently, leading to clumps in the liquid and the pump becoming blocked. Each time this happened, the pump needed to be stopped, dismantled, and cleaned before it could resume working on the batch.

This was costing money in downtime and manpower to fix as approximately 1-2 hours were lost in maintenance per production cycle.

After an initial consultation with one of Verder’s technical sales engineers, it was decided that a shear mixing pump was the best approach. The Packo SFP2 series pump was selected as the perfect choice for the process and a trial pump was provided to

Airedale Chemical for testing. This pump was a success and Airedale Chemical was happy with the outcome. “It’s been a huge success and I’m very pleased with how quiet and effective the pump has been,” says Airedale maintenance manager Craig Wilkinson.

T 01924 221001 W www.verderliquids.com

BOT-GRIPPER

BOTTLE HANDLING SOLUTION

• A pneumatically operated gripper

BRINGING PNEUMATICS AND VACUUM TOGETHER

• Inflates a nylon sleeve enabling it to grip any type of bottle

•Integrated level compensator to allow for varying bottle heights

• B uilt in check valve for quick release

• M aximum lifting weight: 15kg

• Lifting diameter for top of bottle: 18mm – 32mm

www.machineryupdate.co.uk MARCH/APRIL 2023 MACHINERY UPDATE 25

The new pump has met all criteria

01299 877770 sales@simmatic.co.uk www.simmatic.co.uk Unit 11, Sandy Lane, Stourport-on-Severn, DY13 9QB

The 25 kg bags can be filled into woven PP & paper bags or pre-made plastic bags

VMECA product specialist and UK agent for over 20 years. Vacuum challenges? Simmatic has the solutions.

THISWATCHSPACE FORNEWPRODUCTS

Cartoners deliver the flexibility required for handling cosmetics

Flexibility is always key for contract manufacturers, and this was the reason behind Herrco Cosmetics’ decision to invest in cartoning equipment developed by UET and then supplied by Acer Machinery Solutions.

The company was faced with an ever-growing range of combinations and carton formats to handle product ranges in primary packaging such as tubes, bottles, pots and jars for customers.

To increase production, initial capital investment was in liquid filling lines, but the higher outputs demanded faster secondary packaging capabilities too.

This was not a simple procurement task as the wide range of carton formats included cartons with a fifth flap (eurohanger), feet, internal dividing sections and internal stands, which meant flexibility was the over-riding requirement. And this is when Derek Herrman, managing director of Herrco Cosmetics was introduced to the

UET Bernd Siebler’s adaptable range of cartoning machines.

Manufactured in Germany, these compact footprint machines with rotary starwheel, feature patented technology that enables customers to fully adjust the starwheel to accommodate different carton formats and sizes (within range) without needing multiple change parts.

“This quick and easy toolless changeover sees significantly reduced changeover times in under 30 minutes and are quicker for simpler adjustments,” says

Emma Ridgway, founder and director of Acer Machinery.

UET’s machines come in various configurations and, as they met the flexibility needs of Herrco Cosmetics, the company installed two different versions.

The first machine, called Compact 4, is configured to run with reverse tuck and aeroplane tuck cartons (with a replacement tool) –including those with inner dividing sections and feet features. Within the machine frame are two coding stations to print relevant data

on both lower and upper flaps. With some cartons seeing multiple product combinations, this additional loading station enables operators to streamline the operation without slowing down the machine. On the outfeed is an adjustable grouping table which groups cartons into the required counts for end of line handling.

The Compact 5 is the second installation, and with two additional stations, it enables fixed station positions to run reverse tuck cartons, aeroplane tuck cartons and cartons with a fifth flap (eurohanger), including those with special internal features. In addition, it has also been configured to run as a carton erector when needed.

As per the first machine, coding stations are found at both lower and upper flaps and with four loading stations and a grouping table, offers Herrco further flexibility in how it runs the machine.

T 01420 617249

W acermachinerysolutions.co.uk

Installation News 26 MACHINERY UPDATE MARCH/APRIL 2023 www.machineryupdate.co.uk

Herrco Cosmetics is meeting client needs for premium packed products

Packline Ltd • Unit 28 • Newtown Business Park • Ringwood Road • Poole • Dorset • BH12 3LL T: 01202 30770 • E: info@packline.co.uk www.packline.co.uk ■ Bespoke Design ■ Stainless Steel Construction ■ Compact and Manoeuvrable ■ Lifting Capacity up to 300kg ■ Interchangeable Attachments ■ Handle Reels of Film or Foil, Drums and Barrels Packline third

Pallet labelling proves to be a reliable option

The proven reliability and the low maintenance requirements of case and pallet labelling equipment from Logopak was the reason that Princes Gate Water sanctioned its latest installation at its Narberth, South Wales site.

Increased demand lead the company to invest in yet another high speed bottling and packaging line and Logopak was chosen as the supplier of the case and pallet labelling equipment due to the sites positive experience of Logopak labelling machinery over many years.

“Because our bottling plant is located in rural Pembrokeshire, it is vitally important that any equipment we install is reliable and low maintenance,” explains Peter

Moran, Princes Gate technical support manager. “Having used Logopak labelling equipment on site for over eight years, we have found that we very rarely required on-site support from their engineers due to the reliability of the machines; so choosing Logopak equipment for the new line was an easy decision.”

Logopak has installed a pair of ‘Body 1’ case labellers, which are supported above the twin lane pack conveyor by a bespoke portal frame. This portal frame allows the machines to be easily pulled to the operator’s side of the conveyor when consumable changes or any kind of maintenance are required.

After the packs have been automatically palletised and then stretch wrapped, the pallets then travel to the Logopak 920 pallet labeller, which automatically applies two SSCC pallet labels. Logopak’s bespoke Synchro software acts as a middleware between the pallet labeller and the customer’s ERP system, allowing for a simple and reliable data interface.

T 01904 692333

W www.logopak.co.uk

A new vacuum system with the latest digital services is offering big savings

Chicken processor Emsland Frischgeflügel

GmbH is enjoying substantial savings on maintenance costs with a new vacuum system from Busch Vacuum Solutions as well as taking advantage of the benefits offered by the OTTO digital service.

The 36 MINK pumps fitted with OTTO send performance data such as pump temperature, vibrations, and inlet pressure to the cloud, which can then be accessed via PC, tablet or smartphone.

“Not only have we saved an unbelievable amount of time tending to the systems, but we have also saved 70% of maintenance costs,” explains technical manager Johannes Kohne.

T 01952 677432

W www.busch.co.uk

• Proven technology

• Sturdy robust design

• Quick and easy set up between size formats

• Supplied in either tape or hot melt application

• Various options available

• UK engineering support/install

www.machineryupdate.co.uk MACHINERY UPDATE 27

The benefits have upgraded the German facility

“What’s more, thanks to the IE4 motors that drive the MINKs, around 274,500 kWh of energy can be saved in one year.”

The new project at Princes Gate Water, part of Nestlé, was a success

C1000/2000 case erector from Lantech

17 Elizabeth Court, St Neots, Cambridgeshire, PE19 8PF T: 01480 382739 M: 07764 772965 E: andrew@maters.co.uk www.maters.co.uk

Lantech modular case erector capable of up to 30 erected cases per minute

CS1000H

Southern Manufacturing Review

Award-winning components meet a range of design needs

Elesa (UK) exhibited its diverse range of machine components at Southern Manufacturing and Electronics that are marketed to meet all design engineering needs.

Boasting over 60,000 product codes frequently used in production equipment, the range includes adjustable feet, castors, measuring and alignment elements, hinges, handles, indicators and much more. One range that has recently been expanded is industrial wheels, which now includes even more specialist options to meet a wider range of customer needs.

The range has been developed to respond to different sectors, from factory equipment to furniture, from the food industry to the medical, from the handling of heavy loads to ‘ESD protected’ environments.

ESD wheels offer maximum safety to the operator, allowing static electricity to discharge directly to the ground, thus avoiding static

shocks to the individual. They find applications in the textile as well as the packaging sectors.

Having a hands-on approach is a core ethic behind Elesa and to ensure the highest quality, the company has an internal testing laboratory with advanced equipment and measuring instruments to study the evolution of new plastics materials and develop products for demanding applications and markets. All standard products in the range are subjected

to mechanical, physical, chemical and also durability testing.

Visitors to its stand learned about a patented product designed by Elesa that was awarded the German Design Award 2023. Elesa identified machine change-over-time in production to be a key issue affecting the profitable operation of packaging lines, and so provided a solution to this problem by developing the DD52R-E-RF wireless indicator system.

T 01526 322670

W www.elesa.com

Advanced microscopy and measurement on show, both feature easy-to-use functionality

Specialist measurement and inspection systems company Keyence demonstrated its newly released VHX-7000N Digital microscope at Southern Manufacturing & Electronics. The advanced system is billed as offering the world’s first 4K resolution along with a range of observation features, meaning the device can deliver images rivalling that of an SEM.

Another product in the Keyence line-up is the IM Series instant measurement

Best of engineering at anniversary event

Companiesofferingthevery latestindesign,innovation, productiontechniquesand processeswereseenatthe 25thanniversaryeventofthe SouthernManufacturing& ElectronicsShow,thattook placeinFebruarythisyear. Here,wehighlightjustsome oftheproductsonshowfrom PPMAmembersattending thethree-dayexhibition

Dust extraction firm exhibits a range of its ‘cleaner’ options

Dustcontrol UK exhibited its collection of high-performance extraction equipment at Southern Manufacturing & Electronics, including both fixed and mobile cyclone-based dust extractors and air cleaners.

Visitors could see the DC Tromb 400, Dustcontrol’s most powerful single-phase dust extractor and the powerful DC 2900 range, which can be used for industrial vacuuming or on-tool dust extraction. Its suction casings make it particularly effective for dust-creating activities.

system. Engineered to reduce time spent on inspection, the system guarantees accurate, reliable and repeatable measurement for all types of small parts including PCBs, turned parts, fasteners, lead frames, and precision moulded or pressed parts. The two systems feature an intuitive interface and

easy-to-use functions.

T 01908 696900

W www.keyence.co.uk

In addition, the range of DC AirCubes were exhibited at the event, which are designed as complimentary background air cleaners to at-source extraction, circulating clean air back into an area used for dust-creating activities and providing greater extraction efficiency.

Rounding off the equipment on display was the DC 1800 EX and DCF 60 pre-separator, along with a range of accessories including ATEX and suction cases.

01327 858001

W www.dustcontroluk.co.uk

New Machinery 28 MACHINERY UPDATE MARCH/APRIL 2023 www.machineryupdate.co.uk

T

Dustcontrols’ DC Tromb 400

Elesa’s patented DD52R-E-RF wireless system won a German Design Award

Solutions offer a safer cable mark

Phoenix Contact showed products from its comprehensive marking portfolio for cable and conductor identification at Southern Manufacturing & Electronics as well as device and system identification for the demanding food and beverage industry. It was also running a fun Strip the Wire competition on its stand, with the three fastest times wining a crimping toolkit.

The Phoenix Contact markings are designed to remain legible, even during cleaning regimes, due to their high chemical resistance and the material not being affected. For rapid visual identification,

The machining centre on show

Mills CNC showcased an advanced high-speed machining centre at Southern Manufacturing & Electronics which proved popular with manufacturers looking to maintain their competitive edge.

The machining centre is a high-speed unit

the identification solutions are blue. This makes them stand out and to be noticed instinctively, as well as more quickly, says the company.

Another advantage of the products is their detectability. This enables them to be detected with a metal detector during final inspections.

Labels with a powerful adhesive system are available for devices and systems with textured surfaces. The chemical-resistant adhesive spreads better throughout the structure of the surfaces and produces high adhesive strength for permanent identifications.

T 01952 681700

W www.phoenixcontact.co.uk

This SVM 4100 high-speed vertical machining centre made its UK debut on Mills’ stand at MACH 2022 and is designed to help manufacturers reduce part processing times, especially when machining aluminium alloys and for the light-duty machining of steel components.

With fast acceleration/ deceleration rates (0.72/0.6/ 0.6G on the machine’s X-, Y- and Z- axes), excellent tool-to-tool change over times (1.3 seconds) and boasting 36m/min rapids on all three axes, the SVM 4100 dramatically reduces noncutting times and, as a result, part cycle times too.

The machine’s speed (and power) is further enhanced by its 18.5kW/12,000rpm/ 95.5N-m directly connected BT 40 spindle which also features the Big Plus face and taper dual contact system, and an integrated thermal displacement correction system to ensure (and maintain) high accuracies even during long machining runs.

“The Southern Manufacturing Show is an ideal platform for us to demonstrate the productivity potential of our latest highspeed machining centre,” said Tony Dale, ceo of Mills CNC.

T 01926 736736

W www.millscnc.co.uk

www.machineryupdate.co.uk MARCH/APRIL 2023 MACHINERY UPDATE 29

FROM SINGLE PACK MANUAL TO HIGH SPEED LINEAR AUTOMATIC MACHINES 2 YEAR RETURN-TO-BASE WARRANTY SOKENENGINEERINGISPARTOFTHEJENTONGROUP QUALITY HEAT SEALING MACHINES FOR SANDWICH,

SALAD AND READY MEAL PACKS

The range of identification solutions from Phoenix Contact were on the stand

WRAP,

life

• Increases shelf

(for up to 3 days)

Parts

• Medical, Pharma,

options

• Greener packaging

Convenience

• Food-to-Go and

packs

P A C K S E A L S E L L www.sokenengineering.com 01525 376 000

• Less food waste

What you’ll find at interpack 2023

Options to meet sustaining goals

Some of the highlights on the Gerhard Schubert stand at interpack include cobots for the rapid feeding of different packaging components on a line, an extremely compact filling machine for cosmetic products and a new, efficient, resourcesaving feeding system for carton blanks.

interpack 2023 opens its doors on Thursday 4 May and runs until Wednesday 10 May and visitors to this fully booked event can expect to find about 2,700 companies from around the world.

Organisers say that no other industry trade fair can compare when it comes to representing the global market in its entire variety and scope with this show offering the packaging and related process industry the biggest international overview of the market. Getting lost is easy to do at the 18-hall event, and so the show features a custom concept based on the core target groups food,

beverages, confectionery and baked goods, pharmaceutical products, cosmetics, non-food and industrial goods.

A day ticket to the event is 65 € online and 75 € on-site, while a season ticket is 145 € online and 180 € on site. The show catalogue costs 35.00 €. As Messe Düsseldorf admission tickets no longer include free travel to and from events by public transport, visitors are also reminded that a ticket must be purchased for travel to and from Messe Düsseldorf.

Ticket-Hotline:

00 49 211 4560-7600

E ticket@messe-duesseldorf.de

W www.interpack.com

Beyond this, the company is gearing up to the challenges of the future – with a concept study for a new generation of machines, in combination with an all-new type of transport system. Together, the company believes the two promise to advance current packaging processes to the next level of automation, flexibility and efficiency. These technologies are complemented by a wide range of new services for more environmentally compatible packaging going forward.

Flexibility, efficiency and availability remain at the heart of the company’s robot-based modular technology. Through many

demonstrations, visitors to the stand will have an opportunity to see for themselves – live and in action – how Schubert combines its proven approach with forward-looking concepts for new packaging processes. Further details of these will be included in the review of interpack in our next issue.

HALL 14 STAND D01

W www.schubert-uk.co.uk

New filling technology will be revealed that is described as a world exclusive in terms of flexibility and space-savings

Cup and bucket filling machinery specialist Grunwald is inviting visitors to its interpack stand to discuss a new filling machine that has what it bills as a world exclusive in terms of flexibility and space-saving machine design. More details will be revealed at the event, but the latest developments on its range of linear and rotary machines capable of running from 2,000 to 50,000 units per hour can also be seen.

The company’s latest

technology which is rapidly replacing time consuming vacuum sealing.

Coupled with its machine quality, Grunwald offers an all-round lifecycle service, with local service support through its partner companies across the world.

“We pride ourselves in offering timely spares and service supply, supported

by our vast spare parts storage and our in-house parts manufacturing,” says Grunwald md James Causebrook.

A 4-lane ultra-clean UC inline machine, an electronically monitored cup filler with ultra-clean equipment that meets the highest hygiene standards and guarantees sterilisation rates of at least LOG 4, will also be demonstrated at the show.

HALL 6 STAND B01

W www.grunwald-uk.com

Preview: Introduction 30 MACHINERY UPDATE MARCH/APRIL 2023 www.machineryupdate.co.uk

The interpack website can help visitors to navigate the 18-hall exhibition

Grunwald’s ultra-clean machine will be on show introductions include filling machines for the paint industry and gas flushing

The new cobot allows users to carry out format changes for themselves

METAL DETECTOR & CHECKWEIGHER RAPTOR COMBI AWARD WInnInG DIGITAL InsPECTIOn sysTEMs fuLLy InTEGRATED X-RAy sysTEM www.fortresstechnology.co.uk RAPTOR X-RAy sEE us AT InTERPACK HALL 11 sTAnD E30

Extensive flow wrapping range offers user benefits

Mobile manipulator supports flexible manufacturing aims

Omron is co-exhibiting with eight co-exhibitors on the Packaging Valley stand at interpack which will include industrial automation solutions for the packaging industry, as well as labelling, sorting, packaging machines and components.

Paramount Packaging Systems, the UK and Ireland’s exclusive distributor of Fuji’s horizontal flow wrapping equipment since 1993, will be demonstrating the Alpha 8 packaging series, alongside Fuji Machinery Japan on the stand at interpack.

The Alpha 8 range includes over 25 different models, all based on the latest in-house software and motion control system, which is driven by a fully industrial computercontrolled PLC. This can control up to nine direct

servo motors, with simple interfacing protocol to interface with upstream and downstream machinery.

Amongst the range are a 3 side seal, 4 side seal and a high speed box motion model, able to produce 400 hermetically sealed packs per minute, which the company says is the fastest box motion machine on the market today.

To complement the flow wrappers, there is a range of infeed and buffering systems to fully automate product collation and feeding, increasing speed/efficiencies while also reducing overall labour requirements.

“We’re excited to have such a large exhibition at interpack this year as Fuji’s range is a fantastic setup for those looking to implement labour-saving automation into their production facility,” says Aaron Bessell, the sales director at Paramount Packaging Systems. “Visitors can expect to experience the fastest flow wrapping machinery on the market today, alongside its user-friendly operation, quick changeover capability and minimal maintenance requirements.”

HALL 5 STAND A05-A16

W paramount-packaging.co.uk

The company will showcase its MoMa mobile manipulator, designed to support flexible manufacturing processes. The MoMa mobile manipulator is a compact, flexible and autonomous mobile platform, equipped with a robotic arm, sensors and control systems to offer customers a flexible and versatile solution to enhance their production processes, without the need for fixed installations.

“We believe that this innovative solution is an ideal solution to improve flexibility and agility packaging and manufacturing, helping customers to streamline and connect their production processes,” says Stuart Coulton, UK marketing manager at Omron. 1 6 D72-6

HALL STAND

W www.industrial.omron.co.uk

A special vertical bagger designed for ultimate hygiene is joined by a new palletiser that helps answer labour issues

At interpack, BW Flexible Systems will be demonstrating its Hayssen vertical baggers along with Symach palletising equipment.