8 minute read

The Community of Potters

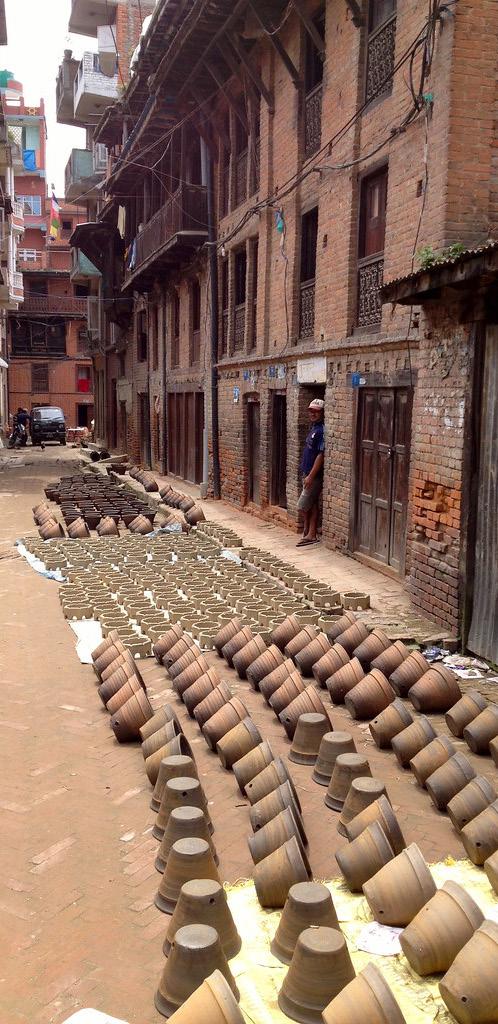

Sun drying the moulded pots

Advertisement

After the pots are made from the clay, they are arranged on trays together and then they are placed in the sunlight for drying. They are stacked on top of each other to store a massive amount of products made on a daily basis.

This takes around seven to eight hours for sufficient drying depending on the climate of different regions. In case of monsoons, the drying process is carried out inside the potter’s house under the fans which takes about two to three days for drying.

Preparing and firing the bhatti

The final stage involves the burning process of the pots using bhatti (kiln) which comprises cotton, hay dust, textile scrap, stones, terracotta and brick pieces. In places like Uttar Pradesh, they add dried goat dunk during the firing to give a black finish to the pots.

During this process, the whole family of the potter takes part to set up the furnace. First, the men assemble and arrange the pathra in sequence in order to form a uniform platform. By this time, the women collect the gunny bags consisting of bhusi and chindi for it to be placed upon the platform which was formed initially. Thereafter, the metal sheets are placed onto the earlier base. The pots are kept on these metal sheets. Once, the bhatti is filled, a final layer of metal sheets is formed as a covering for the bhatti. This restricts the heat from escaping, thereby retaining it and continues for about 9-10 hours and sees the temperature of bhatti reaching upto 900 degrees Celsius.

http://www.dsource.in/

This process of burning is carried out in different styles in different regions depending on their cultures and traditions. The burning process is usually carried out once in a fortnight but it again depends on the potters and their demands. After the burning process is complete, the goods are removed from the bhatti and stored in godown or in a small store area.

In a bhatti of about 100 pots, around 30 percent of it gets broken or dismantled during burning. These are segregated and the repairable ones are mended using cement paste. This is applied by hands, with the help of a small piece of wood. Thereafter, it is left for drying under the sun. After it’s dried, the cement patch is painted over with a mixture of gerua and water.

Benefits of using clay articles

Pottery is more than just any regular art, the use of clay articles in day-to-day life has many benefits. Back in the day, earthenware was a constant in Indian kitchens. Right from storing water to cooking, women managed it all with a single pot or ‘handi’, as it’s called in rural India. And, despite the availability of fancy and expensive cooking utensils, it looks like it’s time to go back to the basics.

Use of clay articles in cooking

We often see terracotta sets, mostly serving as showpieces, at home decor outlets, but a proper earthen pot is hardly ever put to use in the kitchen. However, it comes with a host of health benefits, since it cooks the food slowly. It also scores over aluminium, as studies point out. “As a result of their frequent use in private households, a study was undertaken to detect migration of this metal to foodstuffs from drink containers, coffee-pots, grill pans and camping cookware made of aluminium.

An estimate of the health risk to consumers is calculated, based on the tolerable weekly intake (TWI) specified by the European Food Safety Authority of 1 mg/kg body weight for all groups of people. In some instances, the TWI is significantly exceeded, dependent upon the food contact material and the food itself,” You could also check the weight of aluminium cookware when it’s purchased and after a couple of years, and you’re likely to spot a marked difference.

ancientcookware.com

While it may be difficult to find a pure clay pot, here are some reasons to include it in your kitchen.

Maintains the nutritive value

Due to slow cooking, clay pots allow moisture and heat to circulate through the food, thus retaining the nutritional level. In metal utensils, this tends to get lost. When cooking meats especially, the thermal inertia helps the muscle proteins denature and collagen break down completely, hence keeping it tender for a longer duration.

Neutralise the pH level

As clay pots are alkaline in nature, it interacts with the acidity in the food, hence neutralising the pH balance and making it healthier.

Cut down oil consumption

As they are heat-resistant and the dish cooks slowly, you can cut down on extra oil, such as vegetables. Earthen pots retain the oil and give moisture to food so you don’t add unnecessary fat to make your food tastier.

Adds more nutrients

It is said that clay pots add many important nutrients like calcium, phosphorus, iron, magnesium and sulfur to food, which are extremely beneficial to our body.

Add an earthy flavour

The aroma that your food will have after being cooked in an earthen pot is unbeatable.

Economical

Clay pots are affordable and easy on your pocket. Moreover, as the tradition of cooking in clay pots is almost dying, by purchasing one you indirectly help a family financially.

Use of clay articles in gardening

There are many benefits of using clay garden pots. Clay pots are actually made from unglazed terra cotta, a natural soil product. These were the garden pots of choice for centuries until plastic became both affordable and practical. Today, nearly every gardener has plastic pots lurking about the garden.

There are numerous benefits. Clay pots are porous. Because clay is made from natural materials, both air and water “breathe” through the pot’s shell. If you’re the kind of gardener who kills your plants with kindness and tends to over water them, clay pots can be your salvation, because water evaporates much more quickly from clay than plastic pots.

They are good for house plants that like a dry environment. Again, because clay loses moisture more quickly than plastic, they’re good for plants such as cacti and succulents that are more sensitive to moist environments.

You can use them for plants that tend to get top heavy and they won’t tip. Because clay pots are heavy, it takes a lot to push them over. Clay pots are beautiful. When they’re new, the pretty brick color goes with everything. As they age, they collect mineral deposits, or the white crud as I like to call it. Even that is beautiful because each clay pot is unique. Moss can grow on clay, which also looks attractive outdoors.

The Sustainable Art

When looking for sustainability in pottery, everything from the process of making the craft to using it is sustainable except for the transportation and the painting of the pots with shimmer and other chemicals. This shimmer gets into the drainage system. Since the customers are drawn towards everything glitter, there is a demand in the market. Hence, they are fulfilling it for their survival.

Burning the Bhatti

The bhatti is fired throughout the day and is a 6-9 hour long process. The bhatti is closed from 3 sides. These bhattis are generally located outside the potter’s house. The area nearby gets covered in smoke when the bhatti are fired. This smoke enters their homes. Although most of the people around are not bothered by this as they are accustomed to it. In fact the smoke helps in killing mosquitoes which reduces the risk of malaria.

Raw materials

Since clay itself is derived from the earth, it does not pollute the environment even if there is a wastage. Sun dried pots or diyas can be reused to make new articles before the baking process. Baked pots that face breakage or are over burnt can’t be recycled in clay mounds. Most of these are disposed of, but fortunately do not cause harm to the environment. The entire process of pottery itself is quite sustainable. The materials are either sourced directly from the earth or reuse waste materials such as cotton waste and textile waste for burning the bhatti. The production process is a good system that represents sustainable material sourcing, and could be a model for other unsustainable crafts.

Resusing broken pots

Padmashree Pandit Brahmodev, inspired from the Japanese pottery during a visit to Japan, he explored the method of mixing broken pieces of ceramic along with the new clay powder for better molding and strength. These pieces of ceramics are imported from industries in Surat.

Let’s preserve the Art of Pottery

References

01. www.britannica.com/ 02. www.craftsinindia.com/ 03. issuu.com/kachumpa/docs/tanya-mathew_ potterycraftofmumbai 04. peoplegroupsindia.com/ 05. www.instagram.com/khandekrn// 06. www.thecitizen.in/ 07. youtu.be/Sa3Kc12H-Zc 08. youtu.be/nkPO7KMSRGU 09. youtu.be/S424y8KtQnw 10. youtu.be/SS1cXIOM4DQ 11. www.thestatesman.com/ 01. Unsplash.com 02. Pexels.com 03. deccanherald.com 04. outlookindia.com 05. www.instagram.com/khandekrn// 06. sahapedia.org 07. dsource.in 08. picfair.com 09. kitsa.org 10. siccode.com/ 11. en.wikipedia.org