V Series Valve Solutions

The Flagship of the ValvTechnologies’ Product Line

Applications

ValvTechnologies’ valves are built to withstand the most severe applications. High-pressure, high-temperature, high-cycle, abrasive, corrosive and caustic media have all been considered in the design of our product line.

Fossil Fuel

Above and below seat drains

Ash handling

At temperator spray control

Boiler drains

Boiler feed pump isolation

Continuous boiler blowdown

Electronic relief

Feedwater heater drains

Feedwater isolation

Instrument isolation

Main steam stop

Recirculation

Seal steam regulators

Sight/gauge glass drains

Soot blower regulators

Startup vents

Steam dump

Turbine bypass systems

Turbine drain

Nuclear Generation

Boiler feedwater

Circulating water system

Component cooling

Condensate extraction

Condensate cooling water

Emergency feedwater

Fire protection system

HP safety injection

HP and LP heater drains

Heat exchanger vent and drains

Main steam system isolation, drain and vent

Power operated relief valve (PORV)

Pressurizer drain and vent

Rad waste system

Reactor coolant pump drain and vent

Reactor head vents

Reactor water cooling vents and drains

Safety injection system

Secondary system isolation, drain and vent

Service water system isolation

Steam generator system

Turbine bypass

Turbine drain and vent

Fukushima tie-ins

Reliable hardened vents

Upstream Oil and Gas

Wellhead choke isolation

HIPPS

Emergency shutdown

Compressor recycle and isolation

Sour gas isolation and control

Steam, water and gas injection

Steam chokes

SAG-D isolation

Pig launcher and receiver

Mud drilling isolation and check

Lean and rich amine isolation

Molecular sieve regeneration isolation

Molecular sieve absorber isolation

First and second stage separator isolation

Downstream and Chemical Processing

Coking (delayed and flexi)

Switching

Feed isolation

Overhead vapor line

Cutting water isolation

Fluidized catalytic cracking

Catalyst handling

Slurry isolation and control steam

Ethylene

Steam decoke isolation

Furnace isolation

Steam vent

Quench oil isolation and control

Polyethylene

Isolation

Hig h-cycle (PTO)

Reactor block

Heavy oil upgrading and hydrocracking (H-oil and LC fining)

Catalyst addition and withdrawal

Filter and pump isolation

Overhead vapor isolation and control

Hig h ∆P isolation and control

Reforming (CCR)

Lock hopper

Isolation

Mining and Minerals Processing

High-pressure slurry

Transportation systems

Pump discharge isolation

Pipeline isolation stations

Pipeline choke stations

Rupture disc isolation

Instrument isolation

Autoclaves

Vessel feed and discharge

Acid injection

Gas injection

Steam injection

Mineral concentrators

Thickener underflow

Discharge isolation

Filter press manifold isolation

Slurry transfer systems

PR V isolation

Waste disposal

Tailings pipelines

Paste backfill

Pulp and Paper

Boiler vent and drain

Liquor isolation and control

Rapid drain

Steam isolation

Sk y vents

Dr yer pressure control

Digester steam control

Lime mud isolation and control

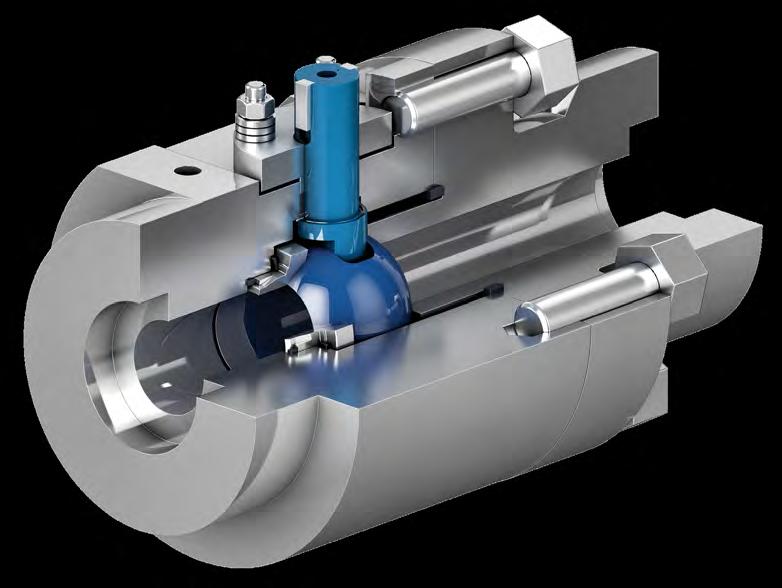

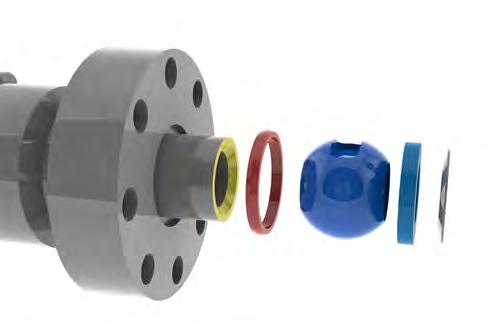

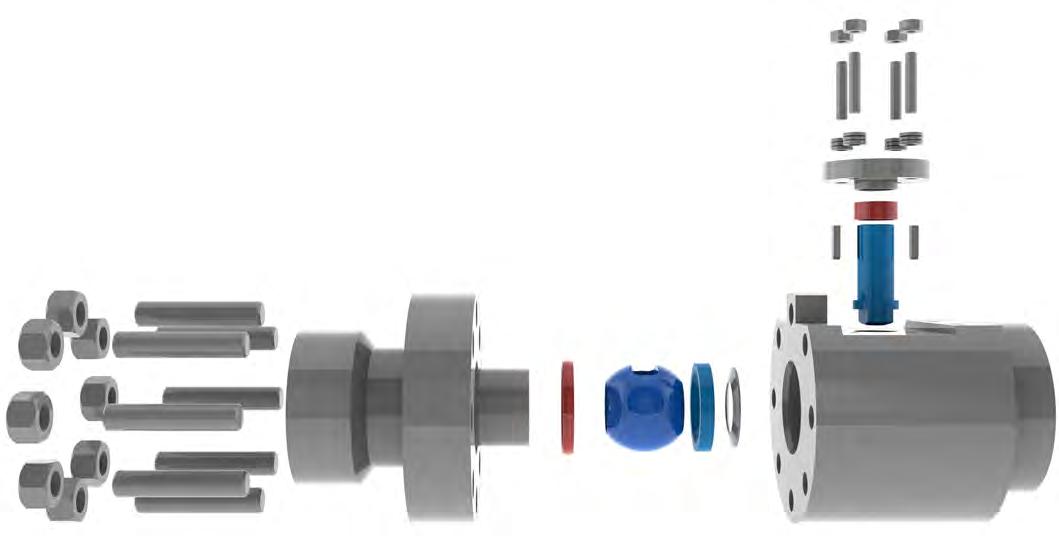

V Series Metal Seated Ball Valves

The flagship of the ValvTechnologies’ product line

1.Integral metal seat

With our patented HVOF RiTech® coating technology, the integral seat in ValvTechnologies’ valves is resistant to the attack of abrasive and corrosive production applications.

2.Body seal ring

ValvTechnologies employs a field-proven seal ring technology to ensure sealing under all operating conditions, up to 1400°F. The body seal ring is loaded at a pressure higher than 20,000 psi. In addition, valves sized 3” and above contain a secondary Grafoil® seal to further guarantee reliability

3.Patented coating process

The sealing surfaces are overlaid with tungsten or chromium carbide using our HVOF RiTech® coating process. These surfaces have a hardness of 68 - 72 Rc to provide uninterrupted operation in the most severe conditions with zero-leakage.

4.Live-loaded gland area

The V Series’ sealing design features a four stud, live- loaded assembly designed for heavy industrial applications. The sealing material is high purity Grafoil® surrounded by stainless steel wire mesh anti-extrusion rings. The six Belleville® springs (per stud) provide constant load pressure through extreme thermal shocks and prevent wear leaks in high-cycle service.

5.Blow-out proof stem

ValvTechnologies’ design utilizes a one-piece, hard-coated, blow-out proof stem that is inserted through the inside of the body cavity eliminating the possibility of blow-out through the gland area. There are no pins, collars or other devices used to retain the stem in the valve body.

V1-1

Forged, high-pressure valves Four-year, zero-leakage warranty*

1/4 - 4“

ANSI/ASME Class 900 - 4500

V1-2

Flanged, low-pressure valves

1/2 - 36“

ANSI/ASME Class 150 - 600

V1-3

Small bore, low and intermediate pressure investment cast valves Four-year, zero-leakage warranty*

1/2 - 2“

ANSI/ASME 150 - 600

V1-4

Large bore, high-pressure valves

4 - 36“

ANSI/ASME Class 900 - 4500

Features

V Series Key Performance Features and Benefits

Benefits

Guaranteed tight shut-off

Quarter turn operation - readily automated

Low pressure drop - high Cv

Custom engineered

Dimensions to ANSI B16.10

Low emission packing and seals

Single piece anti-blow-out stem design

Resistant to solids

Certified to use in SIL 3 loop

Live-loaded gland system (four stud design)

Stem fugitive emissions per ISO 15848-1 Class B

Fire safe certification: API-607

Enhanced process safety

Increased safety, ease of operation, reduced space requirements

Process efficiency

Process optimization

Interchangeable with equivalent valves

Reduced emissions

Enhanced process safety

Reduced maintenance costs, minimum downtime

Enhanced process safety

Reduced emissions

Reduced emissions, enhanced process safety

Enhanced process safety

The Real Cost of Valve Leakage

The cost of leaking steam and process fluids is far greater than the total cost of a valve.

The cost of replacing or repairing a valve is small compared to the cost of lost heat-rate efficiency in power plants caused by leaking valves. Minor leaks will grow to major leakage, causing frequent equipment repair or replacement and costly unscheduled plant shutdowns. Valves can have severe leakage that is not visible to the eye as internal valve leakage can go undetected for long periods of time.

With zero-leakage severe service isolation valves, less fuel is burned to produce megawatts, which lowers emissions and overall costs of plant operations. ValvTechnologies’ decades of engineering experience have designed a superior severe service isolation valve that exceeds industry standards when it comes to defining zero-leakage.

Zero-leakage is defined as no detectable leakage of gas or a liquid for a period of three minutes or greater.

Allowable leakage rates:

MSS SP-61, 4”, ASME/ANSI Class 1500, reduced port:

Allowable leakage per hour = 0.010565 gallons

Allowable leakage per year = 92.5 gallons

Leakage over four years assuming constant leak path:

gallons

FCI-2 Class V, 4”, ASME/ANSI Class 1500, reduced port:

Allowable leakage per hour = 0.069465 gallons

Allowable leakage per year = 608.5 gallons

Leakage over four years assuming constant leak path:

Guaranteed

Would you specify a valve that will have a significant leak after one year in service? If not, then what specifications do you use? All ValvTechnologies’ valves are guaranteed absolute zero-leakage for fouryears in steam and power applications.

All other valves in the industry have a defined leakage rate. ValvTechnologies tests every valve according to ANSI procedures. However, we toughen the standard to zero-leakage on both water and gas. Our standard is zero drops and zero bubbles guaranteed.

Qualified

At ValvTechnologies, we are totally committed to quality. We measure our performance against the standards set in our Integrated Quality Program. Our Quality Assurance department diligently pursues opportunities for improvement, while the entire organization takes ownership of the quality program. In this way, we can improve our processes while increasing manufacturing efficiency.

Efficient

Cycle isolation eliminates energy losses attributable to poorly performing or leaking steam, water cycle isolation valves. ValvTechnologies encourages end users to apply the principles of asset management to their installed valve population. The ValvPerformance Testing™ program, or cycle isolation measurement, utilizes next generation acoustic monitoring instruments to help customers monitor valve performance. These tools allow predictive and preventative maintenance programs to be fine tuned for very large or very small valve populations. Providing cycle isolation services can be as simple as performing a valve survey, or as comprehensive as the management of all valve work during your next outage - from erecting scaffolds to repairing, installing, welding and stress relieving.

Benefits

Plant efficiency improvement

Economic payback in just months

Improved decision making

Reductions in overall valve maintenance spend

Cost avoidance of unnecessary valve repairs or replacements

Zero-leakage Valve Solutions

Find your local Distributor:

NEW CASTLE

2680 New Butler Rd. New Castle, PA 16101

Tel: 724-368-8725

Email: sales@portersvilleprd.com

RICHMOND

700 Southlake Blvd. North Chesterfield VA 23236

Tel: 804-593-2384

Email: sales@portersvilleprd.com

www.portersvilleprd.com

Headquarters & Manufacturing

ValvTechnologies, Inc.

5904 Bingle Road

Houston, Texas 77092 U.S.A.

Telephone +1 713 860 0400 Fax +1 713 860 0499 info@valv.com.

To locate a distributor or satellite office near you, visit us online at: www.valv.com.

To contact sales anywhere in the world, email sales@valv.com

TALLMADGE

143 S.Thomas Rd. Tallmadge, OH 44278

Tel: 330-253-4800

Email: sales@portersvilleprd.com

KINGSPORT

1551 Shipley Ferry Road Blountville, TN 37617

Tel: 423-482-0496

Email: sales@portersvilleprd.com

SOUTH POINT

403 Technology Dr South Point, OH 45680

Tel: 740-377-0018

Email: sales@portersvilleprd.com

RALEIGH

3915 Beryl Road, Raleigh NC 27607

Tel: 984-238-1720

Email: sales@portersvilleprd.com