4 minute read

The Digital or Flexo dilemma

Aniflo, the game changer technology to restore profitability.

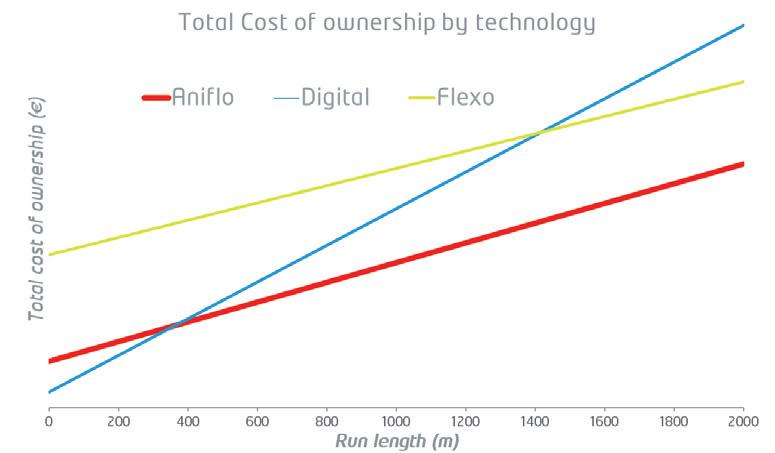

Many studies have been published explaining the benefits of each technology for narrow web printing. We fully agree with their results that conclude to similar figures: Digital printing is more efficient than flexo on short run, and the break-even point is roughly between 1200 m and 3000 m.

Advertisement

By avoiding the cost of plates, digital printing technology, such as dry toner, liquid toner or inkjet, are reducing the fixed costs per job, making them suitable for short run. Many assumptions have to be taken into account to do the maths properly: investment costs, number of jobs per shift/day/year, labour costs, substrate costs, ink costs and volume, tooling costs, waste, make ready time, production speed… All press manufacturers are synthesizing it with the Total Cost of Ownership (TCO) that includes all these costs, allowing the comparison between the different printing technology.

Same approach, same assumptions, same fi gures, but not the same conclusion!

The financial model we are using in computing market prices and costs evocated above, optimizes each technology. Our results show that break-even point between digital and flexo is roughly at 1400m. Of course, the more flexo plates you need, the higher the break-even point will be. Every job is different, every market is different, but figures are figures, and our conclusion won’t change even if this breakeven would be at 1000 or 3000 m, so we have kept conservative assumptions.

In fact, the big picture has to be observed not on one job, but on all jobs. Every converter is facing various run length, depending on size of labels, quantity, different SKU’s. And the same job can be printed once for very small quantity, sometimes for larger quantities. Let’s say that the jobs you are printing are like this chart (similar to real production jobs from various countries on our machines): 25% of the jobs below 400 m, 7% above 8 000 m. - jobs above 10 000m are not displayed in the charts but taken into account in figures. The average run length here is 2500m (comparable to recent publication by FINAT). If you look at figures differently, the same distribution is telling you that 2% of the labels in quantity are printed on short run below 400 m, and 29% on long run above 8 000 m.

And guess what, converters are not selling linear meters, but labels!

What if these publications were considering Anifl o technology?

If you can get the best of the different technologies like flexo productivity with high production speed and low consumables costs, and digital flexibility with very low waste and make ready time, then, you would be able to reduce the break-even point compared to digital on short run length (300-500m), and you will still be competitive against flexo on longer run (8 000-12 000 m). This is where Aniflo helps you.

Aniflo is an inking system, combining offset quality, flexo productivity and digital flexibility. It features an offset unit, with cheap offset plates and a simple anilox delivery system that brings a uniform ink amount across the web. With the lowest operational costs, Aniflo is the most economical choice for short, medium (and even long) runs on any commonly used substrate – filmic, paper, carton... Because it is intermittent and inking consistency is stable, fewer consumables are needed. Make ready time is dramatically reduced, making Aniflo very efficient even for very short run. The high-definition capability and superior stability means Aniflo can print in Extended Gamut Printing, like digital machine, without the inconvenience of high ink costs, click charges or planned obsolescence.

Now, let’s apply this technology and its performance on all your jobs:

Jobs above 10 000m are not displayed in the charts but taken into account in figures.

Aniflo is here the most cost-efficient technology for 73% of the jobs, and 72% of the output (quantity of labels printed).

Restore profitability with Aniflo!

By getting the most cost-efficient technology for your jobs, you are saving money and restoring your margins. To have an idea of the global savings, we can take the example of a converter already equipped with both flexo and digital solution.

By printing the jobs on Aniflo that are suitable for this technology (a conservative approach would be 400 m to 8 000 m), this converter would lower its TCO by 33%.

No surprise then, new Aniflo owners decide to invest in the second Aniflo press on average after just one year and 9 months of the installation of their first Aniflo machine!

At Codimag, we are convinced that Aniflo will meet the jobs you have to print, and all the new markets that converters can conquer. Furthermore, with offset quality, versatility, and ability to print on any substrate!

- Written by Benoit Demol, CEO at CODIMAG