Fundamentals

The United States Army Research Laboratory approached Albany International Inc., our former parent company, to develop a water-resistant synthetic alternative to goose and duck down.

After one year of research and development, we patented the first synthetic microfiber for apparel, and PrimaLoft was born.

L.L.Bean and Polo Ralph Lauren become the first brands to make PrimaLoft available to consumers.

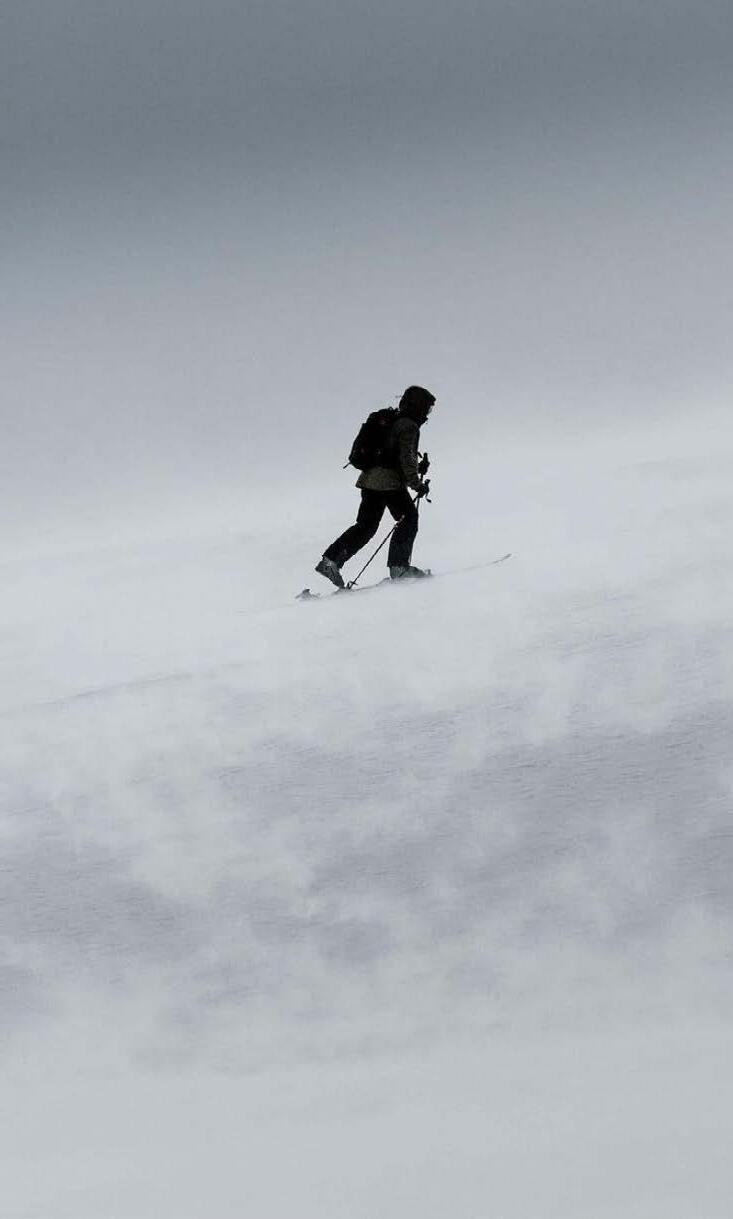

PrimaLoft® insulated jackets were part of the layering system L.L.Bean used to outfit the Mt. Everest Peace Climb led by Jim Whittaker, who became the first-ever American to summit Everest in 1963.

Over the past 40 years, PrimaLoft’s commitment to delivering the highest-performing synthetic insulations on the market has earned the trust of more than 950 global brands.

We deliver this through our Relentlessly Responsible™ Mission

Our commitment to our Relentlessly Responsible™ mission means that we are always striving to provide the highest possible performance while reducing our impact on the planet.

We turn this belief into action through our expertise:

Innovation + Performance + Sustainability

Durable

Water Resistant

Warm when Wet

Down has long been regarded as nature’s best insulator, and it’s been used in apparel to keep us warm for almost a century. But when exposed to moisture, it loses its thermal properties.

provides remarkable warmth but isn’t able to maintain that warmth in wet conditions.

This is where PrimaLoft® synthetic insulation shines.

If you want to stay warm in wet weather, or during activities where you’re breaking a sweat, PrimaLoft® insulation provides the versatility you need. Our expertise in material development enables a wide-ranging portfolio of synthetic solutions.

High Warmth to Weight

Durable

Easy Care

Water Resistant

Warm when Wet

Vegan Friendly

Hypoallergenic

We’ve mastered the recipe for the best products at the lowest impact.

PrimaLoft possesses a unique expertise in textile processing, material finishing, and polymer optimization to create high-performance products. Our material experts relentlessly refine our synthetic recipes by leveraging the interplay of different fiber sizes, structures and finishes to create products with outstanding performance benefits, all while being built on our “sustainable chassis.”

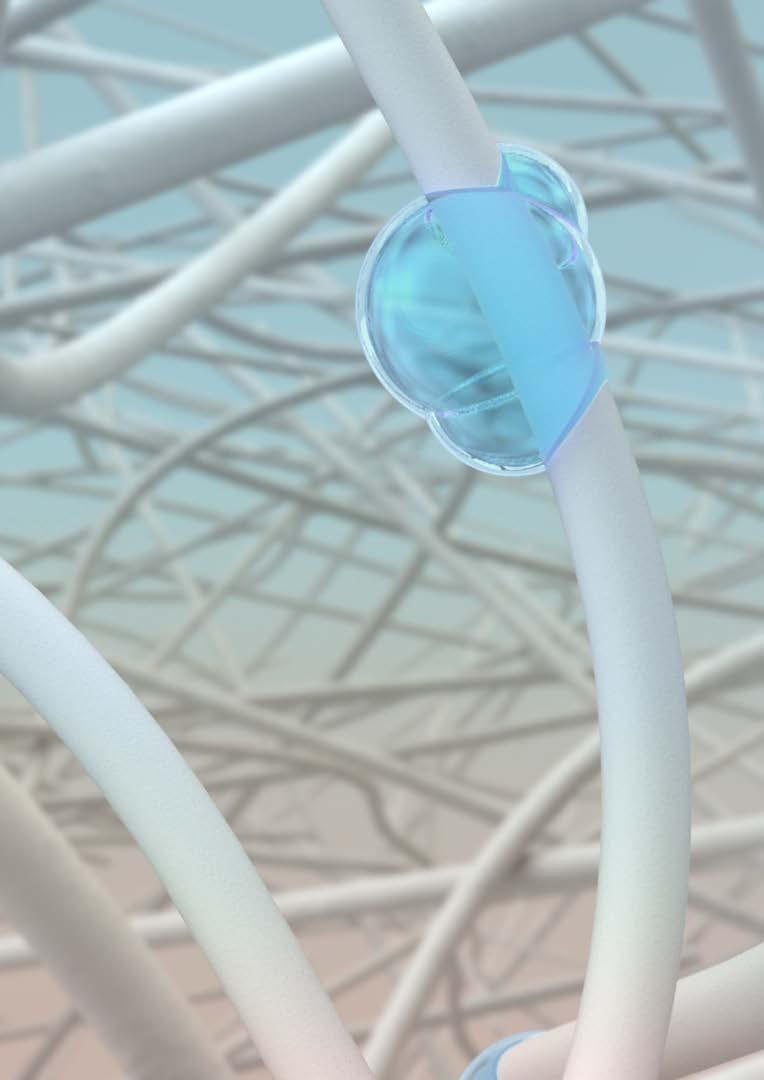

Every great recipe needs a key ingredient that ties everything together. Ours is the use of microfibers and ultra-fine fibers. Since our inception, PrimaLoft’s expertise has been rooted in microfiber technology.

Microfibers are roughly 7x finer than a human hair

PrimaLoft® insulations strategically utilize microfibers and ultrafine fibers. Our proprietary recipes deliver insulations that provide industry-leading performance and sustainability benefits.

Warm

Smaller fibers create a higher number of tiny air pockets, the key to trapping heat and insulating effectively

Durable

Designed to withstand any activity, repeated laundering, and the test of time

Dry

Hydrophobic fibers are inherently water-resistant, repelling water to keep you warm, even in wet conditions

Soft

The thinner the fiber, the softer the material, and PrimaLoft® fibers are finer than cashmere

Packable

Increased compressibility and recovery allows you to efficiently pack your kit

Lightweight

Lightweight, thermallyefficient materials mean lightweight garments that provide the comfort you need

PrimaLoft’s expertise extends to a variety of insulation form factors.

We use post-consumer recycled material, without sacrificing performance.

We reduce our carbon emissions during the production process.

We believe that high-performance products do not need to come at the expense of the planet. So, we’re relentlessly exploring how to innovate at every step of a product’s life, to benefit the earth.

Our products can live on through circular enabled design.

We combat microplastics through products designed to return to materials found in nature.

We make long-lasting products, helping to reduce consumer textile waste.

True mastery of the synthetic recipe requires placing equal value on both performance and sustainability.

We are constantly finding new solutions.

We offer a full portfolio of performance and sustainability technology platforms. Specific products include unique combinations of benefits to meet a variety of needs.

Discover our latest product innovations here:

Whatever you are building, we can help you find what’s best for you.

Gold Series Maximizes Key Benefits

Silver Series Optimizes Key Benefits

Black Series Includes Key Benefits

PrimaLoft® products feature an ever-growing list of key performance and sustainability benefits.

PrimaLoft retains a global network of contract manufacturers, partnering with facilities across Asia, Europe and North America.

We are able to strategically align our production locations so that they are clustered close to our customers’ garment factories.

This asset-light model aligns perfectly with our company’s Relentlessly Responsible™ mission to reduce our impact on the environment, while also reducing lead-times and transit costs.

We have operations based in the following countries:

• United States

• Germany

• Italy

• Taiwan

• South Korea

• China

• Vietnam

We are actively managing a global manufacturing network. For the most accurate country or countries of origin and certifications, please reach out to your PrimaLoft® sales representative.

In textiles, warmth is determined by measuring a material’s thermal resistance in units of Clo. Thermal resistance is how well an insulation traps and retains warmth. A higher Clo value indicates better insulating properties. Warmth

Warmth equivalent to a three-layer ski outfit

3 Clo and above represents the warmth equivalent to a sleeping bag or three-layer expedition outfit

PrimaLoft provides relevant Clo testing data for all applicable products. Clo ratings can be found on our product tech sheets. Outlined here are definitions that will help navigate the information found on these documents.

Total Clo is the thermal resistance of an insulation at a given weight. The higher the weight of a given insulation, the more insulating it will be, resulting in higher total Clo values.

Wet Clo is the thermal resistance of a wet insulation at a given weight. PrimaLoft® fibers are treated with a proprietary PFC-free finish that makes them highly effective at retaining warmth when wet.

Clo ratings per oz/yd 2 or g/m 2 allow you to compare the relative thermal performance of one insulation versus another. A higher clo/ oz/yd 2 represents a higher warmth to weight.

The following section can be used as a reference for textile terminology.

Insulating Textiles are designed improve thermal comfort by managing heat and moisture exchange. Depending on the temperature of the surrounding objects and air, the human body can either gain or lose heat by radiation, conduction, or convection processes of heat transfer.

Thermoregulation is how the human body takes advantage of heat transfer processes to maintain a tight core body temperature in variable climates.

Microclimate refers to the climate conditions that exist between each layer in a layering system, typically consisting of a moisture management base layer, an insulating mid-layer, and a protective waterproof breathable shell.

Evaporation of perspiration happens when the surrounding environment or microclimate temperature is higher than that of the skin. The change from liquid to vapor results in a cooling effect that helps to maintain a comfortable body temperature.

Heat Transfer occurs due to a difference in temperature, in which heat passively transfers from a higher temperature to a lower temperature. There are three methods of heat transfer:

1. Conduction is the transfer of heat through a material. With insulation, the goal is to reduce the effects of conduction by using materials with low thermal conductivity to construct barriers.

2. Convection is the transfer of heat through the movement of a fluid or gas. To manage the effects of convection, it is important to design a garment with appropriate fit and air permeability.

3. Radiation is the transfer of heat in the form of waves through space, such as the warmth you feel from the sun. To reduce the loss of radiant body heat, infrared reflective coatings can be used to reflect heat back to the body.

Thermal Conductivity is the ability of a material to transport heat. The thermal conductivity of water is 25x greater than air – when it comes to staying warm and comfortable, being dry matters

Absorb: Ability of a material to take in water

Adsorb: Ability of a material to hold water on its surface

Hydrophilic: Adsorbs and absorbs water and moisture

Hydrophobic: Does not take up water or moisture. Polyester is inherently hydrophobic

To illustrate the three methods of heat transfer, think of 1. a hot metal pot (conduction) of 2. boiling water (convection) and 3. hovering your hand over the burner and sensing its hot (radiation) !Air Permeability is the ability to allow air molecules to pass through a textile. It is a characterization of wind resistance that is measured in terms of cubic feet per minute (CFM). A high CFM means increased air flow, while a low CFM reduces air flow and protects against wind.

Breathability is characterized by Moisture Vapor Transport Rate (MVTR), which is a measure of a material's ability to allow water vapor to pass through. A high MVTR helps to keep the microclimate dry by allowing perspiration to escape from the garment.

Compression Resistance refers to a material's ability to withstand compression. Compression Recovery refers to a material's ability to rebound from compression.

Durability refers to a material’s resistance to structural instability and fiber migration during wash and wear.

Denier is a unit of measurement used to express the linear density of individual fibers or filaments in textiles and fabrics. A higher denier count indicates a thicker, heavier fiber, while a lower denier count indicates a finer, more lightweight fiber. It is measured in terms of mass in grams per 9,000 meters. Fibers with a denier less than 1 are characterized as microfibers.

Down is a natural insulating material found underneath the feathers of ducks and geese. It consists of clusters of soft and fluffy filament structures called plumules. Each down product is a blend of down clusters and feathers. These products are characterized by their fill power and down-to-feather ratio.

Fill Power is a measure of the volume occupied by a set amount of material (30 grams). Historically, it has been used to distinguish the relative quality of down compared to other down products. Generally, a higher fill power indicates larger, loftier clusters that are more efficient at trapping air. Higher fill power is often associated with thermal performance because increased air entrapment leads to better insulating value.

When it comes to synthetic insulation fills, this measurement of volume does not carry the same association with thermal performance. In synthetics, there is not a direct correlation between thermal performance and fill power, due to the structural variances from product to product. Fill power is simply a measure of a synthetic fill’s loft. To make an accurate comparison between the thermal performance of a down product and a synthetic product, it is necessary to conduct thermal resistance testing.

• Marketing portal with technology/brand videos and assets, as well as branding guidelines

• Product specifications

• Woven labels and hangtags

• Manufacturing guidelines

• Product certificates, including OEKO-TEX®, bluesign®, and GRS

• Global fulfilment and logistics network

• Flexible currency accepted USD, EURO, RMB

• Loose-fill calculator

• PCR calculator

• Orders, invoices, and shipping documents

• Labels and hangtags provided FOC

• On product, in-store, online, and partnership marketing