4 minute read

Kinder Australia’s finger on the pulse

Kinder Australia has brought a novel belt cleaner for cleated conveyors down under. Charles Pratt, Operations Manager at Kinder Australia, explains how a trip to Spain resulted in the valuable finding.

WHILE ON A BUSINESS TRIP

to visit a business partner in Spain, Charles Pratt, Operations Manager at Kinder Australia, was shown a unique innovation for belt cleaning. The Spanish company had been using a belt cleaner that has a unique “finger” shape that could effectively contour to the belt’s surface as it moved, with a flicking motion.

“I’d never seen anything like it in Australia, it was completely unique. I loved how simple the concept was,” Pratt says.

The belt cleaner was originally designed by a company in the United Kingdom, after an engineer had been tasked to find a way to improve the cleaning processes of a Chevron conveyor belt.

When the engineer ran his fingers down the belt, it inspired him to design a cleaner that used polyurethane strips to reach the difficult areas on a cleated belt.

Pratt says that while the cleaner had proved itself internationally, there was a major gap in the Australian market.

“The only other suitable cleaner for cleated belts is a brush cleaner, which some customers find too expensive and require too much to set up. Often an electrician is required to properly install as well,” he says.

“We were surprised to hear from the company in the UK that they had no customers in the Southern Hemisphere. We have an extensive distribution network in Australia, Asia Pacific, Indonesia, South Africa and South East Asia, so it was a good fit for us.

“We made a few phone calls and within a week, we had a contract signed to be the exclusive distributor.”

The cleaner, now called the K-Cleatscrape, can be fitted in any

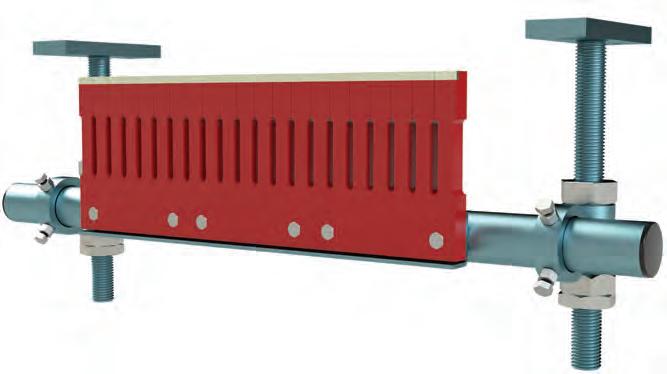

The belt cleaner has a unique finger-shaped design that contour to belt’s surface as it moves.

The cleaner can be fitted in any position from the snub drum backwards and reach the entire width of the conveyor belt.

position from the snub drum backwards and reach the entire width of the conveyor belt.

Various durometer cleaner blade formulas are available to suit a variety of needs, with the addition of stainlesssteel tips or optional tungsten for further robustness if required.

The K-Cleatscrape Duplex Belt Cleaners will work on cleated belts up to 100 millimetres in height. The proprietary finger design ensures optimal and even belt scraping with a double row of off-set combs, to accommodate these extreme ridges.

The design is a good option to ensure old and worn belts are not damaged, as the cleaner is forgiving when it comes up against mechanically fastened splices, belt cover gouges or other belt damage imperfections.

Pratt says the inexpensive, yet effective cleaners have been a godsend for bulk handlers with cleated belts.

“Cleaning a cleated belt wasn’t easy or previously affordable for some, which meant people had been putting up with excessive spillage,” he says.

“Spillage can cause occupational health and safety issues, increase cleanup costs and cause premature roller or tracking failures.”

The cleaner requires very little upkeep, as the only moving parts are designed to be flexible. Due to the construction of the ‘fingers’, they don’t need to be recalibrated. The blades are simple to replace.

Kinder has already air freighted the first two shipments of the product into Australia, which sold out within the first two weeks. Pratt says the cleaners have created a stir in the sector, and plenty of customers are looking to get them.

“We’re going to be setting up a virtual demonstration in our display area and train all of our distributors and field specialists,” he says.

“We want to be able to educate the end users about how effective they can be and provide a demonstration.

“Kinder’s also busy working on new technology for conveyor transfer points and developing our presence in the United States.”

The K-Cleatscrape Duplex Belt Cleaners will work on cleated belts up to 100 millimetres in height.

Need a Hand With Your Material Storage Design?

+61 8 9277 3303 \ info-australia@jenike.com \ jenike.com

Your Source for:

• Storage systems: engineered to ensure reliable, consistent material flow • Processing vessels: developed to purge resin volatiles or act as a dryer • Feeders: optimized screw and belt feeders that maintain reliable flow • Stockpiles: designed to maximize gravity reclaim and avoid ratholing • Pneumatic conveyors: engineered for flow, prevention of wear & attrition • Peer reviews: a review of proposed system design from material flow basis

55

YEARS

Innovating, modelling, and designing. We have been your bulk material solution provider from concept to commercialisation for 55 years.