6 minute read

Taming Telematics Tips for data collection and putting telematics to work

TAMING TELEMATICS

Tawnia Weiss, President A1A Software provides five tips for taming the “wild west” of data collection and effectively putting telematics data to work.

TAWNIA WEISS is President of A1A Software which creates software and interfaces for the heavy construction industry. The company got its start by developing the well-known lift planning program called 3D Lift Plan, and it now offers other business management tools specific to the needs of crane and construction equipment owners.

Telematics is a data collection system that allows owners of machinery to view the current operation and function of their assets. Its true value is when you take the data and turn it into useful information. Owners can then make decisions to optimise their fleet.

When the data is shared with the OEM and is kept for the lifetime of the asset, it allows owners and OEMs to partner in analysing this data. Engineers for the OEM and maintenance personnel for the owner can better predict and make adjustments to improve productivity and reliability of the asset.

In some ways, telematics development is like the wild west. As the technology and its application has evolved, there was not much consistency from manufacturer to manufacturer or machine to machine in what data was measured.

The Association of Equipment Management Professionals and the Association of Equipment Manufacturers developed a standard that identified 19 consistent 19 data points and 42 fault code points to be measured, bringing some order to the “wild west.” In 2016, that standard was published by the International Standards Organization. The ISO mixed-fleet telematics standard specifies the communication schema designed to provide mobile machinery status data from a telematics provider’s server to third-party client applications via the internet. Standardisation reduces the amount of code that software developers have to write. That time and cost savings can be passed onto the user.

However, cranes in their complexity, require far more data points to be collected. AEMP and AEM are currently working on a similar standard for cranes. According to an update published on AEMP’s website in September 2018 from the AEMP Technology Committee, AEMP’s Advanced Standards Committee

Tawnia Weiss President A1A Software.

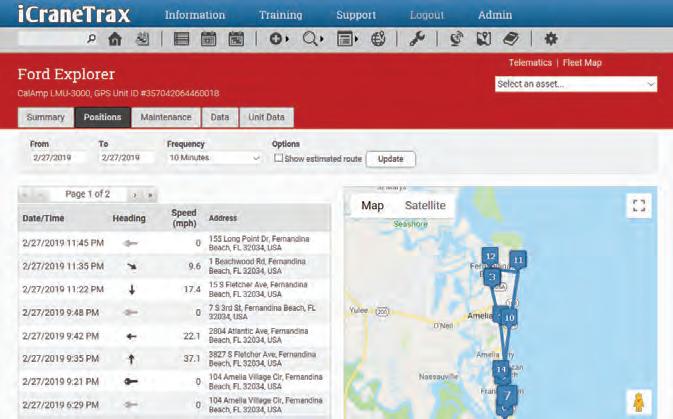

in collaboration with AEM, is in process of “finalising data points for the upcoming crane telematics data standard.” Until that time, telematics for cranes have either been developed by the OEM or customised from third-party systems to meet the needs of crane users. iCraneTrax was the first, and is currently the only, cross-platform crane telematics system available. It provides a portal for Link-Belt crane owners to access Link-Belt Pulse and for Manitowoc crane owners to use Manitowoc’s CraneStar. As proprietary telematics systems, these OEMs each feature their own exclusive data points. A1A’s aftermarket GPS and telematics features are not exclusive to these crane brands. But when combined with access to these OEM telematics systems, iCraneTrax makes for a very robust and user-friendly tool.

Although the integration of telematics in construction equipment is not new, it’s still often a misunderstood tool. Regardless of the kind of equipment you have or the telematics system you use, these five things are common ways you can put your data to work.

Alert: Like the Fitbit or other activity

tracking device so many people wear these days, telematics can be used to alert you when your asset needs attention. Once an hour, my Fitbit reminds me to get up from my desk and go for a walk if I’ve been sitting too long. Likewise, telematics systems might be setup to send you an alert when the crane is nearing the 500-hour service period. The enables operations, fleet and maintenance departments to coordinate time for engine filter replacement, turntable inspection, etc.

Aware: Piggy-backing on alerts, specific reports can be setup to be emailed directly to the right person in your organisation so that alerts can be acted upon. This is not unlike what happens when a person wearing a pacemaker might need attention, as I learned from a friend of mine. Although usually good about not over indulging, this friend really tied one on one night. The next morning, his doctor had received a report from the pacemaker, making him aware of my friend’s activity. The next morning, the doctor called and insisted he needed to see the patient immediately.

In crane terms, this situation might be that a bare rental crane had been running at 90 per cent capacity every day for a week. The safety manager might be designated to receive these reports, who can then decide how to act on the information. Other reports could be generated for fleet cautions, recent faults, or crane usage.

Monitor: Consider the employee who drives a company vehicle. Corporate policy limits the use of the vehicle for work-related driving, but you suspect that he’s using it for personal use. GPS tracking allows you to see that the vehicle was used into the wee hours of the night, far beyond work hours, opening you up to liability exposure. In the same way, a customer bare renting a crane might call late on a Friday to say they are done with the crane, which ceases the billing period. However, knowing that the provider won’t likely pick the crane up until Monday, the contractor continues to use the crane over the weekend. By monitoring usage through telematics, the accounting department can invoice for the additional days, thereby increasing revenue. Or maybe, you need to identify why your asset is using so much fuel. Monitoring idle time, engine load, CO2 emissions are all possible.

Find: A popular location monitoring app for phones called Life360 helped a colleague quickly locate her teenage daughter who had been involved in an accident. When she got the call that her daughter was hurt, she only had to select the directions feature to find out exactly where her daughter was without trying get the information out of a scared and rattled kid. GPS tracking is one of the more familiar features of telematics systems. It can be used for theft prevention or recovery, or simply to improve communications with a customer. On a large jobsite, it might the crane was delivered to the wrong area and the customer can’t locate it. Simply checking the GPS status will help dispatch tell the customer where the crane is on the site. It might also be used more generally to know at a glance where all of the assets are in case something needs to reallocated to a different job.

Diagnose: By now, most of us have had computer issues that are fixed when the help desk remotely taps into your computer to fix the problem. In the same way, cranes can be remotely diagnosed using telematics. Often, the tech can

GPS tracking allows you to see when and where a company vehicle or crane was used.

identify the problem and determine which part is needed without seeing the crane in person, saving considerable time. Link-Belt Pulse even has the capability to monitor everything that is going on with the LMI, engine and boom, transmitting bursts of information to a technician. In some cases, the technician might be able to direct site personnel how to remedy the issue without even having to come to the jobsite.

As the wild west was tamed, so too telematics. Here are just a few things we’ll likely see realised soon. • Two-way communication between asset and owner • Live firmware updates from the OEM • Advanced reporting • Advanced predictive maintenance • ELD and E-log integration • Apps for data access from mobile devices

The level of information that can be available through telematics depends a lot on what type of system is on your equipment. In some cases, simple GPS is all you need. Almost always, OEMinstalled systems will offer the most data points. Some things to think about when selecting a system is how long the data is stored and who has access to it; where the data is stored and how secure that is; and how flexible the interface is.