38 minute read

NEWS

SUPPORTING SPONSORS

EXHIBITION SPACE NOW

ON SALE

1ST - 3RD APRIL 2020 MELBOURNE CONVENTION & EXHIBITION CENTRE

CONFERENCE SPONSORS

ASSOCIATION PARTNERS

CEO: John Murphy Publisher: Christine Clancy Group Managing Editor (Northern): Syed Shah Editor: Mike Wheeler Ph: (02) 9439 7227 mike.wheeler@primecreative.com.au Design Production Manager: Michelle Weston michelle.weston@primecreative.com.au Art Director: Blake Storey Designers: Kerry Pert, Madeline McCarty Sales/Advertising: Luke Ronca Ph: (03) 9690 8766 luke.ronca@primecreative.com.au Production Coordinator: Janine Clements Ph: (02) 9439 7227 janine.clements@primecreative.com.au Subscriptions AUS NZ O/S 1 year subscription 99 109 119 2 year subscription 189 199 209 For subscriptions enquiries please email subscriptions@primecreative.com.au

Copyright Food & Beverage Industry News is owned by Prime Creative Media and published by John Murphy. All material in Food & Beverage Industry News is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Food & Beverage Industry News are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated. © Copyright Prime Creative Media, 2019 Articles All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format. Head Office 11-15 Buckhurst St South Melbourne VIC 3205 Ph: +61 3 9690 8766 enquiries@primecreative.com.au http://www.primecreative.com.au Sydney Office Suite 303, 1-9 Chandos Street Saint Leonards NSW 2065, Australia Ph: (02) 9439 7227

Why food labels offer essential info

Editor: Mike Wheeler

Labelling of food and beverages can be a nightmare for manufacturers, especially in an age where allergens seem to be increasing and a lot of perishables are being imported. Australia has a pretty good record when it comes to labelling, but it pays to be vigilant. In this issue of Food & Beverage Industry News we talk to the AIFST’s Fiona Fleming who gives some insights on how to make sure manufacturers are keeping up to speed with local labelling requirements.

Imagine producing a 20-year-old malt whiskey overnight. Or, how about if almost every house has a 3D food printer in their kitchen ready to produce that late night snack at the push of a button? These are some of the ideas that are spruiked by KPMG’s Trent Duvall in our story that mainly looks at plant-based proteins but also covers some of the latest trends coming to the fore.

As he mentions in the piece, food and beverage manufacturers need to look at who is calling the shots these days, and it may not be who you think it is.

On the back of its story on rules and regulations in our last issue, Total Construction offers up some more, in-depth information on the subject. Company director, Bill Franks, gives some practical hints and insights when it comes to building a new facility or renovating a brownfield site.

There’s plenty of other great stories in this issue. Have a great month.

Mike Wheeler

INSIDE

24

4 NEWS 18 SAFETY 20 SUSTAINABILITY 22 BUILDING PLANT 24 CONSUMER 26 AUTOMATION 28 ROBOTICS 30 DRIVE TECHNOLOGY 32 PACKAGING 34 AIP 36 LEAN MANUFACTURING 39 BELTS 40 F&B AWARDS: PROFILE 44 MARKETWATCH 45 DAIRY REPORT 47 NEW PRODUCTS

Action to protect native fish ahead of hot, dry summer

Murray Cod is just one species that will benefit from the initiative.

The Federal Government is working with the states to protect the Murray–Darling Basin’s native fish ahead of an expected hot and dry summer.

Minister for Drought, David Littleproud, released the Native Fish Emergency Response Plan. Make no mistake, we are likely to see fish deaths this summer,” Littleproud said.

“We’re facing another hot summer with very little water flowing through our rivers. This plan will give the MDBA and the states vital tools to help protect fish populations. The Federal Government has money put aside for fish-death prevention measures and environmental water holders will replenish areas on red alert, where they can.

“Fish deaths are common during summer but what we saw last year were a major wake-up call about the impact of the drought on our rivers. After the Vertessy Review, we have put an emergency plan in place.

“The plan will see more activity in high risk areas, with aerators, fish relocated and algae blooms watched closely. “The last Northern Basin environmental watering program refreshed waterholes and fish refuges although there is little environmental water left.

“NSW emergency measures have seen fish relocated so they survive this summer and re-populate the rivers when conditions improve.

“The Commonwealth is also bringing government officials and experts together this month to

coordinate plans and identify areas at high risk of fish deaths.

“Communities too have their part to play and we also ask the community to report river conditions and fish deaths to help with fish relocations and recovery.

“We want native river fish such as the Murray cod, silver perch and golden perch to have the best chance of surviving this summer.

“We want healthy and thriving fish populations in our rivers during drought and in the good times.”

Background Under the Native Fish Emergency Response Plan, the Commonwealth Government will: • Provide emergency funds from the Emergency Contingency Fund to help states manage urgent and extreme fish death events, with $300,000 set aside. • Provide available Commonwealth environmental water to mitigate fish deaths. • Support the coordination of emergency response activities and sharing of resources. • Maintain a database of significant fish deaths events. • Contribute to water quality monitoring programs to identify areas at risk. In return, the states will: • Identify and monitor high risk sites for fish deaths. • Identify priority refuge areas for native fish. • Prepare on-ground emergency response plans for priority species and areas.

Brownes Dairy switches to plant-based renewable packaging

Brownes Dairy will replace its existing milk cartons with an Australian first, a carton package made entirely from plantbased, renewable materials in a new sustainable packaging move.

Tetra Rex Bio-based package is the world’s first fully renewable beverage carton, with the protective layers derived from sugar cane.

“There is a lot of emphasis on the importance of recycling, but less of a focus on how we can make products more sustainable from the beginning. Brownes Dairy wanted to improve the sustainability of our packaging across the entire lifecycle of our products,” said Brownes Dairy CEO, Tony Girgis.

The bio-based packages offer a more sustainable alternative to the standard milk cartons, reducing the reliance on fossil based polyethylene plastic in the lining.

“Brownes Dairy scoured the planet in search of the best sustainable packaging on the market. Making the switch to a protective layer derived from sugar cane is not only better for the environment, but our consumers can trust the package is made from a renewable source that has a lower carbon impact to climate change,” said Girgis.

Brownes Dairy will switch 25 of its milk carton products to the new sustainable packaging - about 17.8 million milk cartons per year.

“We have done the due diligence o n this packaging format to ensure our product quality, freshness and food safety are fully maintained,” said Girgis.

The Brownes Dairy white milk, cream and CHILL range will all be packaged in a Tetra Rex Bio-based pack.

“Across the industry, we have seen almost all flavoured milk products move to bottles, but Brownes Dairy has made the conscious decision for its

Brownes Dairy will switch 25 of its milk carton products to sustainable packaging.

CHILL range to remain the ‘King in Cartons’,” said Girgis

Tetra Pak has delivered more than half a billion renewable packs since the bio-based package was first introduced in dairy by Finnish brand Valio in 2015.

Brownes Dairy will be the first company in Australia to integrate the renewable cartons across its entire milk carton range.

“Consumers globally are concerned about protecting the planet, with research showing people of all ages believe businesses should take responsibility for their impact on the environment. At Brownes Dairy, we wanted to support the global movement by looking at packaging across its entire lifecycle, from source to end of life,” said Girgis.

Blockchain whiskey released

Consumers can trace the origins of the whiskey using blockchain.

William Grant & Sons’ premium whisky brand, Ailsa Bay, has launched the world’s first-ever blockchain whisky in partnership with specialist blockchain technology company arc-net.

Ailsa Bay aims to transform whisky through experimentation, technology, precision distilling and data driven methods. Its whisky is unique as it undergoes a micro-maturation process in small Hudson whiskey casks.

Ailsa Bay’s use of blockchain captures the full distilling and manufacturing process, allowing customers to track their whisky from source to store; ensuring authenticity and traceability.

Blockchain is a list of registers, or “blocks” which contain information about the previous block and transaction data between them. It acts as an open ledger, and this ledger is managed publicly rather than controlled by one party, meaning stored information can’t be changed or tampered, to track authenticity.

For Ailsa Bay, blockchain data is collected from parent company

Blockchain is used to capture the whiskey’s distilling process.

William Grant & Sons’ existing data sources, cask types, filling dates and bottling dates are all tracked.

Consumers can trace the origins of their whisky via an innovative web experience, which is individually tailored to each bottle. By scanning a QR code, users are presented with a visual history of their whisky, produced using digitally created art generated by blockchain data unique to the drink’s journey.

Blockchain technology also allows Ailsa Bay to gather data from existing and potential customers, using mobile location services to correlate where the whisky is being purchased and consumed to maintain brand protection.

James Macrae, brand ambassador or Ailsa Bay, said, “Innovation is a key part of the William Grant & Sons business. We’re constantly looking to evolve our offering and learn new things in order to push the boundaries within the drinks industry.

“We’re doing something now that we hope will set the bar for the future experience of spirits, and we look forward to seeing how other brands follow suit as innovation within the industry continues to develop in the next few years.”

The concept of using blockchain for whisky emerged from William Grant & Sons’ inaugural Hackadram event that was held last year, in which start-ups and innovation specialists were invited to use their expertise to shape the future of the company’s spirits.

The adoption of blockchain is the latest innovation for Ailsa Bay. It joins other innovative processes, including ‘micro-maturation’, where the spirit is added in small bourbon casks for six to nine months for rapid and intense maturation, and unique taste measuring labelling, displaying both the Phenol Parts per Million (PPM) and Sweet Parts per Million (SPM); bringing a new way of thinking to a traditional drink.

Consumer demand expected to boost cheddar cheese market

Cheddar is said to be being preferred over natural cheese in several snack preparations.

There has been a shift in consumer preferences towards various types of nutrient and protein-rich foods that also promise healthy substitutes to everyday consumable products. Cheddar cheese is a multipurpose food product that has been used in the food industry in numerous applications.

The availability of cheddar cheese in the bakery sector and food product companies is increasing as it is a basic ingredient in most of the food preparations requiring cheese. This has boosted the demand for cheddar cheese in the global market. Increasing consumption of cheese in various types of cuisines is also anticipated to boost the overall production of cheddar cheese in the food industry.

Cheddar cheese is increasingly being preferred over natural cheese in several bakery and snack preparations. This has also led to increased consumption and hence production in the global market. Furthermore, growing consumer demand for cheese-based breakfast products is also expected to lead to a rise in the utilization of cheddar cheese in different breakfast products. A study on cheddar cheese by Fact.MR found that cheddar cheese fanatics are always experimenting with food and manufacturers are coming up with new varieties of food items. The trend of fine gourmet, cuisine and luxury culinary items has inspired manufacturers to innovate their products in order to cater to the taste preferences of consumers. As a result, the development of block cheddar cheese is expected to trigger a mass demand for cheddar cheese especially in hotels, restaurants, and cafes. A growth in the demand for gourmet and artisanal cheese products is a key factor which is likely to boost the cheddar cheese market in the long run. The expansion of online and retail outlets resulting in the easy obtainability of cheddar cheese is anticipated to create lucrative opportunities for manufacturers in the coming years.

European and North American

markets are moving towards a saturation point, so manufacturers of cheddar cheese are looking for regions that will present them with versatile opportunities in the future. The growing cheddar cheese market in Latin America will open a plethora of opportunities for market players to capitalise on.

Europe is the largest consumer of cheese in the world. Several varieties of cheese are available in the region and the application of cheddar cheese is also widespread in the food industry in Europe.

Asia Pacific Excluding Japan (APEJ) is the third largest consumer of cheddar cheese and related products in the world. With the growing acceptance of Western culture in the region, the food habits and taste preferences of people are also increasing at an extensive rate. In spite of the growing disposable income of people in the region, consumers still look for inexpensive food options. As a result, the demand for cheddar cheese is increasing in several countries in APEJ. The study also found that Japan is slowly emerging as one of the lucrative markets for cheddar cheese with the trend of mild snacking increasing in the region.

With the trend of drinking gaining traction in Japan, having light snacks especially cheddar cheese has increased considerably as a home trend. The Middle East and Africa are anticipated to present manufacturers of cheddar cheese with new and lucrative growth prospects. As the governments in these regions are looking to generate revenue from other sources apart from oil reserves, a variety of industries are emerging as highly profitable options. For instance, in September 2019, Arla Foods a Scandinavian dairy products company will scale up its commitment to develop a sustainable dairy sector in Nigeria.

This study underlines key opportunities in the cheddar cheese market and finds that the market would exhibit growth at a value CAGR of – three per cent during the forecast period.

Compostable cucumber wrap from BioBag World A fully compostable shrinkwrap for cucumbers has been developed in South Australia and is set to launch onto international markets.

The compostable wrap is manufactured by BioBag World Australia and took 12 months to develop in partnership with South Australian produce and packaging businesses IG Fresh Produce.

It was launched in September as an environmentally friendly alternative to the traditional polyethylene plastic wrap and has already generated export interest from Qatar and South Africa.

IG Fresh executive director George Antonas said he was approached by South Australian independent grocer Drakes Supermarkets to develop a compostable fruit and vegetable wrap to replace traditional shrink-wrap.

Antonas said the product was being used exclusively on cucumbers sold at Drake’s 38 South Australian supermarkets until October 16, after which it’d be available for a wide range of purposes.

“JP Drake put the challenge to us and so we gave them product exclusivity for the first four weeks,” Antonas said. IG Fresh produce is a fruit and vegetable wholesaler located in Adelaide.

Antonas said a potential investment partner from Qatar had travelled to Adelaide for the product launch with Drakes. He expected to begin exporting cucumbers dressed in the compostable wrap to Qatar by the end of October, with exports to South Africa and Europe to follow.

The bioplastic film is made from a compostable resin called Mater-Bi that uses substances obtained from plants including non-genetically modified corn starch.

While there are other compostable products on the market, Antonas said creating a 100 per cent industrially compostable cucumber wrap required a unique process.

“That’s where Scott Morton’s expertise came into it – because it’s heat shrunk onto the cucumber. There’s plenty of compostable products out there but this one is for a specific purpose,” Antonas said.

“There’s a big push to make all single use packaging compostable. So, you buy a cucumber, you peel off the wrapper and you put it in your greens bin and you know it’s not going to

The cucumber’s bioplastic cover is made from compostable resin.

add to landfill and that sort of thing. Plastic has its place but not for single use, it just creates too much waste.”

According to Antonas, the cucumber compostable wrap has the potential to be used on all fruit and vegetables, and BioBag World Australia director Scott Morton agrees.

“The potential is endless. It’s improving all of the time. I see it as a direct replacement for plastic,” Morton said.

Norway-based BioBag has six factories and 20 market or distribution partners around the world, producing over one billion bags a year.

Morton said BioBag was also working on a non-shrink-wrap compostable product that could replace plastic cling films.

He said the cucumber wrap developed in South Australia could also be distributed in major global markets including the United States.

“We’re trying to enhance the current cucumber wrap. It’s not quite suitable yet as a cling wrap alternative,” he said.

“We’re developing a new product that’s more for the international market. That’s a product that will especially keep fruit and vegetables fresh.

SIA happy with state of fisheries

Seafood Industry Australia (SIA), the national peak-body representing Australia’s commercial fishing industry, is delighted that for the sixth consecutive year its solely Commonwealth managed fisheries are in great shape and being fished sustainably.

The release of the Australian Bureau of Agricultural and Resource Economics and Sciences (ABARES) “Fishery status reports 2019” highlights the quality of Australia’s Commonwealth fisheries management.

“This is great news and is unprecedented internationally,” SIA CEO Jane Lovell said.

“The ‘Fishery status reports 2019’ provides an evaluation of 96 Australian commercial fish stocks. “This positive report card given for the sixth consecutive year to Australia’s solely Commonwealth managed fisheries is the ultimate endorsement that Australia continues to be a leader in world class seafood and sustainability.

“Australians should be proud of their seafood industry which provides fresh, high-quality seafood, year-round. “As fishers, our priority is the ocean. We advocate the health, sustainability, and future of our ocean. It’s our livelihood and the future livelihood of generations to come.”

Developing new processes for new ingredients C rispy roasted crickets were recently served in a sushi restaurant in London, reigniting the discussion about integrating insects into consumer diets. However, less thought has been given to what industry will have to do to handle these new food types.

New ingredients that have been incorporated into diets in recent years include quinoa, avocado and kale.

These new food products, with mass consumer appeal, are even more important when they use ingredients that are nutritious and environmentally sustainable.

However, the sudden increase from low to large volume production can be an issue when a food product emerges to mass popularity.

Scaling up production and processing food that suddenly and rapidly grows in popularity can be a daunting task. Improperly controlled mass production can cause inefficiencies to spiral out of control, or for unknown issues to come to the forefront.

For example, the massive global increase in demand for avocados forced the Kenyan government to ban the export of the fruit as there was not enough to supply local needs.

The increase in demand for new ingredients or products also raises the need to implement proper applications for handling new ingredients.

In the case of the crickets, most food manufacturing processes are built to deter insects and prevent them from contaminating the food. As such, if insect-based foods were to grow in popularity, new processes would have to be developed to ensure proper cleanliness and hygiene levels.

When a product is in high demand and supplies run low there is also the potential for food fraud to come into play.

This is dangerous, with potentially fatal consequences for the end consumer, because the product may have been tampered with, contaminated, and may not be fit for human consumption at all.

To combat these potential issues, producers that are handling new exotic products should ensure that they have measures in place so that operations managers have full control and oversight over their facility.

Systems such as ABB’s Manufacturing Operation Management (MOM) can help keep track of products as they move around the production line and beyond.

The MOM software can give products digital passports allowing producers to accurately tell when the product was produced and exactly what it has come into contact with during production.

MOM’s can also help speed up the implementation period of new products because operation managers

will have more in-depth information regarding their system, allowing them to effectively prepare for using a new or unique ingredient.

Being able to effectively prepare production lines for the introduction of a new ingredient is immensely helpful for producers, especially with the mass adoption of plant-based diets, meaning that more producers will begin introducing animal-free alternatives into production lines. Having the level of control brought by a MOM system will cut down on the time required to begin production.

While insects may not have soared in mass consumption just yet, as people become more interested in what is in their food it is likely that new ingredients will come to the forefront. Preparing for these changes by increasing control will help businesses remain ahead of trends and increase their product security, one crispy cricket at a time.

Marbett: So Many Ways to Accessorise.

Engineered to perform in high-speed and high-sanitation applications, Marbett ® Conveyor Components help extend chain life and provide highly flexible, smooth running conveying conditions. Many products within Rexnord’s complete portfolio of conveyor components are available in plastic and stainless steel to address a wide range of requirements.

Chain Guide • Wear strips • Corner tracks • Return rollers

Product Handling • Guide rails • Roller guides • Clamps and brackets

Frame Support and Leveling • Support bases • Articulated and fixed feet • Connecting joints

Specialty • Modular roller transfer plates • Return rollers • Shaft collars

New director appointed to Jenkins Group Board

Lachie Johnstone has been appointed to Jenkins Group board.

Jenkins Group has announced the appointment of Lachie

Johnstone to its Board of Directors to further strengthen its position as a key industry player throughout Australasia’s horticulture post-harvest industry. Jenkins Group provides an extensive range of labelling, packaging and handling systems to the horticulture industry across New Zealand and Australia via its two subsidiaries – Tauranga-based Jenkins Freshpac Systems and NSW-based J-Tech Systems. Johnstone has extensive links within New Zealand’s primary sector and will now join five other board members to guide Jenkins Group through the current innovation and expansion phase. Johnstone is well positioned to help guide Jenkins Group through these changes. He holds a B.Com from the University of Auckland and is the current chair of Farmlands (New Zealand’s largest farmer-owned rural supplies co-operative), as well as Wellington’s Centreport and Centreport Properties. He is a director of the C. Alma Baker Trust NZ and is the deputy chair of the Board of Governors at Auckland’s King’s College. In addition to these governance roles, Johnstone has private investments and commercial involvement in New Zealand’s agricultural and logistics sectors. He has been at the helm of Farmlands for the past 16 years but will step down at the end of 2019, Johnstone is looking forward to sharing his experience and observations from other industries with Jenkins Group. “I enjoy primary sector and am particularly interested that the Jenkins Group is in the innovation space. It’s an exciting time in the horticultural sector, notwithstanding the likes of environmental challenges and shortages of labour. Our aim should be to bring together solutions that help our customers to solve complex problems,” said Johnstone.

Having been exposed to many different industries has helped Johnstone shape his governance expertise over the past two decades, he said.

Jenkins Group chair Harry Cranefield says the board is delighted to have someone of Johnstone’s calibre and breadth of knowledge join the team.

“His overall farming experience, and his experience at governance level, means he has a lot to add to Jenkins Group board. He brings that primary sector involvement and insight which is what we were looking for,” said Cranefield.

“We specialise in the handling, labelling and packaging of horticultural products post-harvest and that includes everything from the orchard gate right through to the end consumer at the supermarket. Lachie is uniquely placed with a lot of skills and experience in different parts of that supply chain and will help us look towards the future.”

Recent times have seen strong growth for Jenkins, in July the Group invested in Hawke’s Bay based CR Automation, which specialises in mechatronics and automation control systems for a wide range of industries including horticulture. Jenkins has also commenced a new joint venture with US company Van Doren Sales, Global Pac Technologies, to market and support the Robotics Plus apple packing systems across the globe.

How to better manage animal disease threats

Australia will be better prepared to manage significant animal biosecurity threats, such as African swine fever (ASF), through a new comprehensive online field guide for emergency animal diseases.

Head of biosecurity, Lyn O’Connell, said the guide will help vets with early detection, diagnosis and control of exotic and emerging infectious diseases in livestock.

“Early identification and reporting is critical to minimise the devastating impact that these diseases can pose for our animals, industries, jobs and environment,” O’Connell said.

ASF and foot and mouth disease (FMD) could wipe out industries, jobs, impact on trade and availability of the Australian produce we all enjoy, so we need to be as prepared as possible because the threat is real, said O’Connell.

“Australia’s vets are vital for biosecurity. If the unthinkable happened and a significant animal disease was to hit our shores, our vets would play a key role in managing and minimising the risks.

“This guide will help vets identify emergency animal diseases in the field, ensure they consider priority diseases when conducting diagnosis and take appropriate action when they suspect signs of a biosecurity threat.

The disease list included in the guide will be reviewed and updated to address emerging threats so the country is best placed to manage them as they arise.

“We have some of the best vets in the world and this gives them another tool to improve the work they do in protecting Australia from deadly animal diseases.”

The guide is in addition to a range of measures in place to better manage animal biosecurity threats. This includes increased intervention measures at our borders, testing of intercepted meat produce for ASF and FMD, as well as stronger enforcement approaches for biosecurity breaches relating to meat products.

A roundtable was recently held between leaders, scientists and governments to discuss the actions needed to keep African swine fever out of Australia. A simulation exercise will also be held later this year to test our disease response capabilities to make sure we’re as prepared as we can be.

DuPont launches dairy-free protective cultures for plantbased fermented products

YM Vege is designed to prevent spoilage in plant-based beverages.

DuPont Nutrition & Biosciences has announced a new ingredient – Holdbac YM Vege – as the latest addition to DuPont’s Danisco Holdbac line of protective cultures, known for their ability to extend shelflife and secure the quality of products by holding off yeast and mold spoilage – all without use of synthetic preservatives.

Now, Holdbac YM Vege brings this effective and label-friendly spoilage prevention to plant-based, fermented foods and beverages, at a time when customer demand in this space has never been higher.

“The industry has seen enormous growth for fermented plant-based products in recent years, driven by higher numbers of flexitarian, vegetarian or vegan consumers around the world. These shifts in diets are driven by a number

of factors, including the search for improved health that comes with a plant-based diet, ethical choices toward foods with lower environmental impact and which are deemed better for animal welfare, and switching to dairy alternatives for lactose-intolerant consumers,” said Eve Martinet-Bareau, global product manager, cultures for plant-based fermented food and beverages. “DuPont Nutrition & Biosciences has been working with customers for decades as consumer demands for plant-based options have increased, and we are constantly looking for ways to innovate in this space,” added Martinet-Bareau.

“For example, in May 2018, we launched a new cultures line – Danisco Vege Cultures – especially designed for fermented plant-based products, helping customers attain desired taste and texture profiles in a wide variety of plant-based dairy alternatives and beverages.”

However, with that demand came certain challenges for producers of fermented goods, including the need to: • gain market share in the fastgrowing plant-based food sector; • consistently ensure high-quality products with the desired taste and texture, particularly across regions with differing consumer preferences; • secure that quality throughout a product’s shelf-life; • address the fast-growing demand for friendly labelled consumer products; • make a substantial contribution to the sustainability of the food and beverage sector; and • provide consumers with products that improve their health and wellbeing.

“As more consumers look for fermented food and drinks, our Holdbac YM Vege cultures will help our customers meet that demand.”

This innovative new ingredient also offers customers the ability to make a significant difference in terms of environmental and social impact through reduced food waste and plant-based alternatives.

The potential impact is massive: DuPont has estimated that if just five per cent of the global yogurt market is replaced with plantbased alternatives made with Danisco Vege and Holdbac YM Vege cultures, the carbon dioxide emission saving would theoretically be as high as 3,000,000 tons annually.

This would be roughly equivalent to 1,700,000 EU-based cars off the roads.

“We are thrilled to add Holdbac YM Vege to our range of plant-based and sustainable offerings,” said Mikkel Thrane, global sustainability lead for DuPont Nutrition & Biosciences. “We look at our environmental footprint through the lens of the UN’s Sustainable Development Goals (SDGs), and we are proud to say that this culture supports at least three – SDG 3 (good health and well-being), SDG 12 (responsible production and Consumption) and SDG 13 (climate action). Holdbac YM Vege is helping us facilitate the transition to a healthier and more environmental-friendly diet.”

This transition to a healthier diet for people and the planet has been lead by DuPont’s expertise in microbiology, food protection and fermentation, as well its commitment to developing and offering more sustainable ingredients for customers.

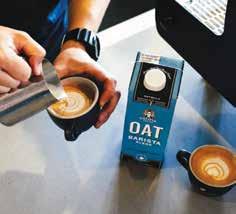

Toby’s Estate partners with Califia Farms with oat milk

In the US, oat milk is the number two dairy alternative after almond milk.

Quite a few Australians are choosing plant milk over dairy including a new player in the market – oat milk. Toby’s Estate has teamed up with Califia Farms to offer oat milk to its café customers nationwide. “With compelling health, ethical and environmental benefits, it’s no wonder more people are turning to plant-based diets. When it comes to coffee, they’re now looking for more options than just soy and almond and so we knew we had to listen to our customers,” said Jody Leslie, Toby’s Estate general manager.

After a launch in the US, Califia Farms recently launched its new Oat Barista Blend in Australia and now Toby’s Estate is the first specialty coffee roaster who will soon be distributing it to its café network across Australia, starting with NSW.

According to Dan Kaplan, national business manager for Califia Farms Australia, in the US, oat milk is the number two dairy alternative in coffee shops after almond milk and it looks like Australia is headed in the same direction.

“Oat milk is not only dairy free and not a nut milk, but it’s free from soy and made from a sustainable grain, which makes it an appealing option for consumers,” said Kaplan.

Califia’s Oat Barista Blend is made from whole rolled oats and is unsweetened with no added sugar, gums, dairy or soy. It also has half the amount of natural sugar than other oat milk brands.

Carlsberg moves to create paper beer bottle C arlsberg Group is trying to create the world’s first “paper” beer bottle made from sustainably sourced wood fibres that is both 100 per cent bio-based and fully recyclable. Carlsberg has unveiled two new research prototypes of its Green Fibre Bottle, which are the first “paper bottles” to contain beer. Carlsberg also announced it has been joined by other global companies that are united in their vision of developing sustainable packaging through the advancement of paper bottle technology.

These developments ar e a continuation of Carlsberg’s sustainable packaging innovation journey and a key part of its sustainability programme, Together Towards Zero, including its commitment to zero carbon emissions at its breweries and a 30 per cent reduction in its full value chain carbon footprint by 2030.

Two new prototypes The two new research prototypes are made from sustainably-sourced wood fibre, are fully recyclable and have an inner barrier to allow the bottles to contain beer. One prototype uses a thin recycled PET polymer film barrier, and the other a 100 per cent bio-based polyethylene furandicarbonxylate (PEF) polymer film barrier. These prototypes will be used to test the barrier technology as Carlsberg seeks a solution to achieve their ultimate ambition of a 100 per cent bio-based bottle without polymers.

Myriam Shingleton, vice president group development at Carlsberg Group, said: “We continue to innovate across all our packaging formats, and we are pleased with the progress we’ve made on the Green Fibre Bottle so far. While we are not completely there yet, the two prototypes are an important step towards realising our ultimate ambition of bringing this breakthrough to market. Innovation takes time and we will continue to collaborate with leading experts in order to overcome remaining technical challenges, just as we did with our plastic-reducing Snap Pack.”

New partners onboard Carlsberg kicked off the project to develop a bottle made from sustainably sourced wood fibres, the “Green Fibre Bottle,” in 2015 alongside innovation experts ecoXpac, packaging company BillerudKorsnäs, and post-doctoral researchers from the Danish Technical University, supported by Innovation Fund Denmark. These combined efforts

Carlsberg’s “paper” beer bottle is made from wood fibres.

have resulted in the emergence of Paboco, the Paper Bottle Company – a joint venture between BillerudKorsnäs and bottle manufacturing specialist Alpla.

Carlsberg will now be joined by The Coca-Cola Company, The Absolut Company and L’Oréal in a paper bottle community – launched by Paboco. The community unites global companies and experts with the vision of advancing sustainable packaging, offering highquality products while reducing their environmental impact.

Shingleton said, “The work with our partners since 2015 on the Green Fibre Bottle illustrates that this kind of innovation can happen when we work together. We’re delighted that other like-minded companies have now joined us as part of Paboco’s paper bottle community. Partnerships such as these, ones that are united by a desire to create sustainable innovations, are the best way to bring about real change.”

“We’re driven by our constant pursuit of better, to create more sustainable packaging solutions that help people to live more sustainable lives. Sometimes that means completely rethinking how things are done – pushing the boundaries of existing technologies and overcoming technical challenges as they present themselves.”

Gittan Schiöld, interim CEO of Paboco said, “It is all about the team! We are collaborating across the value chain, sharing the risks and are united in our vision that the paper bottle will become a reality and fundamentally change this industry for good.”

A constant pursuit of better Carlsberg’s focus on sustainable packaging innovations is not new. In 2018, the Danish brewer launched a number of packaging innovations including recycled shrink film, greener label ink and the innovative “Snap Pack,” which replaces the plastic wrapping around its six-packs with a solution that instead glues cans together.

Carlsberg’s packaging improvements are part of its long-standing progress of betterment and innovation, including developing scientific breakthroughs such as pure yeast and the pH scale.

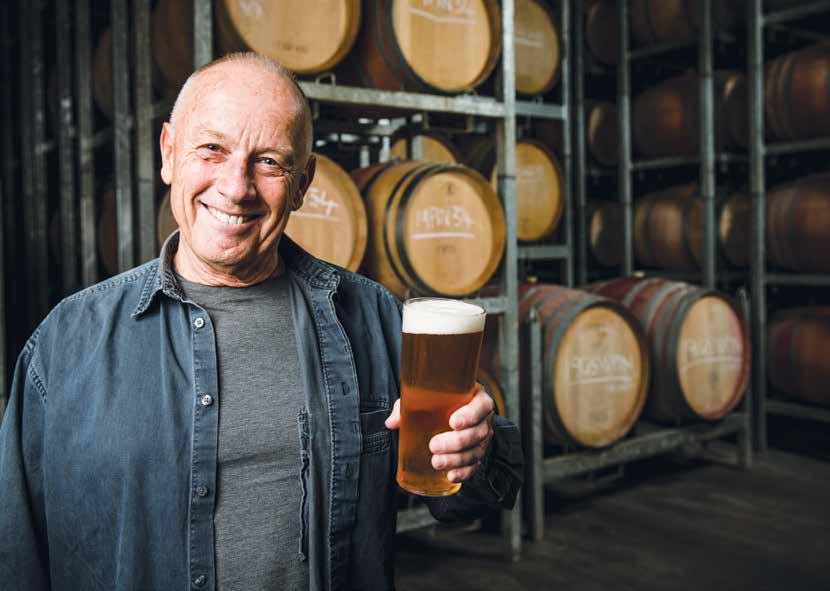

Matilda founder returns to brewery

Phil Sexton will help develop a new Matilda range of beer.

Australia’s original craft brewer Phil Sexton is returning to the label he founded more than 35 years ago to reinvigorate the country’s original craft beer.

This will see Sexton partner with Carlton & United Breweries, which fully acquired Matilda Bay in 1990, to build a new small-batch brewery in country Victoria that Sexton and his team will run.

The brewery will be in Healesville in the Yarra Valley, an hour east of Melbourne, and will have a pub attached. It will exclusively develop and brew a new Matilda Bay range and some Matilda Bay classics such as Redback and Dogbolter.

Sexton said the timing was perfect to re-launch Matilda Bay and help craft beer reach its potential in Australia.

“Restoring Matilda Bay to its rightful place as Australia’s leading craft beer is unfinished business for me,” he said. “I want to grow craft beer by showing people how special good small batch beer can be.

“I founded Matilda Bay in 1983 to give drinkers beautiful craft beer. And as the original craft brewery, it still has a special spot in the consciousness of Aussie beer lovers. It’s the right label to finish what I started and reaffirm what artisanal brewing should stand for: sessionable, flavourful beers that stand the test of time.”

Sexton is one of Australia’s leading brewers and winemakers. In addition to Matilda Bay, he founded Little Creatures and launched Giant

Steps and Innocent Bystander wineries. He said sustainability is a critical part of the new project, with solar panels supplying power and all waste to be recycled. The brewery will use pristine Healesville water.

“This is also about creating a beautiful new attraction in the town I love and live in,” he said. “There is something special about drinking great small-batch beer where it’s brewed.”

CUB CEO, Peter Filipovic, said, “Phil will oversee everything from brewery construction to brewing and marketing. He is a craft beer visionary who revolutionised Australia’s beer landscape. There is no one in the world more suited to delivering this venture than him.

“We’re meeting the changing needs of consumers by creating beautiful new beers in pristine surroundings that live up to Matilda Bay and Sexton’s original vision. We couldn’t be more excited about this opportunity and we know beer drinkers will love it.”

The Matilda Bay brewery and pub will be built on the site currently occupied by Giant Steps winery and restaurant, which, in addition, is owned by Sexton. Construction is expected to start in coming weeks and the brewery is expected to be operational by the end of the year. More than 20 new jobs will be created.

The current Giant Steps site will close Sunday. Tasting will re-open immediately at a new site in Healesville and the winery will re-open soon, with more details to be announced in coming months.

Australian and Chinese meat sectors sign MoU

A MoU signed between China and Australia is the result of 18 months of discussion.

Anew Memorandum of Understanding (MoU) between the Australian and Chinese meat sectors highlights the importance of China to Australian industry and underlines a commitment to collaboration on both sides, according to Australian Meat Industry Council CEO, Patrick Hutchinson.

The MoU is the result of 18 months of preparations and discussions that were initially kicked off at the China International Meat Industry Week that was held in 2018.

Hutchinson signed The China Australia Red Meat Agreement (CARMA) MoU with the China Meat Association in Chengdu, China today on behalf of the Australian Meat Industry Council, Meat & Livestock Australia and the Australian Meat Processor Corporation.

“China is the biggest export market for Australian meat, and maintaining and enhancing our relationship with this critical partner is essential for the future of our industry. This MoU serves to reinforce the strong value our sector places on the relationship and our great respect for China as a very important trading partner,” he said.

In the year to August, Australia has sent more than 172,000 tonnes of beef, 45,000 tonnes of lamb and 39,000 tonnes of mutton to China,

with a total market value of close to $2 billion.

“The aim of this MoU is to establish long-term and formal cooperative relations, strengthen effective and practical food safety processes and enable bilateral exchanges around technical knowhow, marketing, and research and development investment. Ultimately, the MoU will help secure trade outcomes that are beneficial to all parties.”

The longer-term aims of the CARMA include development of both sides’ red meat industries, an enhanced supply chain for Australian meat into China, and working to streamline product specifications and labelling requirements.

“Demand for Australian meat products continues to grow in China and this MoU is another step towards securing and growing this important relationship. I extend my gratitude to the China Meat Association, Meat & Livestock Australia, the Australian Meat Processing Corporation and my own team at AMIC for all their hard work in creating this agreement, and I look forward to continuing to work towards the best outcomes for our industry.”

Under the terms of the MoU, a working group to help implement the goals of the CARMA will be formed to initiate the cooperative program.

Unilever announces new commitments for packaging waste U nilever has announced that by 2025 it will eliminate more than 100,000 tonnes of plastic packaging and collect and process more plastic packaging than it sells. The company, which owns brands like Lipton, Ben & Jerry’s and Walls Ice Cream, has announced new commitments to reduce its plastic waste and help create a circular economy for plastics

Unilever has confirmed that by 2025 it will: • Halve its use of virgin plastic, by reducing its absolute use of plastic packaging by more than 100,000 tonnes and accelerating its use of recycled plastic. • Help collect and process more plastic packaging than it sells.

This commitment makes Unilever the first major global consumer goods company to commit to an absolute plastics reduction across its portfolio.

Unilever is already on track to achieve its existing commitments to ensure all of its plastic packaging is reusable, recyclable or compostable by 2025, and to use at least 25 per cent recycled plastic in its packaging, also by 2025.

“Plastic has its place, but that place is not in the environment. We can only eliminate plastic waste by acting fast and taking radical action at all points in the plastic cycle,” said company CEO, Alan Jope.

“Our starting point has to be design, reducing the amount of plastic we use, and then making sure that what we do use increasingly comes from recycled sources. We are also committed to ensuring all our plastic packaging is reusable, recyclable or compostable.

“This demands a fundamental rethink in our approach to our packaging and products. It requires us to introduce new and innovative packaging materials and scale up new business models, like re-use and re-fill formats, at an unprecedented speed and intensity.”

Unilever’s commitment will require the business to help collect and process around 600,000 tonnes of plastic annually by 2025. This will be delivered through investment and partnerships which improve waste management infrastructure in many of the countries in which Unilever operates. “Our vision is a world in which everyone works together to ensure that plastic stays in the economy and out of the environment. Our plastic is our responsibility and so we are committed to collecting back more than we sell, as part of our drive towards a circular economy. This is a daunting but exciting task which will help drive global demand for recycled plastic,” said Jope.

Since 2017, Unilever has been transforming its approach to plastic packaging through its “Less, Better, No” plastic framework.

Through the initiative, Unilever has explored new ways of packaging and delivering products – including concentrates, such as its new Cif

Eco-refill which eliminates 75 per cent of plastic, and new refill stations for shampoo and laundry detergent rolled out across shops, universities and mobile vending in Southeast Asia.

Better plastic has led to pioneering innovations such as the new detectable pigment being used by Axe (Lynx) and TRESemmé, which makes black plastic recyclable, as it can now be seen and sorted by recycling plant scanners, and the Lipton “festival bottle”, which is made of 100 per cent recycled plastic and is collected using a deposit scheme.

As part of the initiative, Unilever has brought to the market innovations including shampoo bars, refillable toothpaste tablets, cardboard deodorant sticks and bamboo toothbrushes. It has also signed up to the Loop platform, which is exploring new ways of delivering and collecting reusable products from consumers’ homes.

Unilever is committed to cutting its plastics footprint.