42 minute read

BENZ TECHNOLOGY ON TRIAL

TECHNOLOGY ON

LET’S FLICK BACK to the good ol’ days. Like, last year’s Brisbane Truck Show.

It already seems a lifetime ago, but back in May 2019, when people stood shoulder-to-shoulder as the truck industry presented its latest and greatest hardware in all its glittering glory, it’s doubtful anyone had heard the term ‘social distancing’. If they had, it was probably in reference to inmates and introverts rather than the general population. Likewise, in most minds ‘Corona’ was just another beer and ‘virus’ was an annoying bug that seemed to affect computers more than people.

But as we now all know only too well, there’s nothing flippant or frivolous about a pandemic. The changes in society and industry over a very short time have been breathtaking. Literally!

Yet, without downplaying the seriousness of current conditions, there’s no escaping the fact that change is a constant theme in every aspect of modern life and that includes the technological changes seeping into every brand of truck, everywhere in the world. Ultimately, Covid-19 will be nothing more than a speed hump in the path of inexorable progress.

Meanwhile, back in Brisbane last year, there was arguably no greater example of emerging trends in truck technology than a sparkling blue Mercedes-Benz 2663 model sporting a few features never before seen in Australia.

Sure, many of the features in the Benz show truck remain specific to Daimler family brands – Freightliner, Fuso, Mercedes-Benz – but equally, there’s no question most leading makes around the world are well advanced with their own unique versions of similar themes. What’s more, as technology continues to evolve, the feasibility and acceptance of the many varied systems that may today appear futuristic and even impractical will only escalate as global corporations continue to push the technological envelope.

Right now though, and despite the difficulties of current circumstances, Mercedes-Benz – or rather, Daimler Truck & Bus Australia – is proving beyond any doubt that its upmarket presentations in Brisbane were the real deal and far more than simply ‘show specials’. They are, in fact, the platform for a progressive

TRIAL

update of models within the family portfolio.

As the PR blurb on the flagship 2663 show truck in Brisbane stated: “Mercedes-Benz has announced it will launch an advanced new truck in Australia next year [and] confirmed it has begun a comprehensive Australian validation program for the truck, which features a range of driver-focussed improvements including MirrorCam; a system that uses aerodynamic cameras connected to two large screens in the cabin that dramatically boost driver vision.”

But is it actually a new truck as the press release purported, or simply a collection of new features and options within an existing truck? Definitely the latter!

Whatever, the truck “… also features a new multimedia interface system with two high-resolution tablet-style screens that can be customised for driver preference, much like displays in prestige Mercedes-Benz cars.”

Additionally: “The new truck also features GPSassisted Predictive Powertrain Control for increased fuel efficiency, enhanced connectivity and the latest generation of advanced safety technology that delivers further improvements.”

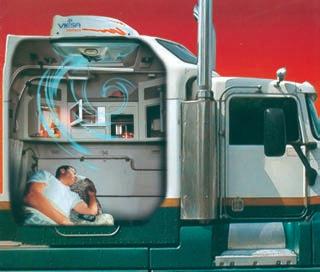

And then there’s “the SoloStar Concept which introduces a vast fold down bed with an 850mm wide symmetrical inner-spring mattress and lounge-style seat that takes advantage of generous legroom and a fully-flat walk-through floor”.

So now, keen to keep the ball rolling and with the confidence of a year-long validation and customer trial program of around 20 trucks under its belt, MercedesBenz presented all these features in a superbly prepared and suitably sanitised 2663 test truck hooked to a B-double combination at Daimler Trucks’ Huntingwood dealership in Sydney’s south-west, recently.

Obviously, we didn’t need to be asked twice if we’d like to take the big Benz for a stroll and equally, it didn’t take a lot of brainwork to figure a simple plan that would at least provide some real world perspective of the truck’s latest features: drive 260km down the Hume to Yass, camp for the night to get a feel for the SoloStar bunk arrangement, then head back up the Hume to Huntingwood. Easy!

While COVID-19 has shackled new product plans for some truck suppliers and excused others to cut staff and chop budgets to the bone, Daimler Trucks Australia appears determined to maintain the momentum of a vastly upgraded product portfolio. Among several offerings in recent times was a MercedesBenz 2663 SoloStar demonstrator housing a heap of hi-tech wizardry and a bunk with a big difference, in more ways than one. Steve Brooks takes the burly Benz for an overnight run to file this detailed report

Above right & below: Two views of the ‘Multimedia Cockpit’. It’s now standard issue across the entire range, from rigids to topshelf linehaulers, controlling a vast array of functions and information. Familiarity comes surprisingly fast Mercedes-Benz line-up with a pugnacious 625hp (460kW) and 3,000Nm (2213ft-lb) of torque feeding out of the 15.6 litre OM473 Euro 6 engine. And like its DD16 counterpart in the new Freightliner fold, the straight six is the heavy hitter in Daimler’s HDEP (heavyduty engine platform) global engine family, married to the exceptional smoothness and remarkable intuition of the PowerShift 12-speed overdrive automated transmission. It’s worth noting that with a standard gross combination mass (GCM) rating of 106 tonnes, the ’63 comes in Powershift’s heavy-duty G330 form.

Benz’s big banger is, however, just one of many in the new range and after numerous stints in different models since the introduction of the all-new line-up just three years ago, there’s no hesitation in asserting that the line-up runs second to none in the delivery of efficient performance and superb road manners. Across the board, it is an entirely impressive line-up but it’s in the premium cab-over class with the 2.5 metre-wide, flat floor cab that the flagship 2663 and its similarly stoic 2658 sibling epitomise at the highest level the reasons for the brand’s formidable resurgence.

Make no mistake, Mercedes-Benz, and specifically the Actros name, were going backwards at a great rate of knots in this country before the arrival of the current crop and the turnaround since late 2017 has been nothing short of stunning. And no doubt, the new features and options revealed in Brisbane last year are all part of a plan to at least maintain and hopefully accelerate the momentum.

True, the B-double combination in this exercise was disappointingly light at a gross weight of just 47 tonnes but that said, from behind the wheel there can be no denying that the superb steering, ride quality and overall comfort of the high-set StreamSpace cab are critical fundamentals on which so much of the Benz business is today built. Road manners are simply first-class.

Moreover, the Benz brigade is forging an enviable reputation for fuel efficiency and while the big bore test truck was lighter than ideal, fuel economy was at least indicative of the model’s inherent efficiency. On the gradual ascent of the southbound run to Yass, for instance, with the overdrive (0.77:1) transmission and 3.583:1 diff ratio producing 100km/h at less than 1,450rpm, the ’63 returned 1.8km/litre, or near enough to 5.1mpg for us more mature types. On the steady descent from Yass back to Huntingwood, the figure was 2.2km/litre (6.2mpg) for an estimated trip average of 2.0km/ litre, or 5.65mpg.

Given that the truck had barely 4,000km on the clock, plus the impediment of multitude stops and starts for photographic and video purposes, the fuel figures certainly weren’t uncomplimentary.

But with these fundamentals firmly in place, are the various new features and options showcased in Brisbane last year capable of taking the brand to greater success in a premium cab-over category jammed with classy contenders?

It’s a difficult question but with advances such as MirrorCam, Mercedes-Benz obviously isn’t shy about bringing the future into current focus and in the process, giving customers plenty to consider. What’s more, no one should be surprised that the advanced digital imaging system which uses tablet-style screens mounted on the A-pillars inside the cab instead of the bulky standard mirror housings, is now a real option rather than just another piece of prospective wizardry to excite technocrats.

However, the first thing that needs to be emphasised is that MirrorCam is an optional feature and like most options, it comes at an added cost. Mercedes-Benz insiders including the brand’s Australian boss Andrew Assimo are reluctant to publicly put a cost on MirrorCam over the standard glass package but it didn’t take a lot of digging to unearth a figure “more than four grand but well under five”.

Yet even before its appearance in Brisbane last year, the revolutionary mirror system was fitted to an earlier demo truck towing a single trailer and fortunately, we were among several groups invited to experience the system and supply feedback to Mercedes-Benz’s local leaders.

Then, as now, it was easy to appreciate the positives. First, and arguably the most important benefit of all, the system provides a spectacular improvement in side vision and subsequent safety over Benz’s bulky external glass mirror housings.

Second, unobtrusive and mounted high on the cab, just above the top of the doors, the cameras are largely out of harm’s way and with their sleek styling, deliver an unquestionable improvement in

REMEMBERING ROBBIE’S ROADHOUSE

It would be difficult to find a worse place than the Yass service centre on the Hume Freeway to park a B-double for an overnight camp. Finding a worse place to eat than this public pig pen would, however, be more difficult. Vastly more difficult.

It was a cold July night and the ‘Specials’ on the menu at the Coolabah Tree Café included curried sausages and rice, so being hungry and a tad adventurous, it seemed a reasonable if potentially risky repast. No worries, I had Quick-eze in the bag.

Soon enough, surprisingly soon when I think about it, a grubby hand in a grubby glove delivered a bowl of tepid slush. “Sorry mate, they’ve run out of rice,” the grubby owner of the grubby hand in the grubby glove confessed with a sodden sniff.

A short and somewhat blunt discussion thus followed but rather than dwell on the diatribe as I belched and blurted under the blankets, memories of a different time and a different place flooded back. A thriving place called Robbie’s Roadhouse which existed just a few kilometres away down the old Hume.

Robbie’s was a good place for truck drivers. Fresh home-cooked food, plenty of it, reasonably well priced, and a quality that didn’t change with a change of staff or the hours of the day or night. Heading north or south, it was somewhere to look forward to, where truck drivers were valued customers rather than just a maligned meal ticket for fuel and fast-food cartels with a stranglehold on freeway traffic.

There were once numerous places like Robbie’s on the old Hume, where the camaraderie and conversation were often as hot and stimulating as the coffee. But on modern freeways from Brisbane to Sydney to Melbourne, those places are largely gone now and on a cold, early morning sprint to a grubby bathroom in Yass as the curried afterburner fired up, I couldn’t help thinking that far more than appetites have been lost. aerodynamic efficiency and accordingly, fuel economy.

The camera housing is also designed to swing in when struck hard but if damage is sufficient to require a replacement, MercedesBenz contends “the cost of replacing the camera assembly will be in line with, or less than, replacing a traditional mirror assembly”.

And third, the system’s ability to pan out as the combination makes a sharp turn at T-sections and the like keeps the rear of the trailer in view, thus minimising the risk of running trailer axles over kerbs or even a parked car.

Importantly, the digital system also provides better night vision than glass mirrors, especially reversing into dark areas.

But now, as then, there remain question marks surrounding the system’s broad acceptance on the Australian market, and perhaps the greatest drawback is the convex image of MirrorCam’s main screen. Convex mirrors are the norm in the UK and Europe but they’re certainly not the norm here and brief attempts decades ago by one or two continental brands to introduce convex glass were met with derisive dismissal. Consequently, it’s easy to suggest that MirrorCam’s chances of widespread driver and customer acceptance will remain negligible until the main screen provides a flat image.

It’s an issue accentuated with the extra length of a B-double, notably when reversing. According to several sources, some early adopters of the system have reverted back to external glass mirrors due in large part to drivers struggling to judge the distance from the rear of the trailer when backing into a dock or the like.

What’s more, when moving back into the traffic flow after a roadside stop on a freeway, it is difficult to judge the distance of vehicles approaching fast from behind. If you’re not sure what I mean, think of that classic scene in Jurassic Park when T-rex was chasing a Ford Territory as the driver looked into the wide angle side mirror stencilled with the words ‘Objects in mirror may be closer than they appear’. You’ll get the idea!

And finally, when swapping from single trailer to B-double configuration and vice versa, it’s imperative for drivers to be shown how to change the parameters which, through lines on the screen, indicate a safe margin for changing lanes or merging. Failure to make the change, particularly from a single trailer to a B-double, could easily lead to an embarrassing and even messy event.

All things considered though, MirrorCam has too many benefits to ignore its potential as the mirror system of the future. Increased safety through unobstructed side vision and the economic benefits of significantly enhanced aerodynamics and fuel efficiency will almost certainly be the main drivers but in the interim, evolution will need to continue. For our neck of the woods, that’ll require Daimler’s technical gurus in Europe to give more consideration to Australian customers, combinations and critically, drivers.

Beyond the norm

While MirrorCam is for looking back, Predictive Powertrain Control (PPC) is all about looking ahead.

Simply stated, it’s an option costing ‘one or two grand’ with the stated aim of providing a more efficient, safer truck – specifically, a safer and more efficient linehaul truck – by connecting GPS data into existing cruise control, retarder and advanced safety functions to ‘memorise’ a route for the most effective provision of performance and fuel efficiency.

Sound confusing? Well, from behind the wheel, it’s not. In fact, it’s as simple as setting cruise control and letting the system do its thing. PPC does, however, certainly have the ability to surprise and newcomers to its nuances need to be ready for some interesting traits.

As Australia’s busiest highway, for example, the Hume was already logged in the PPC system’s data bank and the southbound run down the Mittagong dipper was the first indication of how remarkably intuitive the technology is. With cruise set at 99km/h, power and speed came off surprisingly early as the descent approached, briefly bringing ‘eco-roll’ into play and allowing the truck’s mass to build momentum before re-engaging the transmission and soon after, activating Benz’s highly effective retarder. The result was an entirely smooth and slick run down the grade, all while adaptive cruise control continued to maintain a pre-set distance from vehicles in front.

On the climb up the other side, it was simply a case of sitting back and allowing the 2663’s ample grunt go to work. Easy, safe and stunningly smooth, uphill and down.

Indeed, as the trip continued, it was easy to be amazed and occasionally surprised by PPC’s exceptional ‘forward thinking’. The biggest surprise, however, came on the long, demanding southbound drag up Manton’s Ridge. With the ’63 digging deep into its formidable torque reserves as the truck was about to pull over the crest, a momentarily disturbing drop in power and road speed occurred. But then, just as the outfit rolled over the top, the

transmission went to neutral and the combination’s mass took speed close to its cruise setting before gears were again engaged and the retarder kept a lid on progress. Again, a remarkable indication of just how intuitive the system can be with the driver doing nothing more than keeping the truck pointed in the right direction.

Justifiably, especially if there’s another big banger on your tail, some drivers may be genuinely concerned at the prospect of power suddenly coming off just before the top of a climb. Fair enough, too, but the simple solution in these instances is to simply put the right foot down and keep power on the boil until over the top, then let the system go back to work.

Of course, Mercedes-Benz isn’t the only maker with systems similar to PPC but no matter whose technology it is, the goal is the same: To deliver a pin-point balance between performance and

Right: Winged wonder. MirrorCam may not be for everyone just yet but from a truck design viewpoint, the benefits are too great to ignore

Opposite top: SoloStar cab concept provides a wider mattress but the inconvenience of raising and lowering the bunk is significant. The mesh cover is to keep bedding in place when the bunk is raised

FATIGUE MANAGEMENT SOLUTIONS

Evaporative air conditioners like our VIESA model are ideal for the hot and dry conditions found in the bottom half of Australia. They work best with the window about 10mm open to ensure sufficient airflow. The VIESA system can be mounted to the roof or internal wall of a sleeper cab, depending on the layout of the truck, and runs on both 12 and 24-volt trucks. Meantime, the humid tropical conditions in the top half of Australia require a refrigerated air conditioner like our Pure Air, Kompressor, Kool Kat or EcoWind model. Refrigerated air conditioners work best with window closed and run on truck or independent batteries or diesel (EcoWind).

REFRIGERATED PURE AIR & KOOL KAT ECOWIND DIESEL POWERED 3

1

KW 1

KW

ROOF EVAP VIESA PLATINUM

PURE AIR

INTERNAL EVAP VIESA

REFRIGERATED VIESA KOMPRESSOR

KOOL KAT

2

KW 2

KW KW

Independent sealed, deep cycle battery system RECOMMENDED OPTION, DC POWER SLEEPER CAB COOLING SOLUTIONS Sleep anywhere, anytime for as long as you want, because the NO FLAT BATTERIES SLEEPER CAB COOLING SOLUTIONS managed by Redarc charger gives you longer sleep time without compromising your truck batteries. Ecowind is charging your truck batteries. You can watch TV, get a coldy from your fridge and charge your ipad or phone, SLEEPER CAB COOLING SOLUTIONS Can be fitted in locker box, behind cab or side sweet. Ecowind is the only unit recommended for up North, mount off chassis rail, whichever option you prefer. WA, NT & QLD, spoil yourself with Australia’s Quietest diesel air Recommended for 1Kw Kompressor and Pure Air. conditioner, we can customize to suit your requirements. 2Kw Kool Kat must have own batteries.

Roof mount refrigerated air conditioner, 24 volt only, also good for day cabs when waiting to load up as you don’t need your engine running, saves fuel and engine Idle time.

1

KW NATIONAL NETWORK BACKUP FOR PARTS & SERVICING

SUPPORT BRANCHES

ALBURY/ WODONGA (02) 6024 2133 SHEPPARTON (03) 5821 3172 DUBBO 0423 057 844 NEWCASTLE (02) 4964 2255 SYDNEY (02) 9833 1900 BRISBANE (07) 3277 0980 SWAN HILL (03) 5032 1174 HORSHAM (03) 5381 1532 BORDERTOWN (08) 8752 0077

AUSTRALIA WIDE NETWORK

WAGGA WAGGA (02) 6926 0400 MELBOURNE (03) 8360 3166 PERTH (08) 9356 2545 ADELAIDE (08) 8262 6399

TRUCK ART WAGGA WAGGA YOUR TRUCK SMASH REPAIR SPECIALIST

efficiency. However, at this point it needs to be pointed out that with the transmission in ‘economy’ mode, the test truck was limited to a European top speed setting of 85km/h and consequently, the ‘economy’ setting was not used at any time during this exercise.

What’s more, the PPC system in the test truck had been retrofitted and while it performed faultlessly on day one, it failed to work at all on the return run. Moreover, as the fuel figures revealed, notably more fuel was used on the run to Yass with PPC operating than on the trip back the next day when the system wasn’t working.

Sure, much of the difference in fuel economy can be credited to the ascending grade of the southbound leg compared to the less demanding northbound run, but exactly how much is open to debate. Perhaps PPC’s fuel-saving potential is wafer-thin on such short trips, thus requiring far more time and toil to show its true value and determine if the added cost and complexity are worthwhile.

For their part, and with ample European experience and extensive local trial results to back their claims, Benz insiders are in no doubt that Predictive Powertrain Control is a significant step in further strengthening the brand’s fuel economy status.

Whatever, PPC defines a thread of technology which will only mature and multiply as fuel efficiency becomes even further entwined in the connectivity that now rules so many safety and operational aspects of a modern truck.

Yet whereas MirrorCam and Predictive Powertrain Control are options – and likely to remain so for the foreseeable future – the vastly new and decidedly different digital dash layout, or ‘Multimedia Cockpit’ as Benz calls it, is now standard issue across the entire range, from rigids to top-shelf linehaulers.

It is, of course, no coincidence that the new arrangement is entirely similar to high-end Mercedes-Benz cars and as such, presents a major departure from the general perception of a truck dash. Equally, however, it is a major indication that in the Daimler world, technology transfer is today greater than ever before. No longer is the three-pointed star the only obvious similarity between Mercedes-Benz cars and trucks.

Another indicator of shared componentry is the stylish park brake controller, copied straight from the console of any late model Benz car.

Typically, it takes time to adjust to the new layout and with such a multitude of functions and information available through the two ‘tablet style’ screens, and the various ways those functions and information can be gleaned and operated, driver education appears a prerequisite. Then again, younger generations familiar with all manner of electronic ‘devices’ will probably have no trouble adapting to the new system and for fleet applications, word from within Mercedes-Benz is that the amount of available information can be tailored to suit a particular operation.

Nonetheless, after two days in the truck, even this Luddite became mildly adept and even appreciative of the new system’s attributes.

Yet, while there are far too many aspects of the system to detail in this report, there’s no denying it is a classy layout designed with a high regard for logic.

The primary screen in front of the driver is controlled by a fingerswipe button on the right arm of the steering wheel and along with cruise control functions, provides the driver with several options for a preferred instrumentation cluster. Similarly, a button on the left arm of the steering wheel controls functions displayed in the smaller screen on the left, such as heating and air conditioning, interior lighting, radio and importantly, changing the mirror parameters for different trailer lengths. Many of the functions through the smaller screen can be also sourced through a touchpad immediately below the screen or by simply swiping a finger across the screen.

Meanwhile, windscreen wipers, retarder and transmission continue to be operated by wands at fingertip reach on the steering column.

Again, it’s worth emphasising there’s far more to the multimedia cockpit than the bare details mentioned here but suffice to say, it is immensely comprehensive and for the most part, logical and user friendly after initial instruction and a day or two of handson operation.

New features also include a keyless start/stop button. There’s still a key, of course, but it only has to be in the cab or even in the driver’s pocket to allow the truck to start. Wisely, the key also has a ‘check light’ function which automatically checks the status of all external lights.

Right: There was a time when it seemed the only similarity between Mercedes-Benz cars and trucks was the three-pointed star. Technology transfer is changing all that, fast!

Opposite top: European thinking. With the SoloStar bunk locked upright, drivers can relax in the new passenger seat. The seat, however, can’t be adjusted except to lay the back rest down to lower the bunk.

Dreamtime

No question, some people will like the optional SoloStar cab configuration. And for good reason, whether it’s the 850mm-wide symmetrical mattress, the unique passenger seat which makes greater use of available space, a nifty fold-out table built into the dash in front of the passenger seat, the extra overhead lockers which house a micro-wave, the twin 35-litre fridges in the space between the seats, or simply all these features combined.

Whatever it is, Benz insiders say they’ve had plenty of positive feedback from customer trials of the SoloStar option despite an extra cost said by one source to be “something approaching 10 grand”.

There will, however, also be those who won’t like SoloStar. I’m one of them and for one reason alone: the prospect of rearranging

driver and passenger seats, fiddling with clips and latches to lower the bunk, and refashioning bedding before laying down to grab even an hour or two of sleep, and then going through the reverse process before hitting the road again, is a pain in the proverbial.

It could be argued, of course, that the new ‘relaxation seat’ on the passenger side might be right for an hour or two dozing, but nothing beats laying down full stretch to ward off fatigue. What’s more, the reinvented passenger seat is not adjustable, except to fold the seat back forward so the bunk can be lowered, and unless you’re equipped with telescopic arms, using the folding table from the passenger chair isn’t entirely practical.

The simple fact is that SoloStar was conceived for European operations where drivers aren’t nearly as time-constrained as their Australian linehaul counterparts, so the prospect of stretching your legs and sitting back in the new passenger chair to read for a while isn’t normally part of the trucking life. At least, not in this country. Furthermore, it may be a disputable suggestion in some minds but in a flagship model such as the 2663, the SoloStar arrangement actually diminishes the overall appeal of a cab which is otherwise extremely functional and comfortable.

Sure, at 850mm wide, the SoloStar bunk is 100mm wider than the standard bed but then again, I’ve slept in the standard Benz bunk enough to suggest that other than Volvo’s enlarged XXL cab, it is the pick of the premium continental sleepers. Still, it’s worth pointing out that both SoloStar and the standard bunk are equipped with symmetrical inner-spring mattresses vital for a comfortable night’s sleep.

Meantime, SoloStar features such as the extra overhead lockers, the microwave and twin fridges can be optionally specified in the standard cab anyway.

Mercedes-Benz Australia chief Andrew Assimo firmly refutes any suggestion of SoloStar being an imported gimmick. He does, however, acknowledge it is certainly different to anything currently on the market and given the reported feedback to date, at least provides another string to the Benz bow.

Time will tell but from the outside looking in, Mercedes-Benz’s local leaders have been extremely wise to not only extensively trial advances such as MirrorCam, Predictive Powertrain Control and even the SoloStar concept, but offer them as options rather than standard appointments. For now, the standard inclusion of an entirely new and decidedly different multimedia dash layout is perhaps enough high-tech change for the market to contend with.

After all, given the grief of the original Actros with a swathe of troublesome technology applied in one huge hit, Mercedes-Benz’s Australian operatives know better than anyone the dangers of delivering too much technology too soon.

Besides, as technology and markets evolve, it seems certain that features like MirrorCam and PPC will become intrinsic parts of future models anyway. In the interim, Mercedes-Benz is in exceptionally good shape to build on the established performance, fuel efficiency and road manners of a model range which has made the brand a star performer on the Australian heavy-duty truck market.

SUPERCHROME WHEELS ARE OFFERING SPECIAL COVID-19 PRICES NOW

STANDING BY AUSSIE TRUCKERS WHEN IT COUNTS MOST

NEVER POLISH YOUR WHEELS AGAIN 7 YEAR CHROME WARRANTY

CALL (02) 9060 1610 or VISIT SUPERCHROME.COM.AU

WIRELESS HEADSET FIT FOR TRUCKING

BLUEPARROTT has announced the introduction of its next generation B450-XT noise-cancelling Bluetooth headset, which the company says is engineered for superior calls in high-noise environments.

The B450-XT boasts enhanced comfort, durability and more flexible charging and firmware update options, while the design of the upgraded headset is said to keep pace with the demands of life on the go.

The new B450-XT headset is reported to deliver improved comfort through its padded headband and large, cushioned earcups for all-day use. BlueParrott says the headset is even more durable with an IP54-rating to protect against dust and moisture for the toughest environments, and now comes with USB-C charging to streamline charging across devices.

The new headset is also claimed to enable easy firmware updates on the go using the BlueParrott App and features Bluetooth 5.0 for better connectivity across devices.

Following on from the original B450-XT, BlueParrott says the new headset comes with all the standard features, including noise cancellation that blocks out 96 per cent of background noise and up to 24 hours of talk time. With BlueParrott’s VoiceControl, users can answer or reject calls with just their voice, providing a hands-free experience. Users can also customise the headset using the exclusive Parrott Button for one-touch access to favourite features and applications.

Out of Oregon’s shadows

AFTER several years of rumour and speculation, Daimler Trucks North America (DTNA) headquarters in the riotstricken city of Portland, Oregon has announced it will reveal an entirely new Western Star platform later in September.

Due to Covid-19 restrictions, the launch will be a ‘virtual reveal event’ from DTNA headquarters in the US.

Australian fans should not, however, raise their hopes that the new Star will be arriving here anytime soon.

Due to the pandemic and other factors, a right-hand drive version is apparently still a long way off. A very long way, according to Owner//Driver’s sources.

Used truck program’s approved warranty

SCANIA AUSTRALIA has announced the launch of an Approved Used Truck program across its nationwide network of branches which it says will take the risk out of the purchase of a pre-owned truck.

In order to qualify for Scania Approved status, the pre-owned Scania vehicles must be less than five years old and have covered less than 800,000km. Companytrained technicians will undertake a stringent and probing 108-point check at a Scania workshop, which concludes with a thorough test drive.

Trucks passing the inspection will be sold with a three-month Scania Driveline Protection Warranty as well as any of the remaining original factory warranty (where applicable). For an additional modest fee, the Scania Driveline Protection Warranty may be extended to 12 months from the date of purchase, so long as maintenance is undertaken in line with Scania recommendations.

Scania advises that approved trucks fitted with the Scania C300 Communicator also gain 10 years of Scania vehicle and driver monitoring and reporting.

Scania says it is also making available a choice of maintenance, or repair and maintenance programs, tailored to the customer’s needs and the approved vehicle’s condition.

It adds that the programs ensure the approved trucks are looked after in the best possible way, using only factory-trained technicians equipped with the correct tools and diagnostic equipment, as well as fitting only genuine Scania parts and lubricants as specified for each individual vehicle. The maintenance programme keeps track of software updates for each vehicle and has a pro-active service scheduling feature to ensure no maintenance is overlooked.

Scania Fleet Management collects and delivers valuable information regarding the performance of the vehicle, presented in weekly email summaries, covering fuel consumption, mileage, driver performance and more. All information is secured under the strictest privacy regulations.

“The launch of the Scania Approved Used Truck Program in Australia delivers our customers an increased level of confidence in their purchase and greater faith and peace-of-mind in the vehicle,” says Anna Marie Taylor, national manager used truck sales for Scania Australia.

“We believe the Scania Approved Used Truck Program will increase our sales of used vehicles through our network. The inspection in the Scania workshop by Scania trained and experienced technicians will ensure that the vehicles that meet the Approved Program criteria are in excellent condition and will deliver reliable uptime for our customers.

“As a result of Scania’s growing market share in Australia, and the increasing uptake of Scania Repair and Maintenance contracts, we have seen a larger number of very high quality, good condition preowned Scania trucks return to us when our customers repurchase,” Taylor says.

“We know these trucks’ histories through their digital tyre-print, which gives customer’s far more insight into what they are buying. So, unlike in typical used truck buying situations, when purchasing a Scania Approved vehicle, customers are not buying blind or taking a risk.”

Taylor says Scania is funnelling low-mileage, excellent condition trucks from its rental fleet that have been serviced by Scania into its used truck business. “These will qualify for the Approved Program as well,” she adds.

“Thanks to the volume of new Scania deliveries in recent years, we can source a specific vehicle for a customer, if the specification they desire is not currently in stock.

“Scania has access to a huge amount of data generated by its trucks across Australia and across the world, so we understand how much working life is left in individual vehicles when they come to us. This is not necessarily only dictated by kilometres travelled or age, but is influenced by driver performance, payload and the type of topography the truck has traversed over its working life.

“All this data gives us a far clearer picture of the value of the pre-owned truck for the second owner, providing them with a vehicle that will deliver uptime with confidence,” Taylor says.

The Scania says it’s Approved Used Trucks concept has been accepted in markets such as the United Kingdom and throughout Europe.

Fruitful endeavour for SEA Electric Hino

ENERGY INFRASTRUCTURE firm Jemena is running what it says an Australianfirst electric powered ‘cherry picker’ truck as part of its effort to reduce carbon emissions across the Jemena Electricity Network in Melbourne’s north-west.

The addition of the electric elevated work platform truck aims to reduce Jemena’s carbon output by 30 tonnes per year and is the result of a partnership with Australian electric propulsion company SEA Electric.

“SEA Electric [is] a Melbourne-based manufacturer of electric vehicles and leader in converting commercial vehicles from diesel to electric,” Jemena executive general manager for electricity distribution Shaun Reardon says.

“The cherry picker was converted into an electric vehicle as part of a major reconstruction over a 12-month period.”

SEA Electric sales director for Australia and New Zealand Joe Di Santo says his team is excited to see the industry-first vehicle join Jemena’s Victorian fleet.

“It’s been a special and historical project for the management and engineering staff at SEA Electric to partner with Jemena in the development of this Australian-first 100 per cent electric elevated work platform service truck,” Di Santo continues.

“The SEA Hino FG all-electric vehicle is anticipated to reduce Jemena’s carbon output by 30 tonnes per annum.”

Reardon sees other gains from such a vehicle and foreshadows additions to the fleet.

“Not only is this electric powered cherry picker the first step in greening our fleet, it will also benefit our customers with a quieter operation and zero exhaust emissions,” he says.

“We will look for new ways to further reduce the carbon emissions across our electricity network in the future.”

Originally a Niftylift-built diesel cherry picker, SEA Electric converted the truck into a 100 per cent electric vehicle equipped with a 138kW/h battery pack said to provide around 200km of range.

The elevated work platform is powered by the truck’s battery which will be charged at the end of each day and takes around six hours.

The vehicle began operating within the Jemena Electricity Network recently.

FIX BLOWBY AND AVOID THE REBUILD.

Proudly 100% Australian Made and Owned

#1 BLOWBY?

Most blowby can be easily fixed… even at 1.5 to 2 million kms. Sticking piston rings are the main culprit.

“This fixed my Series 60. It was fuming badly, using 6-7L of oil every 2 days.” – Merv Sweetman.

PHONE (07) 3376 6188 #2 ENGINE SLUDGE

Sludge prevents good lubrication, lowers oil pressure, causes overheating and valve noises!

Get pristine clean again…FAST & EASY!

#3 DIRTY ENGINE OIL?

It should never stain your hands. Even at oil change. If it does you will have engine sludge & power loss.

“My T650 Kenworth lost power, was smoking badly and using oil. Cummins said it needed a $32,000 rebuild! I tried FTC Decarbonizer and Flushing Oil Concentrate. I was absolutely amazed how much rubbish came out on the flush. Now the power’s great! No smoke! No oil use!” – Hugh Maslin

costeffective.com.au

2/18 Boron St, SUMNER PARK QLD 4074 E: sales@costeffective.com.au FREE DELIVERY AUSTRALIA WIDE

Cow encounter tests cab structure

DETAILS HAVE emerged on the Volvo Group Trucks Technology (GTT) Wacol-based team’s ongoing testing of the truck maker’s heavy haulage componentry in local conditions.

According to Volvo, a recent incident in the Northern Territory underscores not only the gruelling conditions trucks operate in but just how much damage a Volvo FH can handle “and still get the job done”.

“Heat, dust and heavy gross weights all conspire to push engineering capabilities to the test,” Volvo’s account of the incident notes.

“The team of 40 engineers are tasked with engineering locally manufactured Volvo and Mack products to create a uniquely Australian range of trucks,” the report notes.

“However, the Australian team also provide support to other markets when it comes to torture-testing components destined for other parts of the globe.”

In this case, in the dark of night, a Simon National Carriers FH16, pictured above, collided with a spooked cow on the Barkly Highway, South east of the Three Ways junction.

“Powering the 131-tonne triple road train combination was a Europeanspec Euro 6 16-litre engine that was being evaluated by Volvo Group’s local GTT team.

“In the spirit of international engineering cooperation, the Australian team were pushing the continental power plant out of its Northern Hemisphere comfort zone.

“The resulting cow-related collision damaged much of the cab structure around the engine and even relocated some of the cooling package.”

Volvo notes that, post-collision both drivers inspected the damage, with no coolant lost and the major components of the cooling system still intact.

“The trucks was subsequently able to drive the remaining 18 hours to Darwin, completing the trip before heading to the local dealership for repair.

“No mean feat for a badly damaged vehicle. Whilst in Darwin the truck received a new cooling package, including the air-conditioning condenser and gearbox cooler.

“Both bent front cab shock mounts were also replaced as well as an electrical repair to the throttle assembly.”

Back in Brisbane the truck received further repairs, including a new wild-bar and some panel work.

“The impact with over half a tonne of bolting beef failed to damage the chassis or steering components of the FH.

“Not a bad testament to the strength and durability of the Volvo FH at all.”

MAXITRANS UPBEAT DESPITE ANNUAL LOSS

MAXITRANS has recorded a net after tax loss of $35.5 million as the trailer-maker joins many other listed companies in a sea of red ink during this annual reports season.

This represents a fall of 31.3 per cent on a 9.9 per cent revenue fall to $317.5 million and the dip into the red is put down to “impairments and other nonunderlying costs” of $36 million after tax.

Most of this effort is centred on the main plant in Ballarat.

“Despite these measures delivering a $10.1m benefit, these weren’t significant enough to offset the decline in volume, mix and manufacturing overhead recoveries of $17.1m,” the company states.

The trailer segment’s revenues fell 15.4 per cent to $205.5 million, though it is noted the second half of last year was better than the first half.

There was also extra income from federal government pandemic employment aid of $5.15 million.

Given much of the current position is outside its control, the company will see a silver lining in the order bank at June 30 being 40 per cent higher than this time last year, as a result of stronger agricultural markets and good orders in support of the food and grocery sector.

The MaxiParts business stands up the best of the segments, defying the downturn with revenues steady at $130.8 million and gross earnings up from $8.7 million to $13.2 million.

Executives will also be happy to have reduced net debt 62 per cent to $12 million and found efficiency savings of $8.4 million, with another $1.6 million to be saved this financial year.

Notable developments during the coming financial year include relocation due in the second quarter of Queensland manufacturing operations from Richlands to a purpose built $4 million facility at Brisbane’s Carole Park.

The move is expected to generate manufacturing efficiencies of more than $2.3 million a year “plus add product portfolio flexibility”.

“It is expected market conditions in the Australian trailer market will continue to be slow as the impact of COVID-19 is compounding the already low levels of consumer confidence and other macro-economic drivers remain soft while operators continue to age their fleets,” the company says of its expectations for the coming year.

“This has the potential to affect performance in both the MaxiParts business as well as the Australian trailer business.

“MaxiParts has shown strong resilience through the COLVID-19 period to date and whilst growth may be slower, the underlying business is expected to remain strong.

“The Australian trailer business has been supported in offsetting this risk through the Australian federal government incentive to increase the instant asset write off threshold from $30,000 to $150,000 (through to 31 December 2020) combined with the 15 month investment incentive (through to 30 June 2021) and is expected to continue to benefit the Trailer Solutions business during this period.

“Rains in South Eastern Australia should also support a higher production rate of Bulk Tipper trailers during the grain season in H1 FY21.

“In the short term, order intake is improving, in food and grocery, general freight and tipper sectors, benefiting the Group’s Maxi-Cube, Freighter, Hamelex White and Lusty products.

“These product lines are directly affected by the broader economic conditions, the crop outlook and the timing of commencement of new housing and infrastructure projects.”

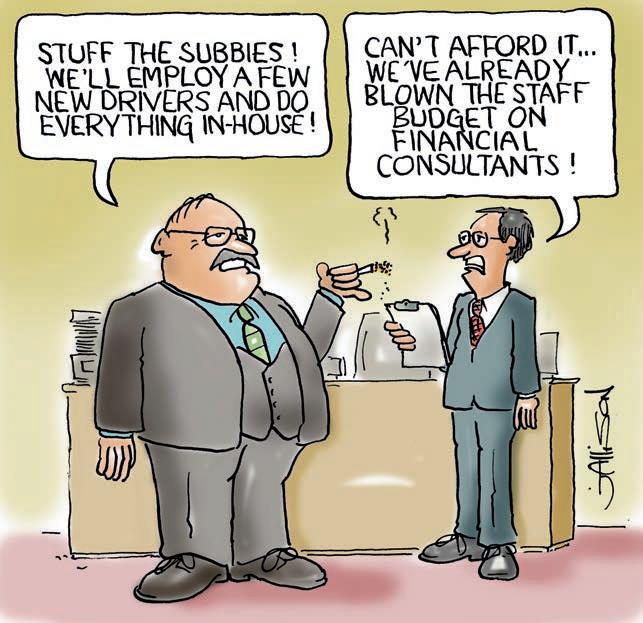

FOR THE OWNER-DRIVER Frank Black

Lacking consistency

The top-down decision-making process is failing truckies at every turn

DURING the last few months we’ve been: hailed as heroes, put under extra pressure to stock shelves, had truck stops closed and only reopened after political campaigning, dealt with daily changes to health and safety procedures, been held up at closed borders, been fined for breaches out of our control, suffered a decline in work, and been shocked by a jail threat for speaking out on low rates.

It’s a complicated time for everyone. In trucking, there’s an underlying theme to all the chaos: decisions that impact truck driver jobs are made by people in suits, in offices far away from the cab of a truck.

I’ll demonstrate with this with three examples from the last few months.

GOVERNMENT FREIGHT CODE

I’ll start with the obvious – the constantly changing government restrictions on border crossings and COVID requirements for essential workers.

While it is understandable that governments must be cautious and adapt as we learn more about this pandemic, it is also important that rule changes are clear, reasonable and communicated broadly. I find myself reading up on rule changes daily, which I often have only been alerted to by word of mouth or vague radio announcements. These rule changes are then open to interpretation by both truckies and law enforcement. The inconsistency is exhausting.

After working out what we need to do, it’s then a case of finding out how to enact these rule changes. Here’s a good example: getting tested once a week is made difficult when testing stations are often not truck friendly and close before peak hours of trucks arriving at state borders.

The onus is on drivers to abide by these rules, or else risk a hefty fine. We must source appropriate PPE, keep records of where we’ve been and who we’ve had contact with, and self-isolate if symptomatic, which is most likely going to be in the cab of the truck.

It goes without saying, then, that drivers should be consulted and well informed about how all of this can be made possible. Instead, we’re treated like naughty school children and issued fines for breaches we may not even be aware of or are out of our control.

I even saw a Victorian truck driver refused a shower and a table to sit at to eat a meal at a truck stop.

The so-called heroes of the pandemic

FRANK BLACK has been a long distance owner-driver for more than 30 years. He is the current ownerdriver representative on the ATA Council.

ATA RESIGNATIONS

I’ve said it throughout my years as the owner-driver representative on the Australian Trucking Association (ATA) General Council: truck driver representation at the ATA is, aside from me, non-existent.

Let’s remember, the ATA was set up to improve safety in the industry following Australia’s worst truck crash, which claimed 21 lives in October 1989. You cannot improve safety in trucking without involving truck drivers in decision-making.

Fast forward to 2020, and the ATA is being run by an exclusive club of the managing directors of trucking companies that make up the board, with just two token positions on the General Council: one owner-driver representative and one small fleet representative.

The last few months have seen both the ATA Chair and CEO resign, with each serving short terms in their respective positions. This in itself is alarming and should be the wake-up call the association needs to rethink its leadership.

This time around, rather than elevating another two of their rich corporate mates, the board should be transparent about an open and inclusive nomination and selection process. The General Council at the very least should be more involved and informed about the process, not simply delivered a polished nominee to vote in.

This is the opportunity to return the ATA to the industry and its principles, rather than reinforcing its employerfocused agenda. Unfortunately, speaking with the lived experience of many General Council meetings, I have no hope of this happening.

ACCC THREAT

On June 1, I received a threatening letter from the Australian Competition and Consumer Commission (ACCC) in response to an Owner//Driver column I wrote about the implication of low rates on truck drivers’ safety and viability. Rather than investigating the serious nature of my column – that truck drivers’ lives and businesses are at risk because clients at the top won’t pay fair rates – the ACCC threatened me with 10 years in jail.

What’s worse, the ACCC has refused to withdraw the threat in several correspondence letters between the ACCC and the Transport Workers Union (TWU), who are acting on my behalf. The TWU called for a withdrawal and an apology, an investigation into the problems in trucking, and information on how the ACCC got my contact details. The ACCC has refused on all counts.

I have since sent a formal request under privacy laws for information the ACCC has on me and my personal contact details. Despite requesting a speedy response, I so far have received nothing at the time of writing this column.

The transport industry was in crisis long before the pandemic came along and made everything worse. If we want our industry to be viable, truck drivers must come together and fight to be heard.