8 minute read

In Good Company

Skyroad Logistics has a strategy aimed at saving the planet by saving fuel.

Peter Assel took a slightly unique path into the freight and logistics industry and obtained his truck licence while studying for his engineering degree. He drove trucks on weekends to pay for the tuition fees and after graduating he worked as an engineer for Boeing and Qantas, yet maintained his interest in road freight and logistics. Through contacts in jet engine sales and leasing Peter went to work at Jets Transport Express both part and full time for almost 13 years, ultimately moving on to be a founder and Managing Director of Skyroad Logistics in 2015. Peter’s background provides him with an engineer’s perspective and the requirement for exhaustive research in order to formulate any business plan. This saw him venturing to Europe and the United States to take a good look at air cargo road feeder services. The PBS scheme in Australia was also closely examined to determine what was needed to be done with trailers to provide more productivity while retaining general access. Skyroad’ s customers now include airlines, freight forwarders and freight

Skyroad Logistics relies on Kenworth prime movers.

integrators, and includes global operators such as UPS and DHL, along with seven of the top ten air cargo operators in Australia. The Skyroad network is very dynamic. Typically, allocators only know what’s loading and what’s moving on the day of operation rather than planning full trailer loads a week ahead or on a regular rotational basis. Skyroad has utilised Kenworth prime movers since the company’s inception. In meeting the PBS design requirements, the iconic truckmaker has been a key factor. There are, however, other significant reasons in support of aligning with Kenworth. “Driver retention is important so we had the view that the Kenworths would provide a more attractive workplace for drivers with a decent sized bunk so our guys could sleep,” says Peter. “And ultimately the other deciding factor was reliability. We still have our first two trucks with original engines and gearboxes, although we are now transitioning them out of air cargo operations to other work because they are getting a bit older, however they are still doing really well after six years and travelling more than 1.5 million kilometres. We think those engines will go to 1.8 million because they are still very low on crankcase breathing, their compression is good and everything is still very strong. We’ll probably be pulling those engines down as a precaution at 1.8 or 1.9 million ‘Ks’. That’s just unheard of.” Kenworth and Cummins were able to provide Skyroad Euro 6 level emissions well before its general availability in Australia. Computer emission simulations of Skyroad’s key mission profiles conducted in partnership with Cummins allowed for the team to use the Cummins Integrated Power drivetrain with down-speeding, according to Peter, resulting in a theoretical better-than 17.5 per cent reduced fuel consumption. “Our real life fuel economy results were within 3.0 per cent of the simulations,” he says. Skyroad’s engagement with its engine supplier Cummins became closer as their tier one customers and other forward-looking global corporations moved towards better managing carbon emissions. “It was obvious to us that in the future contractual obligations that were going to come in we would have to report our carbon emissions to such parties,” says Peter. “We worked out what it would take for Skyroad to be net zero carbon for these customers and determined what the cost of our own carbon emissions was. We then did a cost/ benefit analysis on the cost of offsetting versus the cost of actually reducing our carbon emissions. The beauty of where we ended up was that Cummins and Kenworth were very positive when they learned that our first prospective customer in that space was UPS because Kenworth and UPS are both very strong partners in the United States.” Factors such as approximate payloads, trailer designs, and tare weights were analysed for the current fleet and the data was subjected to the computer modelling by Cummins and a number of opportunities were identified to reduce Skyroad’ s carbon emissions specific to the UPS task. Aerodynamics on trailers provided a degree of improvement, as did building the trailers out of highgrade steel to reduce weight along with the use of alloy hubs, laser cutting the cross beams and using a bolt-in floor system which saved a lot of structure

Cummins X-15e5.

which would normally have to be built into the trailer itself. However, the Cummins Euro 6 engines were a major contributor due to their fuel economy over the projected life of the trucks. “We were doing 2.5-2.6 km/lt on a similar network and the Cummins modelling said we were going to do 2.88 km/lt and in the first run of that engine it was a very close 2.83 km/lt,” Peter recalls. “We have a program with Cummins where they tune the engines and we let the trucks go through their run-in period and at around 200,000 kilometres they were getting down to 2.7’s [lt/km] so Cummins did a ‘hot set’ engine tune and

Cummins Euro 6 engines have delivered supreme fuel burn figures.

we ended back in the 2.8s. “What it really shows is the computer modelling and data that we have is extremely accurate which allows us to predict with confidence where we are going to be in terms of fuel burn and emissions.” The success of the Euro 6 Cummins X15 engines highlights the close collaboration between Cummins and Eaton in developing a more fuel efficient powertrain package and Skyroad has also transitioned from manual to automated transmissions to enable control of performance and fuel efficiency variations. “We have moved totally to AMT. All trucks from now on are Cummins Integrated Power and the beauty of the integrated powertrain is we have full authority over the gearbox and engine behaviour,” says Peter. “We lock out manual shifting and although there was an initial driver backlash, though some fine tuning over the past two years and continual reviews with our Cummins representative, we’ve arrived at a pretty good outcome. A lot of it is perception and we can look at the drivers who are saying the truck is slow, and we’ve actually got the data to show their pointto-point times are hardly affected.” By way of example, Peter explains the difference between Sydney and Melbourne can be less than ten minutes. At current, Skyroad Logistics is operating two trucks with the optional Hill Climb Assist (HCA), a feature which detects when the vehicle is on a grade and delivers an alternate transmission shifting strategy and access to increased power. “The drivers who were providing feedback that they thought the truck was slow,” Peter adds, “have now got Hill Climb Assist and most of the objections have gone.” Going from 2.5-2.6km/lt up to 2.8 without hurting trip times makes the efforts worthwhile. A long-term trial involving a European prime mover provided similar results and proved to the Skyroad team that specifying a Kenworth/ Cummins combination with a similar strategy will achieve the same, or even better, fuel efficiency figures. “We’re getting the same fuel, but getting better reliability based on what we saw in the trial and in terms of total cost of ownership these Kenworths hold their value,” Peter says. “For what we do, reliability and performance are what people pay extra for so the efficiencies of the Euro 6 Cummins is really the answer for us.” There’s also an advantage in the Euro 6 Cummins engines having all of their emission technology produced internally rather than relying on components from external suppliers according to Peter. “The reliability of the emissions system has improved drastically since Euro 5,” he

says. “Cummins has the ability to actually deal with it and get the truck back on the road with a much lower cost.” As an engineer, Peter has a pragmatic view on the topic of climate change. He insists they aren’t supporting either side of the debate. “We’re just taking the conservative view that if we look after it and later on its proven to be true then we’ve done the right thing,” he says. “If later on its proven to be not true then we haven’t done any harm.” Peter considers Skyroad Logistics very privileged to have key support from Cummins and Kenworth as it seeks to further its operational efficiencies. “Mike Fowler at Cummins and Andrew Hadjikakou at PACCAR have been personally involved in supporting that, believing in it and wanting to do the right thing,” he says. “A lot of customers talk it but these are actually people who do it. It says a lot about the ‘can do’ attitude we have in Australia.”

The Cummins program is designed to moderate carbon emissions.

CHAIN OF RESPONSIBILITY LEGISLATION GOT YOU WORRIED? RELAX!

With TWS and Axtec there is no longer any reason or excuse for your vehicles to be overloaded

ONBOARD AXLE LOAD INDICATOR

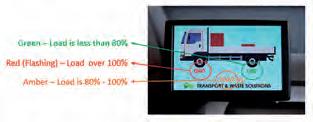

DISPLAYS AXLE AND GROSS WEIGHTS SIMPLE COLOURCODED DISPLAY

Visual and audible warnings alert drivers to load errors Side and rear cameras Single touch-screen displays all functions - less driver distraction

WITH AXTEC ONBOARD

You can: • Load vehicle to capacity every time • Avoid fi nes and threats to Operating License • Avoid excessive wear and tear to associated with overloads • Reduce environmental impact • Receive real-time notifi cations via GPS / telematics system • Connect cameras to improve safety to pedestrians and cyclists ph: 02 9623 1800 e: chris.coleman@twsaust.com.au www.twsaust.com.au